Plastic fresh-keeping box injection molding surface finishing processing method

A technology of injection molding and processing methods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of damage to cutting blades and grinding heads, affecting the quality of processing, cumbersome processing methods, etc., to achieve improved processing quality, cutting Thoroughly improve the quality of the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

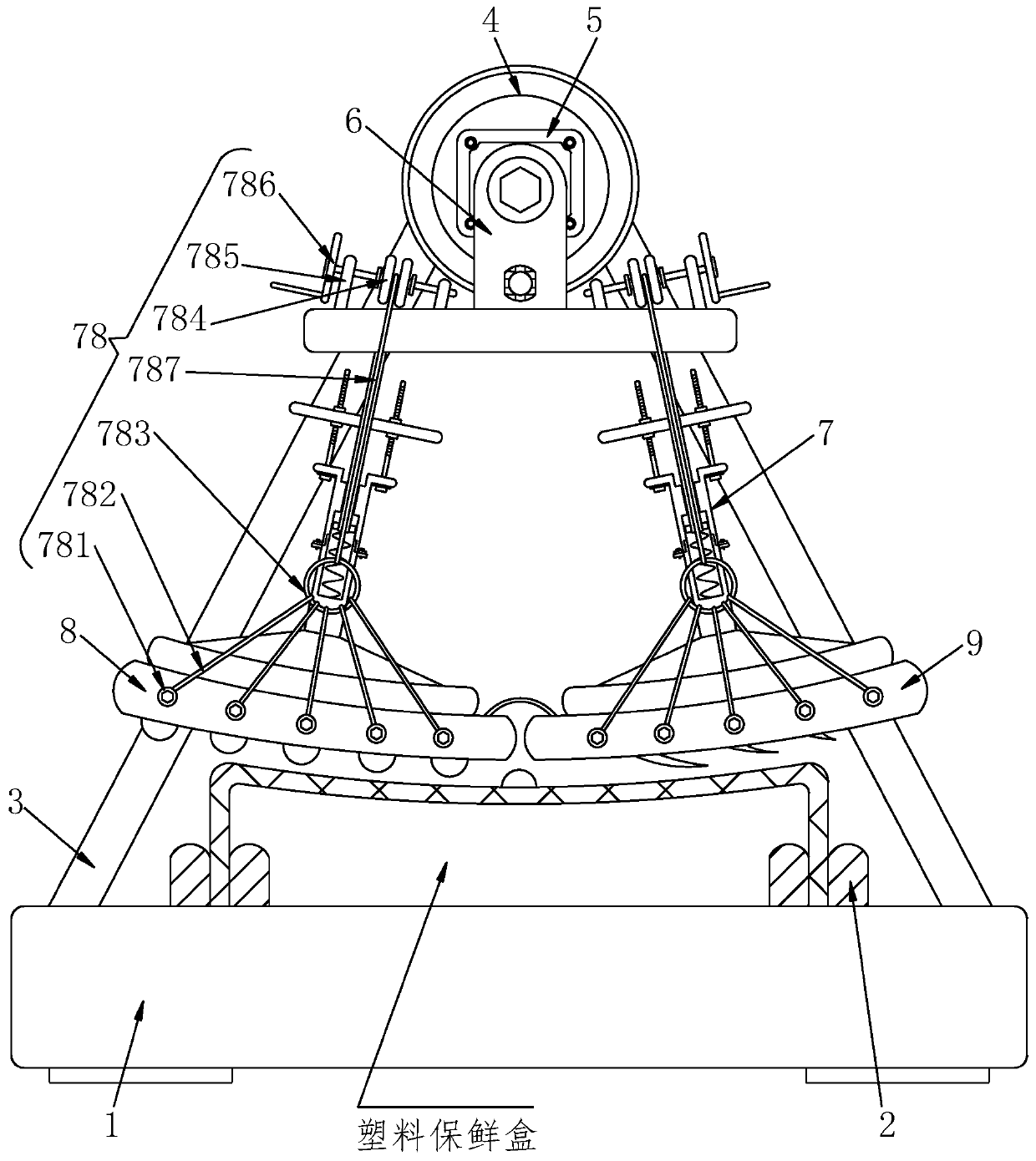

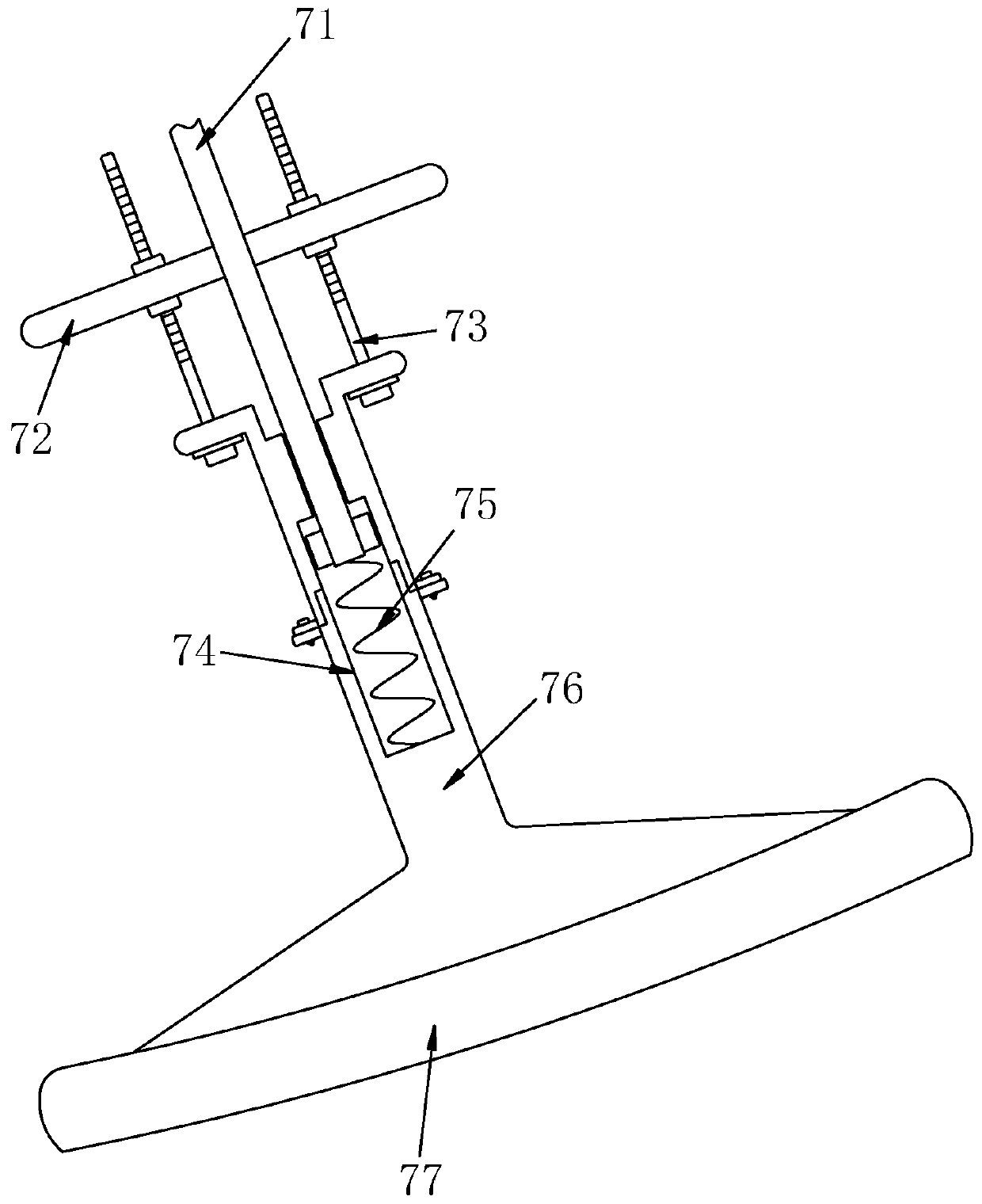

[0030] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

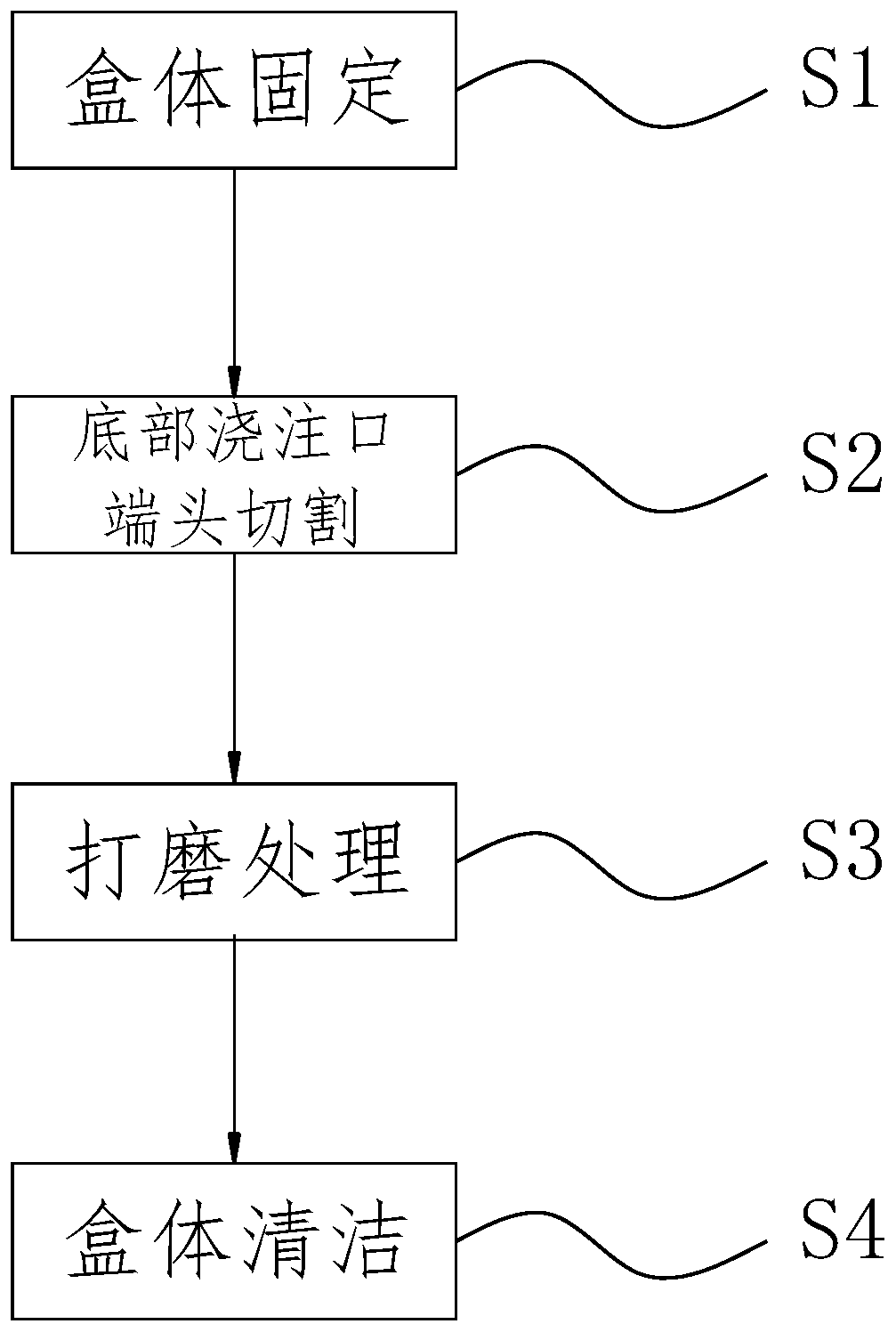

[0031] Refer to 1-6, a plastic fresh-keeping box injection molding surface finish treatment method, the plastic fresh-keeping box injection molding surface finish treatment method specifically includes the following steps:

[0032] S1. Fixing the box body: the operator manually buckles the plastic fresh-keeping box to be processed on the upper end of the shelf 2;

[0033] S2. Cutting of the end of the sprue at the bottom: the operator manually starts the switch of the motor 5 and controls it to enter the working state. The motor 5 drives the T-shaped frame 6 to swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com