Multi-workpiece drilling equipment with movable fixture

A drilling equipment, multi-workpiece technology, applied in drilling/drilling equipment, metal processing equipment, boring/drilling, etc. The hole process is reliable and accurate, the sliding distance is accurate, and the effect of avoiding the replacement of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

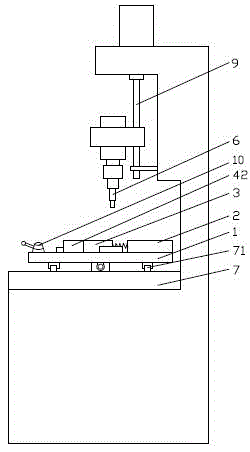

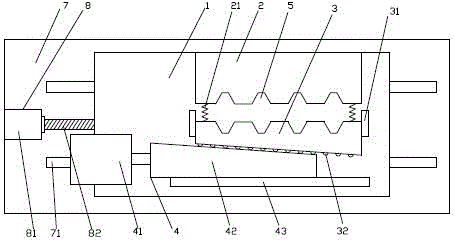

[0011] figure 1 , figure 2 Shown is the clamp displacement type multi-workpiece drilling equipment provided by the present invention, including a frame and clamps positioned on the frame, a drill bit 6 is arranged above the corresponding clamps on the frame; The slide table 7 of rail 71, fixture is fixed on the slide rail 71; Fixture is connected with the fixture driving device 8 that drives it to slide, and fixture driving device 8 comprises motor 81, the lead screw 82 that is connected with motor 81, the screw on the lead screw 82 The rod nut and the lead screw nut are connected with the fixture; the fixture includes a fixture bottom plate 1, a positioning block 2 and a clamping block 3 located on the fixture bottom plate 1 and oppositely arranged, and a clamping block drive that drives the clamping block 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com