High-temperature and high-strength insulating tube and manufacturing method thereof

A manufacturing method and insulating tube technology, which is applied in fuse manufacturing, electrical components, circuits, etc., can solve the problems of low adhesion between resin glue and insulating materials, poor moisture resistance and compression resilience of semi-finished products, and low Tg value of finished products. , to achieve better mechanical impact performance, stable heat release, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

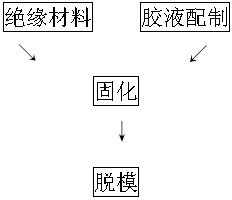

Image

Examples

Embodiment 1

[0018] First, the resin glue is made of 100 parts of high Tg and low viscosity modified epoxy, 82 parts of anhydride curing agent, 2 parts of accelerator, and 5 parts of silane coupling agent in the glass fiber by weight and number. Stir well, then pour into the glue tank.

[0019] Then wind the glass fiber passing through the glue tank on the mold at a certain angle, and run back and forth until it reaches the size.

[0020] After the winding is completed, it can be put into the oven, then adjust the temperature control and time control regulator for the first curing, adjust the temperature to 98°C and keep it for 55 minutes, then perform the second curing, adjust the temperature to 117°C and keep it at 118°C Minutes, the third curing is to adjust the temperature to 195 ℃ and keep it for 298 minutes.

[0021] After the mold is cooled, the high-performance insulating tube can be removed.

Embodiment 2

[0023] First, the resin glue is made of 100 parts of high Tg and low viscosity modified epoxy, 84 parts of anhydride curing agent, 2 parts of accelerator, and 5 parts of silane coupling agent in the glass fiber by weight and number. Stir well, then pour into the glue tank. Then wind the glass fiber passing through the glue tank on the mold at a certain angle, and run back and forth until it reaches the size.

[0024] After the winding is completed, it can be put into the oven, then adjust the temperature control and time control regulator for the first curing, adjust the temperature to 100°C and keep it for 60 minutes, then perform the second curing, then adjust the temperature to 120°C and keep it 119 minutes, the third curing is to adjust the temperature to 200°C and keep it for 300 minutes.

[0025] After the mold is cooled, the high-performance insulating tube can be removed.

[0026] The invention provides a high-temperature-resistant and high-strength insulating tube a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com