Convenient-to-move rebar cutting machine

A cutting machine and steel bar technology, which is applied in the field of steel bar cutting, can solve the problems of easy displacement of steel bars, inaccurate cutting, and laborious movement, etc., and achieve the effect of reasonable structure, convenient cutting and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

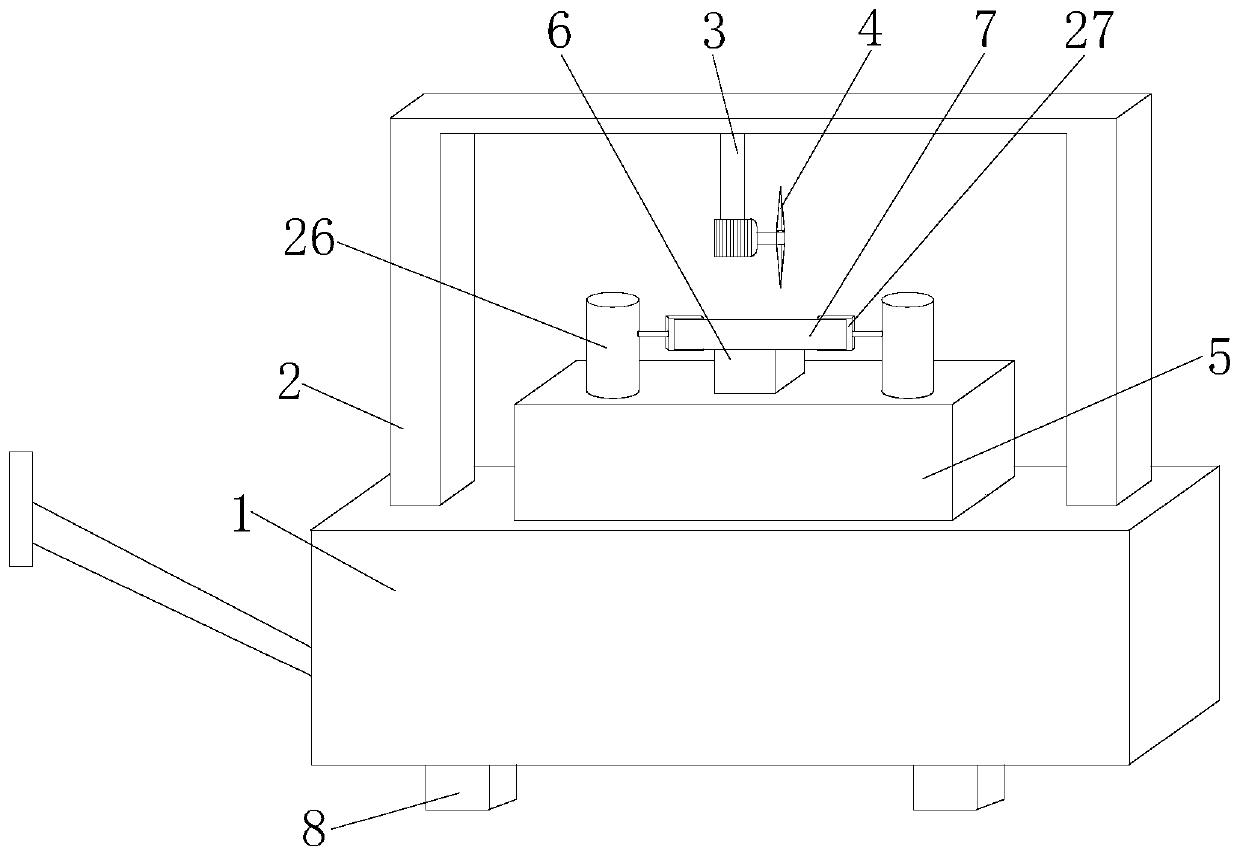

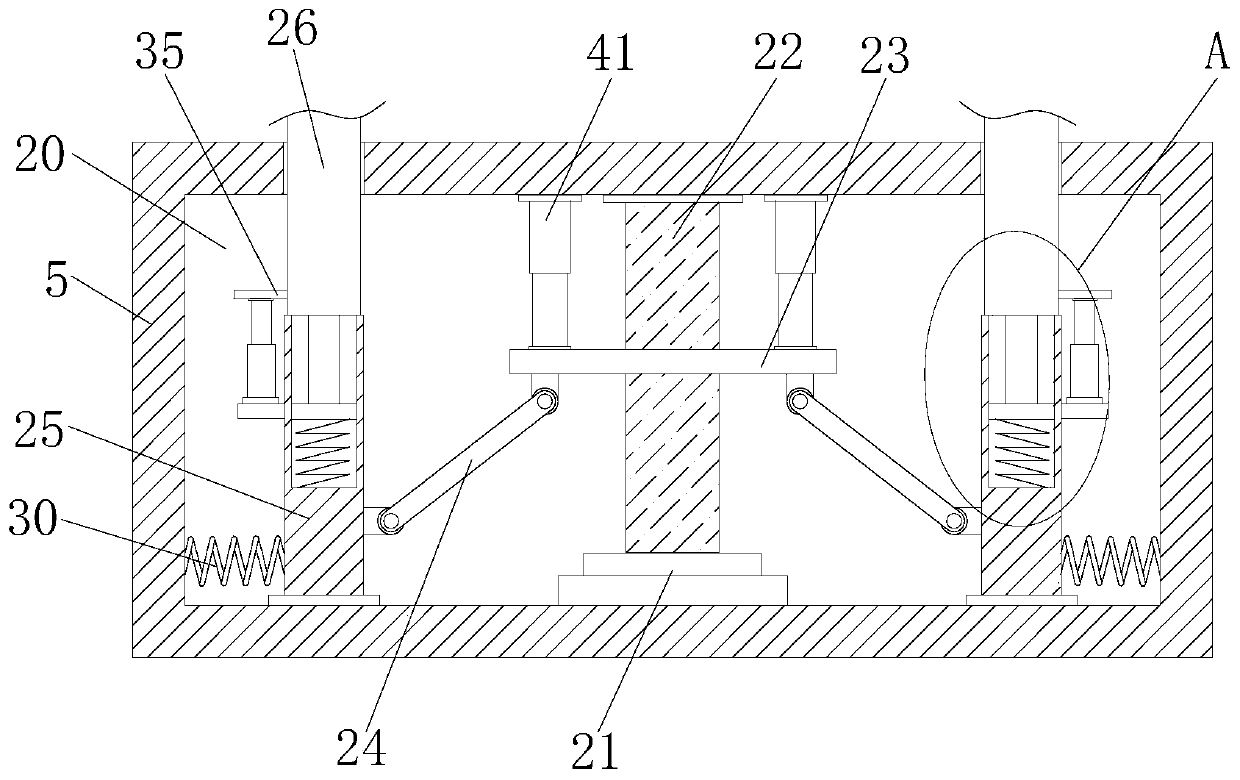

[0026] refer to Figure 1-5 In this embodiment, a steel bar cutting machine that is easy to move is proposed, which includes a base 1, a handle is fixedly connected to one side of the base 1, a fixed frame 2 is fixedly connected to the top of the base 1, and a fixed frame 2 is fixedly connected to the inside of the top of the fixed frame 2. There is a fixed plate 3, the bottom of the fixed plate 3 is fixedly connected with a cutting machine main body 4, the top of the base 1 is fixedly connected with a fixed seat 5, the top of the fixed seat 5 is fixedly connected with a placement plate 6, and the fixed seat 5 is provided with a drive assembly. There are two vertical boards 26 connected by transmission on the component, and the sides of the two vertical boards 26 close to each other are fixedly connected with a clamping plate 27, and the same steel bar main body 7 is clamped and fixed on the two clamping plates 27, and the base 1 The bottom is symmetrically fixedly connected w...

Embodiment 2

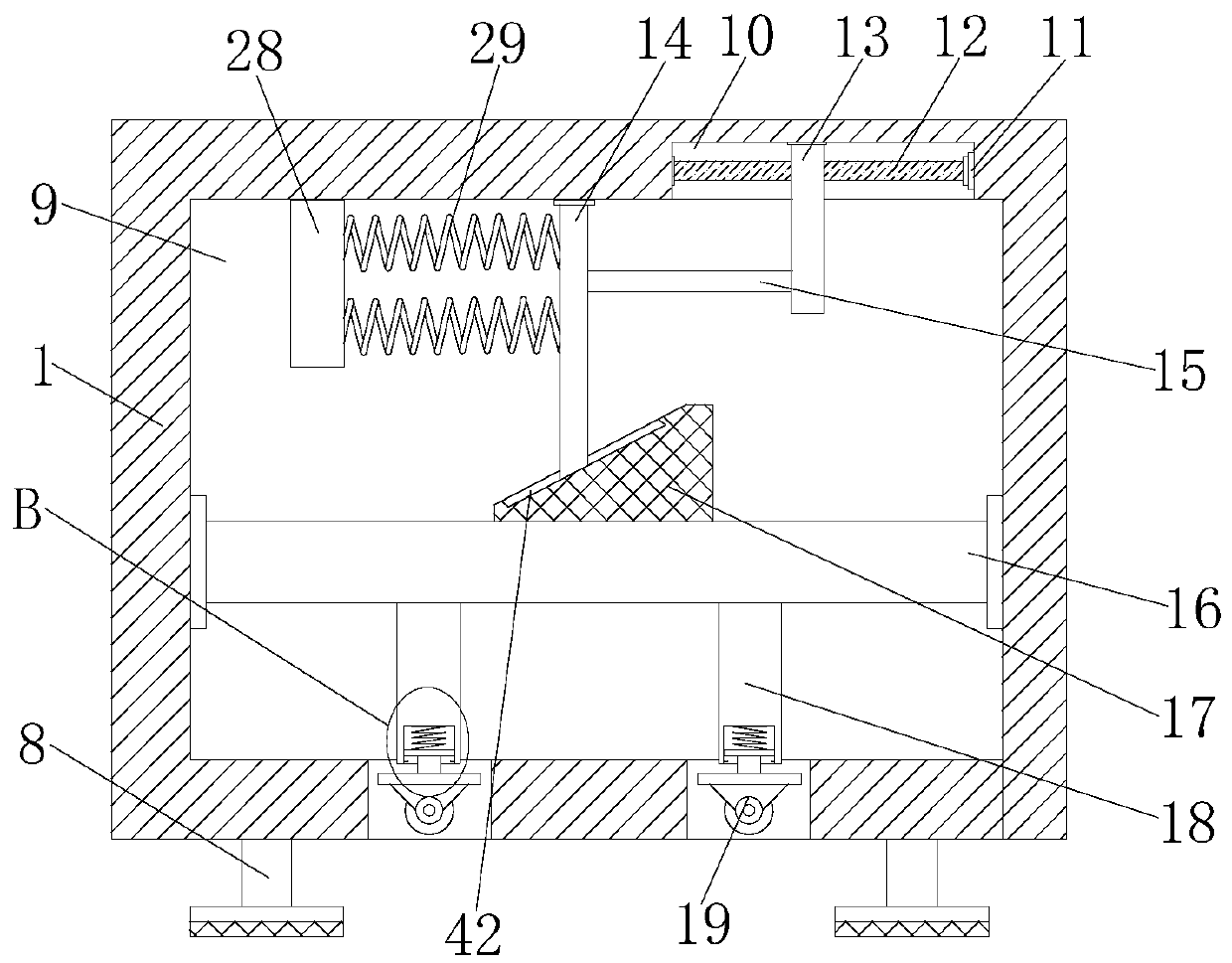

[0028] In this embodiment, the moving assembly includes a fixed chamber 9 arranged on the base 1, a mounting groove 10 is opened on the top of the fixed chamber 9, and a first motor 11 is fixedly connected to the inner wall of one side of the mounting groove 10. A rotating shaft 12 is fixedly connected to the output shaft of a motor 11, and one end of the rotating shaft 12 is rotatably connected to the other side inner wall of the mounting groove 10. The rotating plate 13 is screwed on the rotating shaft 12, and the top inner wall of the fixed chamber 9 is slidably connected to a Moving bar 14, one side of moving bar 14 is fixedly connected with fixed bar 15, and one end of fixed bar 15 is fixedly connected with one side of moving plate 13, and sliding plate 16 is slidably connected in fixed chamber 9, and the top of sliding plate 16 is fixed A swash plate 17 is connected, and the bottom of the moving rod 14 is slidingly connected to one side of the swash plate 17. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com