Circuit board device, wiring board connecting method, and circuit board module device

A technology for circuit boards and wiring boards, which is applied in the structural connection of printed circuits, stacking and separating printed circuit boards, circuits, etc. The effect of stable electrical connection, thin circuit board equipment, high stability electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

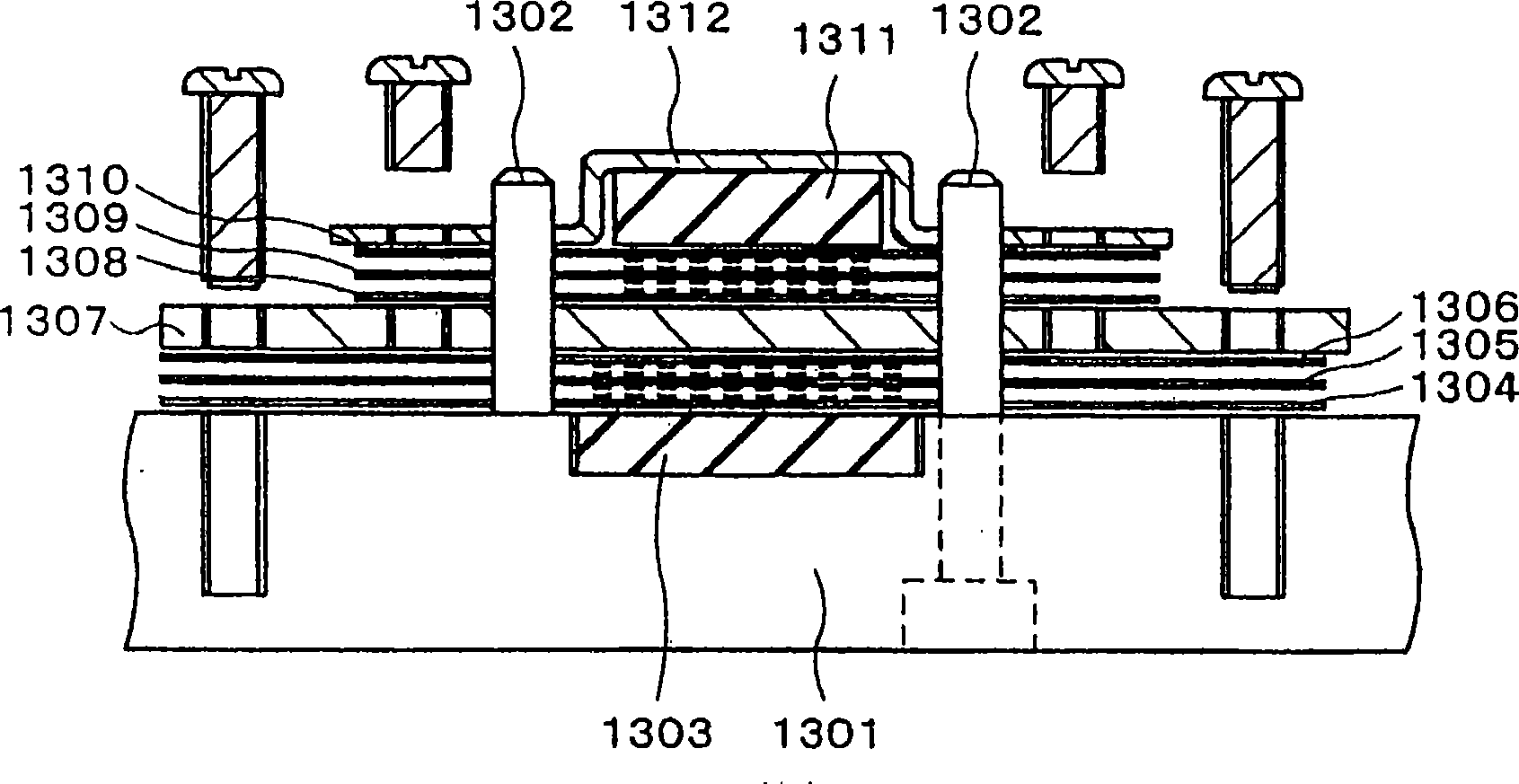

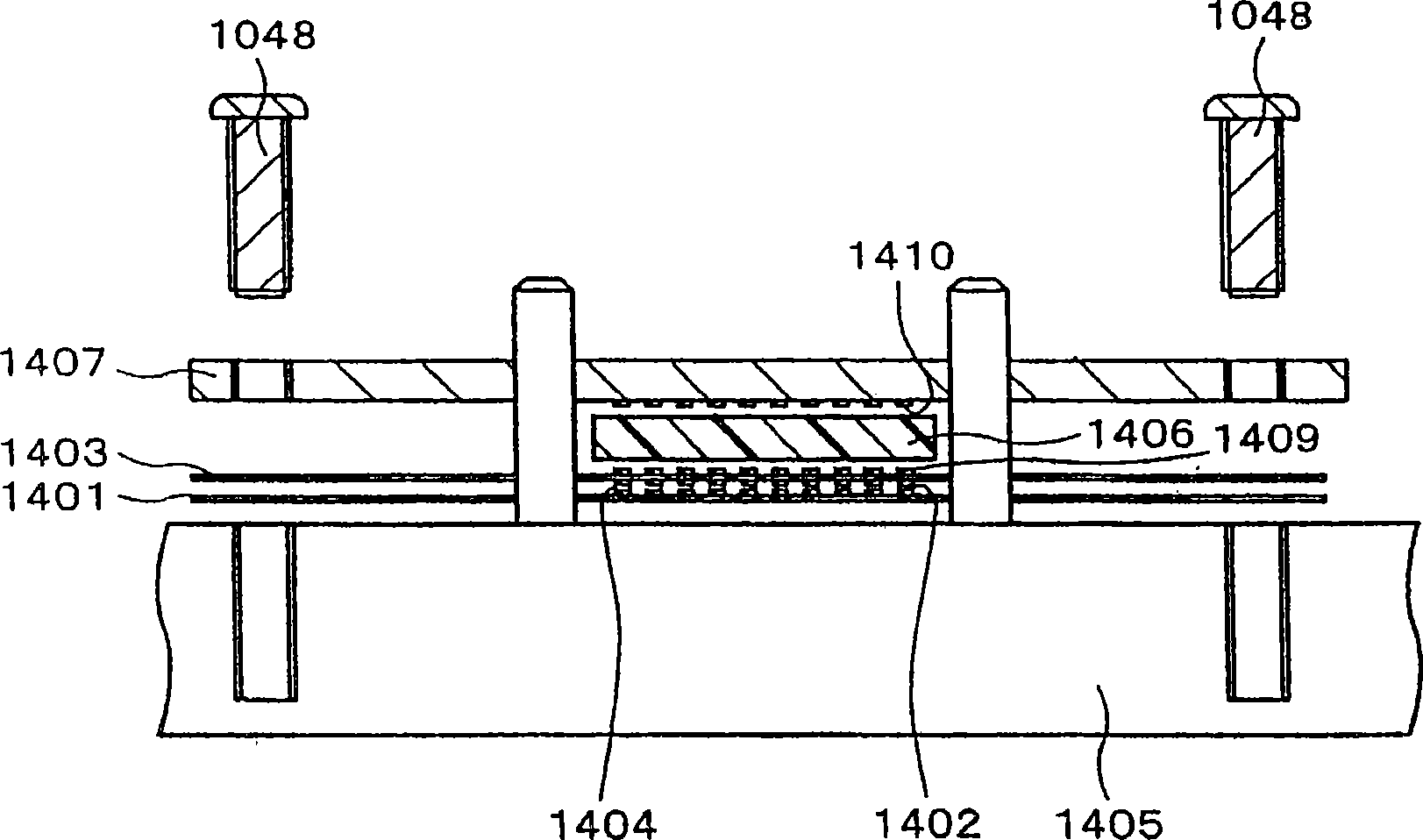

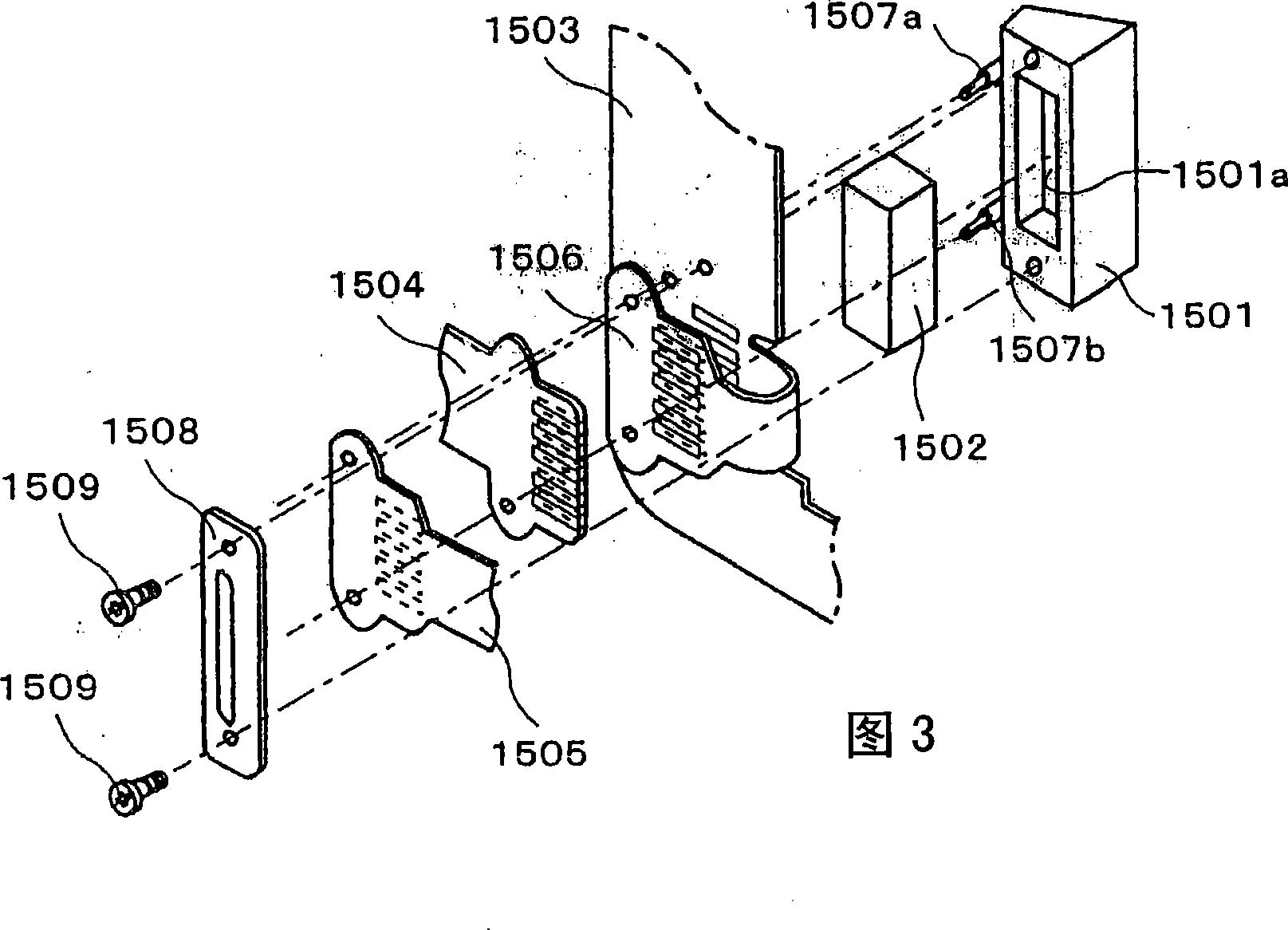

[0188] Hereinafter, examples for demonstrating the effects of the present invention will be described. First, the effect of the present invention will be described in comparison with a comparative example not within the scope of the present invention. As an example of the present invention, the circuit board according to the second embodiment described above was created in the following manner.

[0189] A rigid printed wiring board mainly made of FR4 was used as the first wiring board 101; a flexible printed wiring board mainly made of polyimide was used as the second wiring board 102; a flexible printed wiring board mainly made of polyimide was used as the second wiring board 102; A printed wiring board was used as the third wiring board 103 ; and a flexible printed wiring board mainly made of polyimide was used as the fourth wiring board 104 .

[0190] In addition, for example, the electrode terminal 109a provided on the front surface of the first wiring board 101 and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com