Device for cutting polycrystalline silicon wafer through diamond wires and cutting method

A technology of diamond wire cutting and polycrystalline silicon wafers, which is applied in the field of diamond wire cutting polycrystalline silicon wafers and cutting polycrystalline silicon wafers. Edge chipping and chipping, wire mesh balance, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

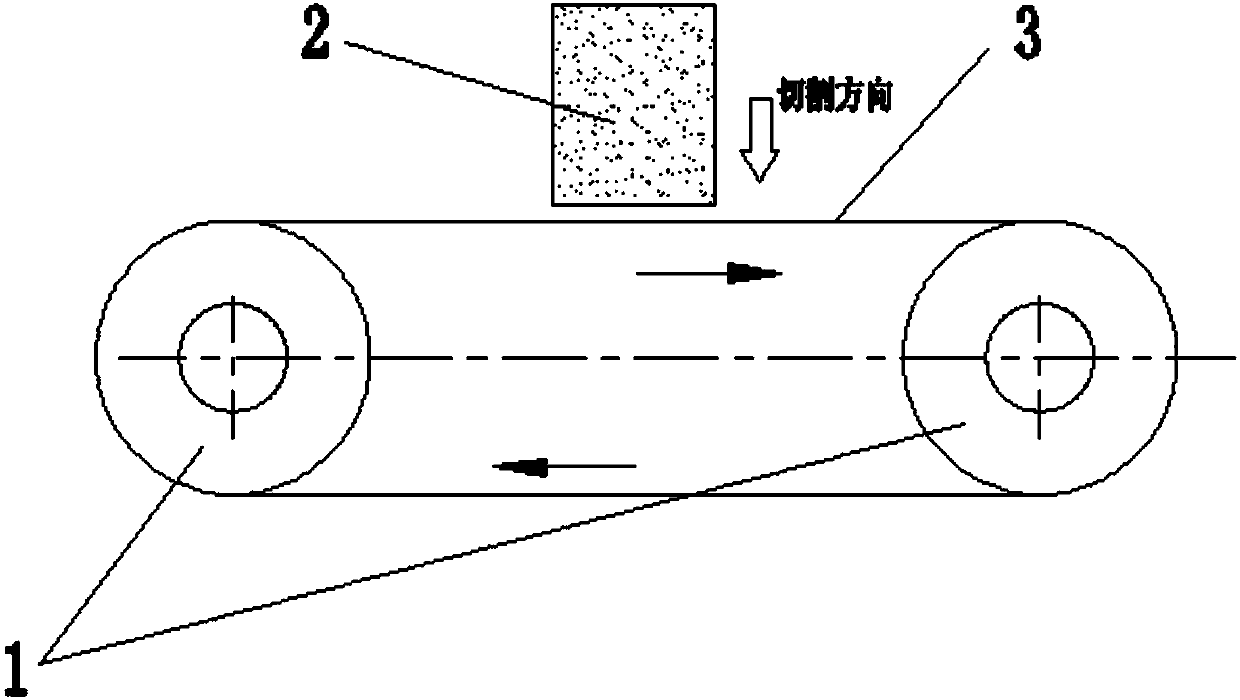

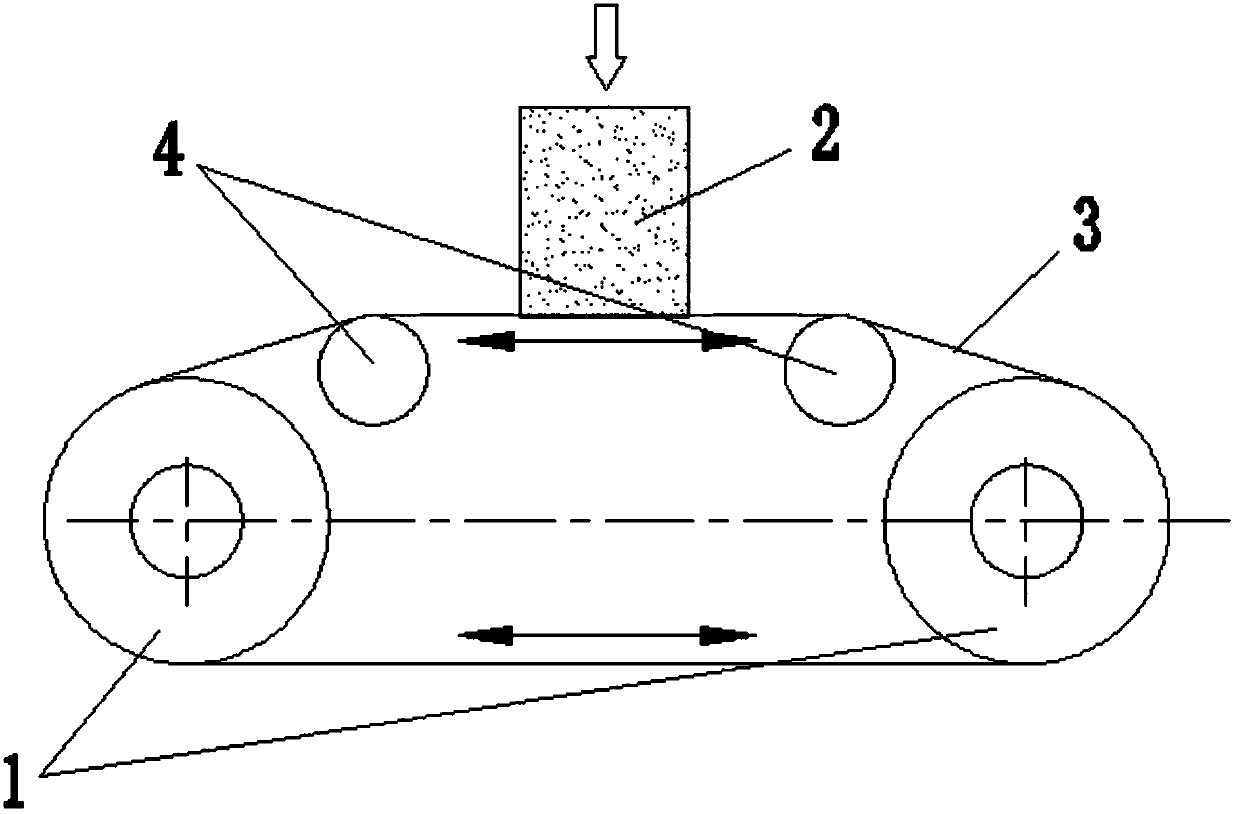

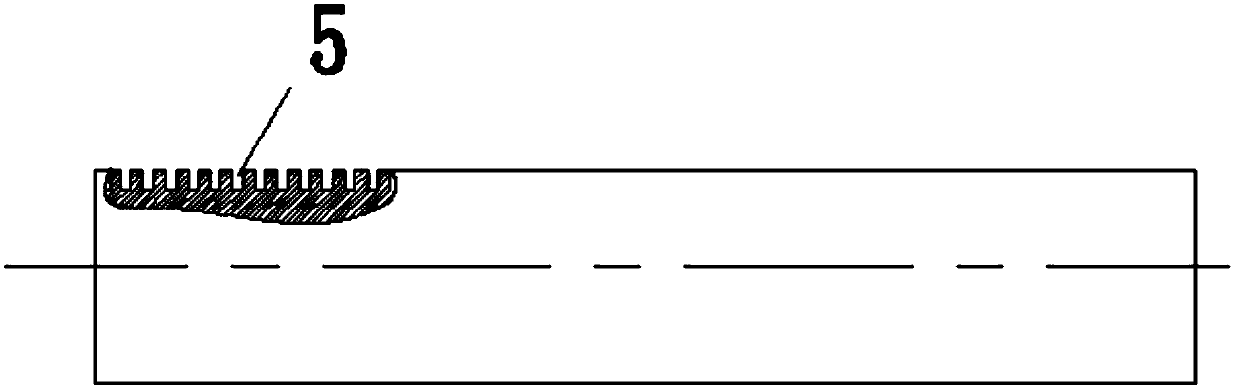

[0027] As shown in the accompanying drawings, a device for diamond wire cutting polysilicon wafers includes a cutting machine, which is improved from a silicon wafer cutting machine that adopts linear cutting in the prior art, and the cutting machine includes two The large guide wheels 1 arranged at intervals, several diamond wires 3 wound between the two large guide wheels 1, and the coolant nozzle, the improvement is that they are arranged in parallel above the two large guide wheels 1 There are two small guide wheels 4 whose diameter is smaller than the diameter of the large guide wheel 1, the two small guide wheels 4 are located on the inner side between the two large guide wheels 1 and the upper surfaces of the two small guide wheels 4 flush, the surface of the small guide wheel 4 is provided with several wire grooves 5 at intervals, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com