Miniature methane sensor and methane detection method

A methane sensor, methane detection technology, applied in the direction of material resistance, can solve the problems of poor consistency, complex circuit, power consumption, etc., to achieve the effect of improving anti-interference performance, enriching sensing signals, and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

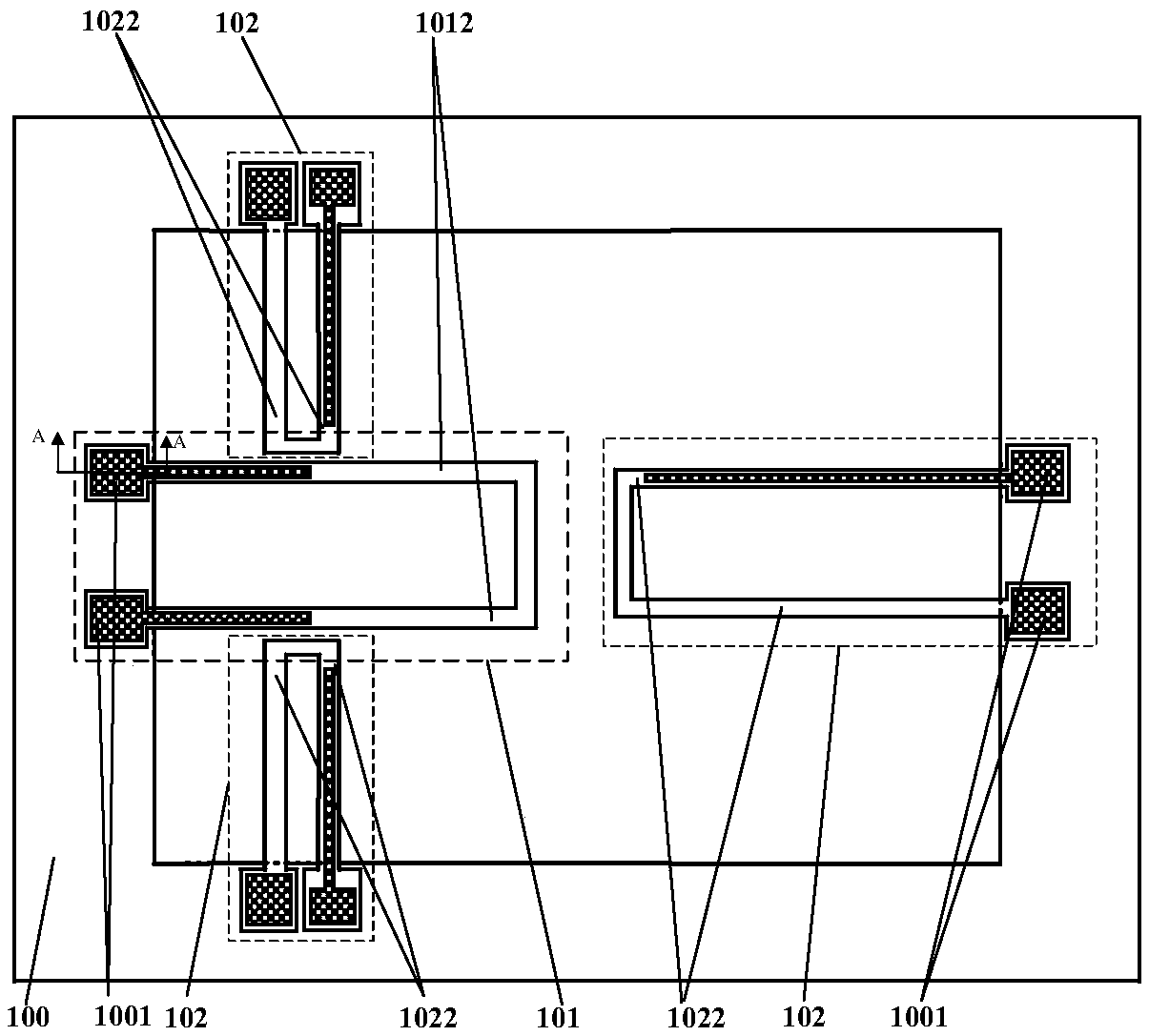

[0032] Such as figure 1 As shown, the miniature methane sensor of the present invention includes a support 100, a heating element 101 and one or more mutually independent measuring elements 102;

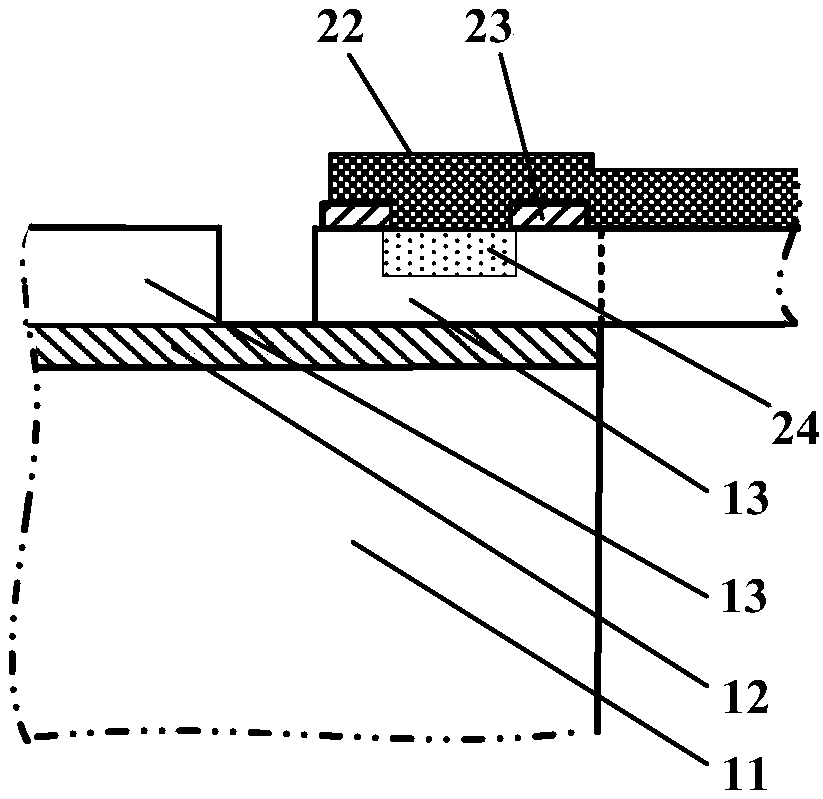

[0033] The support 100 includes a substrate 11 and an isolation silicon oxide layer 12 disposed on the substrate 11, and a single crystal silicon layer 13 is disposed above the isolation silicon oxide layer 12;

[0034]The heating element 101 and each measuring element 102 include a U-shaped cantilever arranged side by side on the support 100 and two fixed ends 1001; the fixed end 1001 of the heating element 101 is independent of the fixed end 1001 of the measuring element 102 The heating element 101 and the measuring element 102 are set on the support 100 through their respective two fixed ends 1001, and the U-shaped cantilever I 1012 of the heating element 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com