Chili chopping device for chopped chili production

A shredding device and pepper technology, applied in grain processing and other directions, can solve the problems of not being able to block peppers, not removing peppers, and not being able to cut peppers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

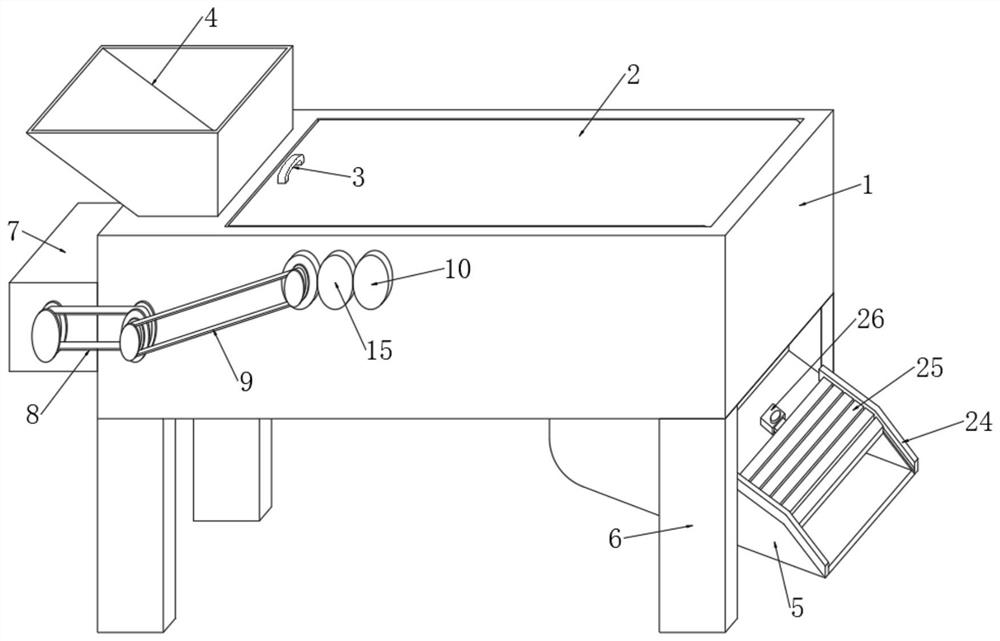

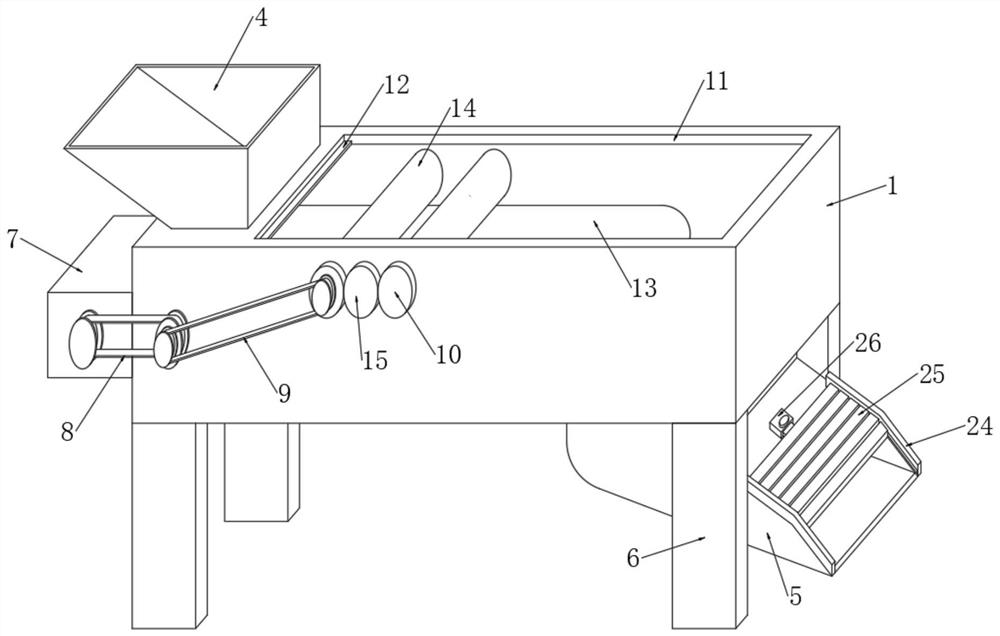

[0032] Embodiment one, by Figure 1-10Given, the present invention comprises processing box body 1, and the interior of processing box body 1 is provided with cavity, and the top of processing box body 1 is fixedly installed with the feed inlet 4 that communicates with processing box body 1 inner cavity, in processing The bottom of the box body 1 is fixedly installed with a discharge port 5 communicating with the inner cavity of the processing box body 1, and the top of the processing box body 1 is provided with an opening 11, and a fixed shaft is fixedly connected to the end of the opening 11 away from the feeding port 4 23, the opening 11 is provided with a cover 2, and one end of the cover 2 is sleeved on the fixed shaft 23 and can rotate around the fixed shaft 23, and the inner cavity of the processing box 1 is provided with a conveyor belt 13 that can run , and two first round rollers 14 are also arranged in the inner cavity of the processing box 1, and the two first roun...

Embodiment 2

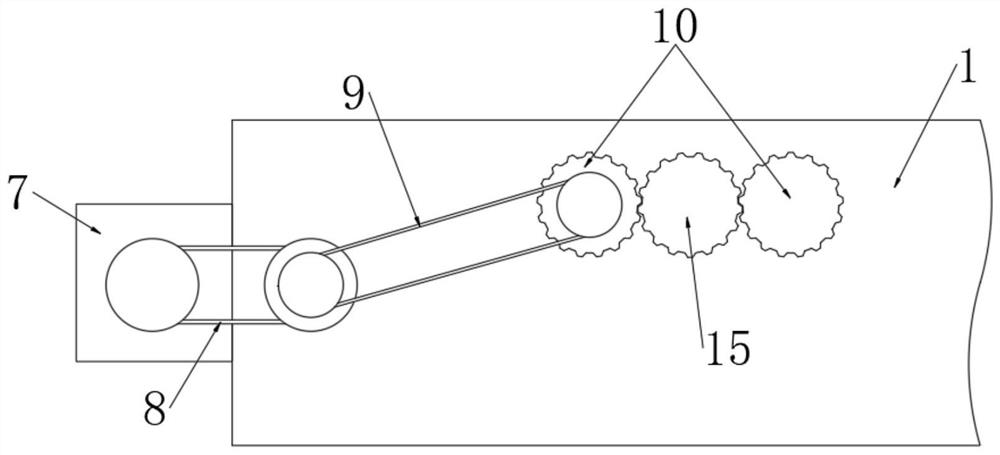

[0033] Embodiment 2, on the basis of Embodiment 1, a motor 7 is fixedly installed at one end of the processing box 1, and a first transmission belt 8 is fixedly installed on the output end of the motor 7, and the rotating shaft at the end of the conveyor belt 13 close to the motor 7 runs through the processing The box body 1 extends to the outside thereof, and the end of the first transmission belt 8 away from the motor 7 is fixedly connected to the conveyor belt 13 on the rotating shaft outside the processing box body 1, and the ends on the same side of the two first round rollers 14 all extend to the processing box body 1, and two first round rollers 14 are fixedly installed with the first gear 10 at one end of the outside of the processing box 1, the side of the processing box 1 is provided with a second gear 15 that can rotate, and the second The gear 15 is located between the two first gears 10, the outer walls of the two first gears 10 and the outer walls of the second ge...

Embodiment 3

[0034] Embodiment three, on the basis of embodiment two, several groups of chopping blades 18 are evenly distributed on the outer surfaces of the two round rollers 14, and each group of chopping blades 18 is made up of a horizontal blade and several longitudinal blades, several The longitudinal blades are evenly distributed on the horizontal blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com