Powder electrostatic charge detection and calibration short section

An electrostatic charge and powder technology, which is applied in the field of powder electrostatic charge detection and calibration nipples, can solve the problems of unsuitable continuous control of power dissipation, difficult measurement, calibration equipment without static elimination monitors, etc., to ensure accuracy and The effect of traceability, reliable accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

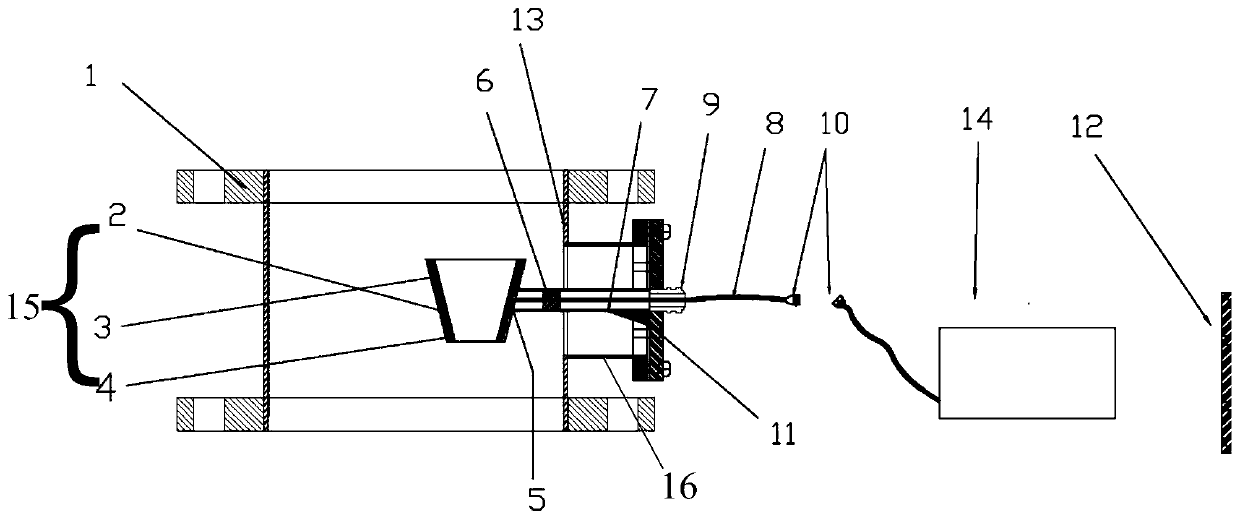

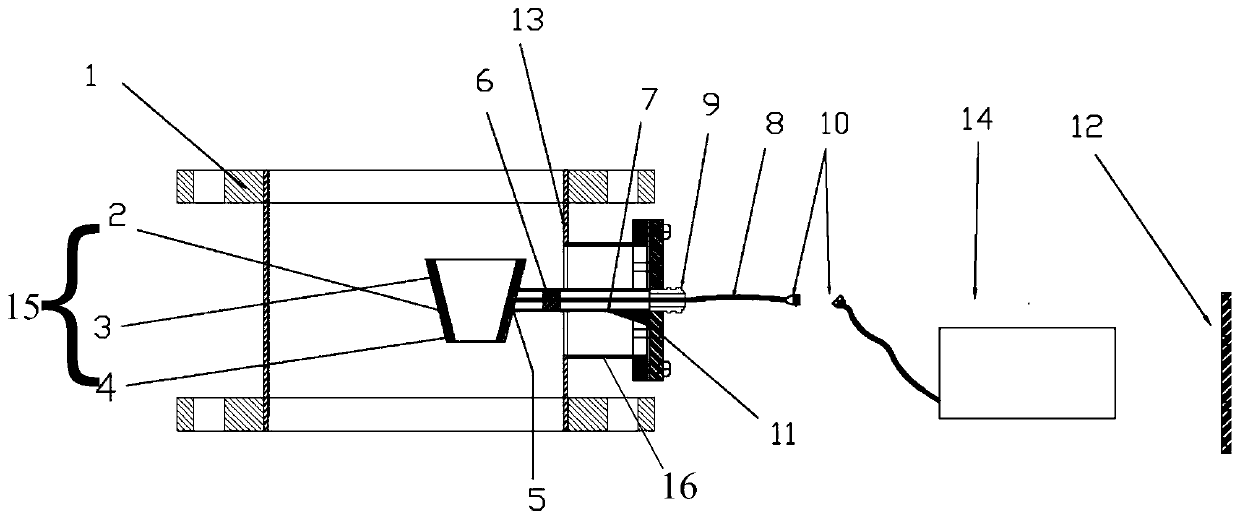

[0021] Such as figure 1 As shown, a powder electrostatic charge detection calibration pup is composed of a docking flange 1, a sampling cup 15, an electric lead wire structure 5, a sealing letter 6, a support frame 7, an electric lead wire 8, an explosion-proof gland head 9, and a joint 10 , detection cover 11, operation replacement cover 12, outer cylinder 13, charge-to-mass ratio detector 14, and calibration frame 16.

[0022] Such as figure 1 As shown, the sampling cup 15 has an inverted conical structure as a whole, and is composed of a sampling cup insulating layer 2, a sampling inner cup 3, and a sampling outer cup 4; the sampling cup insulating layer 2 is located between the sampling inner cup 3 and the sampling outer cup 4 The upper opening of the sampling cup 15 is large, and the lower opening is small. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com