Method and device for treating sewage through electrocatalytic oxidation

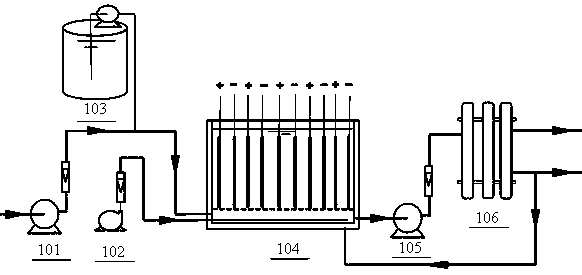

An electro-catalytic oxidation and sewage technology, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. To achieve the effect of not easy to fall off, good electron transfer performance and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

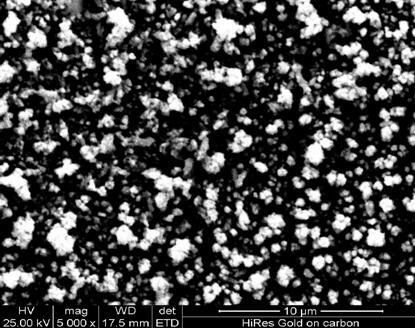

[0032] The preparation process of titanium-based boron-doped diamond film electrode is as follows:

[0033] (1) Use a titanium plate with a thickness of 0.5 mm as the substrate, soak it in dilute hydrochloric acid for 30 minutes to remove the oxide layer on the surface, then put it in alcohol for ultrasonic cleaning, take it out and dry it with inert gas; use ultrasonic technology to inoculate diamond on the titanium plate Seed crystal, ultrasonic time is 5min; the preparation method of diamond seed crystal is: disperse powdered diamond with a particle size of about 0.5 μm in acetone solution, and the mass ratio of powdered diamond to acetone solution is 1:200; the prepared titanium plate Put it into the reaction chamber of microwave plasma vapor-phase chemical deposition equipment, use a vacuum pump to remove the air in the reaction chamber, and then pass CH 4 and H 2 As a reactive gas, mixed with H 2 The borane in the boron is used as a boron dopant, and the reaction press...

Embodiment 2

[0038] Concentrated water from an ultrafiltration reverse osmosis recycling unit in a petrochemical sewage treatment plant has a COD of 100-130mg / L and a salt content of 2580mg / L. The prepared titanium-based boron-doped diamond film / porous carbon / lead dioxide ternary composite electrode was used as the anode for electrocatalytic oxidation, and the activated carbon fiber electrode was used as the cathode. The distance between the plates was 10mm, and the applied voltage was 5V. The volume ratio of aeration rate to water inflow is 10:1, and the hydraulic retention time is 30 minutes. Add wood powder activated carbon 35mg / L, the mesh number is 250 mesh. The membrane separation system uses a ceramic membrane with a pore size of 100nm, and the reflux rate from the membrane separation system to the electrocatalytic oxidation system is 80%. After long-term operation, the effluent COD<50mg / L meets the requirements of the subsequent evaporation and crystallization device, and the oper...

Embodiment 3

[0040] The circulating water discharge of a chemical plant has a COD of 120-150mg / L and a salt content of 6550mg / L. The prepared titanium-based boron-doped diamond film / porous carbon / lead dioxide ternary composite electrode was used as the anode for electrocatalytic oxidation, and the activated carbon fiber electrode was used as the cathode. The distance between the plates was 100mm, and the applied voltage was 20V. Add wood powder activated carbon 40mg / L, mesh number is 250 mesh. The volume ratio of aeration rate to water inflow is 4:1, and the hydraulic retention time is 60 minutes. The membrane separation system uses a ceramic membrane with a pore size of 100nm, and the reflux rate from the membrane separation system to the electrocatalytic oxidation system is 50%. After long-term operation, the effluent COD is less than 50mg / L, which meets the discharge requirements. After 30 days of continuous use, the electrode is intact and the surface layer does not fall off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com