Patents

Literature

67results about How to "No activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

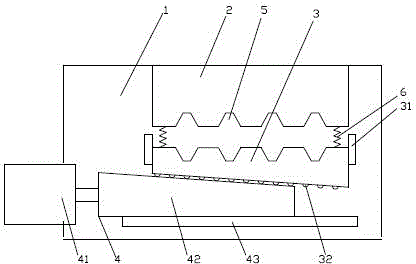

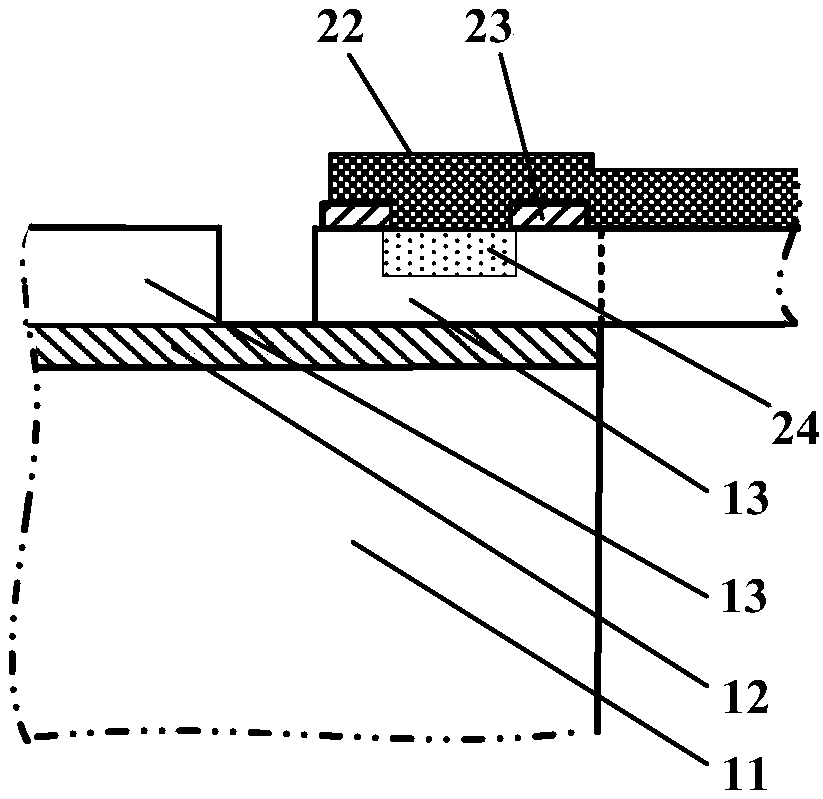

Self-resetting drilling fixture

InactiveCN104476277AMeet the clamping positioning requirementsAvoid replacementWork clamping meansPositioning apparatusEngineeringSelf locking

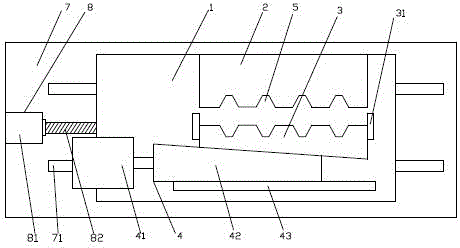

The invention belongs to the technical field of machining equipment and discloses a self-resetting drilling fixture comprising a bottom plate, a positioning block, a clamping block and a driving device; the positioning block and the clamping block are disposed on the bottom plate face to face; the driving device drives the clamping block to slide to the positioning block; a reset spring is connected between the positioning block and the clamping block; opposing faces of the positioning block and the clamping block are provided with at least two V-grooves facing each other; the driving device comprises a cylinder and a wedge connected to a piston rod of the cylinder; a sliding direction of the wedge is perpendicular to that of the clamping block; the surface, corresponding to certain V-grooves, of the wedge is a slope matching with a slope of the wedge; rollers are arranged and supported on the slope of the clamping block; the slope of the wedge is tangent to the surfaces of the rollers. The self-resetting drilling fixture has the advantages that machining efficiency is improved, self-locking after clamping is available, self-resetting after completion is available, and a drilling process is more reliable and accurate.

Owner:CHENGDU FANXINJIA TECH

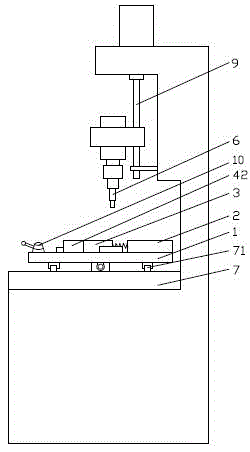

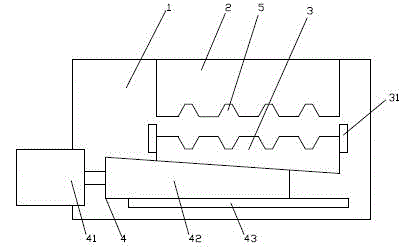

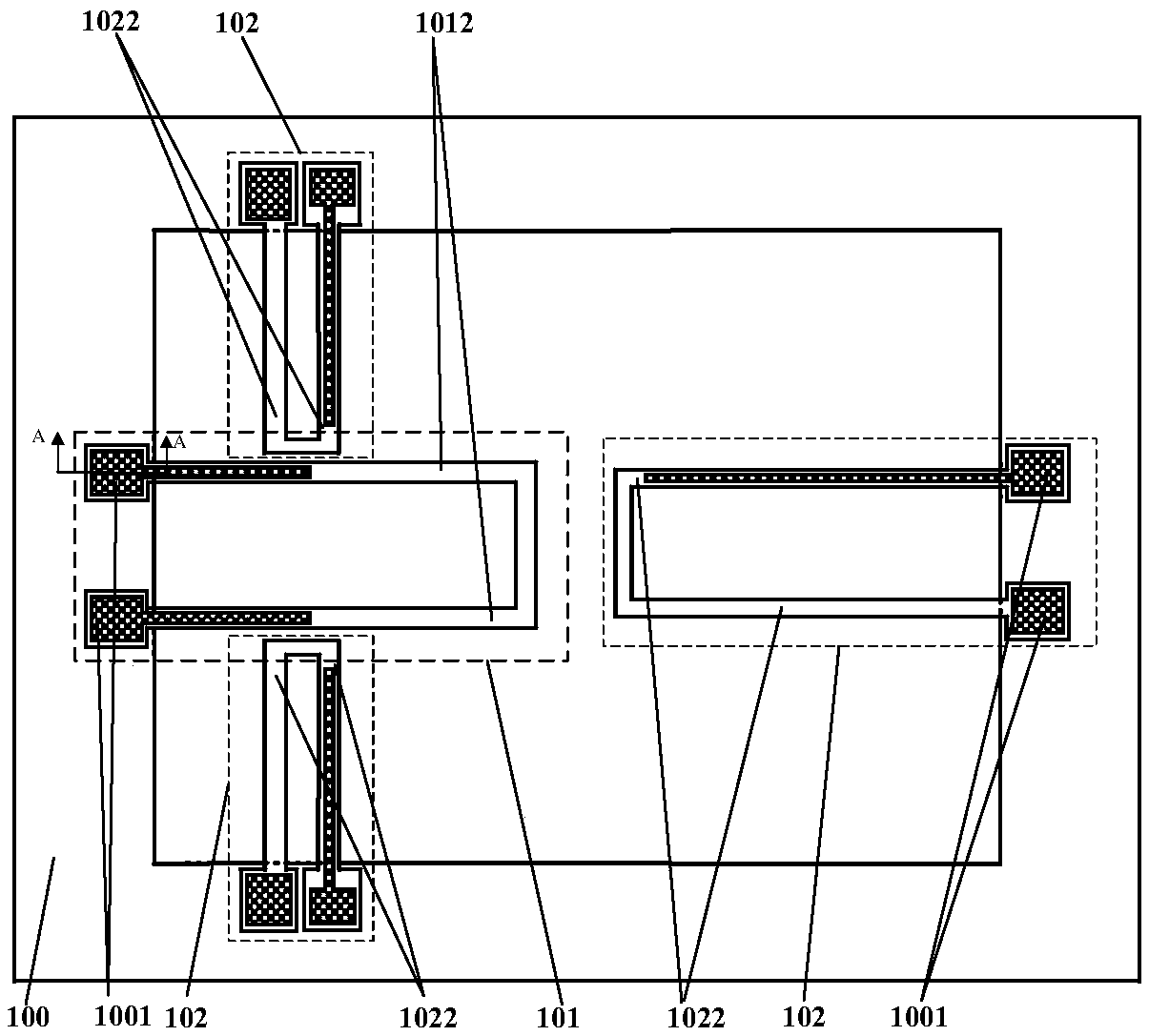

Multi-workpiece drilling equipment with movable fixture

InactiveCN104475808AMeet the clamping positioning requirementsAvoid replacementWork clamping meansPositioning apparatusSelf lockingEngineering

The invention discloses multi-workpiece drilling equipment with a movable fixture, and belongs to the technical field of machining equipment. The multi-workpiece drilling equipment comprises a framework and the fixture. The fixture is positioned on the framework; a drill bit is arranged on the upper side of the framework and corresponds to the fixture; a slide table is further arranged on the framework, and slide rails are arranged on the surface of the slide table; the fixture comprises a fixture bottom plate, a positioning block, a clamping block and a clamping block driving device, the positioning block and the clamping block are positioned on the fixture bottom plate and are opposite to each other, and the clamping block driving device can drive the clamping block to slide towards the positioning block; a return spring is arranged between the positioning block and the clamping block in a connected manner; V-shaped grooves which correspond to one another are formed in opposite surfaces of the positioning block and the clamping block; the clamping block driving device comprises a cylinder and a wedge block, the wedge block is connected with a piston rod of the cylinder, and an oblique plane is arranged on the surface, which is opposite to the corresponding V-shaped grooves, of the clamping block and is matched with an oblique plane of the wedge block; rollers are arranged and supported on the oblique plane of the clamping block, and the oblique plane of the wedge block is tangential to the surfaces of the rollers. The multi-workpiece drilling equipment has the advantages that the machining efficiency can be improved, self-locking effects can be realized after workpieces are clamped, the multi-workpiece drilling equipment can be automatically reset after the workpieces are completely machined, and drilling procedures can be reliably and accurately carried out.

Owner:CHENGDU FANXINJIA TECH

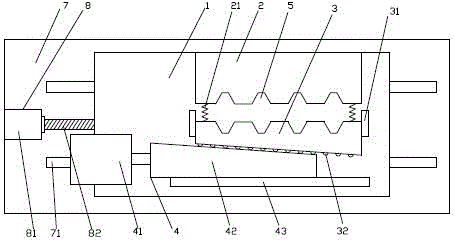

Sliding-type multi-workpiece clamping and drilling equipment

InactiveCN104476278AMeet the clamping positioning requirementsAvoid replacementPositioning apparatusBoring/drilling componentsSelf lockingEngineering

The invention discloses sliding-type multi-workpiece clamping and drilling equipment and belongs to the technical field of machining equipment. The equipment comprises a rack and a clamp located on the rack, and a drill bit is arranged on the rack and over the clamp correspondingly; a sliding table provided with sliding rails on the surface is arranged on the rack; the clamp is connected with a clamp driving device driving the same to slide; the clamp comprises a clamp baseplate, a positioning block and a clamping block located on the clamp baseplate and arranged oppositely, as well as a clamping block driving device driving the clamping block to slide towards the positioning block; mutually-corresponding V-shaped grooves are formed in opposite faces of the positioning block and the clamping block; the clamping block driving device comprises a cylinder and a wedge block connected with a piston rod of the cylinder, the sliding direction of the wedge block is perpendicular to that of the clamping block, the surface, opposite to the V-shaped grooves, of the clamping block is a bevel, and the bevel is attached to a bevel of the wedge block in a matched manner. Frequent manual workpiece replacement is avoided, machining efficiency is improved, self-locking can be realized after clamping, and the drilling process is more reliable and accurate.

Owner:CHENGDU FANXINJIA TECH

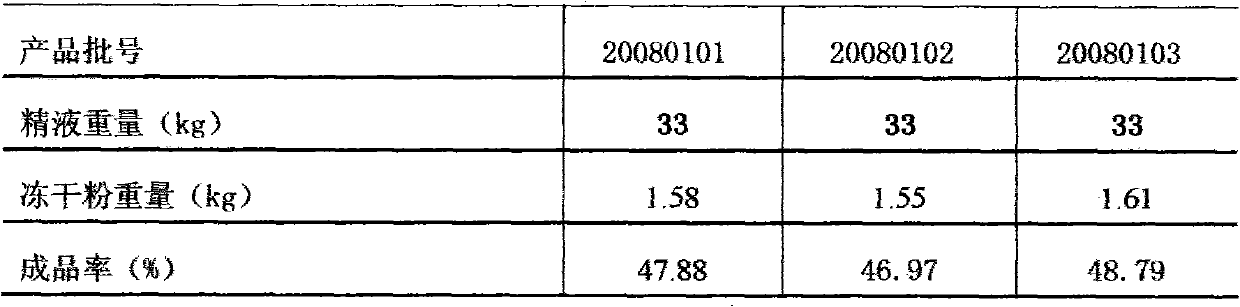

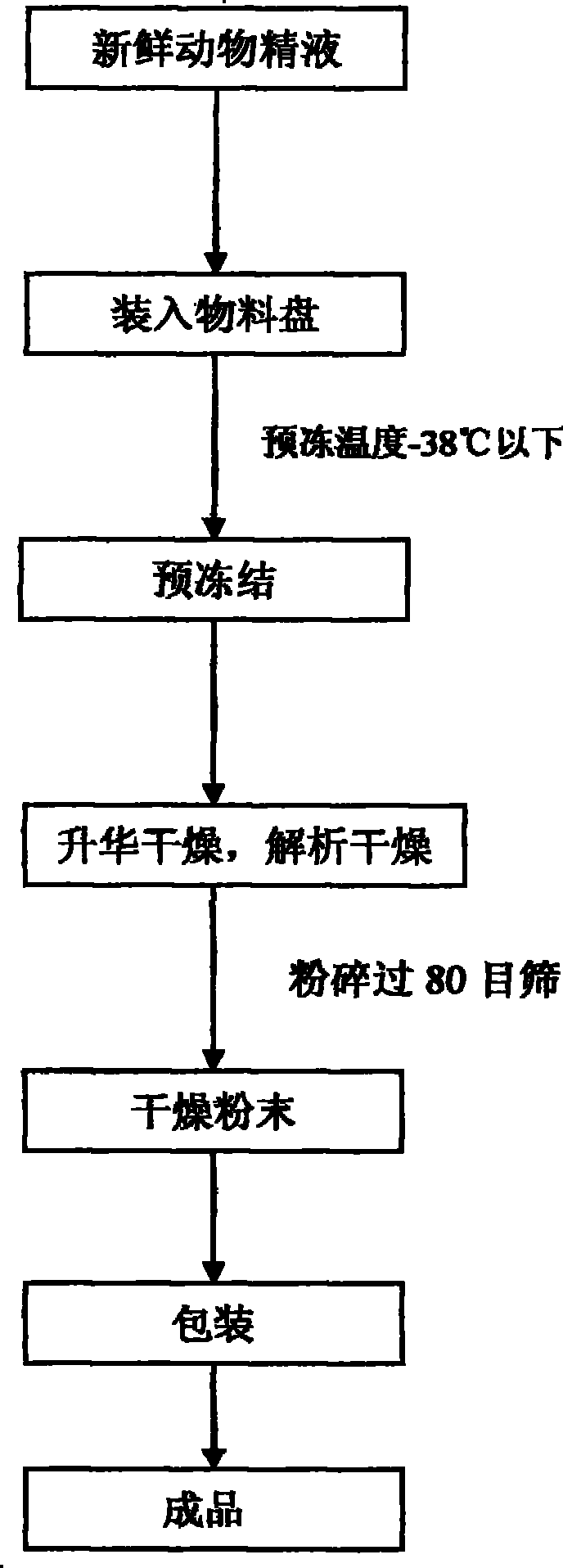

Method for preparing animal semen freeze-dried powder

ActiveCN101904869AHigh medicinal valueReduce lossesPowder deliveryMetabolism disorderMicroorganismFreeze-drying

The invention relates to a method for preparing animal semen freeze-dried powder, which is used for preparing by adopting freeze-dried fresh semen and comprises the steps of prefreezing, sublimation drying and analysis drying. The invention has the following advantages that: (1) protein, microorganisms and the like can not denature or lose biological activity; (2) the loss of certain volatile components in the matter is small; (3) the growth of microorganisms and the action of enzymes are prohibited, so that the original nature of the freeze-dried powder can be maintained; (4) the volume is almost unchanged, the original structure is maintained, and the phenomena of concentration and hardening do not occur; (5) the dried matter is loose, porous and spongy, the dissolution is quick and complete after water addition, and the original nature can be recovered immediately; (6) certain easily oxidized substances in vacuum are protected; and (7) more than 95-99% of water can be removed by drying, and the dried product can stored for a long time without deterioration.

Owner:程辉

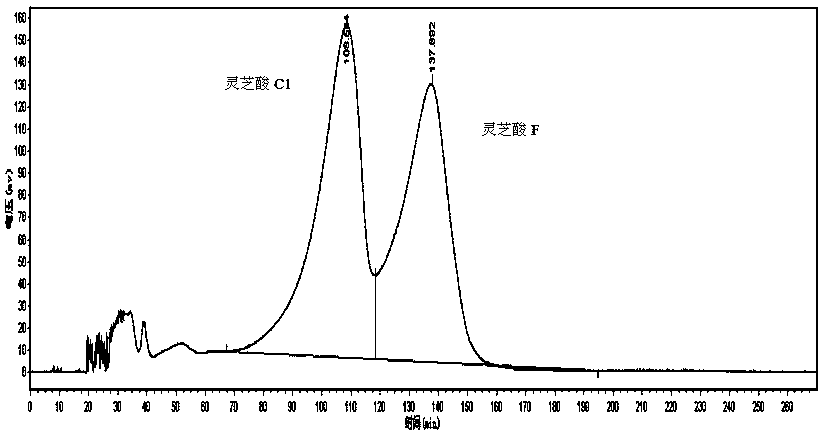

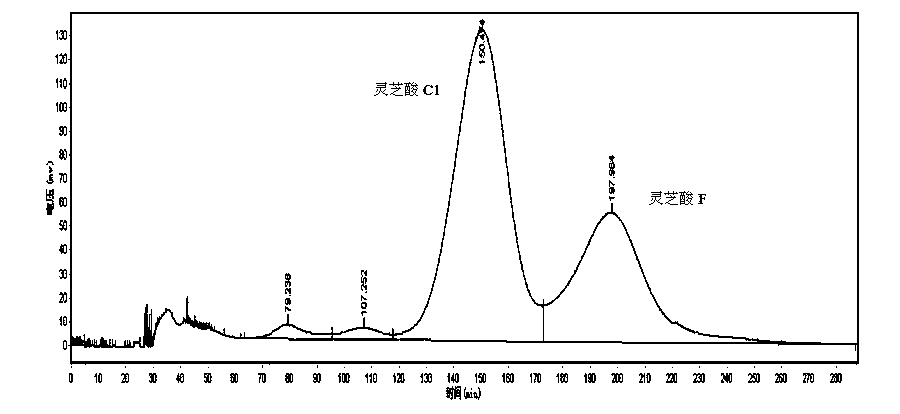

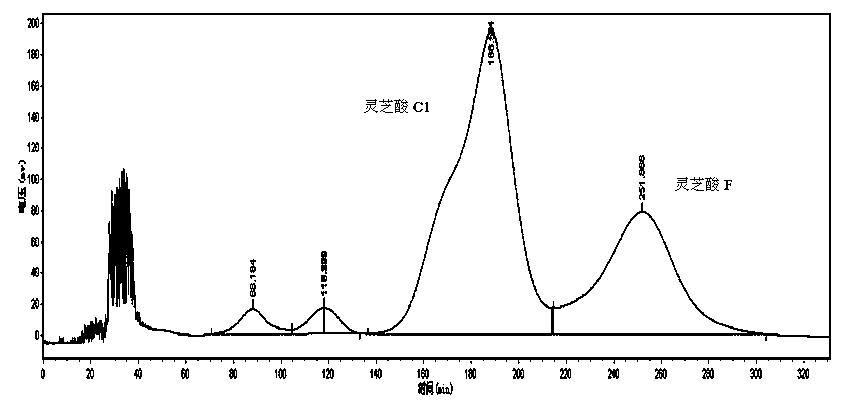

Method for separating and preparing anti-tumor components ganoderic acid C1 and ganoderic acid F

ActiveCN103724389ALarge amount of processingEliminate pollutionSteroids preparationFraction CollectorGanoderiol

The invention discloses a method for separating and preparing anti-tumor components ganoderic acid C1 and ganoderic acid F, which comprises the following steps: (1) primarily enriching and purifying the alcohol extract of lucid ganoderma by use of macroporous resin, and separating a ganoderic acid part with purity of 30-60% from the alcohol extract of lucid ganoderma; (2) separating the separated ganoderic acid part through high-speed counter-current chromatography to obtain ganoderic acid with relatively high purity, wherein a solvent system consists of petroleum ether, ethyl acetate, methanol and water at a volume ratio of 5:(3-7):(1-6):(4-9); the upper phase of the solvent is a stationary phase, and the lower phase is a mobile phase; a sample is dissolved with the lower phase solution and fed; the flow velocity of the stationary phase is 10-20mL / min, the flow velocity of the mobile phase is 1.5-3mL / min, and the rotation speed of the host is 600-1,000rpm; the separated object is collected by an automatic fraction collector, and one fraction is collected from every 4-10mL; (3) analyzing and detecting the components of the liquid collected by each test tube by high performance liquid chromatography, collecting, concentrating and drying according to different components, and separating to obtain ganoderic acid C1 and ganoderic acid F with purity up to 95%. The method has the characteristics of high efficiency, high speed, large separation quantity, high recovery rate, solvent saving and the like.

Owner:福建仙芝楼生物科技有限公司

Production method and application of compound enzyme liquid for bagasse papermaking pulping

ActiveCN103555700AImprove accessibility and utilizationIncrease vitalityOxidoreductasesCellulose treatment using microorganisms/enzymesMannoseChemistry

The invention discloses a production method of a compound enzyme liquid for bagasse papermaking pulping, the production method is characterized by weighing component enzymes, mixing and blending in a compound tank, corrosion preventing, checking, packing and then storing in a storehouse at 5 DEG C, wherein the component enzymes are alkaline pectinase, xylanase and mannose or alkaline pectinase, xylanase, mannose and ligninase; the application of the compound enzyme liquid in the bagasse papermaking pulping comprises the following steps: feeding papermaking raw materials into a distilling pan to perform enzyme treatment after being pre-treated, that is, soaking the raw materials in the compound enzyme liquid, wherein the enzyme treatment condition is as follows: the temperature is at 40-60 DEG C, the mass ratio of the absolutely dry raw material to the compound enzyme liquid is 100: (1.2-1.8), and the enzyme soaking time is 20-60 min; and cooking in the distilling pan after the enzyme treatment. The component enzymes in the compound enzyme liquid are high in activity and inactive to crystalline cellulose and carboxymethyl cellulose; compared with the traditional chemical pulping method, the alkali dosage is reduced about 50%, the COD content in wastewater is reduced by more than 30%, the production cost is lowered by about 20%, and the product quality of the paper is improved.

Owner:江苏富星纸业有限公司

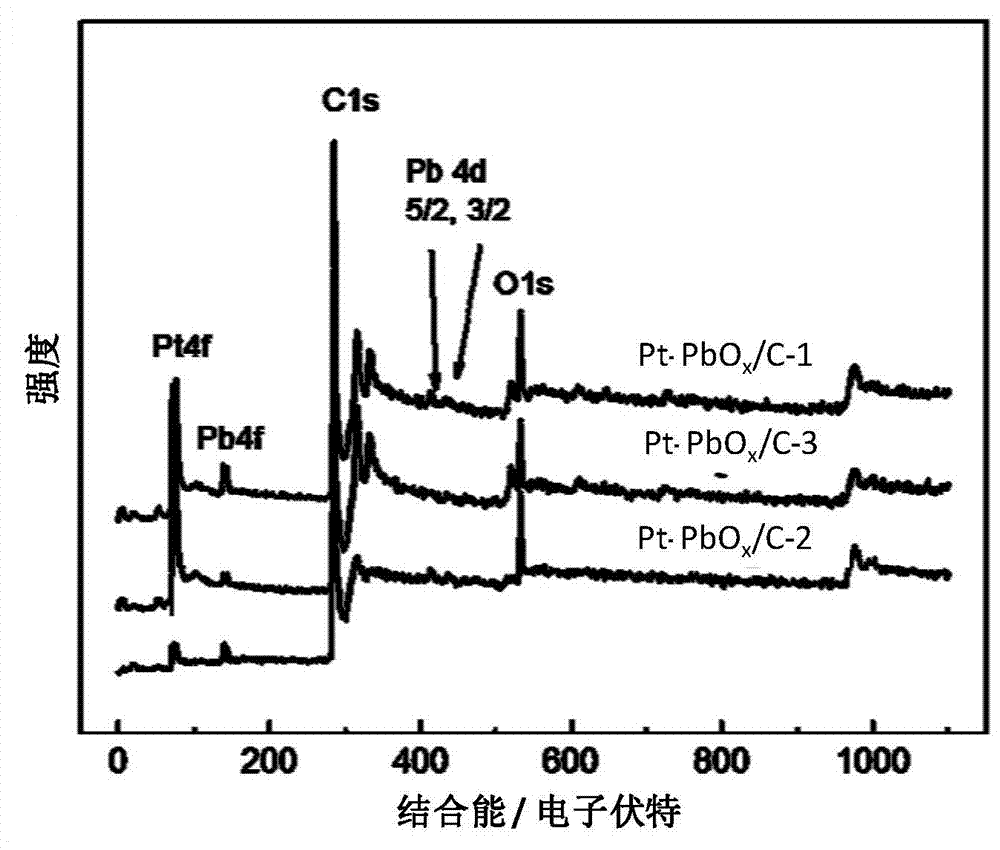

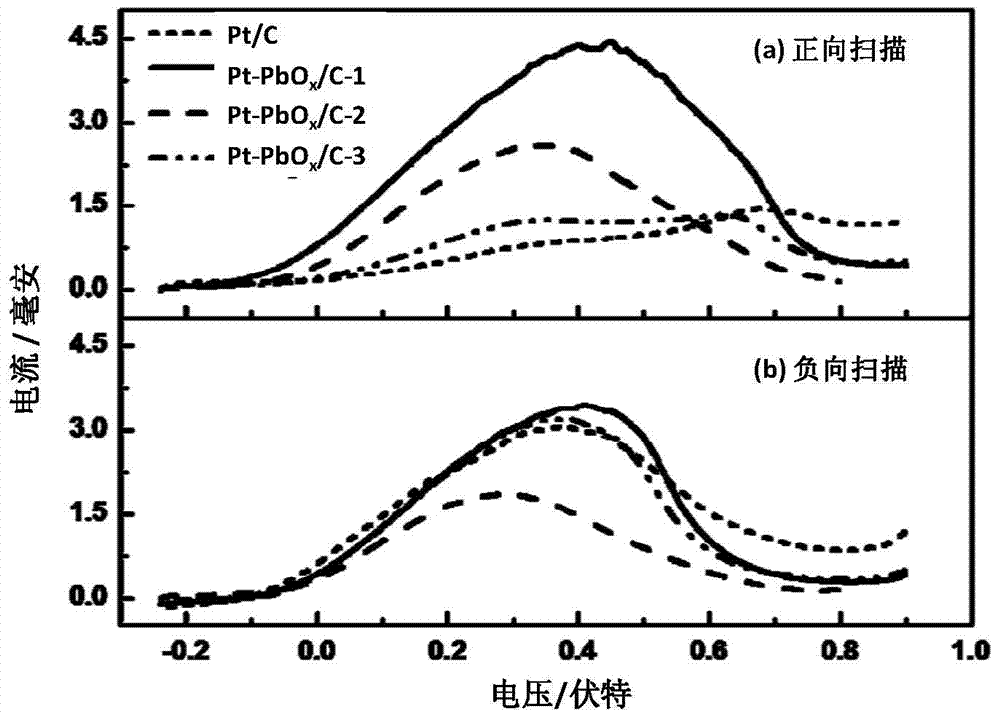

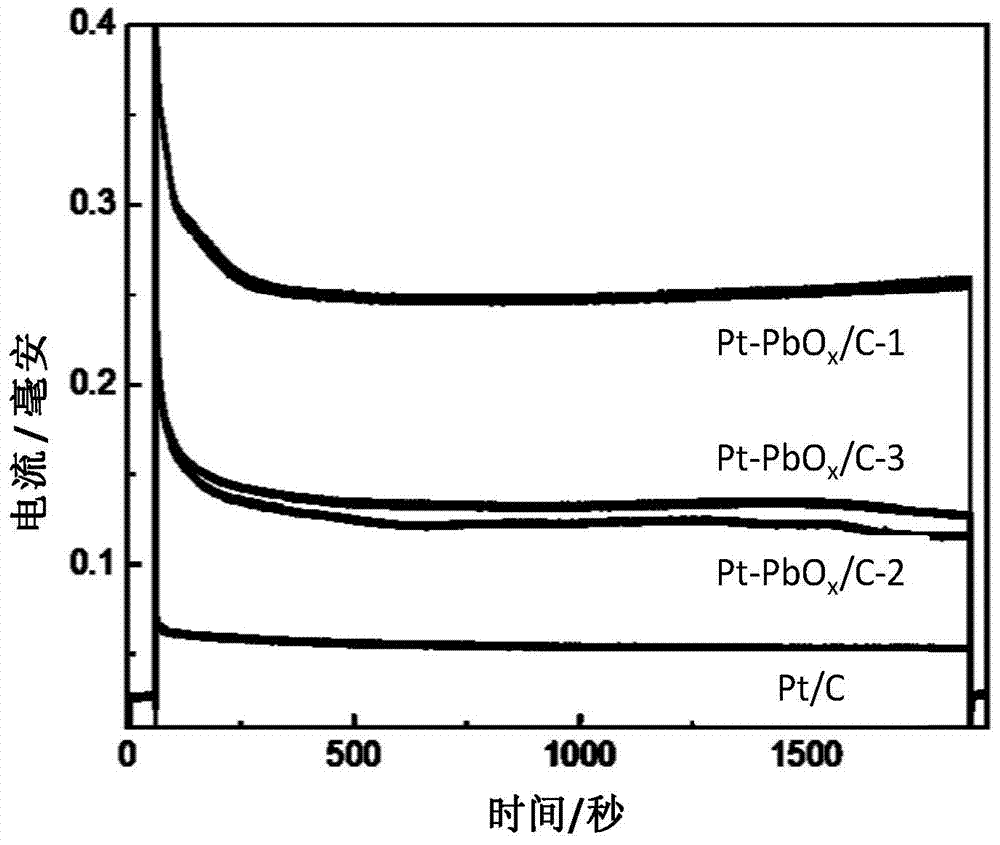

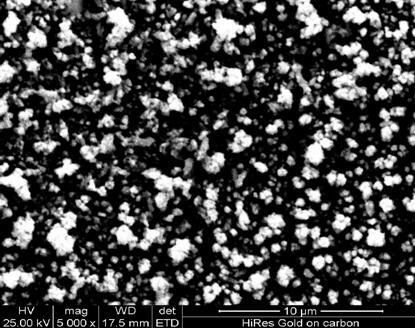

Pt-PbOx/C catalyst and preparation method thereof

InactiveCN104707603AHigh reactivityImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsColloidHydrolysis

The invention relates to a preparation method of a Pt-PbOx / C catalyst. The catalyst comprises 1-50mass% of Pb and below 85mass% of Pt. The catalyst is obtained through the hydrolysis-modified ethylene glycol method, and the preparation method comprises the steps of preparation of PbOx colloid, and preparation of the Pt-PbOx / C catalyst. The Pt / Pb atom ratio of the surface of the catalyst is controlled by controlling the sequence of the supporting of the PbOx and Pt colloid to the surface of a support in the preparation process of the catalyst, and the catalyst has the advantages of high catalysis activity on a formic acid electrooxidation reaction, good stability, simple preparation process and amplified production realization, and is used as a formic acid electrochemical oxidation reaction catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

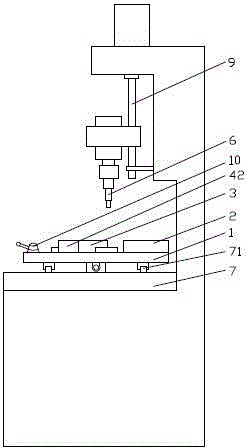

Self-locking drilling fixture

InactiveCN104476275AMeet the clamping positioning requirementsAvoid replacementWork clamping meansPositioning apparatusSelf lockingPiston rod

The invention belongs to the technical field of machining equipment and discloses a self-locking drilling fixture comprising a bottom plate, a positioning block, a clamping block and a driving device. The positioning block and the clamping block are disposed on the bottom plate face to face; the driving device drives the clamping block to slide to the positioning block; the positioning block is fixed; opposing faces of the positioning block and the clamping block are provided with at least two V-grooves facing each other; the driving device comprises a cylinder and a wedge connected to a piston rod of the cylinder; a sliding direction of the wedge is perpendicular to that of the clamping block; the surface, corresponding to one V-groove, of the wedge is a slope fitly attaching to a slope of the wedge. The self-locking drilling fixture has the advantages that manual frequent changing of workpieces is avoided, machining efficiency is improved, self-locking after clamping is available, and a drilling process is more reliable and accurate.

Owner:CHENGDU FANXINJIA TECH

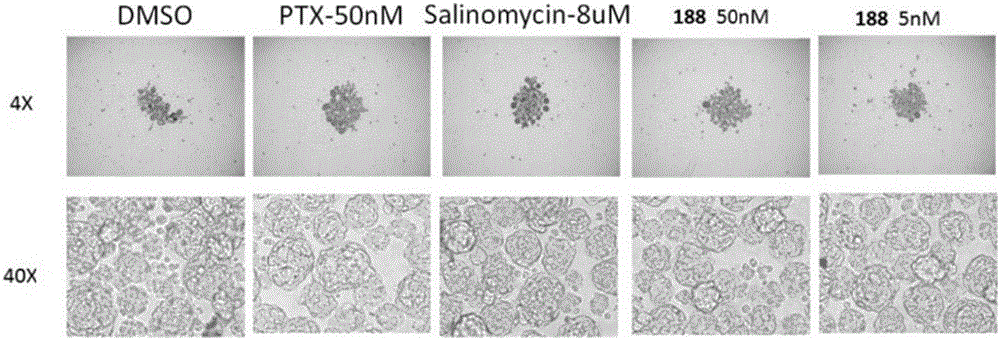

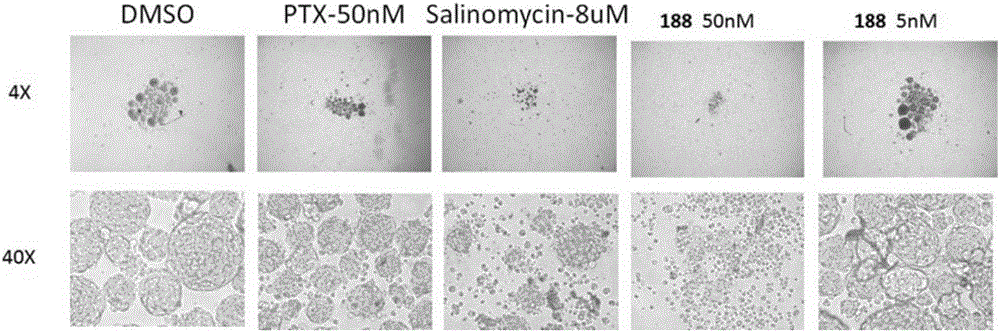

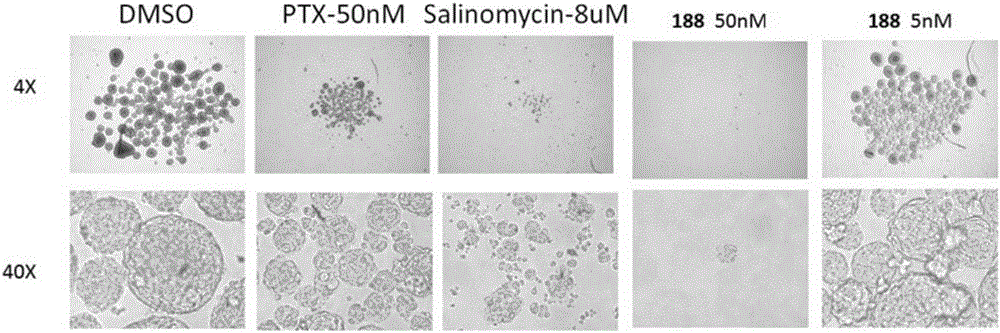

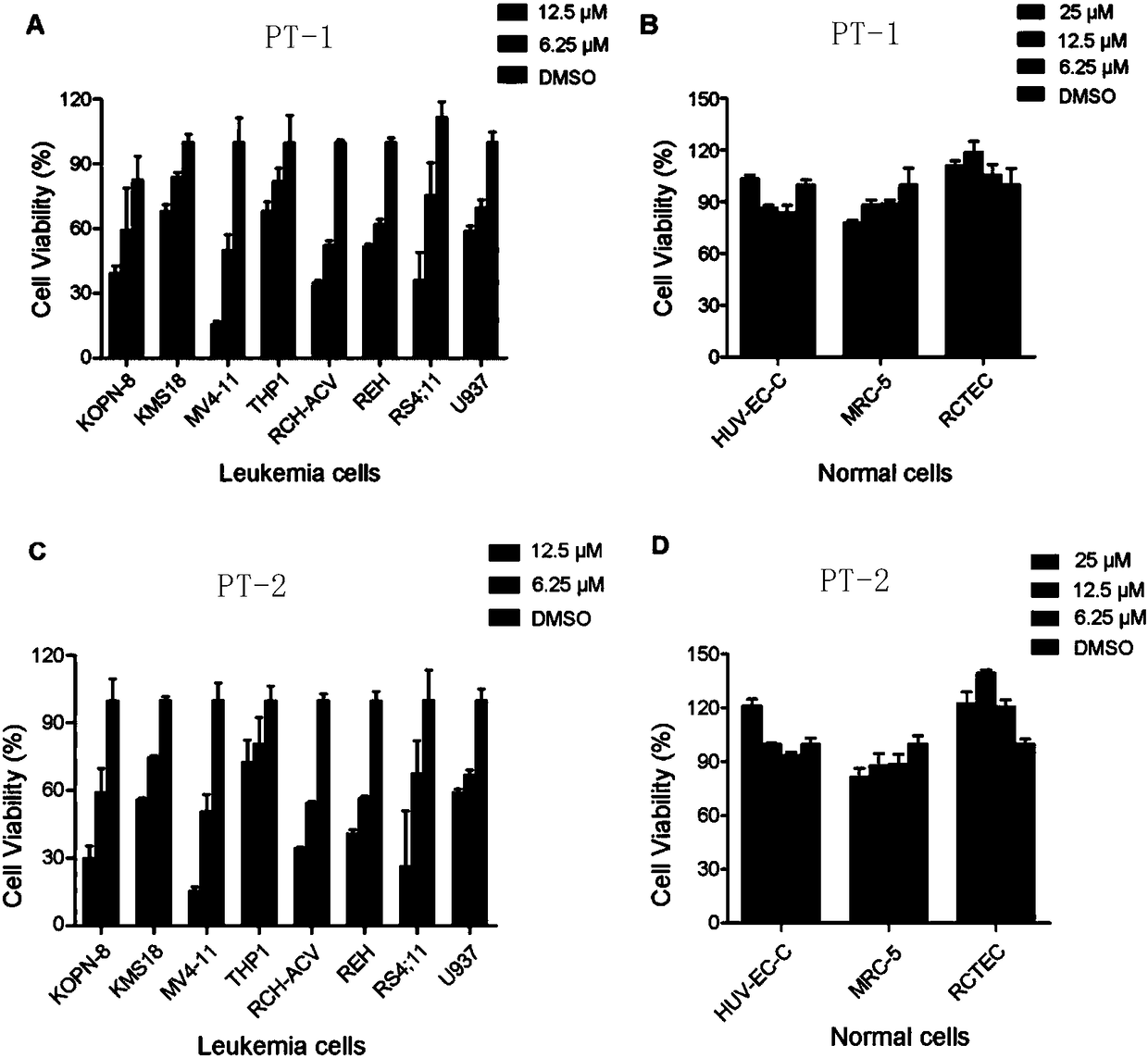

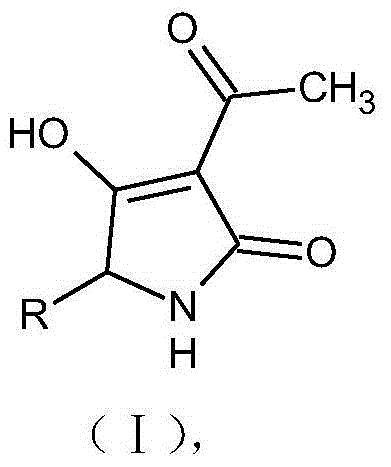

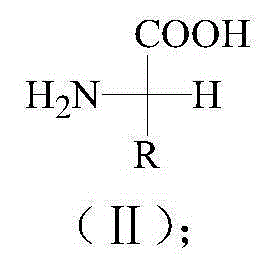

Compound and application thereof

ActiveCN105693634APrevent proliferationPrevent regenerationOrganic active ingredientsGroup 5/15 element organic compoundsMedicineTumor stem cell

The invention discloses a compound and application thereof. The compound is the compound shown in the formula (I) or a stereoisomer or a pharmaceutical acceptable salt or solvate or a prodrug of the compound shown in the formula (I). The compound can restrain tumor cell proliferation through the effect RRM2, and restrain tumor stem cell regeneration, thereby being effectively used for preparing medicine for preventing or treating proliferative diseases and particularly anti-cancer medicine.

Owner:TSINGHUA UNIV

Regeneration method of amination catalyst of polyetheramine used for polyether polyol hydro-amination

ActiveCN107961797AHigh activityNo structureOrganic compound preparationCatalyst regeneration/reactivationOrganic acidHydrogen

The invention discloses a regeneration method of an amination catalyst of polyetheramine used for polyether polyol hydro-amination. The method comprises the following steps: A) adding an inactivated amination catalyst in an organic acid solution, heating the material for backflow, filtering the material, washing the material, and drying the material; B) performing carbon burning regeneration on the amination catalyst obtained through washing and drying treatment under existence of hydrogen peroxide to obtain the amination catalyst after roasting regeneration; and C) using hydrogen for reducingthe amination catalyst after roasting regeneration to obtain the amination catalyst after reduction regeneration. The regeneration processing method solves the problem of inactivation of the amination catalyst due to coking even carbon formation, active ingredient copper sintering of the catalyst, and Ni0 crystal-phase aggregation. The regeneration method mainly used for preparing the amination catalyst of polyetheramine for polyether polyol hydro-amination.

Owner:WANHUA CHEM GRP CO LTD

High-temperature and high-strength insulating tube and manufacturing method thereof

InactiveCN102332372AImprove dispersionImprove adhesionFuse device manufactureSilane couplingFirming agent

The invention discloses a high-temperature and high-strength insulating tube and a manufacturing method thereof. The manufacturing method comprises the following steps of: firstly, soaking a resin adhesive comprising the following components in parts by weight:100 parts of modified epoxy, 80-85 parts of anhydride curing agent, 2 parts of accelerator and 5 parts of silane coupling agent into glass fiber for sufficiently stirring; pouring a soaked insulating material into an adhesive chute; then, winding the soaked insulating material on a mould according to an angle corresponding to the requirement, and placing into an oven after the winding is completed; and adjusting a temperature control and time control adjuster for curing for the first time; curing for the second time after the curing for the first time is ended; curing for the third time after the curing for the second time is ended; and obtaining the insulating tube when the mould is cooled after the curing for the third time is ended. The method can be used for improving the ductility, the ageing resistance, the cold and hot impact resistance and the mechanical impact resistance of the insulating tube; and the insulating tube has high moisture resistance, compression springback amount and insulating property.

Owner:太仓市华强玻璃钢五金厂

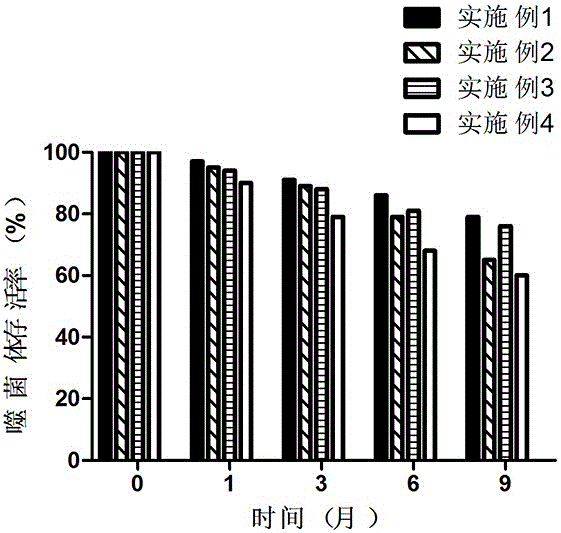

Freeze-drying preservation method for bacteriophage

InactiveCN105950475ANo sex changeNo activityMicroorganism based processesMicroorganism preservationHorticulture

The invention provides a freeze-drying preservation method for bacteriophage. The method comprises the steps that bacteriophage liquid and a bacteriophage preservation protecting agent are mixed to be uniform to be prepared into freeze-dried bacteriophage powder, and the freeze-dried bacteriophage powder is preserved in ampoules in a sealing mode under the aseptic condition. The freeze-drying preservation method for the bacteriophage is reasonable and convenient to apply, and the bacteriophage can be preserved at room temperature or refrigerated, is low in requirement for the preservation environment and good in adaptability and can be preserved for a long term.

Owner:SUZHOU IRIVET BIOTECH

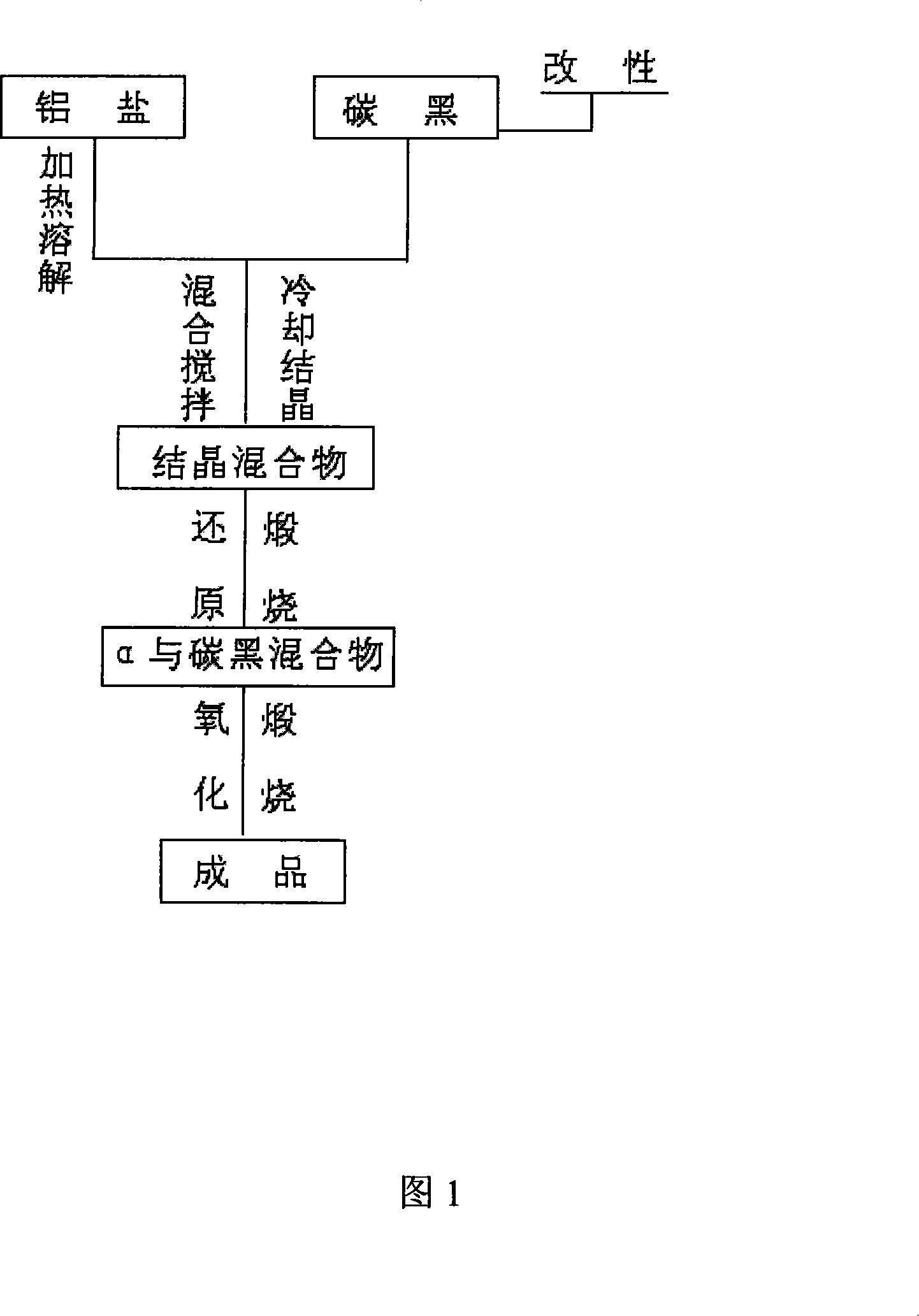

Method for preparing alpha-alumina powder

ActiveCN101200300ANo activityHigh activityAluminium oxide/hydroxide preparationUltrafiltrationActive agent

Owner:中铝郑州有色金属研究院有限公司

Production method and application for organic yeast protein selenium product with life combined state

InactiveCN103756922ASmall particle sizeLarge specific surface areaFungiAnimal feeding stuffBiotechnologyYeast Proteins

The invention relates to a production method and an application for an organic yeast protein selenium product with a life combined state. According to the production method and the application disclosed by the invention, a selenium source used during a fermentation process is nano-selenium; nano-selenium has the advantages of being low in toxicity, large in specific surface area, high in bioactivity, and the like, and is capable of increasing the tolerance dose of yeasts to selenium and the bioavailability; protease is added in a yeast fermentation culture medium to increase the utilization rate of fermentation materials and reduce cost. Compared with the previous method of converting inorganic selenium to organic selenium by yeasts, the selenium source used in the production method and the application disclosed by the invention is nano-selenium, and has the advantages of being low in toxicity, high in conversion rate, high in absorption rate, good in product safety performance, high in bioactivity, convenient for large-scale production and collection, and the like.

Owner:广州市博仕奥生物科技有限公司 +1

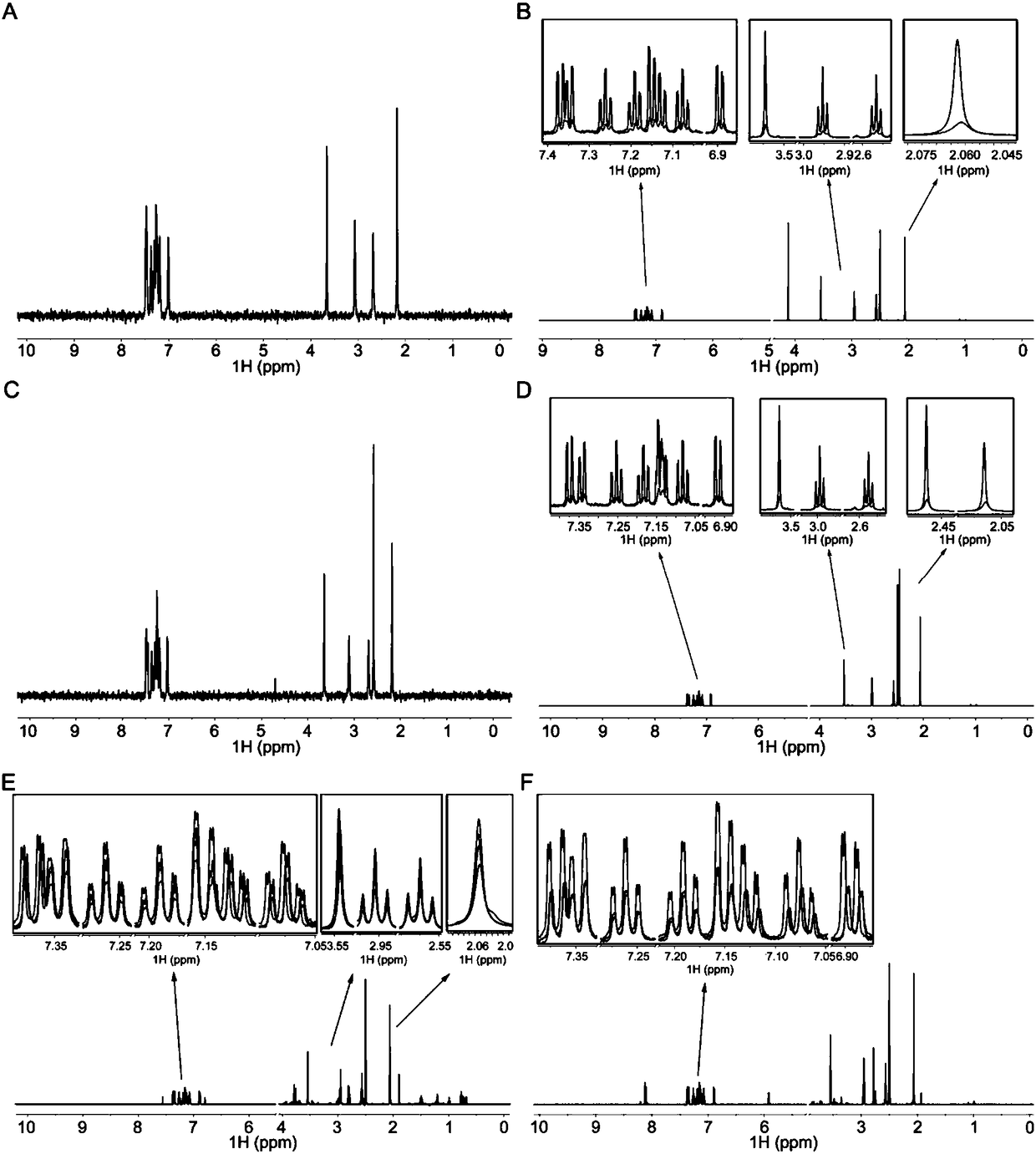

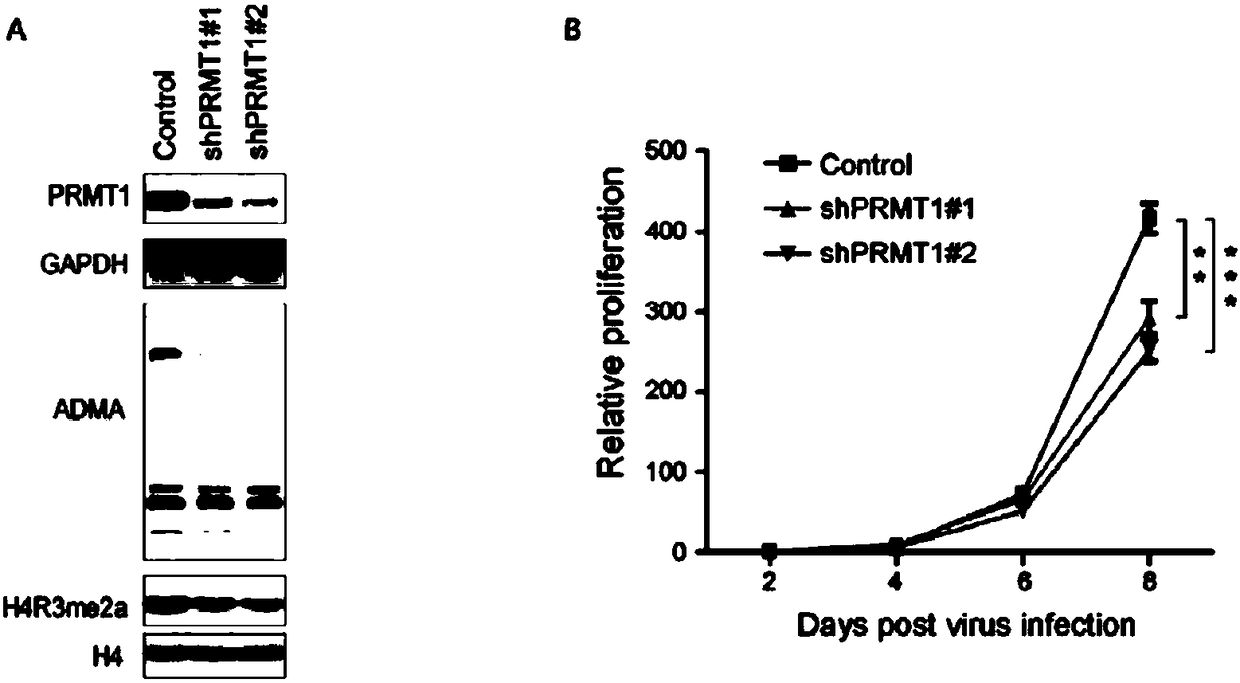

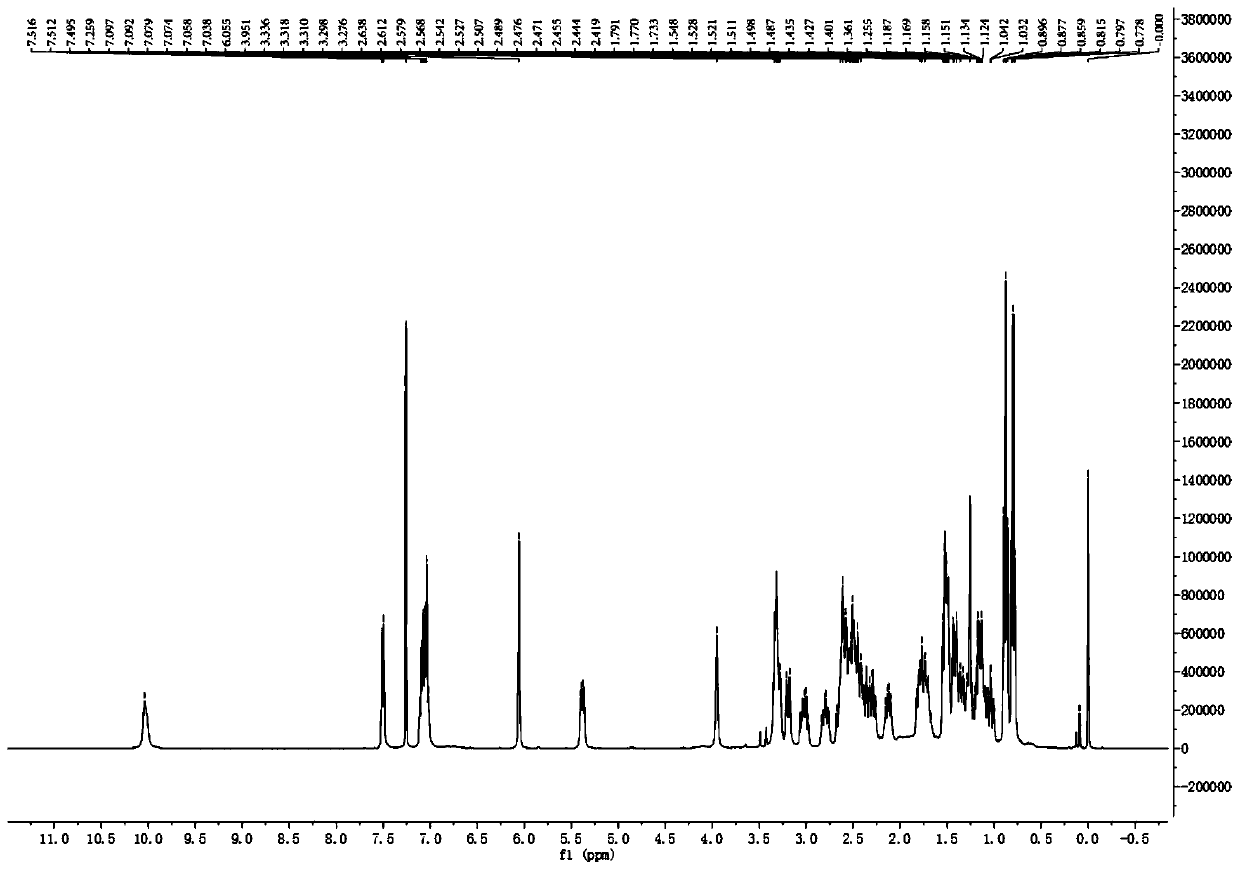

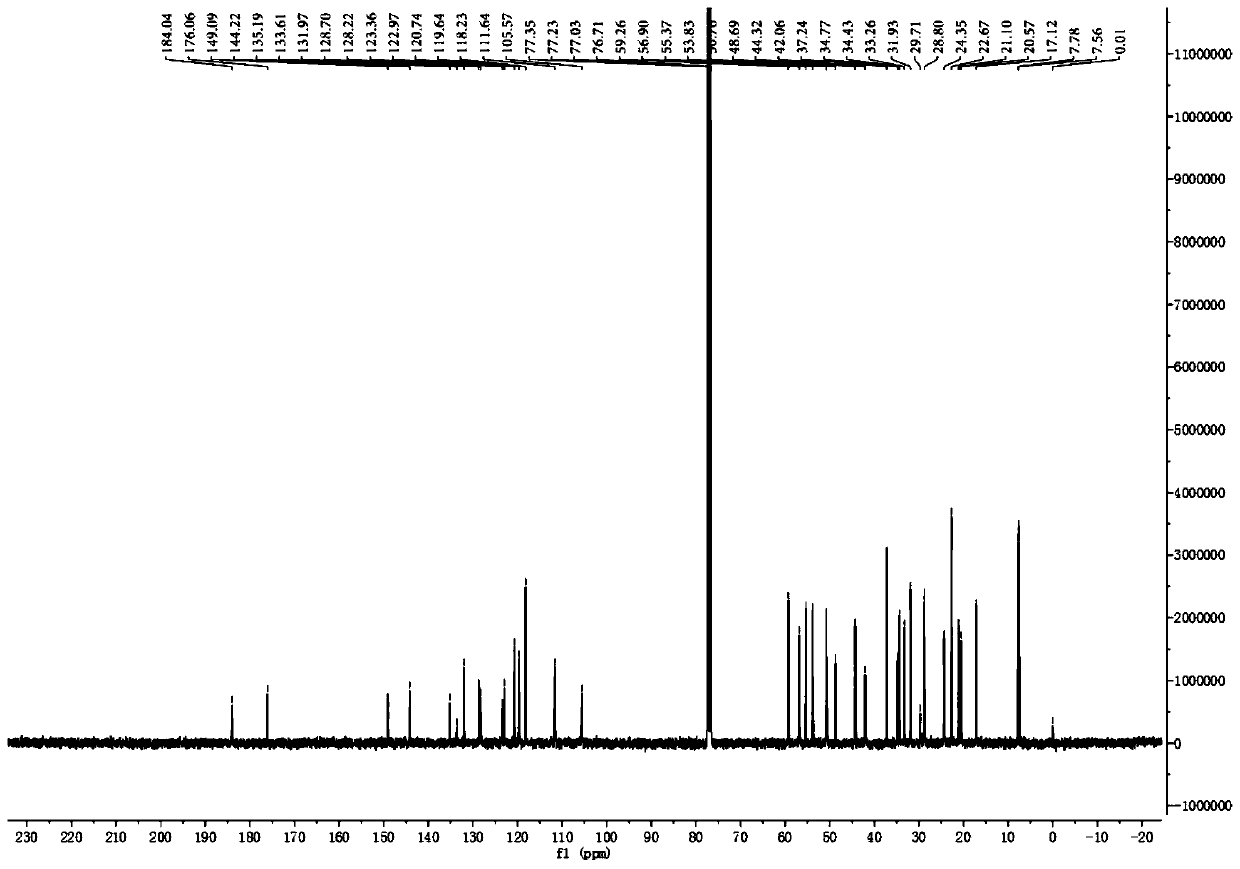

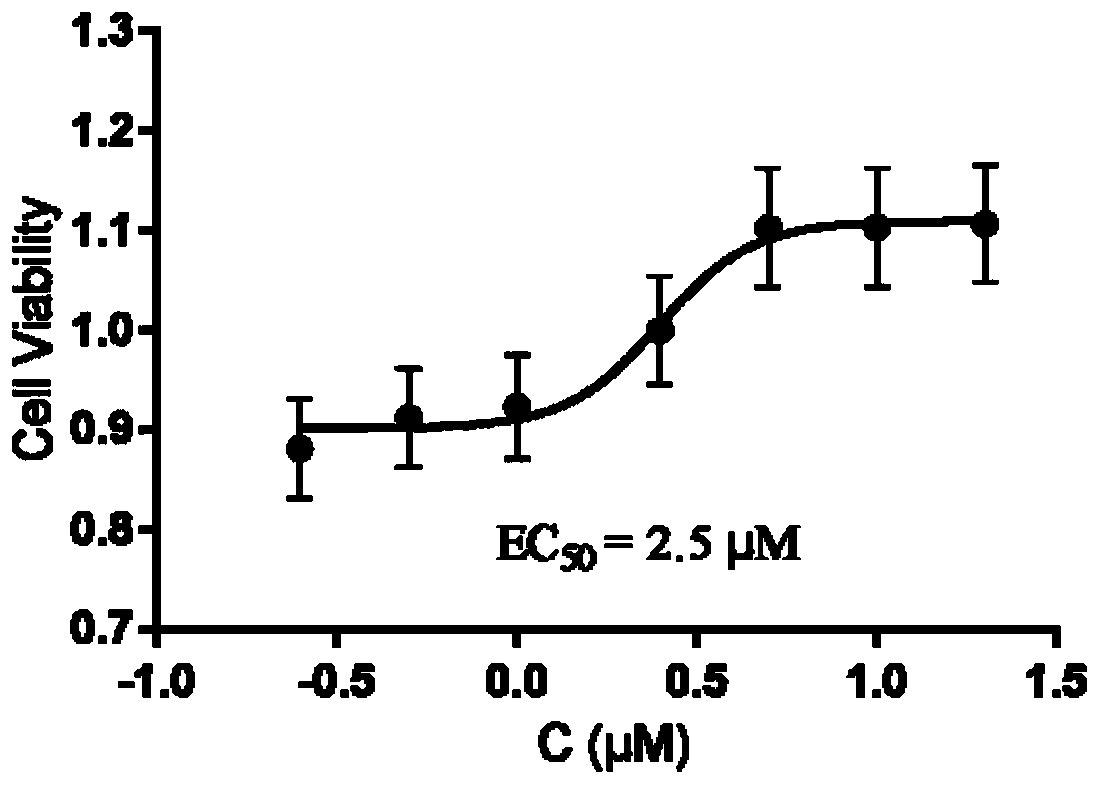

PRMT type-I inhibitor, and preparation method and application thereof

The invention discloses a PRMT type-I inhibitor, and a preparation method and an application thereof. The PRMT type-I inhibitor has a structure as shown in a formula I which is described in the specification. In the formula I, substituents are as defined in the specification and the claims. The compound provided by the invention can prepare a drug used for treating or preventing human and mammalian diseases associated with modulation of PRMT type-I abnormalities.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

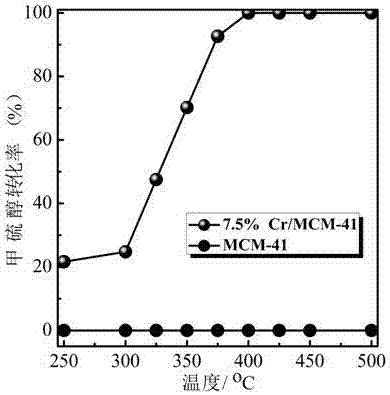

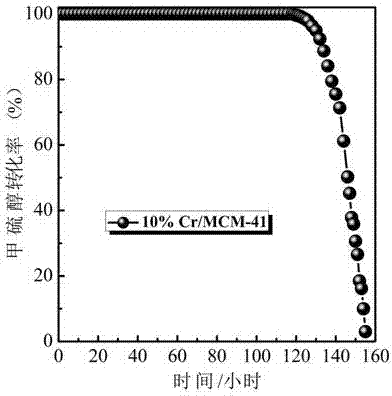

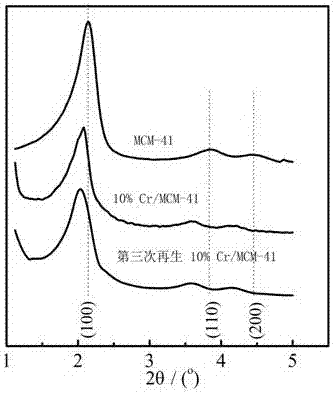

Preparation method of reproducible catalyst for efficient catalytic decomposition of methyl mercaptan

ActiveCN107081169AHigh activityNo activityGas treatmentMolecular sieve catalystsMolecular sieveCatalytic decomposition

The invention discloses a preparation method of a reproducible catalyst for efficient catalytic decomposition of methyl mercaptan. The preparation method comprises uniformly dipping a roasted mesoporous molecular sieve into a chromium-containing compound solution and carrying out drying and calcination to obtain a finished product. The catalyst has catalytic activity and a catalysis life obviously higher than those of an unmodified mesoporous molecular sieve. The catalyst can be used for multiple regeneration recycling processes and the methyl mercaptan catalytic decomposition performances of the used catalyst can be recovered to a fresh catalyst level. The preparation method has a good industrial application prospect.

Owner:KUNMING UNIV OF SCI & TECH

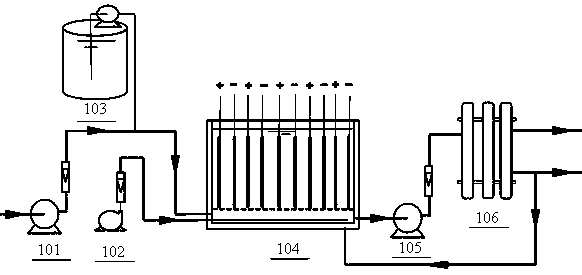

Method for synthesizing phenylamine through nitrobenzene liquid phase continuous hydrogenation

ActiveCN107382745AImprove performanceNo lossOrganic compound preparationCatalyst activation/preparationNitrobenzeneAniline

The invention discloses a method for synthesizing phenylamine through nitrobenzene liquid phase continuous hydrogenation. The method comprises the following steps: exchanging nitrogen with a reactor filled with an active metal / metal packing catalyst for 8-12 minutes, heating the reactor to 60-200 DEG C, and continuously introducing nitrobenzene and hydrogen which are respectively preheated to 40-120 DEG C into the reactor for a reaction, wherein the liquid space velocity of the nitrobenzene is 0.01-3h<-1>, the gas space velocity of the hydrogen is 100-2000h<-1>, and the pressure in the reactor is 0.3-2.0MPa; condensing a gas-liquid mixture discharged from the reactor by a condenser, and feeding back the hydrogen into the reactor, thereby obtaining a liquid phase, namely a reaction product phenylamine. The active metal catalyst used in the method is high in active metal utilization rate, good in activity, large in heat and mass transfer surface area, small in resistance, free of diffusion influence in the reaction process, high in reaction speed, simple in equipment and production process and high in production efficiency, and can be operated for a long time stably.

Owner:HEBEI UNIV OF TECH

Manufacturing process of leonurus

The invention discloses a manufacturing process of leonurus. The process comprises the following steps of: selecting leonurus, washing and cutting and then draining off till the water content is 78-82%; placing the drained leonurus in a tray, wherein the weight in each tray is 2-4kg / m<2> and thickness is 2-3cm; gradually cooling for 2.5-3.2 hours and freezing at -30 to -37 DEG C; vacuumizing till the absolute pressure of the system is 70-100Pa, starting heating to 60-70 DEG C, and drying for 15-18 hours; and maintaining the temperature at 30-40 DEG C, and discharging till the water content is below 3%. The leonurus decoction piece obtained by the manufacturing process disclosed by the invention not only has the essential characteristics of fresh medicines to store the drug properties of fresh traditional Chinese medicines for a long time and ensure the effect, but also is convenient to store and convey and suitable for industrial production and clinical use. The effective components are further effectively prevented from being decomposed in the storage process, and the leonurus decoction piece has good use value and wide market prospect.

Owner:西藏求本生物科技发展有限公司

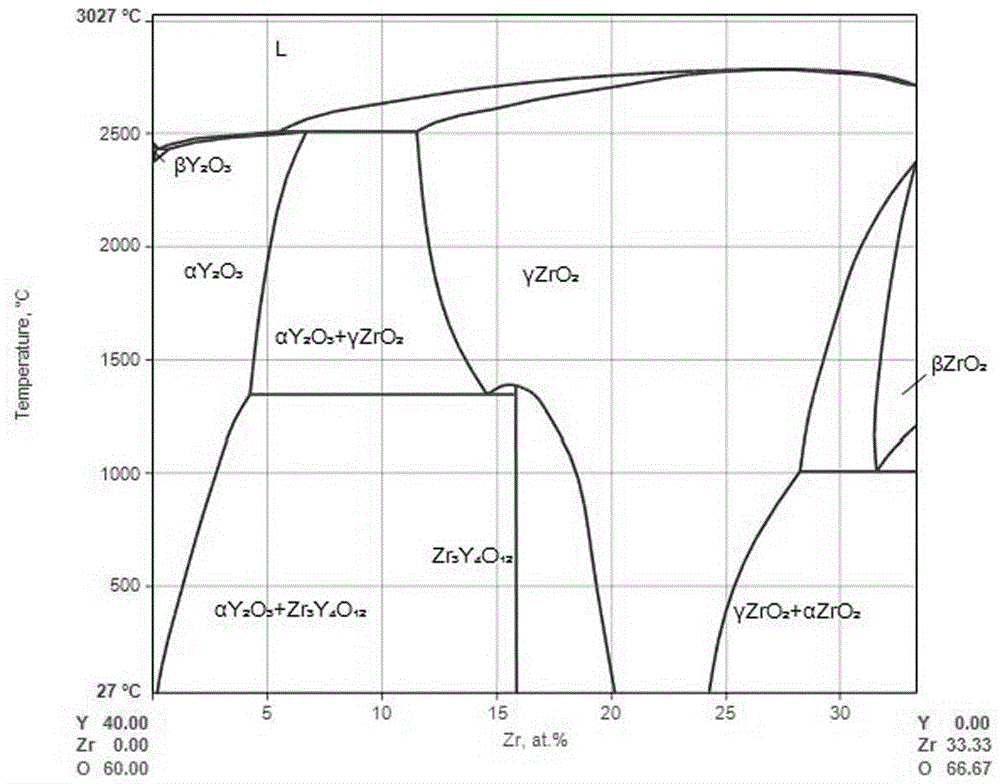

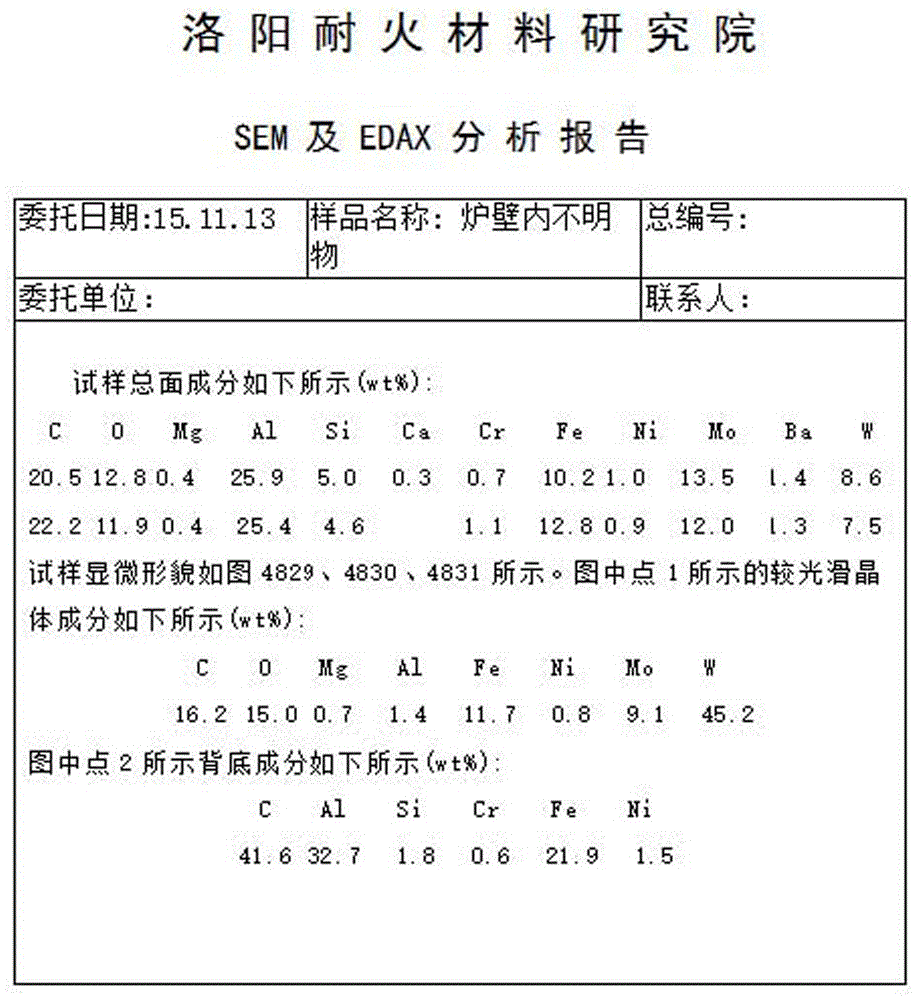

Yttria-zirconia sosoloid ceramics for temperature field of ultrahigh-temperature crystal growing furnace and preparation method for yttria-zirconia sosoloid ceramics

ActiveCN105948739AAvoid high temperature over-shrinkageAvoid problems such as crackingMetallic materialsTwo step

The invention relates to the field of application of zirconia ceramics and particularly relates to yttria-zirconia sosoloid ceramics for a temperature field of an ultrahigh-temperature crystal growing furnace and a preparation method for the yttria-zirconia sosoloid ceramics. The yttria-zirconia sosoloid ceramics are prepared from the following chemical ingredients: 80% of (ZrO2+HfO2), 19.5% of Y2O3 and 0.5% of other trace impurities, wherein the other trace impurities are oxides. A high-purity yttria-zirconia sosoloid ceramic product for an artificial crystal furnace is obtained through thoroughly and uniformly mixing zirconia and yttria, carrying out magnetic stirring, smelting and crystallizing on yttria-zirconia sosoloid by using a high-frequency heating shell melting method, carrying out yttria-zirconia sosoloid crushing and granularity preparing and shaping, and carrying out sintering on yttria-zirconia sosoloid ceramics by adopting a two-step sintering method. Compared with metallic molybdenum materials, the yttria-zirconia sosoloid ceramic material has the advantages that the service temperature is higher, the safe service temperature is below 2,500 and is higher compared with that of the traditional metallic molybdenum materials, and the problems such as high-temperature supercontraction and cracking caused by high-temperature deformation of metallic materials are solved.

Owner:ZHENGZHOU FANGMING HIGH TEMPERATURE CERAMIC NEW MATERIAL CO LTD

Organic fertilizer containing traditional Chinese medicine dregs as well as preparation method of

InactiveCN108083892APromote growthReduce dosageBioloigcal waste fertilisersMicroorganism based treatmentPotassiumAmmonium chloride mixture

The invention discloses organic fertilizer containing traditional Chinese medicine dregs as well as a preparation method of the organic fertilizer. The problems in the prior art that different biological properties of different traditional Chinese medicine dregs are not taken into full consideration, different fertilization methods are not adopted according to the biological properties and the effects are not exerted completely are solved. The organic fertilizer containing the traditional Chinese medicine dregs is prepared from the following raw materials in parts by weight: 40 to 60 parts oftraditional Chinese medicine dregs, 10 to 25 parts of kaolin, 5 to 10 parts of urea, 12 to 20 parts of ammonium chloride, 4 to 10 parts of potassium chloride, 20 to 40 parts of an oil cake, 12 to 24 parts of bean pulp and 1 to 3 parts of an organic fertilizer leavening agent. The invention also provides application of the organic fertilizer containing the traditional Chinese medicine dregs. The design is scientific, the formula is reasonable, the method is simple, the organic fertilizer can serve as base fertilizer for crops, the growth of the crops can be promoted, the microorganisms in soilare killed and the use amount of pesticide is reduced.

Owner:四川曼殊佳华酵素生物科技有限公司

Catalyst capable of directly loading reactive metals on metallic packing

ActiveCN107570146ALarge surface area for heat and mass transferReduce resistanceOrganic compound preparationAmino compound preparationNitrogenNitrogen gas

The invention discloses a catalyst capable of directly loading reactive metals on metallic packing. The catalyst is prepared by the following method, and the method comprises the following steps: 1, filling the metallic packing into a reactor, wherein the filling volume of the packing is 80-90% of the volume of the reactor, and replacing a treatment device and a pipeline system with nitrogen; 2, pumping a treatment solution in a solution storage tank into a preheater by a pump, enabling the solution to enter the reactor in the first step, condensing the gas exhausted from the reactor and emptying, collecting the discharged liquid into the solution storage tank to serve as the treatment solution to continuously participate in treatment; continuously treating for 1-2 hours in the reactor, thereby obtaining the reactive metal / metallic packing catalyst. The catalyst prepared by the method disclosed by the invention is high in reactive metal utilization rate, the heat and mass transfer superficial area is large, the resistance is low, and any inner-diffusion effect is avoided in the reaction process.

Owner:HEBEI UNIV OF TECH

Method and device for treating sewage through electrocatalytic oxidation

ActiveCN109879373AHigh activityGood electrocatalytic oxidation activityWater/sewage treatment by oxidationFiberLead dioxide

The invention relates to a method for treating sewage through electrocatalytic oxidation. An electrocatalytic oxidation reactor with the following structure is adopted, an anode material of the reactor is a boron-doped diamond film / porous carbon / lead dioxide ternary composite electrode, and a cathode material is a good conductor of electricity generally, such as one or more of carbon steel, stainless steel, activated carbon fiber, graphite and the like, preferably activated carbon fiber; and activated carbon is added during sewage treatment. The boron-doped diamond film / porous carbon / lead dioxide ternary composite electrode material is adopted as an anode, and the filling particle coupling effect is combined, so that the method has the advantages of high oxidation efficiency, high pollutant degradation speed, low energy consumption and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation for enhancing immunity and preparation method thereof

InactiveCN103251816AEnhance phagocytosisImprove the level ofAnthropod material medical ingredientsImmunological disordersBiotechnologyDendrobium candidum

The invention provides a preparation for enhancing immunity and a preparation method thereof. The preparation consists of the following components in parts by mass: 10-15 parts of dendrobium candidum powder, 4-10 parts of notoginseng powder, 1-1.5 parts of astragalus root extract, 0.2-0.5 part of fructus corni extract, 0.1-0.4 part of red sage root extract, and 98-105 parts of honey. The preparation method comprises the steps of uniformly mixing the dendrobium candidum powder, the notoginseng powder, the astragalus root extract, the fructus corni extract and the red sage root extract, then adding the honey, and uniformly stirring to obtain the preparation for enhancing the immunity. The preparation is suitable for persons with low immunity, can enhance the immunity of human bodies, and has the advantages of quick and obvious effect, high safety, low cost, simplicity and convenience in operation and the like.

Owner:云南云尚生物技术有限公司

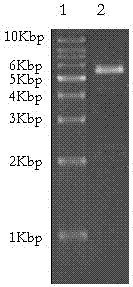

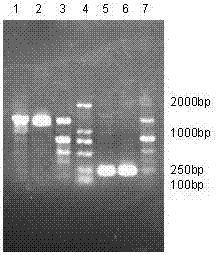

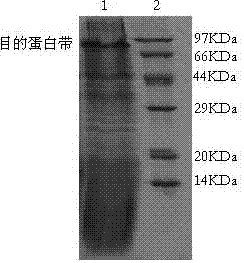

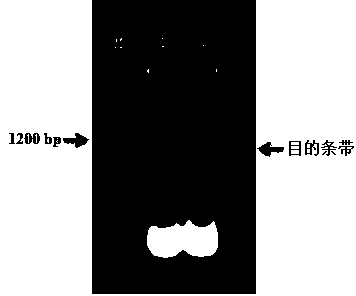

Yeast expression system for expressing HAS-Vmip-II fusion protein and construction method thereof

InactiveCN102220256AConvenience to workSimplify the screening processFungiPeptide/protein ingredientsEscherichia coliPichia pastoris

The invention discloses an expression system for expressing an HAS-Vmip-II fusion protein, and the expression system is produced by the transformation of plasmid pPICZaA-HSA-vMIP-II into Pichia pastoris. The invention also discloses a construction method of the expression system, comprising the following steps of: extracting recombinant plasmid from escherichia coli containing the plasmid pPICZaA-HSA-vMIP-II, linearizing the recombinant plasmid, transforming Pichia pastoris competent cells by electrotransformation, followed by resistance screening, performing the PCR identification to obtain positive clones, carrying out an inducible expression by the use of a positive clone, followed by the SDS-PAGE analysis of the expression product and Western-Blot identification. According to the invention, the half life of vMIP-II in blood plasma is greatly prolonged without the loss of vMIP-II functions. Therefore, the HAS-vMIP-II fusion protein will reduce the administration frequency and dosage, and exert a drug effect similar to that of vMIP-II.

Owner:JINAN UNIVERSITY

Miniature methane sensor and methane detection method

A miniature methane sensor and a methane detection method are suitable for methane detection and are further suitable for methane detection of underground coal mine. The methane sensor comprises a heating component and one or more of measurement components, wherein the heating component is separately heated to a high-temperature working state, and the measurement component independent to the heating component does not apply an external current or voltage and is used for directly measuring the voltage so as to detect gas concentration. A methane sensor processing technology is compatible with aCMOS process. The methane sensor has the advantages of simple structure, low power consumption, high sensitivity, good interference resistance and low cost.

Owner:CHINA UNIV OF MINING & TECH

Bisindole alkaloid compound or pharmaceutically acceptable salt thereof, and preparation method and application thereof

ActiveCN110256468AInhibitory activity not shownHigh activityOrganic active ingredientsNervous disorderHalogenHydrogen

The present invention provides a bisindole alkaloid compound or a pharmaceutically acceptable salt thereof, and a preparation method and an application thereof. The compound has a structure represented by formula (I) shown in the description; and in the formula, R1 is selected from hydrogen, a hydroxyl group, COOR', a C1-10 alkoxy group, a C2-10 alkenyloxy, a C2-10 alkynyloxy group and a halogen atom, the hydroxyl group can be substituted with a C1-10 alkoxy group, a C2-10 alkenyloxy group, C2-10 alkynyloxy or a halogen atom when the R1 is the hydroxyl group, R3 is selected from hydrogen or COOR', R2, R4 and R5 are respectively independently selected from hydrogen, a hydroxyl group, a carbonyl group, a C1-10 alkoxy group, a C2-10 alkenyloxy group and a halogen atom, R' is selected a C1-10 alkyl group, a C2-10 alkenyl group and a C2-10 alkynyl group, and the halogen atom is preferably fluorine, chlorine, bromine or iodine. The bisindole alkaloid compound of the formula or the pharmaceutically acceptable salt thereof has an amyloid protein-beta inhibition activity, and also has an activity of inhibiting podocyte injuries caused by high sugar.

Owner:SHANDONG ANALYSIS & TEST CENT

Method for catalytic synthesis of 2,3,5-trimethylbenzoquinone

InactiveCN107488110ANo activityCollapse phenomenon noMolecular sieve catalystsQuinone preparation by oxidationSynthesis methodsMesoporous material

The invention discloses a method for catalytic synthesis of 2,3,5-trimethylbenzoquinone. The method comprises the following steps: weighing trimethylphenol and Cu-ZSM-5 catalyst according to a mass ratio of 10:(1-3):1, adding a polar solvent and an oxidant, carrying out a reaction at 30-80 DEG C for 2-6 h, and filtering the obtained reaction product to obtain a filtrate which is the 2,3,5-trimethylbenzoquinone. The Cu-ZSM-5 catalyst having the stability of a traditional catalyst and the also having the characteristics of a micro-mesoporous material selectively catalytically oxidizes 2,3,5-trimethylphenol or 2,3,6-trimethylphenol into the 2,3,5-trimethylbenzoquinone in water, methanol, ethanol, a mixture solvent thereof or other green solvents under the action of H2O2, so the synthesis efficiency is high, and the Cu-ZSM-5 catalyst has no inactivation or collapsing phenomenon after being used multiple times. The method for synthesizing the 2,3,5-trimethylbenzoquinone is a new 2,3,5-trimethylbenzoquinone synthesis method having a high efficiency and an environmental protection property.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

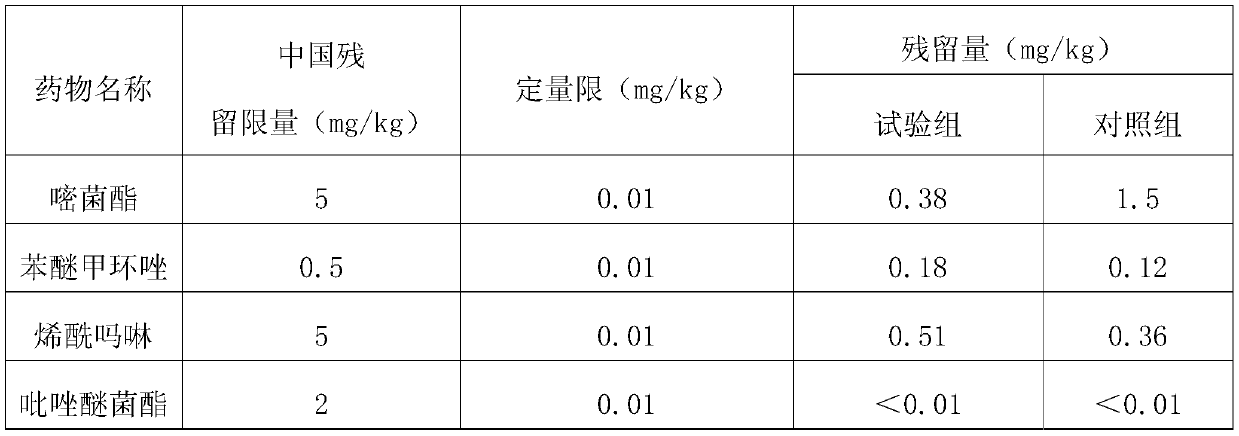

Method for preventing and controlling powdery mildew of winter fruit grape 'No.6 Grape' cultivated in two harvests

ActiveCN110810090AEasy to degradeGood antiviral effectPlant growth regulatorsBiocideBiotechnologyPesticide residue

The invention relates to a method for preventing and controlling powdery mildew of winter fruit grape 'No.6 Grape' cultivated in two harvests, and belongs to the field of plant powdery mildew prevention and control. The method for preventing and controlling powdery mildew of winter fruit grape 'No.6 Grape' cultivated in two harvests includes the following steps: (1) spraying a lime sulfur agent before a second fruit crop sprouts; (2) spraying a biological preparation when the second fruit leaves are spread; and (3) spraying diniconazole ester, mineral oil concentrate, a compound agent of aminooligosaccharide and alternaria protein, phenylazoxystrobin and a biological agent in sequence before and after the flowering of the second fruit crop, and timely adopting a compound agent of auxiliary agent alkyl aryl polyoxyethylene ether and Butanedioicacid. The method adopts a combination mode of biological preparations and organic preparations to prevent and control powdery mildew, reduces the infection probability of powdery mildew, reduces the use of organic chemical pesticides with larger pesticide residue risks to the greatest extent, and meets the requirements of national food safetystandards.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

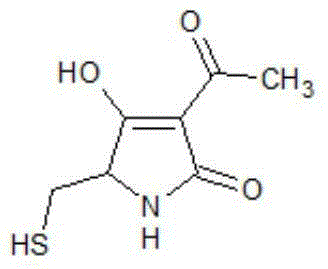

Pyrrolidone sulfur derivatives and their preparation method and application

ActiveCN105130871ASafe and effective controlBroad-spectrum herbicideBiocideOrganic chemistryDiseaseContact position

The invention belongs to the field of pesticide and plant protection and discloses pyrrolidone sulfur derivatives or their physiologically soluble salts. The pyrrolidone sulfur derivatives have a structural formula (I), wherein R=-(CH<2>)nSCmH<2>m<+1>, n is an integer of 1-7, m is an integer of 0-5, the case of n=2 and m=1 is excluded and the case of n=2 and m=2 is excluded. The invention also discloses a preparation method of the pyrrolidone sulfur derivatives or a use of the pyrrolidone sulfur derivatives in prevention and control of weeds. Compared with the original compound, the pyrrolidone sulfur derivatives or their physiologically soluble salts have higher weeding activity and a lower synthesis cost and can be stored easily. After contacting with the pyrrolidone sulfur derivative liquid, weeds produce cell death and brown disease spots at the contacting positions. The pyrrolidone sulfur derivative liquid can kill weeds usually in 3-5 days, has weeding broad spectrum activity, has small environmental pollution and less residue, has little activity after entering into solid in use, can be passivated fast and has very high environment safety.

Owner:NANJING AGRICULTURAL UNIVERSITY

Engineered escherichia coli for expressing lignin peroxidase, preparation method and application of engineered escherichia coli

InactiveCN103540606AStrong lignin degradation abilityPromote degradationBacteriaMicroorganism based processesEscherichia coliCompetent cell

The invention relates to engineered escherichia coli, and also provides a preparation method of engineered escherichia coli. The preparation method comprises the following steps: cloning cDNA (complementary Deoxyribose Nucleic Acid) of a gene of phanerochaete chrysosporium lignin peroxidase; performing double digestion on the cDNA; connecting the digestion fragments with a pCold-TF vector; authenticating whether the obtained plasmid pCold-TF-LiP is subjected to positive expression; and introducing the positive plasmid pCold-TF-LiP into escherichia coli BL21 competent cells to obtain the engineered escherichia coli for expressing lignin peroxidase. The invention also provides an application of the engineered escherichia coli, namely, inoculating the engineered escherichia coli into a liquid culture medium, adding ampicillin to the liquid culture medium, culturing until OD600 (Optical Density) reaches 0.58 to 0.62, and adding a protein inductive agent IPTG (Isopropyl Thiogalactoside) to induce the expression of recombinant protein. The engineered escherichia coli is high in expression quantity and extremely high in activity, and the enzyme activity reaches 3,528U / L.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com