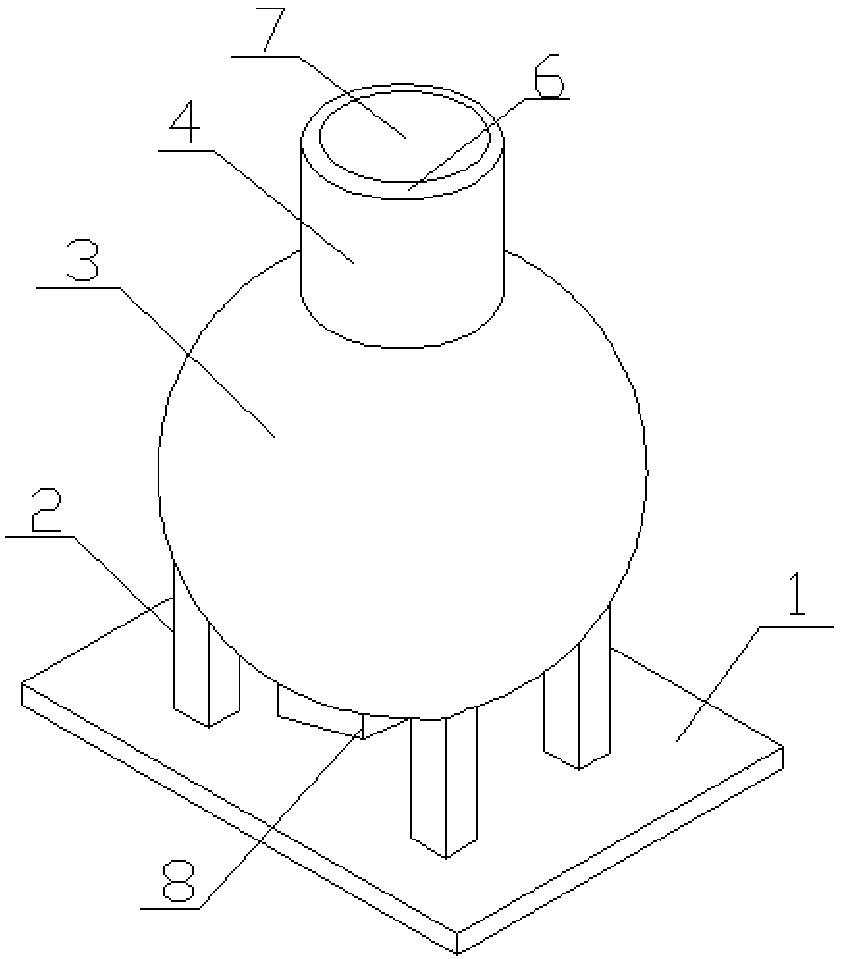

Novel plastic processing crusher

A shredder and plastic technology, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of reducing the service life of the crushing blade and uneven size of the crushed fragments, so as to improve the service life, achieve good crushing effect, and thoroughly cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

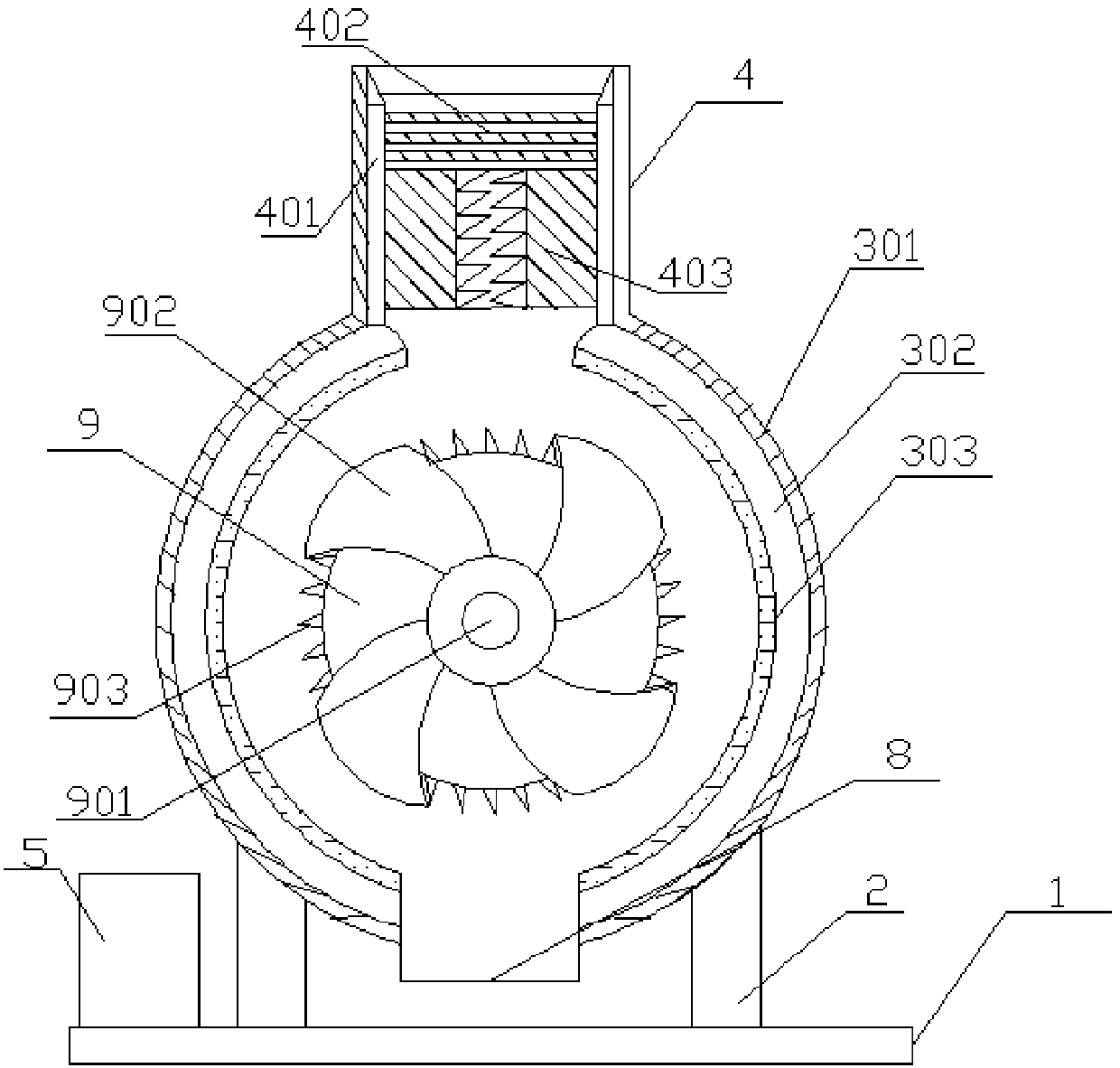

Embodiment 1

[0037] Specific embodiment 1 of the present invention: the number of the third blade group is 2, the number of the fourth blade group 903 is 1, and the 2 third blade groups 902 and 1 fourth blade group 903 are alternated with the rotating shaft in turn 901 connection. Connect the plastic feeding pipe to the feeding pipe fixing groove 6, start the pulverizer through the motor control box 5, the plastic enters through the feeding port 7, and the vibrator on the fixing seat 401 drives the horizontally arranged first blade group 402 to form scissors In the traditional cutting mode, the first blade set 402 cuts in the horizontal direction, and the vibrator on the fixed seat 401 drives the vertically arranged second blade set 403 to form a vertical cut, and then falls to the first casing Inside the inner shell 303 of 3, there is a crushing device 9 for crushing, and the rotating shaft 901 moves. The fan-shaped structure of the third blade group 902 can not only be crushed but also h...

specific Embodiment 2

[0038] Embodiment 2 of the present invention: the number of the third blade group is 1, the number of the fourth blade group 903 is 2, and one third blade group 902 and two fourth blade groups 903 are staggered with the rotating shaft 901 in turn connect. Connect the plastic feeding pipe to the feeding pipe fixing groove 6, start the pulverizer through the motor control box 5, the plastic enters through the feeding port 7, and the vibrator on the fixing seat 401 drives the horizontally arranged first blade group 402 to form scissors In the traditional cutting mode, the first blade set 402 cuts in the horizontal direction, and the vibrator on the fixed seat 401 drives the vertically arranged second blade set 403 to form a vertical cut, and then falls to the first casing Inside the inner shell 303 of 3, there is a crushing device 9 for crushing, and the rotating shaft 901 moves. The fan-shaped structure of the third blade group 902 can not only be crushed but also has a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com