Multi-cutting-edge internal rotation shearing safflower filament harvesting machine and method

A cutting edge and filigree technology is applied in the field of multi-cutting edge internal rotation shearing safflower filigree harvesting machinery. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

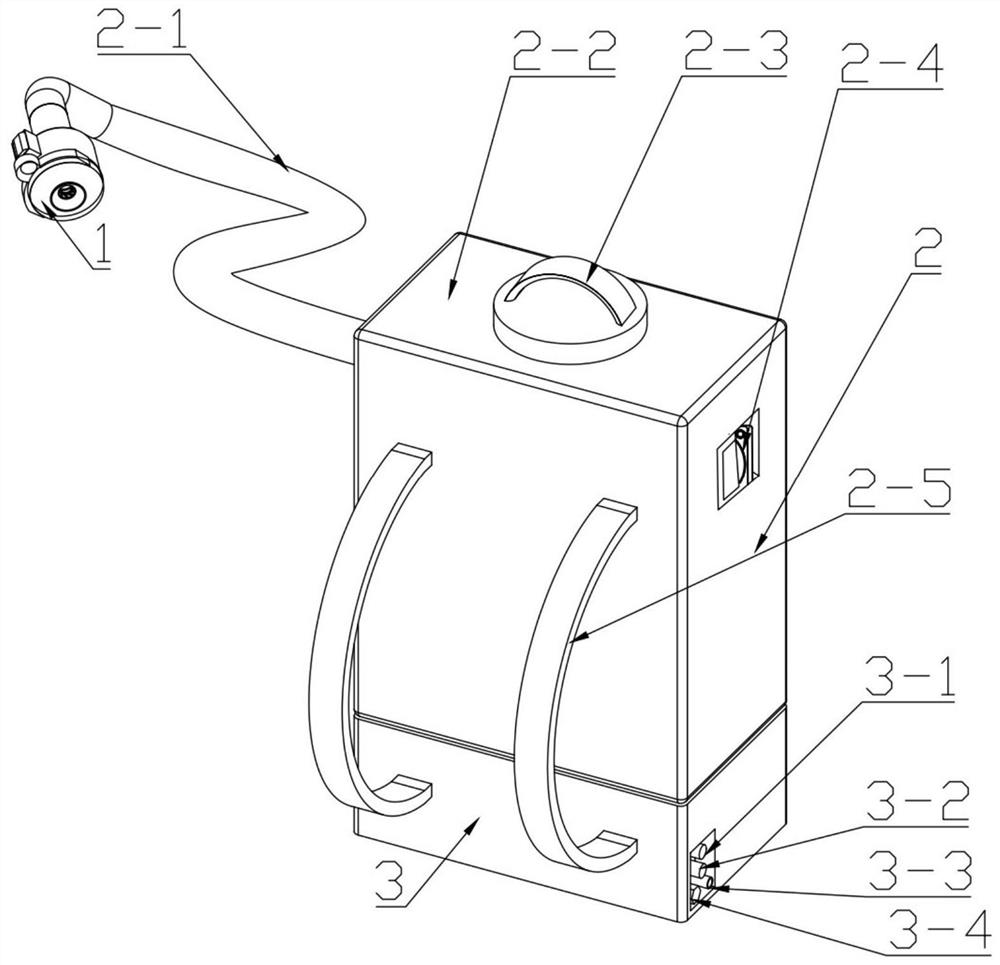

[0077] Such as figure 1 As shown, a multi-cutting-blade internal rotation shearing safflower filament harvesting machine includes a picking manipulator 1 , a filament collection box 2 and an electric control system 3 .

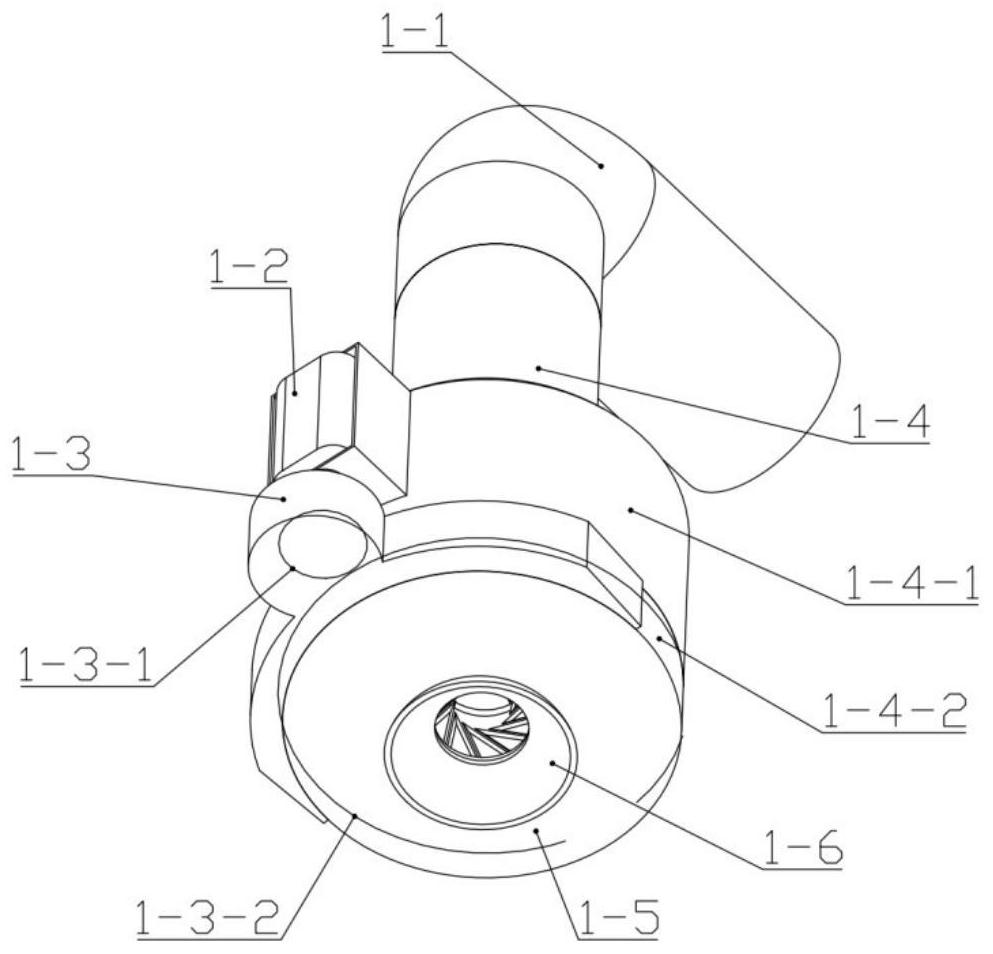

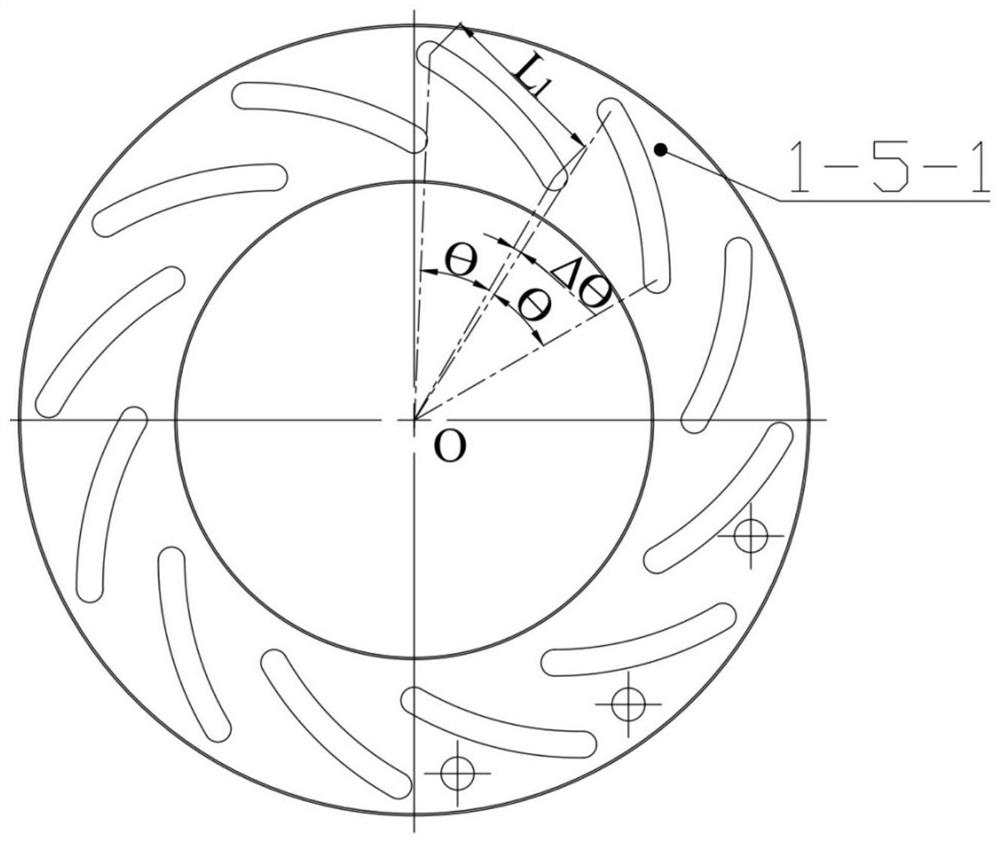

[0078] Such as figure 2 As shown, the picking manipulator 1 includes a conveying elbow 1-1, a driving motor 1-2, a transmission device 1-3, a manipulator shell 1-4, a cutting device 1-5 and a laser beam shooting device 1-4-3.

[0079] The manipulator shell 1-4 includes a manipulator box 1-4-1 and a cutting device shell 1-4-2 for accommodating the transmission device 1-3 and the cutting device 1-5. The upper end and the lower end of the manipulator box 1-4-1 are respectively connected with the conveying elbow 1-1 and the cutting device shell 1-4-2 by threads, and the manipulator box 1-4-1 is connected with the cutting device shell 1-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com