Preparation method of reproducible catalyst for efficient catalytic decomposition of methyl mercaptan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put the commercially available MCM-41 molecular sieve into a muffle furnace, and bake it at 550°C for 5h, and set it aside. The equal-volume impregnation method is used to load the active component chromium (Cr) element. Weigh 0.2g of roasted MCM-41 in advance and add deionized water dropwise on the watch glass to determine the ability of the carrier to absorb the solution. It is determined that the water needed to completely impregnate the carrier is 1.25g, and 0.2697g of analytical pure hexahydrate chlorinated Dissolve chromium in 6.25g of deionized water, stir, after it is completely dissolved, add 1g of roasted MCM-41 into the chromium chloride solution, stir evenly, make it fully soaked and absorbed for 12 hours, then dry at 90°C for 6 hours Move it into a muffle furnace and bake it at 550°C for 5 hours to obtain a 5wt% Cr / MCM-41 catalyst containing chromium as the active component.

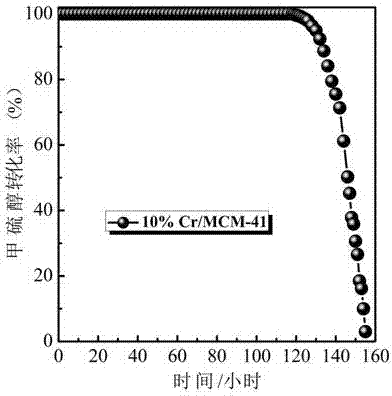

[0026] Sieve the prepared catalyst to 40-60 mesh, and pack it in the reactor, th...

Embodiment 2

[0030] Put the commercially available MCM-41 molecular sieve into a muffle furnace, and bake it at 550°C for 5h, and set it aside. The equal-volume impregnation method is used to load the active component chromium (Cr) element. Weigh 0.2g of roasted MCM-41 in advance and add deionized water dropwise on the watch glass to determine the ability of the carrier to absorb the solution. It is determined that the water needed to completely impregnate the carrier is 1.25g, and 0.4155g of analytical pure hexahydrate chlorinated Dissolve chromium in 6.25g of deionized water, stir, after it is completely dissolved, add 1g of roasted MCM-41 into the chromium chloride solution, stir evenly, make it fully soaked and absorbed for 12 hours, then dry at 90°C for 6 hours Move it into a muffle furnace and bake it at 550°C for 5 hours to obtain a 7.5wt% Cr / MCM-41 catalyst containing chromium as the active component.

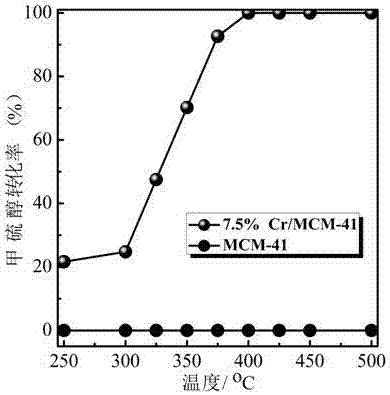

[0031] Sieve the prepared catalyst to 40-60 mesh, and pack it in the reactor, ...

Embodiment 3

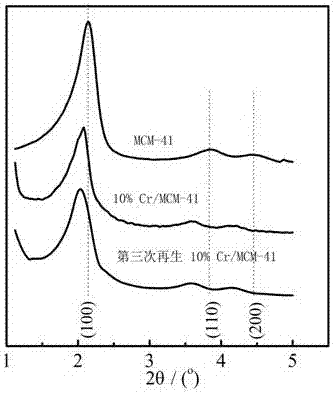

[0034]Get 0.2g of commercially available MCM-41 molecular sieve (without any modification treatment) and fill it in the reactor. The reaction conditions for the decomposition of methyl mercaptan are the same as in Example 1. The conversion rate of methyl mercaptan is 0, and the catalytic activity Such as figure 1 As shown, the XRD pattern is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com