Engineered escherichia coli for expressing lignin peroxidase, preparation method and application of engineered escherichia coli

A technology of peroxidase and Escherichia coli is applied in the field of preparation of Escherichia coli engineering bacteria expressing lignin peroxidase, and can solve the problems of difficult lignin waste biodegradable pulp bleaching, limited promotion and use, low reproduction speed and the like , to achieve high protein yield, facilitate gene cloning, and increase solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Cloning the cDNA of lignin peroxidase gene

[0034] The protein sequence (P21764) of lignin peroxidase obtained from the database UniProtKB screening is SEQ ID: NO: 01, which is Met Ala Phe Lys Gln Leu Phe Ala Ala Ile Ser Leu Ala Leu Ser Leu Ser Ala Ala Asn Ala Ala Ala Val Ile Glu Lys Arg Ala Thr Cys Ser Asn Gly Lys Thr Val Gly Asp Ala Ser Ser Cys Ala Trp Phe Asp Val Leu Asp Asp Ile Gln Gln Asn Leu Phe His Gly Gly Gly Gln Cys Gly Ala Glu Ala His Glu Ser Ile Arg Leu Val Phe His Asp Ser Ile Ala Ile Ser Pro Ala Met Glu Ala Gln Gly Lys Phe Gly Gly Gly Gly Ala Asp Gly Ser Ile Met Ile Phe Asp Asp Ile Glu Thr Ala Phe His Pro Asn Ile Gly Leu Asp Glu Ile Val Lys Leu Gln Lys Pro Phe Val Gln Lys His Gly Cys Thr Pro Gly Asp Phe Ile Ala Phe Ala Gly Ala Val Ala Leu Ser Asn Cys Pro Gly Ala Pro Gln Met Asn Phe Phe Thr Gly Arg Ala Pro Ala Thr Gln Ala Ala Pro Asp Gly Leu Val Pro Glu Pro Phe His Thr Val Asp Gln Ile Ile Asn Arg Val Asn Asp Ala Gly Glu Phe Asp Glu Leu Glu Leu Val Trp Me...

Embodiment 2

[0050] Application of the above-mentioned Escherichia coli engineering bacteria in expressing lignin peroxidase

[0051] The Escherichia coli engineering bacteria prepared in Example 1 were inoculated in LB liquid medium, containing 100 mg / L of ampicillin, 37 ° C, 200 rpm, and cultivated to OD 600 About 0.6, add protein inducer IPTG, 16°C, 200 rpm, induce recombinant protein expression for 12-16 h. The formula of the LB liquid medium is: 0.5 g of peptone, 0.25 g of yeast extract, 0.5 g of sodium chloride, and 50 ml of water.

Embodiment 3

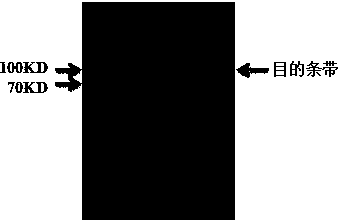

[0053] Separation and Purification of Lignin Peroxidase

[0054] Put the engineered Escherichia coli bacteria induced and cultured in Example 2 into a centrifuge tube, centrifuge at 12000 rpm for 1 min, discard the supernatant, add PBS buffer to resuspend, ultrasonicate, add 1 mL of nickel column, and purify.

[0055] The Escherichia coli engineering bacteria induced and cultured in Example 2 were centrifuged at 10000rpm for 5min, collected by centrifugation and analyzed for protein solubility, ultrasonically crushed, and the total protein, supernatant and precipitate were respectively taken for SDS-PAGE protein electrophoresis analysis. The specific results are as follows image 3 As shown, it shows that the lignin peroxidase protein can be highly expressed in Escherichia coli BL21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com