A cutting device for modifying a computer

A cutting device and computer technology, applied in the computer field, can solve problems such as affecting cutting and inconvenient adjustment of cutting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

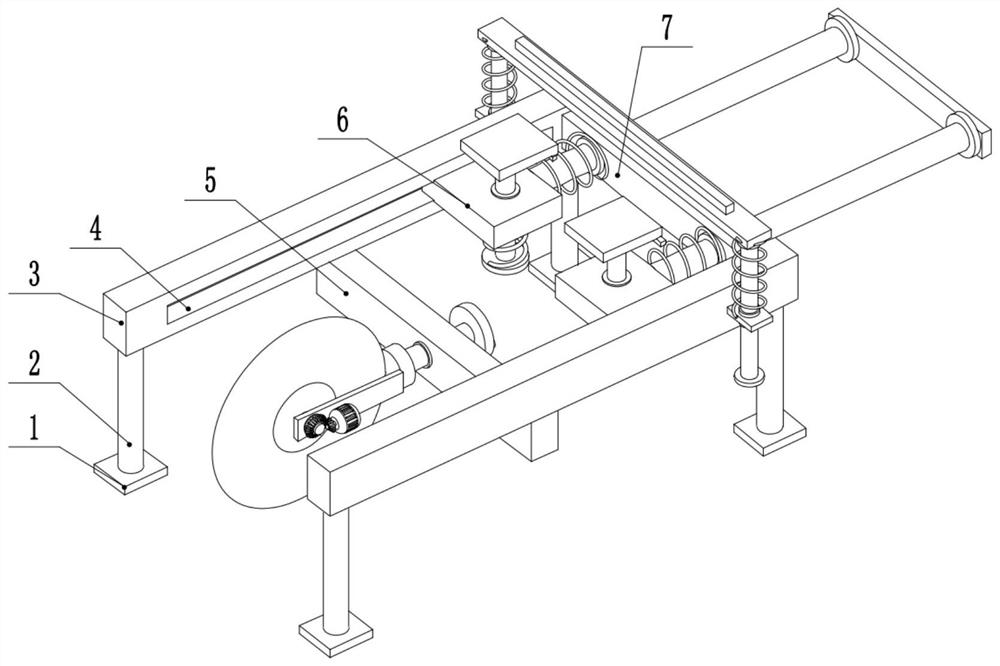

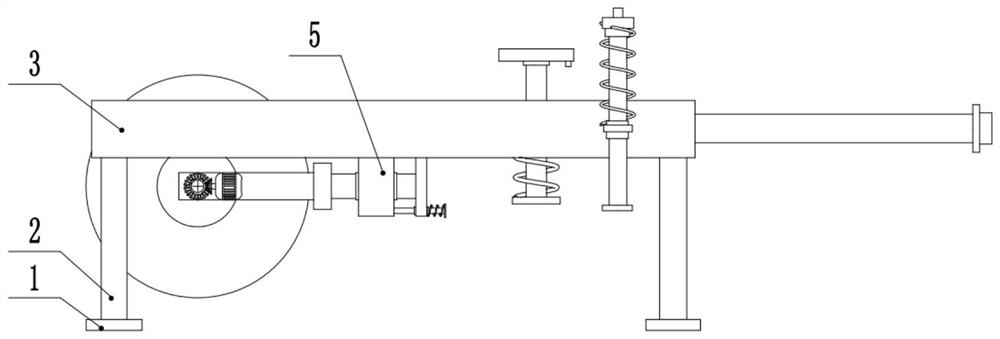

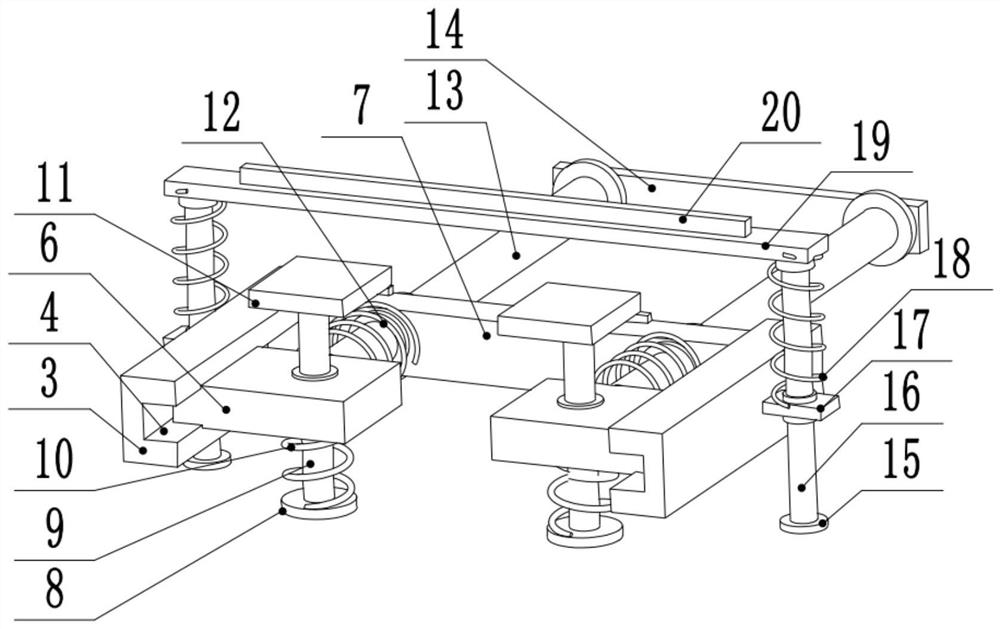

[0029] see Figure 1-6 , a cutting device for refitting a computer, comprising a fixed rod 3, the left and right sides of the lower surface of the fixed rod 3 are provided with support columns 2, the lower end of the support column 2 is provided with a cushion block 1, and the middle of the fixed rod 3 is provided with There is a chute 4, the middle part of the chute 4 is slidably connected to the end of the slider 6 away from the center of the device, the right end of the fixing rod 3 is provided with a second fixing plate 7, and the front and rear sides of the second fixing plate 7 are slidably connected to the second fixing plate 7. The guide rod 13, the left end of the second guide rod 13 is fixedly connected to the right side of the slider 6, a second spring 12 is arranged between the slider 6 and the second fixing plate 7, and the second spring 12 is sleeved on the second guide rod 13 Externally, the right end of the second guide rod 13 is provided with a push plate 14 ,...

Embodiment 2

[0032] see Image 6 , the other contents of this embodiment are the same as those of the first embodiment, the difference is that the lower part of the rotating disk 30 is slidably connected to the limit rod 31 , the right end of the limit rod 31 is provided with a third limit block 33 , and the third limit A fourth spring 32 is provided between the position block 33 and the rotating disk 30 . In order to ensure that the angle of the cutting wheel 29 is locked during the cutting process, a limit rod 31 is provided at the right end of the rotating disk 30. When the rotating disk 30 is rotated, the limiting rod 31 can be pulled out to the right, and the rotating disk 30 It can be rotated freely. After the angle adjustment is completed, the limit rod 31 is released. Under the action of the fourth spring 32, the limit rod 31 moves to the left, and the left side of the limit rod 31 bears against the first fixing plate 5. , the angle of the rotating disk 30 is locked at this time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com