High-adhesion oxidation-resisting UV-curable ink and preparation method thereof

An anti-oxidative and high-adhesion technology, applied in inks, household appliances, applications, etc., can solve the problems of ink adhesion and anti-oxidation that are not mentioned, achieve strong solvent resistance, easy to implement, and broaden the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

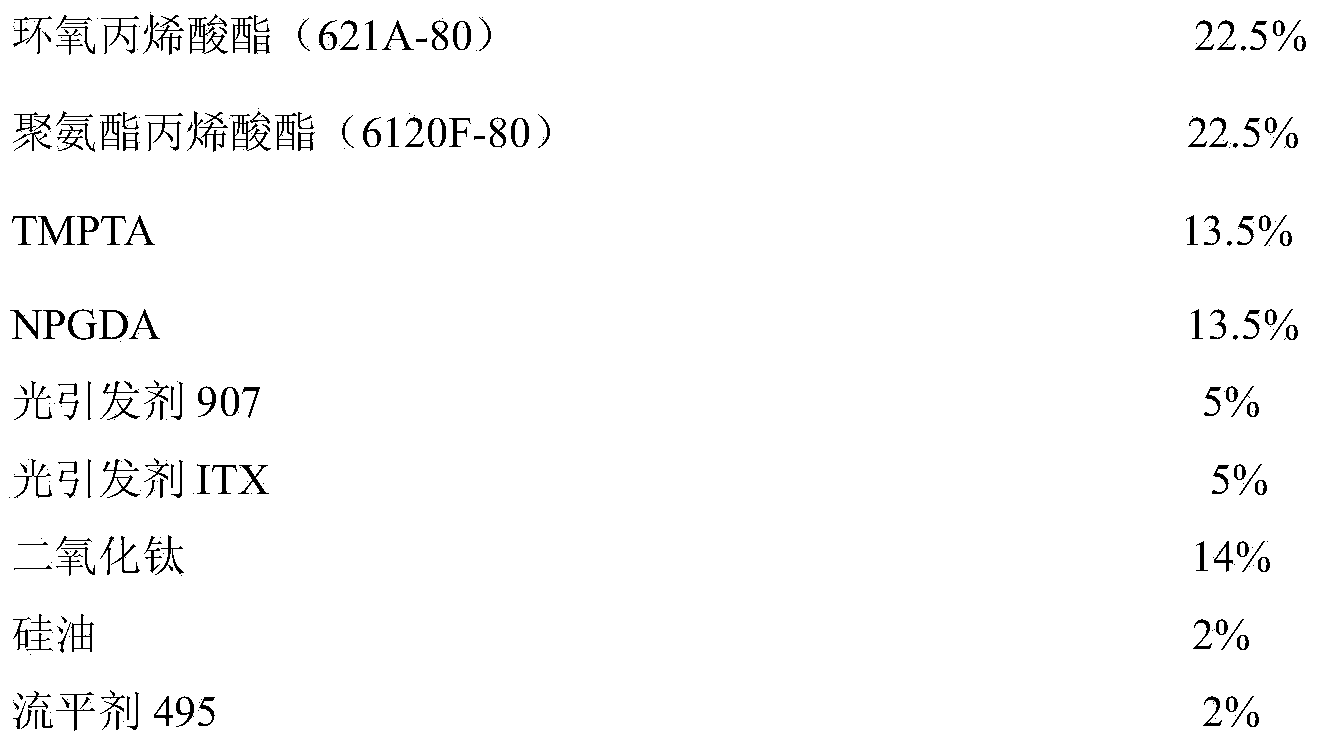

[0037] Step 1, take the following components by weight percentage:

[0038]

[0039] Step 2. Mix the above components in the reactor, disperse evenly, put them in an oven to soften, control the temperature at 40°C, and soften the time for 30 minutes;

[0040] Step 3. Stir the softened liquid in step 2 with a high-speed disperser. The stirring time is 10 minutes, and the stirring speed is 3000r / min;

[0041] The fineness, curing speed, solvent resistance, adhesion and peracetic acid solution cooking resistance of the prepared UV curable ink were tested, and the results are shown in Table 1.

Embodiment 2

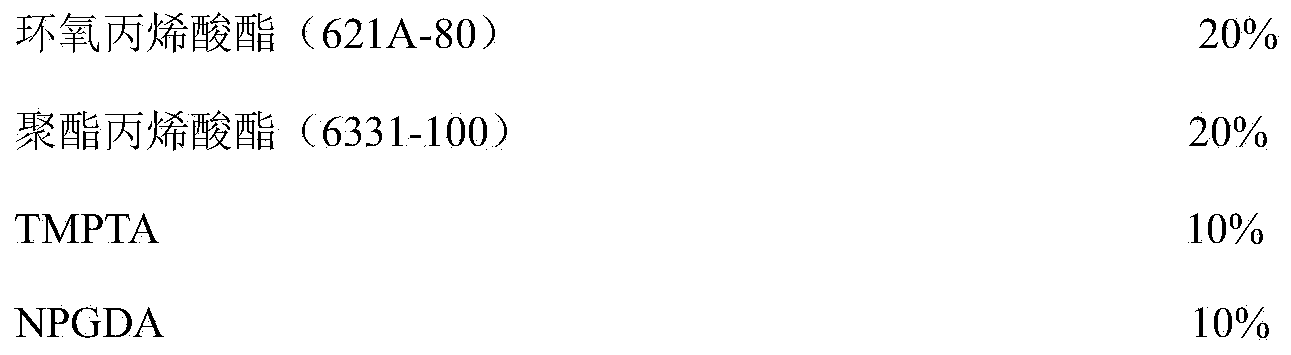

[0043] Step 1, take the following components by weight percentage:

[0044]

[0045]

[0046] Step 2. Mix the above components in the reactor, disperse evenly, put them in an oven to soften, control the temperature at 30°C, and soften the time for 15 minutes;

[0047] Step 3, stir the softened liquid in step 2 with a high-speed disperser, the stirring time is 10 minutes, and the stirring speed is 1000r / min; the fineness is controlled to 5um, and it is stored in a tank for later use.

[0048] The curing speed, solvent resistance, adhesion and peracetic acid solution cooking resistance of the prepared UV curing ink were tested, and the results are shown in Table 1.

example 3

[0050] Step 1, take the following components by weight percentage:

[0051]

[0052] Step 2. Mix the above components in the reactor, disperse evenly, put them in an oven to soften, control the temperature at 50°C, and soften the time for 50 minutes;

[0053] Step 3. Stir the softened liquid in step 2 with a high-speed disperser. The stirring time is 30 minutes, and the stirring speed is 5000r / min;

[0054] The curing speed, solvent resistance, adhesion and peracetic acid solution cooking resistance of the prepared UV curing ink were tested, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com