Anticorrosive paint coated under rusted and moist conditions

An anti-corrosion coating and coating technology, applied in the field of coatings, can solve problems such as non-coating and rust, and achieve a good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

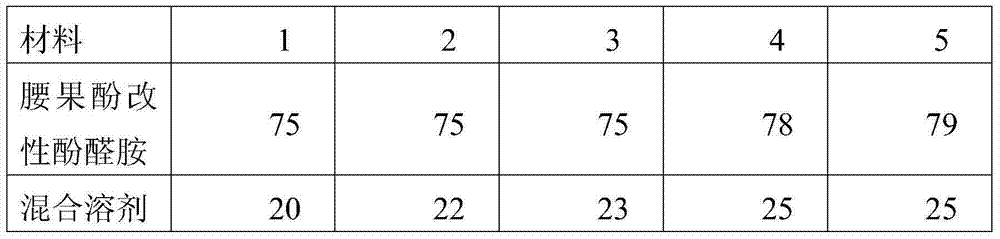

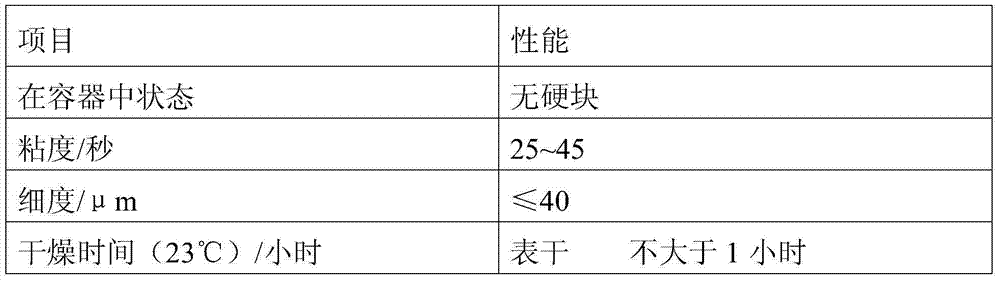

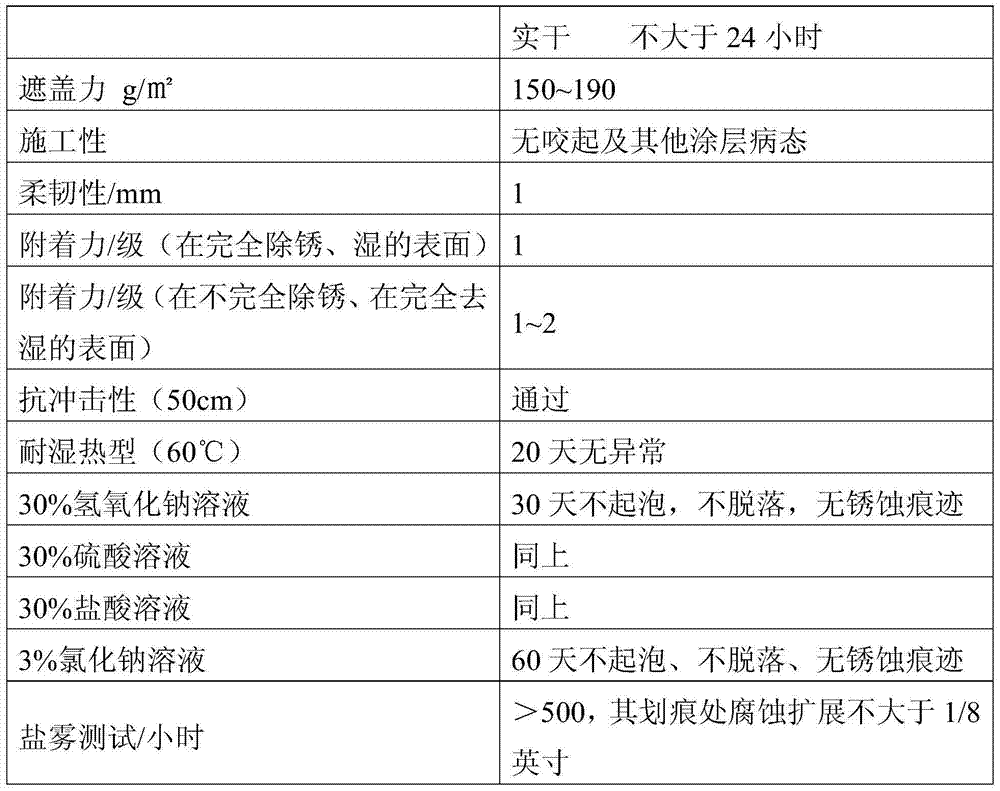

[0040] An anti-corrosion coating for wet coating with rust and band, according to parts by weight, has the following components, specifically as shown in Table 1 to Table 6:

[0041] Component A:

[0042] Resin: bisphenol A epoxy resin E20;

[0043] Pigments and fillers: titanium dioxide, zinc oxide, zinc phosphate, calcium phosphate, aluminum tripolyphosphate, barium sulfate;

[0044] Rust conversion agent: phosphoric acid, potassium ferrocyanide, tannic acid, butanol;

[0045] Mixed solvent: methyl isobutyl ketone, xylene, butanol;

[0046] Auxiliaries: anti-settling agent, leveling agent, dispersant;

[0047] Component B:

[0048] Cardanol modified phenalkamine;

[0049] Mixed solvents: methyl isobutyl ketone, xylene, butanol.

[0050] According to the ratio of parts by weight, component A: component B = 90 ~ 100: 1 ~ 1.2 (mixed before use);

[0051] In component A, in terms of parts by weight, resin: pigment and filler: rust converting agent: mixed solvent = 25-28: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com