Method for preparing aluminium alloy trapezoidal conductor

An aluminum alloy and trapezoidal technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of large twisting gap, large internal stress, and reduced bending performance of conductors, etc., to achieve smooth and clean surface, small torsional stress, The effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

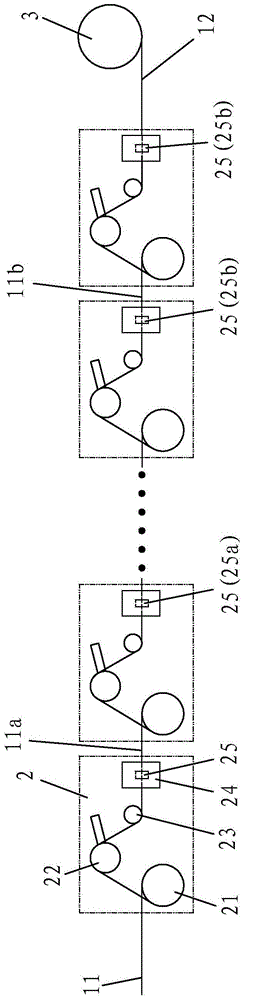

[0032] Such as Figure 3 to Figure 7 Shown, the preparation method of aluminum alloy trapezoidal conductor of the present invention, comprises the following steps:

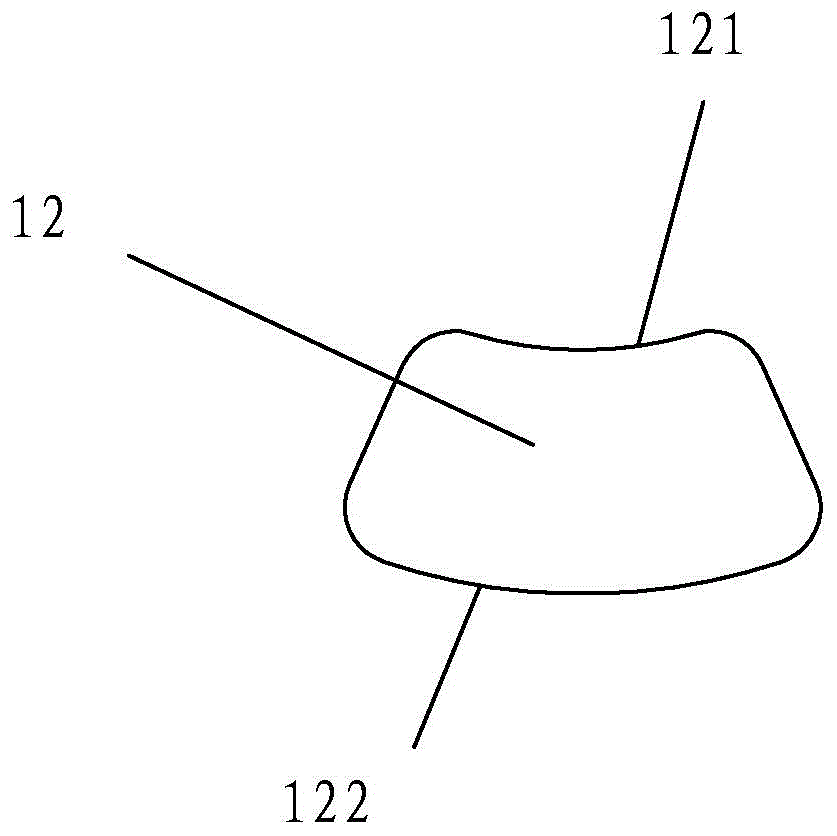

[0033] Drawing step: use a non-sliding wire drawing machine to draw a trapezoidal single wire 12, the non-sliding wire drawing machine includes several drawing groups 2, use aluminum alloy rods as wires 11 to lay out the wires, and draw them into trapezoidal shapes through each drawing group 2 in turn Single wire 12, the trapezoidal single wire 12 is wound up by the wire reel 3, and the large arc surface 122 of the trapezoidal single wire 12 is ensured to fit the wire reel 3;

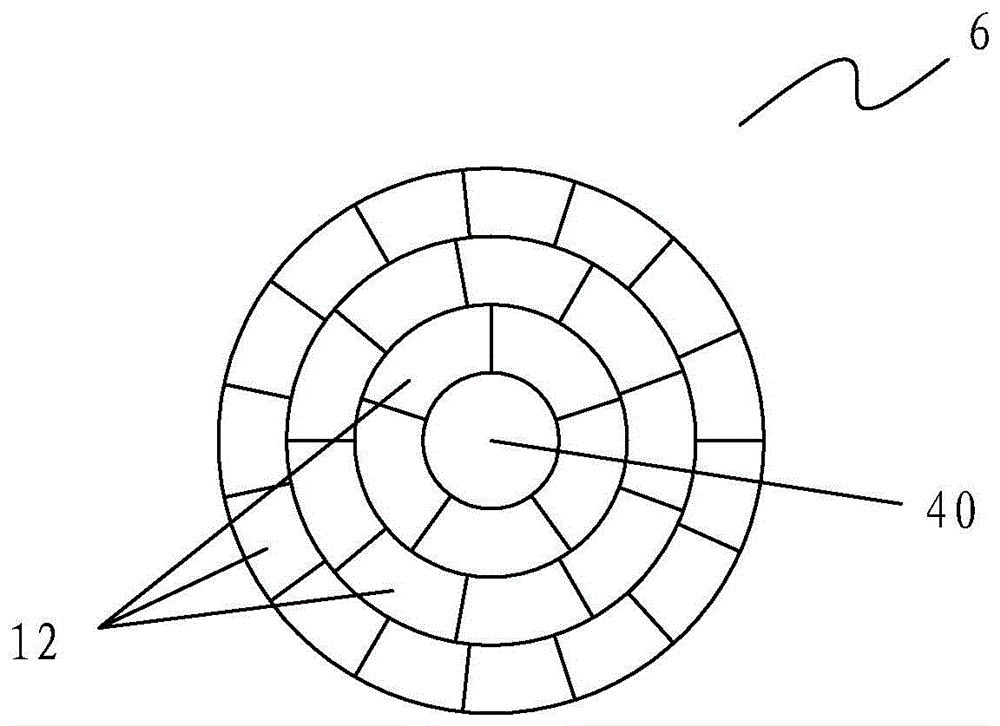

[0034] Stranding step: using a frame-type stranding machine 5 to twist the trapezoidal conductor 6, the pay-off device releases the central round wire 40, the central round wire 40 is used as the core wire X, and several trapezoidal single wires 12 are used as the outer covering wire Y to pass through the frame-type twisted wire The machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com