Construction reinforcement cutting machine after construction

A technology for building steel bars and cutters, applied in the field of cutters, can solve problems affecting steel bar cutting, shaking, wasting manpower, etc., and achieve the effects of prolonging service life, avoiding shaking, and avoiding damage to cutting blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

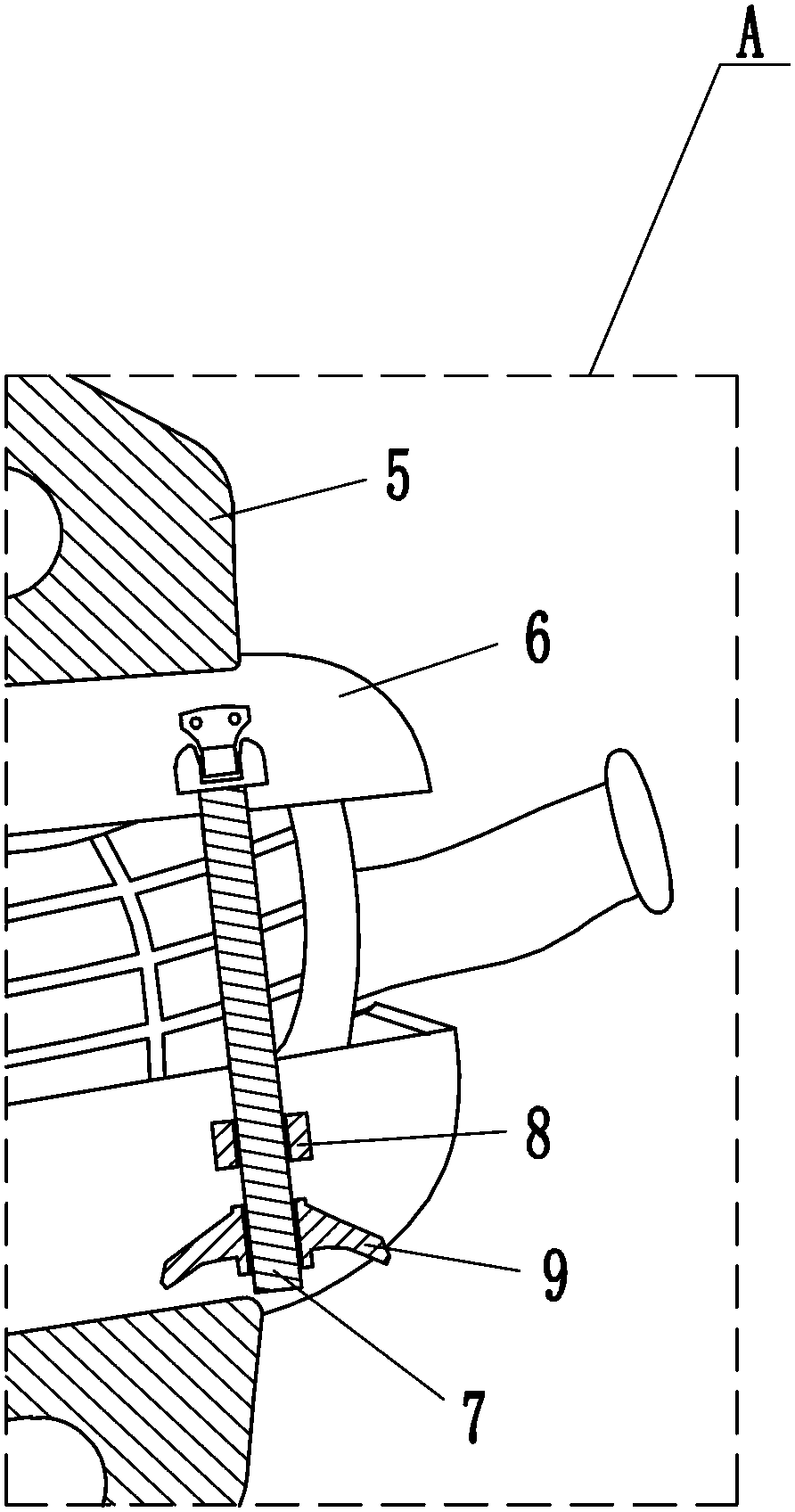

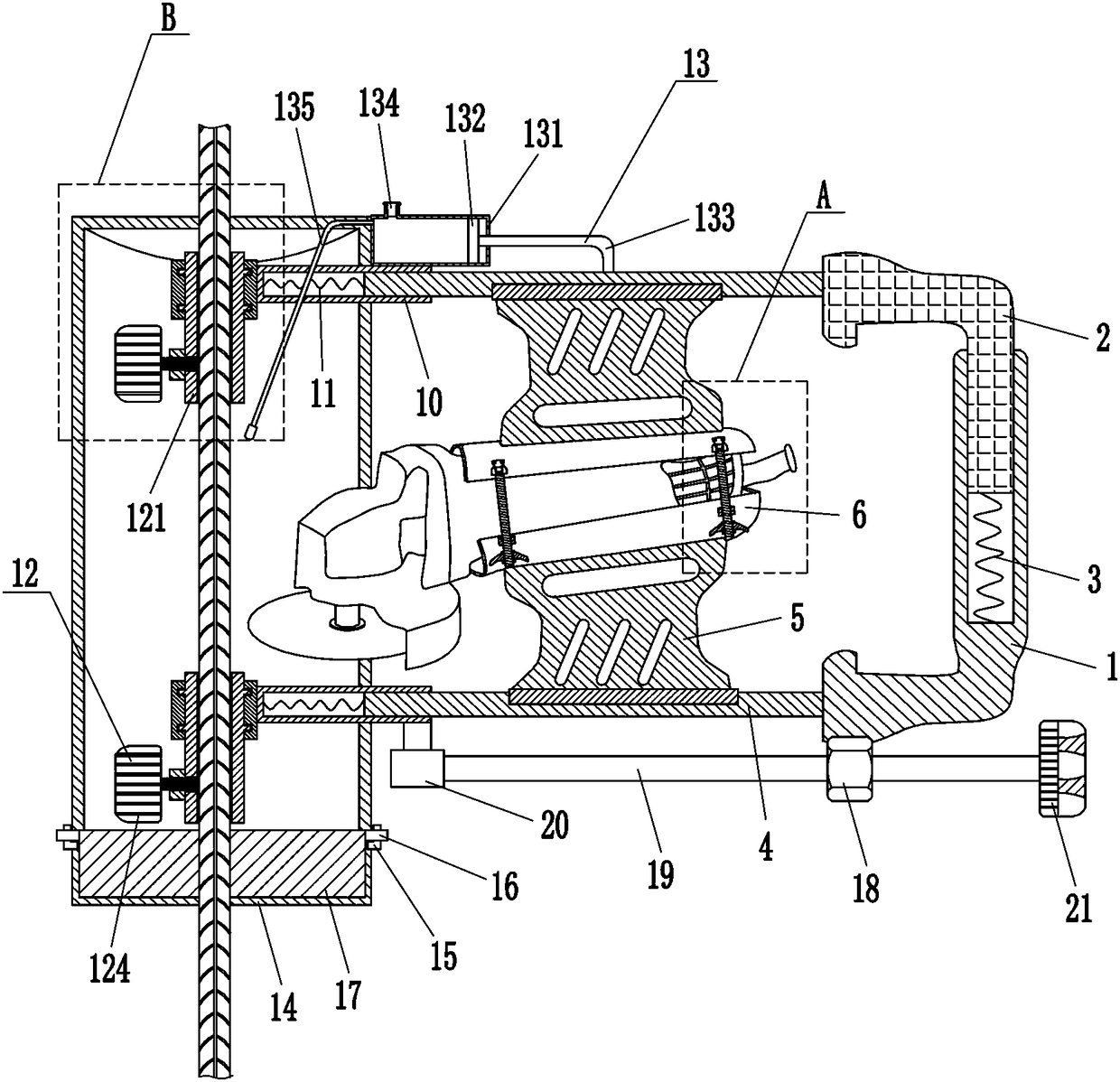

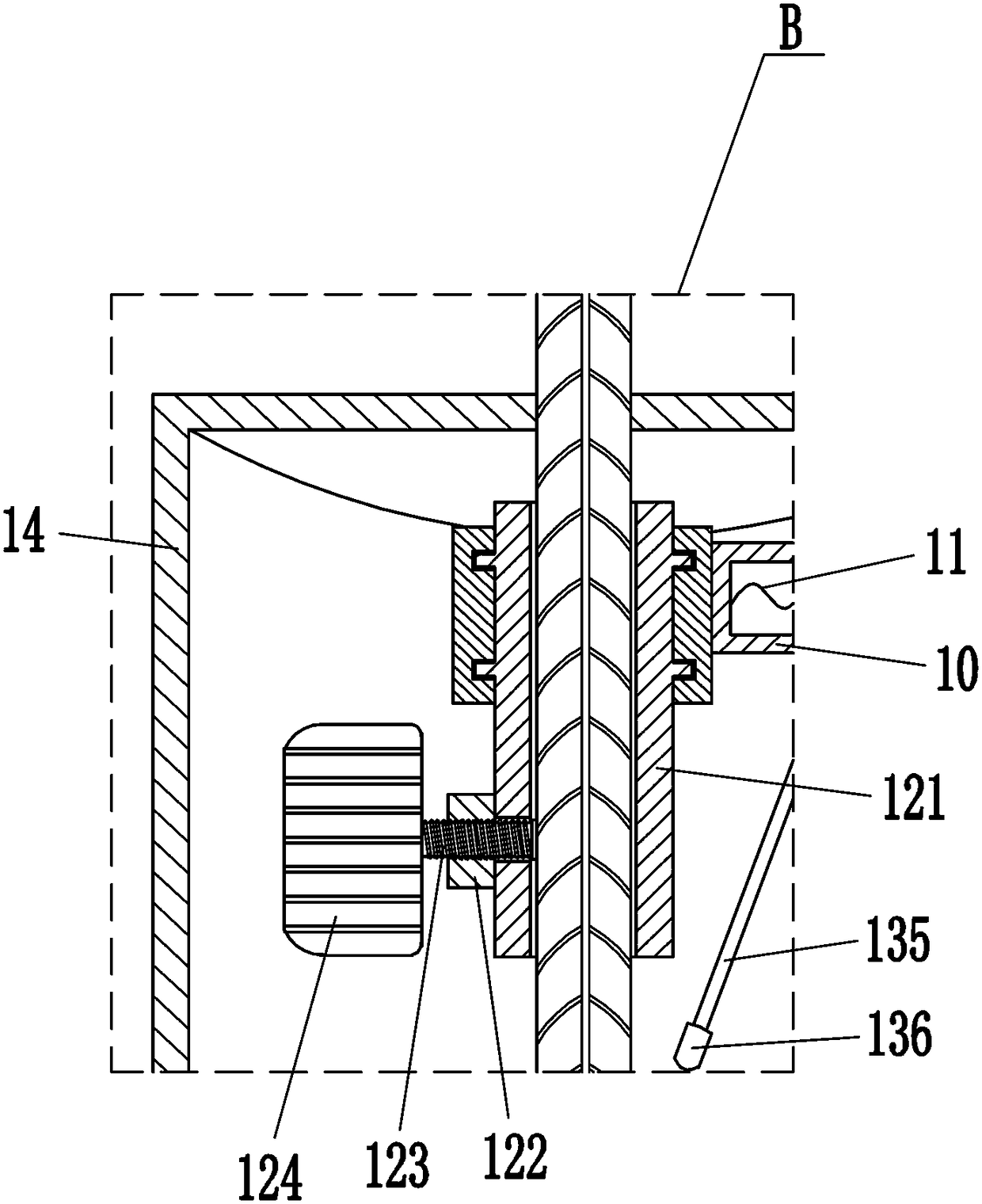

[0021] A post-construction cutter for building reinforcement, such as Figure 1-3 As shown, it includes hollow handle 1, movable handle 2, first spring 3, connecting rod 4, connecting plate 5, arc clamping plate 6, first screw rod 7, ferrule 8, wing nut 9, sleeve 10, The second spring 11 and the clamping mechanism 12, the hollow handle 1 is provided with a movable handle 2, the first spring 3 is connected between the bottom of the movable handle 2 and the inner bottom of the hollow handle 1, and there are two connecting rods 4, which are respectively arranged in the hollow The handle 1 and the left end of the movable handle 2, the inner sides of the two connecting rods 4 are connected with the arc-shaped clamping plate 6 for fixing the cutting machine through the connecting plate 5, and the front and rear sides of the upper arc-shaped clamping plate 6 are rotatably connected with two first Screw 7, two ferrules 8 for clamping the first screw 7 are fixedly connected to the fron...

Embodiment 2

[0023] A post-construction cutter for building reinforcement, such as Figure 1-3 As shown, it includes hollow handle 1, movable handle 2, first spring 3, connecting rod 4, connecting plate 5, arc clamping plate 6, first screw rod 7, ferrule 8, wing nut 9, sleeve 10, The second spring 11 and the clamping mechanism 12, the hollow handle 1 is provided with a movable handle 2, the first spring 3 is connected between the bottom of the movable handle 2 and the inner bottom of the hollow handle 1, and there are two connecting rods 4, which are respectively arranged in the hollow The handle 1 and the left end of the movable handle 2, the inner sides of the two connecting rods 4 are connected with the arc-shaped clamping plate 6 for fixing the cutting machine through the connecting plate 5, and the front and rear sides of the upper arc-shaped clamping plate 6 are rotatably connected with two first Screw 7, two ferrules 8 for clamping the first screw 7 are fixedly connected to the fron...

Embodiment 3

[0026] A post-construction cutter for building reinforcement, such as Figure 1-3As shown, it includes hollow handle 1, movable handle 2, first spring 3, connecting rod 4, connecting plate 5, arc clamping plate 6, first screw rod 7, ferrule 8, wing nut 9, sleeve 10, The second spring 11 and the clamping mechanism 12, the hollow handle 1 is provided with a movable handle 2, the first spring 3 is connected between the bottom of the movable handle 2 and the inner bottom of the hollow handle 1, and there are two connecting rods 4, which are respectively arranged in the hollow The handle 1 and the left end of the movable handle 2, the inner sides of the two connecting rods 4 are connected with the arc-shaped clamping plate 6 for fixing the cutting machine through the connecting plate 5, and the front and rear sides of the upper arc-shaped clamping plate 6 are rotatably connected with two first Screw 7, two ferrules 8 for clamping the first screw 7 are fixedly connected to the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com