Glass knife with electronic level meter

An electronic level, glass knife technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as consumption of manpower and material resources, low work efficiency, glass size deviation, etc., to improve work efficiency and low production costs. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical scheme and characteristics of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. Here, the following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

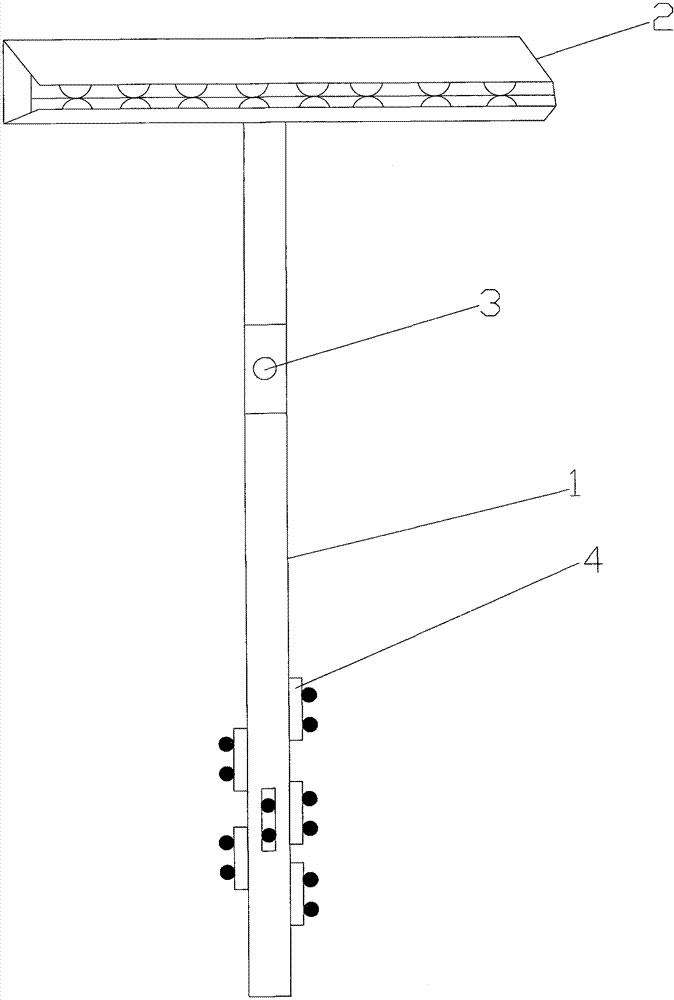

[0014] like figure 1 As shown, the present invention includes a glass backing plate 1, a push knife body 2, and an electronic level 3, the electronic level 3 is installed on the bottom surface of the push knife body 2, and the sensor installed on the electronic level 3 transmits the glass level to the electronic level 3. The electronic level 3 is also connected with a liquid crystal display to display the glass level data transmitted by the sensor on the liquid crystal display. The structural design of the electronic level 3 improves the cutting accuracy of the glass, and is not affected by the levelness of the table top where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com