Method for preparing alpha-alumina powder

A technology of alumina powder and powder, which is applied in the field of preparation of α-alumina powder, can solve the problems of difficult preparation of large single crystal particles and reduced resintering activity, and achieve complete crystal form, narrow particle size distribution, active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

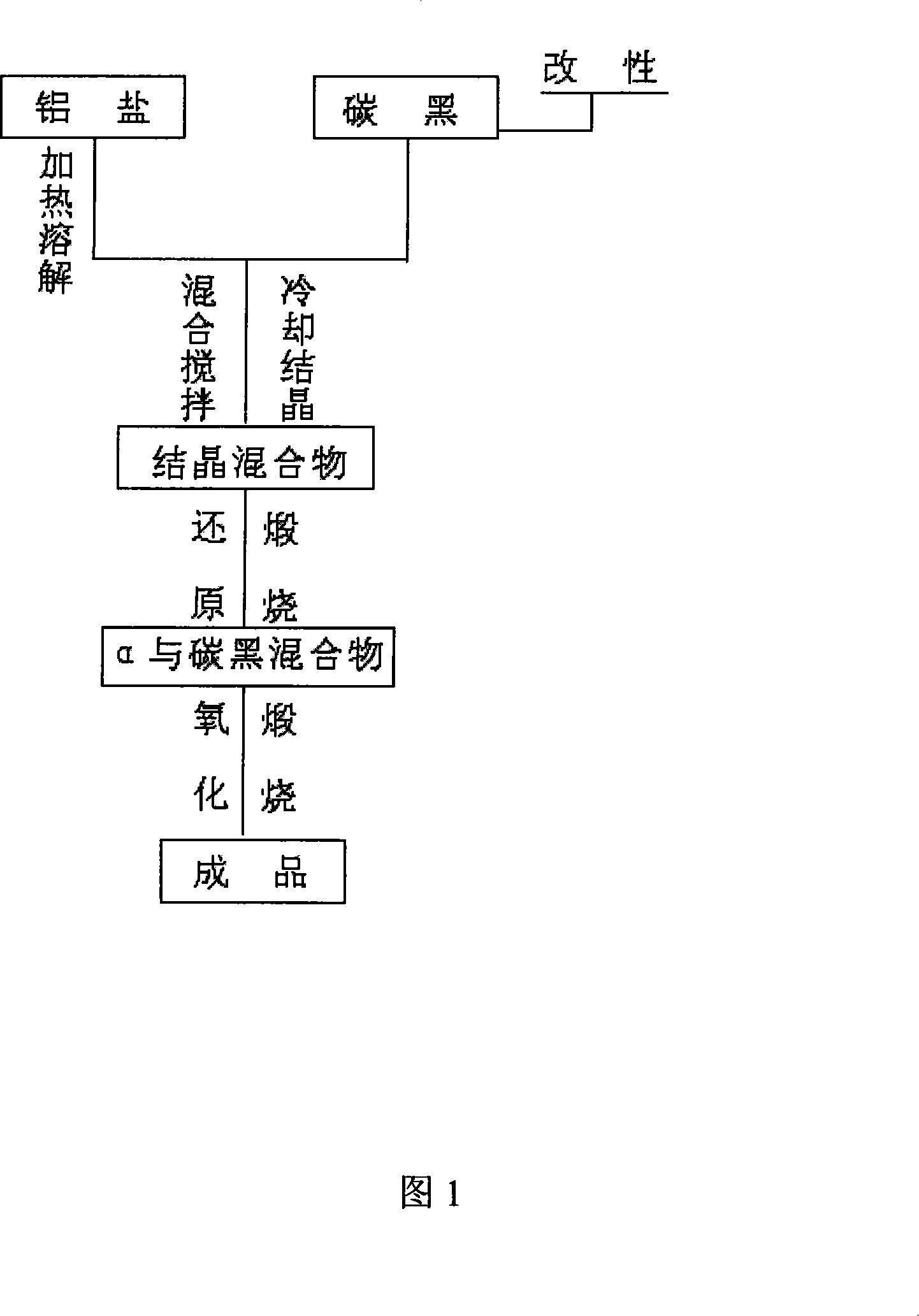

[0016] A preparation method of α-alumina powder, the preparation process is first heating and dissolving high-purity aluminum salt, adding surfactant and surface modifier, then adding modified high-purity activated carbon black, stirring, slowly Cool down and crystallize into a mixture of carbon black and aluminum salt crystals; then the black mixture is calcined once in a reducing atmosphere furnace, and then calcined for a second time in an oxidizing atmosphere to obtain a highly active non-agglomerated α-alumina powder .

[0017] The specific operation steps are:

[0018] a: High-purity carbon black is modified with additives Tween and / or alcohol. The additives are water-soluble. The purpose of adding additives is to make carbon black well combined with aluminum salt in aqueous solution;

[0019] b: Dissolve high-purity aluminum salt in a nearly saturated solution at about 85°C, add polyethylene glycol as a surfactant, and add in an amount of 0.3% to 0.9%. The purpose of a...

Embodiment 1

[0025] Using aluminum ammonium sulfate as the raw material, firstly mix 150g of carbon black and 5g of Tween / 10g of alcohol in a high-speed disperser for 5 minutes, take it out and set aside. Take 1000g of ammonium aluminum sulfate and dissolve it in water (85°C) to obtain a nearly saturated solution, add 5g of polyethylene glycol, and then add the modified carbon black into it, stir evenly, put it in a water bath and cool slowly, the cooling speed -0.3°C / min, pour off the upper aqueous solution after cooling, take out the black crystals in the lower layer, and put them into the crucible. Then put it into a vacuum carbon tube furnace, and calcine in a hydrogen atmosphere at a calcination temperature of 1200°C for 1 hour. After the calcined powder is taken out, it is calcined in a muffle furnace (ventilated, oxidizing atmosphere) at 750°C for 1 hour to obtain the required high activity non-agglomerated α-alumina powder. The distribution of the obtained powder is narrow, betwee...

Embodiment 2

[0027] Use ammonium aluminum carbonate (synthesized by yourself) as raw material. First, stir and mix 200g of carbon black and 20g of Tween / 40g of alcohol in a high-speed disperser for 5 minutes, take it out and set aside. Dissolve 1000g of ammonium aluminum carbonate in water (85°C) to obtain a nearly saturated solution, add 8g of polyethylene glycol, and then add the modified carbon black into it, stir evenly, put it in a water bath for slow cooling, the cooling speed -1°C / min, pour off the upper aqueous solution after cooling, take out the black crystals in the lower layer, and put them into a crucible. Then put it into a vacuum carbon tube furnace, and calcine in a hydrogen atmosphere at a calcination temperature of 1300°C for 1 hour. After the calcined powder is taken out, it is calcined in a muffle furnace (ventilated, oxidizing atmosphere) at 750°C for 1 hour to obtain the required high activity non-agglomerated α-alumina powder. The distribution of the obtained powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com