Yttria-zirconia sosoloid ceramics for temperature field of ultrahigh-temperature crystal growing furnace and preparation method for yttria-zirconia sosoloid ceramics

A crystal growth furnace and solid solution technology, applied in the field of yttrium zirconium solid solution ceramics and preparation, can solve the problems of sticking pot crystal yield, high power consumption, crystal stress cracking, etc., and achieve high purity, accurate control, thermal stability and isolation. good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

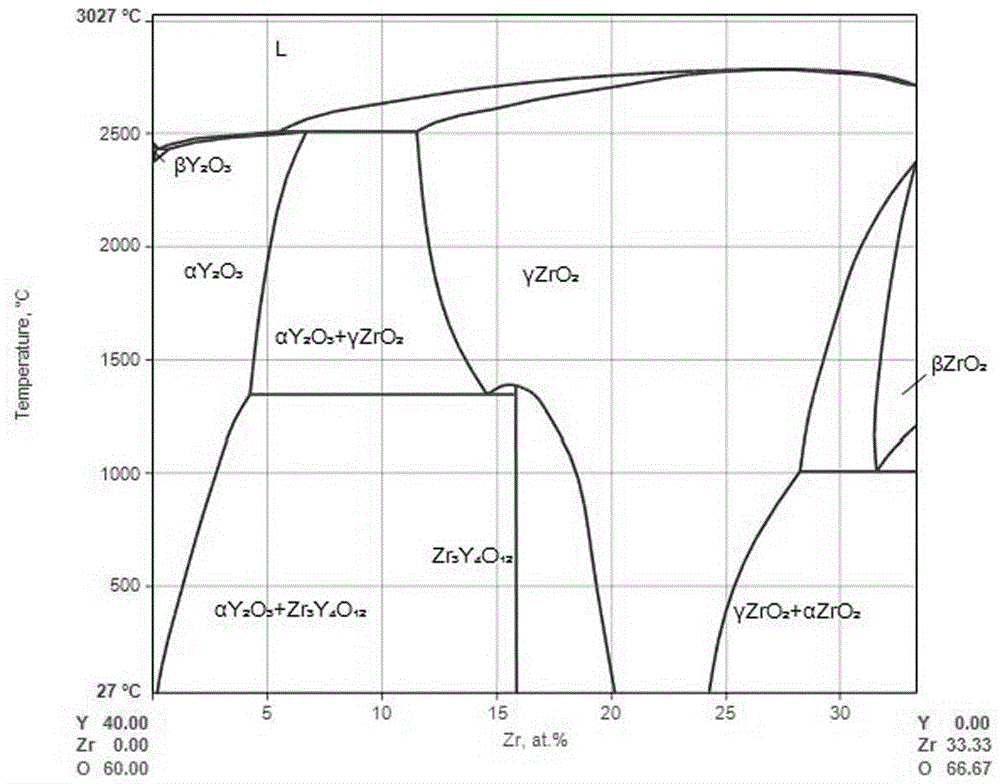

[0032] A yttrium-zirconium solid solution ceramic used in the temperature field of an ultra-high temperature crystal growth furnace, the percentage by weight of oxides is 100% in total, and it has the following chemical composition:

[0033] (ZrO 2 + HfO 2 ): 50%-80%;

[0034] Y 2 o 3 : 19.5%-49%;

[0035] 0.5%-1% other trace impurities, other trace impurities are oxides, including Fe 2 o 3 、Cr 2 o 3 、TiO 2 , CaO, K 2 O.P 2 o 5 , SiO 2 、Al 2 o 3 , MgO, Na 2 O.

[0036] Preferably, a yttrium-zirconium solid solution ceramic used in the temperature field of an ultra-high temperature crystal growth furnace according to the present invention has a total of 100% by weight of the oxide, and has the following chemical composition:

[0037] (ZrO 2 + HfO 2 ): 80%;

[0038] Y 2 o 3 : 19.3200%;

[0039] Other trace impurities are oxides, including Fe 2 o 3 、Cr 2 o3 、TiO 2 , CaO, K 2 O.P 2 o 5 , SiO 2 、Al 2 o 3 , MgO, Na 2 O, its weight percent is:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com