Waterborne half-PU leather bottom material and preparation method thereof

A water-based, leather-based technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, adhesive additives, etc., can solve system instability, poor adhesion of semi-PU leather, water resistance and water resistance. Poor alkalinity and other problems, to achieve the effect of high peel strength, soft hand feeling and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

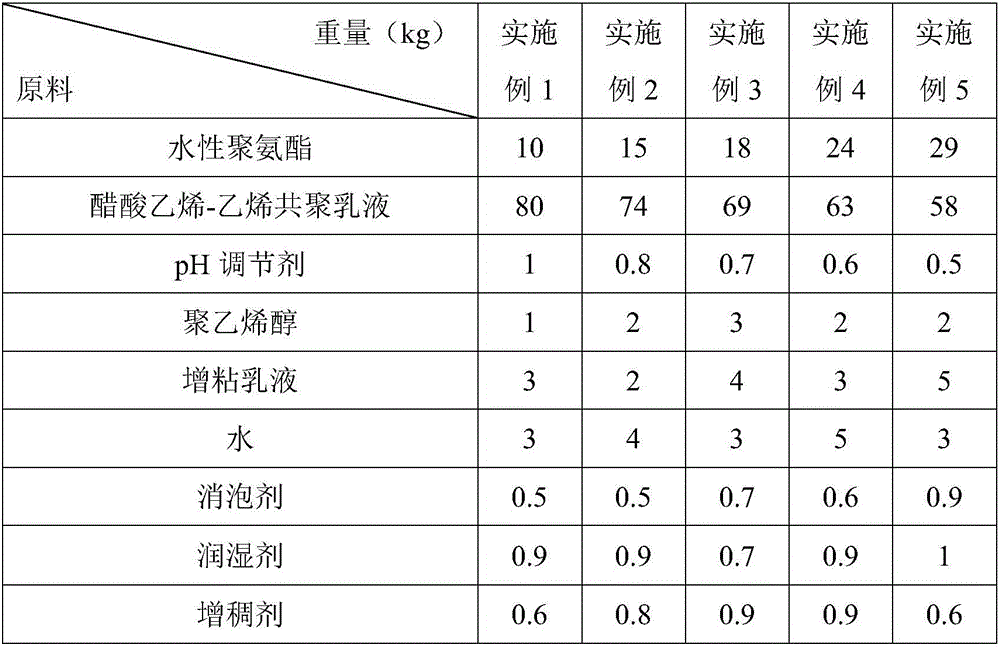

Embodiment 1

[0038] 1) Place 80 kg of vinyl acetate-ethylene copolymer emulsion (model 707) in a stainless steel container on a high-speed disperser, then add 0.5 kg of pH regulator, turn on the disperser, control the speed at 700 rpm, and add 1 kg of polymer in turn. Vinyl alcohol (model 2499), uniform dispersion; high-speed dispersion for 15 minutes;

[0039] 2) Control the rotation speed at 500 rpm, slowly add a mixture of 10kg of water-based polyurethane resin and 3kg of water into the stainless steel container, add while stirring, and mix well;

[0040] 3) Keep the speed constant, adjust the pH value to 7.0-8.5 with 0.5kg pH adjuster, then add 3kg thickening emulsion (model TR602), 0.5kg defoamer (model 8044), 0.9kg wetting agent ( Model YMT-329), and finally slowly add 0.6kg thickener (model MH30), adjust the slurry viscosity to 10000cps, and obtain the water-based semi-PU leather base material.

Embodiment 2

[0042] 1) Place 74 kg of vinyl acetate-ethylene copolymer emulsion (model 707) in a stainless steel container on a high-speed disperser, then add 0.4 kg of pH regulator, turn on the disperser, control the speed at 700 rpm, and add 2 kg of polymer in turn. Vinyl alcohol (model 2499), uniform dispersion; high-speed dispersion for 15 minutes;

[0043] 2) Control the rotation speed at 500 rpm, slowly add a mixture of 15 kg of water-based polyurethane resin and 4 kg of water into the stainless steel container, add while stirring, and mix well;

[0044] 3) Keep the speed constant, adjust the pH value to 7.0-8.5 with 0.4kg pH adjuster, then add 2kg thickening emulsion (model TR602), 0.5kg defoamer (model 8044), 0.9kg wetting agent ( Model YMT-329), finally slowly add 0.8kg thickener (model MH30), adjust the slurry viscosity to 12000cps, and obtain the water-based semi-PU leather base material.

Embodiment 3

[0046] 1) Place 69 kg of vinyl acetate-ethylene copolymer emulsion (model 149) in a stainless steel container on a high-speed disperser, then add 0.35 kg of pH regulator, turn on the disperser, control the speed at 700 rpm, and add 3 kg of polymer in turn. Vinyl alcohol (model 20-99), uniform dispersion; high-speed dispersion for 15 minutes;

[0047] 2) Control the speed at 500 rpm, slowly add a mixture of 18kg of water-based polyurethane resin and 3kg of water into the stainless steel container, add while stirring, and mix well;

[0048] 3) Keep the rotation speed unchanged, adjust the pH value to 7.0-8.5 with 0.35kg pH adjuster, and then add 4kg thickening emulsion (model T-100), 0.7kg defoamer (model NXZ), 0.7kg wetting (Model BYK-346), finally slowly add 0.9kg thickener (model 450VF), adjust the slurry viscosity to 13000cps, and obtain the water-based semi-PU leather base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com