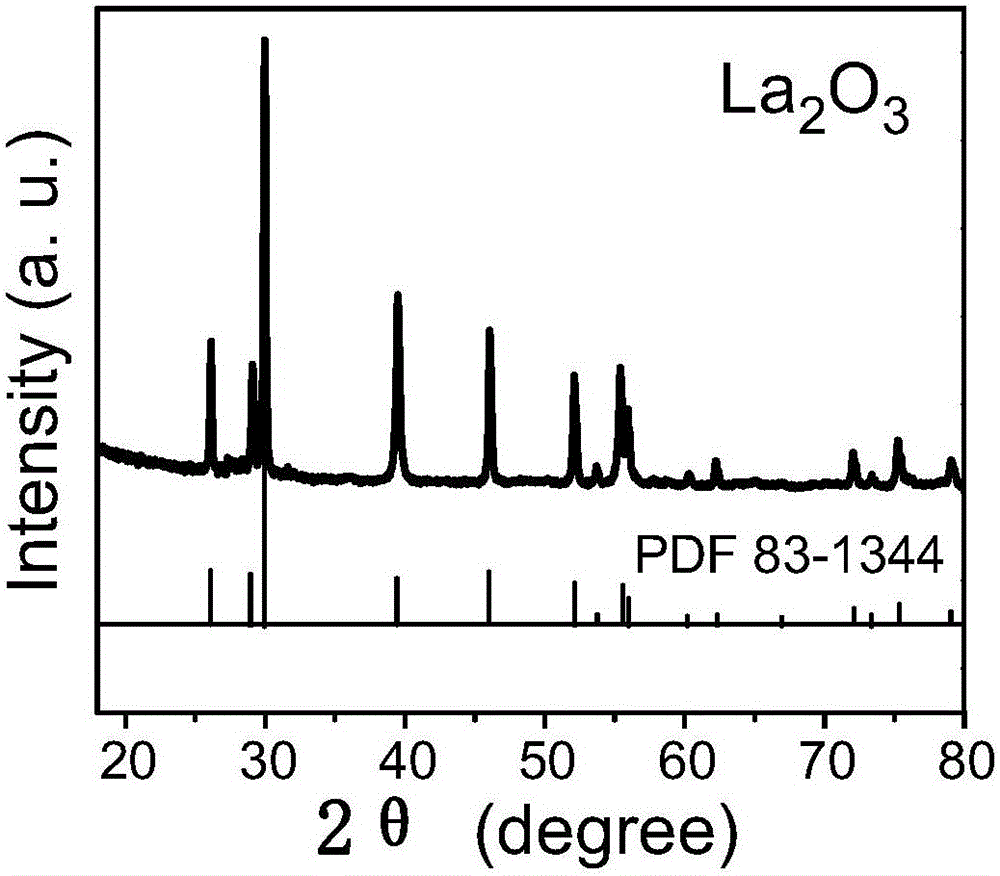

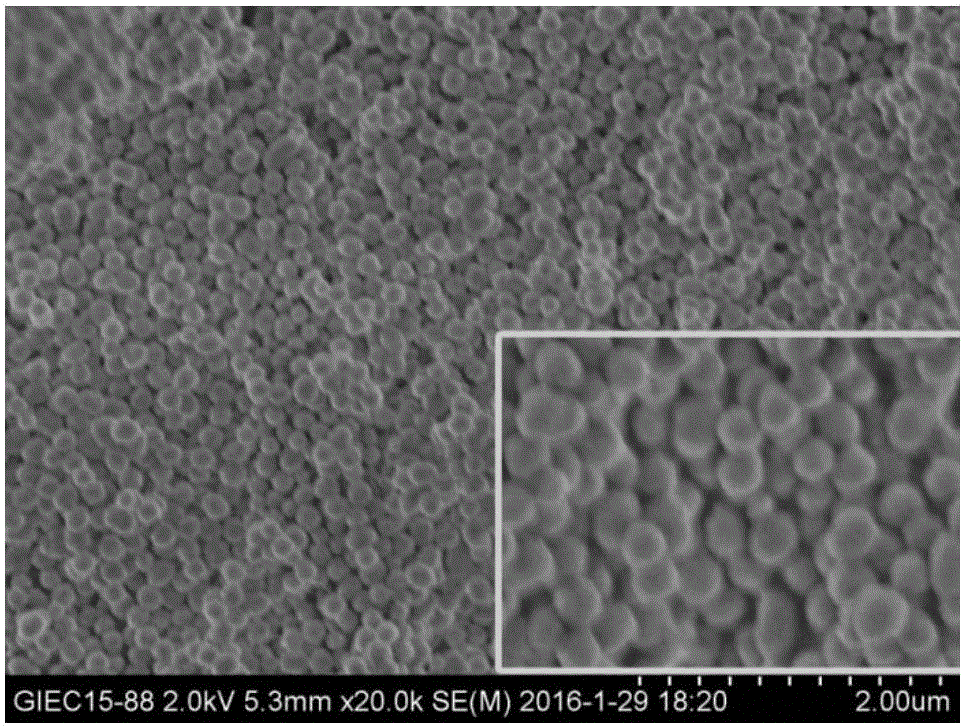

Spherical lanthanum oxide

A lanthanum oxide, spherical technology, applied in rare earth metal oxides/hydroxides, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of cumbersome operation methods, low catalytic efficiency of motor vehicle exhaust, etc., and achieve uniform product morphology, Reduced nucleation and growth rate, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

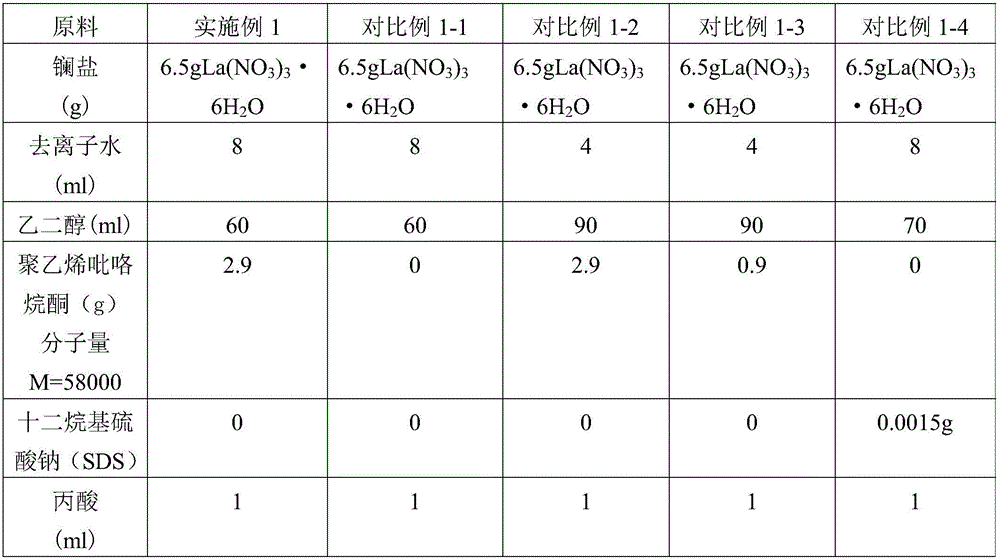

Embodiment 1

[0029] A kind of spherical lanthanum oxide is prepared, comprising the following steps:

[0030] (1) Weigh La(NO 3 ) 3 ·6H 2 O was dissolved in the mixture of deionized water and ethylene glycol, stirred until it was completely dissolved, then added polyvinylpyrrolidone (PVP, molecular weight M=58000), stirred for about 1 hour to obtain a transparent and clear solution, added propionic acid, and continued to stir 0.5h;

[0031] (2) Transfer the transparent and clear mixed solution into a 100ml polytetrafluoroethylene lining, put it into a stainless steel reactor, and react at 200°C for 200min;

[0032] (3) After the reactor was cooled to room temperature, the product was centrifuged at a speed of 10000r / min for 5min to obtain a precipitate, which was washed alternately with deionized water and ethanol for 3 times, and then dried at 80°C for 12h to obtain lanthanum oxide.

[0033] Test preparation: (1) Dry the lanthanum oxide prepared in Example 1, and grind it into a fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com