Recycling method of waste lithium battery

A waste lithium battery and recovery method technology, which is applied in the field of waste lithium battery recycling, can solve the problems of difficult waste gas treatment, large equipment investment, and low recovery efficiency, and achieve low pollution, improved recovery rate, and high recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

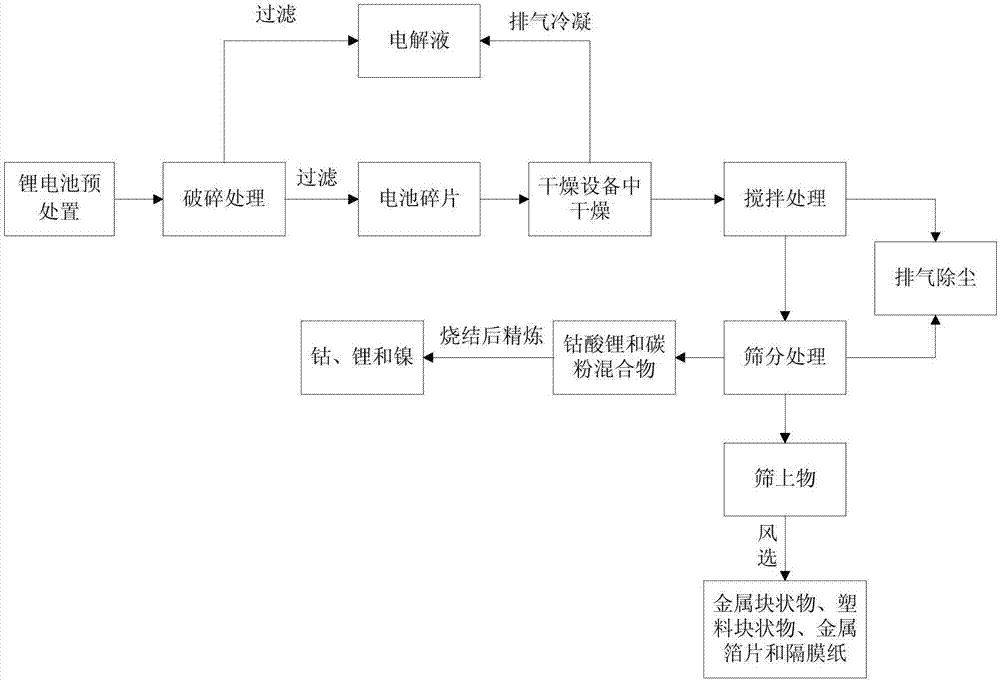

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] combine figure 1 As shown, the waste lithium battery recycling method includes lithium battery pretreatment steps, crushing and drying steps, battery fragment separation steps and isolate treatment steps;

[0023] Lithium battery pretreatment step: put the lithium battery into the discharge battery and discharge it for more than 2 hours. The discharged lithium battery is washed with water and filtered to complete the pretreatment; in this step, the discharge battery is filled with a conductive liquid for discharging the lithium battery. ; The conductive liquid can be various, preferably a sodium chloride aqueous solution with a concentration of 5% to 20%; generally, the waste lithium battery is put into the battery after being framed;

[0024] Crushing and drying steps: use crushing equipment to crush the filtered lithium battery, and then filter to obtain battery f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com