Flux-cored welding wire for repairing hot forging die and using method thereof

A technology of flux-cored welding wire and hot forging dies, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of short service life of hot forging dies, low service life of hot forging dies, difficulty in realizing all-position welding, etc. , to achieve the effects of improving production efficiency, excellent welding processability, and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

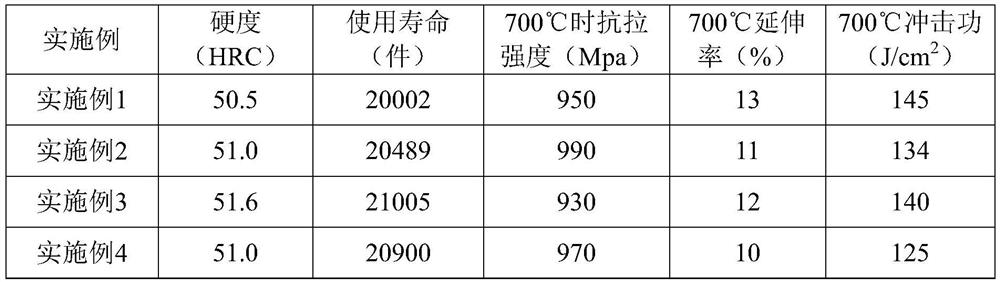

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention more clearly understood, the present invention is described with the following specific embodiments, but it is by no means limited thereto. The following descriptions are preferred embodiments of the present invention, which are only used to describe the present invention and should not be construed as limiting the present invention. It should be pointed out that any modifications, equivalent replacements and improvements made within the spirit and principle of the present invention , should be included within the protection scope of the present invention.

[0021] The functions and contents of each component in the alloy steel strip sheath of the flux-cored welding wire prepared in the embodiments of the present application are as follows:

[0022] C is the main element to improve the strength and hardness of the weld metal. When the C content is too low, the strength and hardn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com