Uncoated electric welding electrode for high-chromium cast iron repair welding

A high-chromium cast iron and welding rod technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of casting defects that cannot be repaired by welding, and achieve the effects of high average hardness, good crack resistance, and good arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

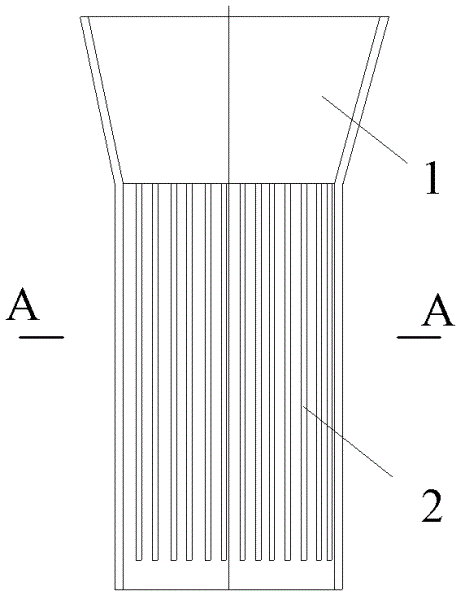

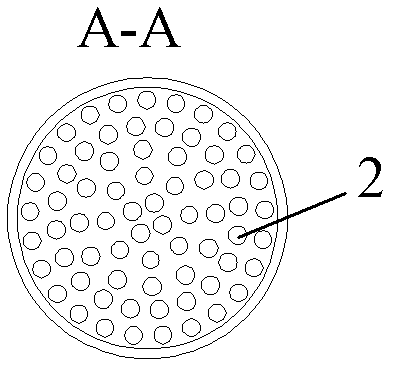

[0025] The electric welding electrode for repair welding of high chromium cast iron without coating of the present invention has no coating and only a welding core, and the components forming the welding core are shown in Table 1 below. Each component was weighed according to the weight percentage of the components in the following Table 1, and the mixed solution of the above-mentioned components was melted by an intermediate frequency induction furnace for multi-element alloying treatment. According to the required welding rod diameter, use the corresponding welding rod model, and make such as figure 1 and figure 2 As shown in the welding core sand mold, the sprue 1 is located at the top, and the electrode type 2 is below the sprue 1. In this embodiment, it is a high-chromium alloy electrode with a diameter of φ2mmx200mm. The electrode sand mold can be water glass sand carbon dioxide hardened sand mold or For clay sand molds, there is no need to paint in the cavity. The gra...

Embodiment 2

[0027] The procedure of Example 1 was repeated at the levels of components specified in Table 1 below.

Embodiment 3

[0029] The procedure of Example 1 was repeated at the levels of components specified in Table 1 below.

[0030] Table 1. Weld core composition table (wt%) in embodiment 1-3

[0031] Example

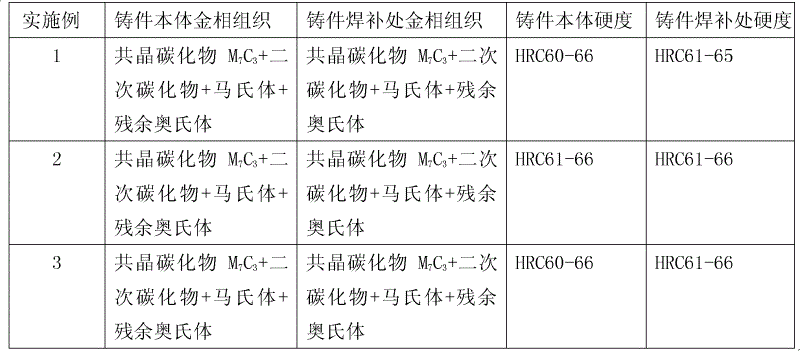

[0032] After testing, the performance indicators of high chromium cast iron after welding repair using the welding rods obtained in the above embodiments 1-3 are shown in the following table 2. From the data, it can be seen that the metallographic structure and hardness of the welding repair part of the casting and the casting body is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com