Pt-PbOx/C catalyst and preparation method thereof

A pt-pbox and catalyst technology, applied in the field of electro-oxidation catalysts, can solve the problems of unclear influence of catalytic activity, inability to realize controllable preparation of metal components on the surface of the catalyst, etc., and achieves the advantages of environmental protection and simple and easy preparation process. , the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: PbO x Colloid preparation

[0045] Preparation of PbO by Hydrolysis of Lead Tetraacetate x colloid. Add 50 mL of water to a 500 mL volumetric flask, then add about 447 mL of ethanol, and add about 3 mL of acetic acid liquid-sealed Pb(CH) after mixing evenly. 3 COO) 4 Solid, quickly and uniformly dispersed by ultrasonic to obtain orange-yellow PbO x colloid.

Embodiment 2

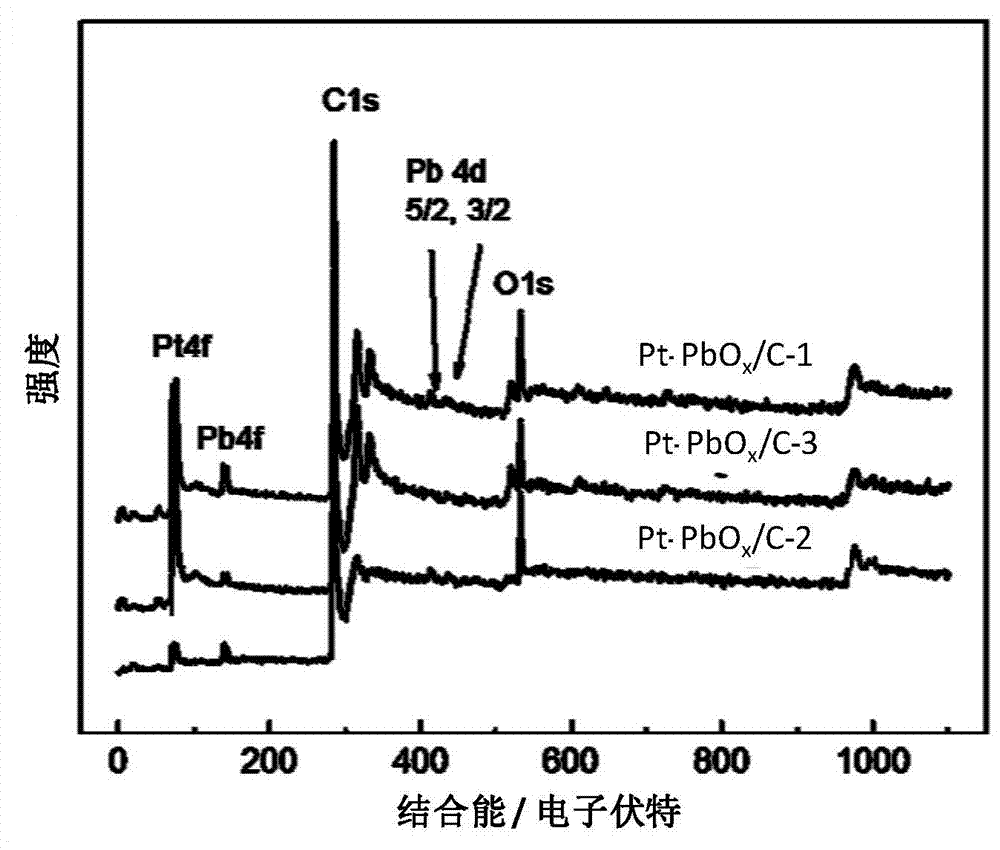

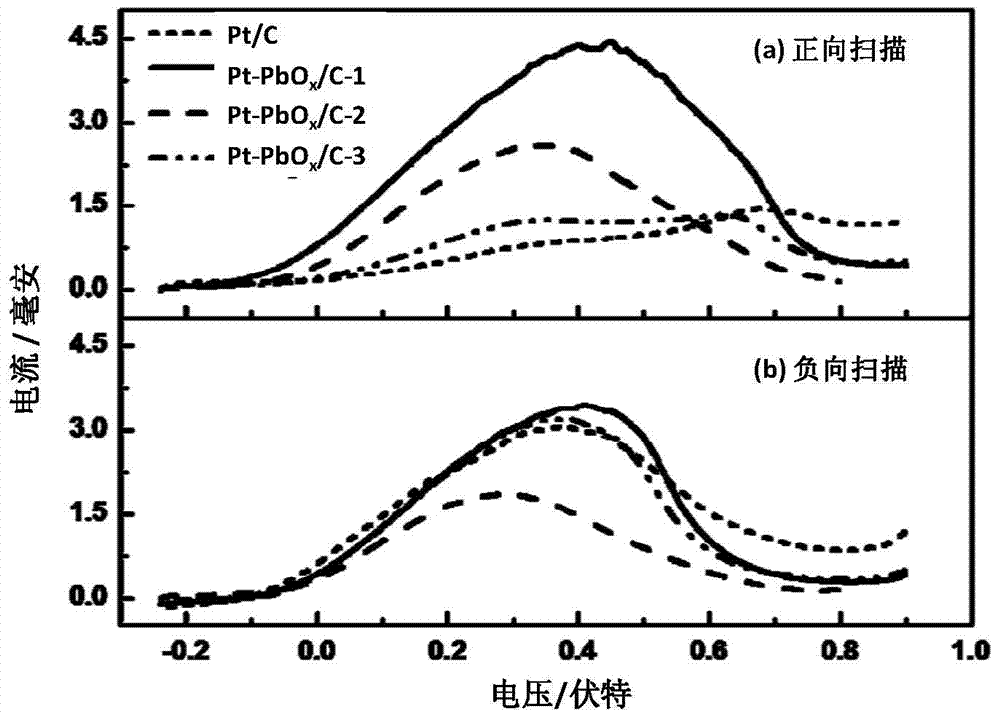

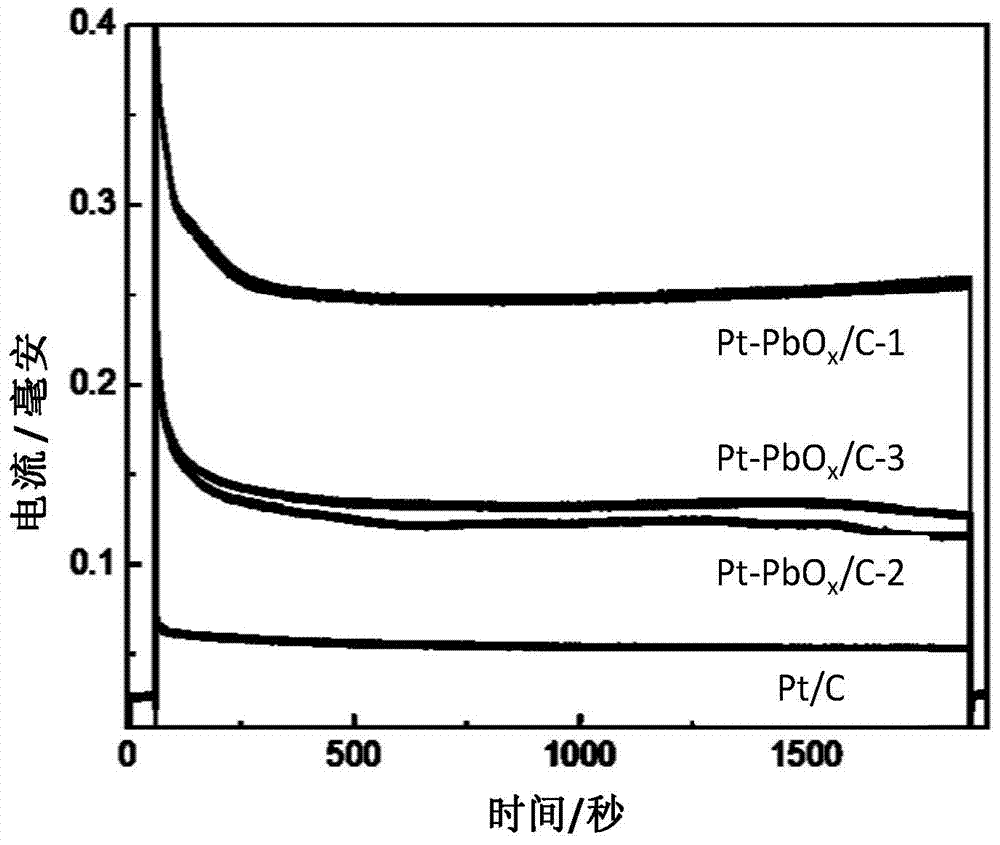

[0046] Embodiment 2: adopt the first method to prepare Pt-PbO x / C catalyst, labeled Pt-PbO x / C-1

[0047] PbO x / C preparation: take 330 mg of C carrier and add it to 150 mL of the above PbO x In the colloid, ultrasonically stirred for 3 min, filtered, and dried in an air oven at 80 °C for 6 h to obtain PbO x / C precursor. Pt colloid supported by ethylene glycol reduction method: add 5.41mL7.4mg to a 250mL three-necked bottle Pt mL -1 H 2 PtCl 6 EG solution, then add 8mL 1M NaOH / EG solution, then add 7mL ethylene glycol, after ultrasonic dispersion is uniform, electromagnetic stirring in oil bath and heating to 125 ℃, after constant temperature reaction for 2h, black Pt colloid is obtained. The ethylene glycol solution of the Pt colloid was cooled to 70°C, and 160 mg of ethylene glycol-dispersed PbO was added. x / C, add about 80 mL of high-purity water after stirring for 30 min, and adjust the pH to 6-7 with 1M HCl aqueous solution, stir for 3 h, filter, wash, and ...

Embodiment 3

[0048] Example 3: Pt-PbO was prepared by the second method x / C catalyst, labeled Pt-PbO x / C-2

[0049] According to Pt / PbO x Preparation steps of Pt colloid in / C catalyst Prepare 40mg Pt colloid in ethylene glycol solution, add 72.7mL PbO at 70°C x colloid, after stirring for 30min, add about 20mL of ethylene glycol dispersed C, after electromagnetic stirring for 30min, add high-purity water until the total solution volume is about 250mL, adjust the pH value to 5-6, react for 3h and then drop to room temperature, filter, wash, 75 ℃ vacuum dried for 7h to obtain Pt-PbO x / C-2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com