Method of preparing tribasic lead sulphate using lead mud in waste lead battery

A tribasic lead sulfate and waste lead storage battery technology, applied in lead sulfate, chemical instruments and methods, lead compounds, etc., can solve the problems of waste of resources, energy, long process flow, environmental pollution, etc., and achieve energy saving and simplification. Process, the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

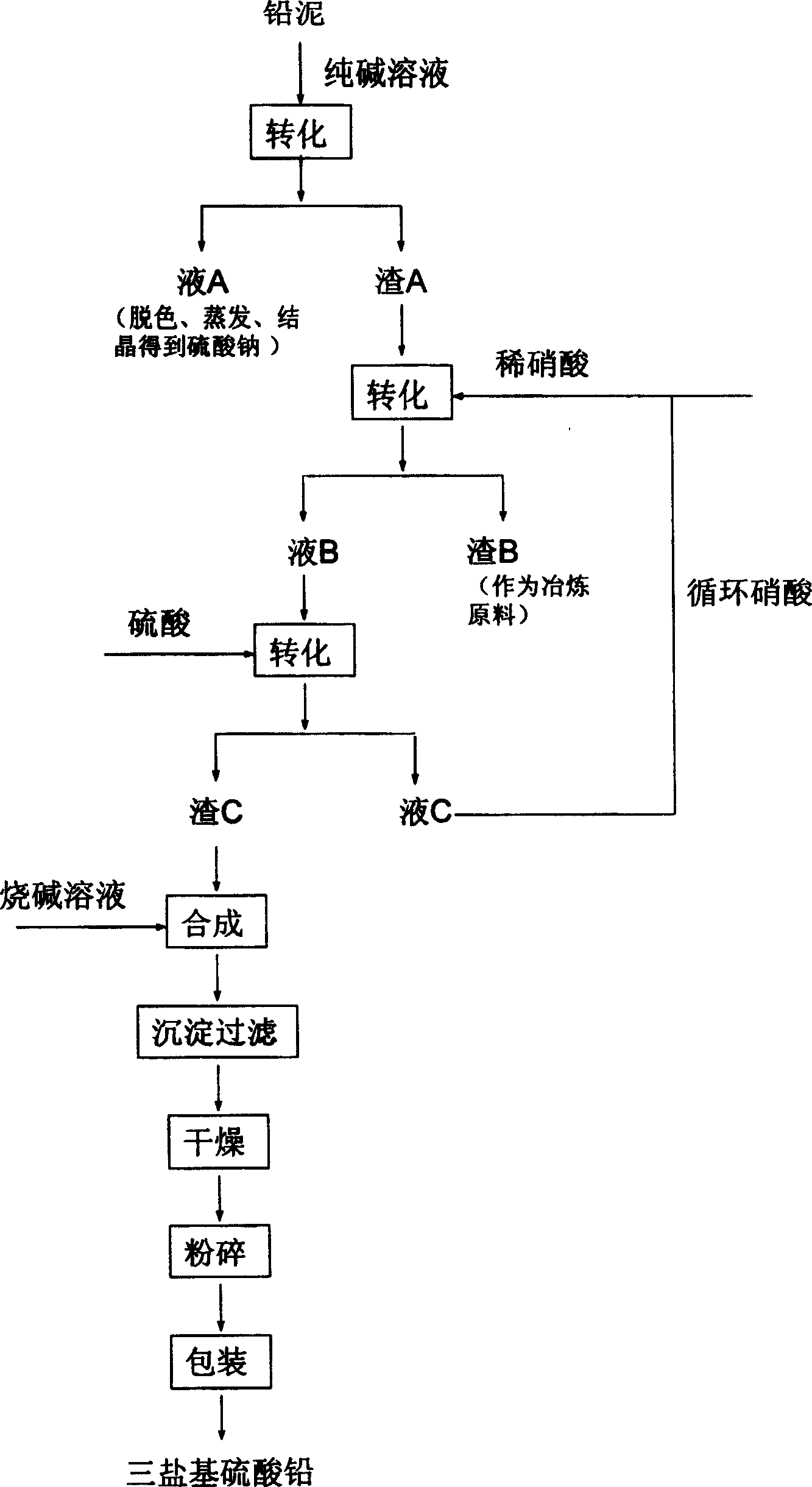

[0030] Embodiment 1. With reference to figure 1

[0031] The first step is the preparation and purification of lead carbonate. 43g of 96% soda ash is heated and dissolved at 30-50°C, and prepared into 30% Na 2 CO 3 Solution, under stirring at 120r / min, slowly add 100g of lead sludge, stir for 60min, keep the reaction temperature at about 30°C, filter after the reaction is completed, wash the filter residue with water to obtain pure PbCO 3 The solid (slag A) was about 60 g. At the same time, the filtrate (liquid A) was obtained.

[0032] The second step, the preparation of lead nitrate solution, under the condition of normal temperature and normal pressure, 60g PbCO 3 Solid with 120g 30% HNO 3 Solution reaction, stirring speed is 80r / min, filter after 90min reaction, obtain relatively pure Pb(NO 3 ) 2 solution (solution B).

[0033] The third step, the preparation and purification of lead sulfate, the lead nitrate solution obtained above was reacted with 44g 50% sulfuri...

Embodiment 2

[0037] Embodiment 2. by the method and step described in embodiment 1, lead slime amount is still 100g, only the concentration of adjusting the 4th step NaOH solution is 15%, and add-on is 96g, and the reaction times is 40min, obtains tribasic sulfuric acid equally The lead qualified product is about 55g, and the PbO content of the product is 89.5%.

Embodiment 3

[0038] Embodiment 3. adopt the method and step identical with embodiment 2, carry out enlarged experiment, disposable utilization 2000g lead mud, other chemicals are added by the same concentration of embodiment 2 and the amount of corresponding ratio, produce tribasic lead sulfate The qualified product is about 1102g, and the PbO content of the product is 89.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com