Self-resetting drilling fixture

A drilling fixture and self-reset technology, applied in the directions of clamping, positioning device, clamping device, etc., can solve the problems of easy workpiece loosening, low processing efficiency, and many loading and unloading times, so as to achieve reliable and accurate drilling process and reduce labor. Strength, the effect of avoiding workpiece replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

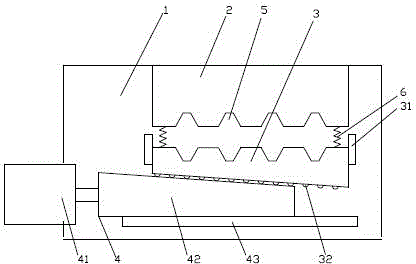

[0010] figure 1 It shows the self-resetting drilling jig provided by the present invention, including a jig base plate 1, a positioning block 2 and a clamping block 3 located on the jig base plate 1 and oppositely arranged, and a drive that drives the clamping block 3 to slide in the direction of the positioning block 2 The device 4, the positioning block 2 is fixedly arranged; the return spring 6 is connected between the positioning block 2 and the clamping block 3; the opposite surface of the positioning block 2 and the clamping block 3 is provided with a V-shaped groove 5 corresponding to each other, and the positioning block 2 and the There are at least two V-shaped grooves 5 on the clamping block 3; the driving device 4 includes a cylinder 41 and a wedge block 42 connected with the cylinder piston rod, the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com