High-temperature-baking resistant and water-based paint

A water-based coating, high-temperature technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, chloroprene homopolymer coatings, etc., can solve the problem of slow volatilization process, drying speed dependent on environmental humidity, and large differences in drying environment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

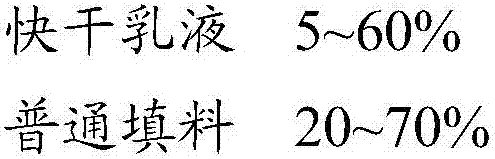

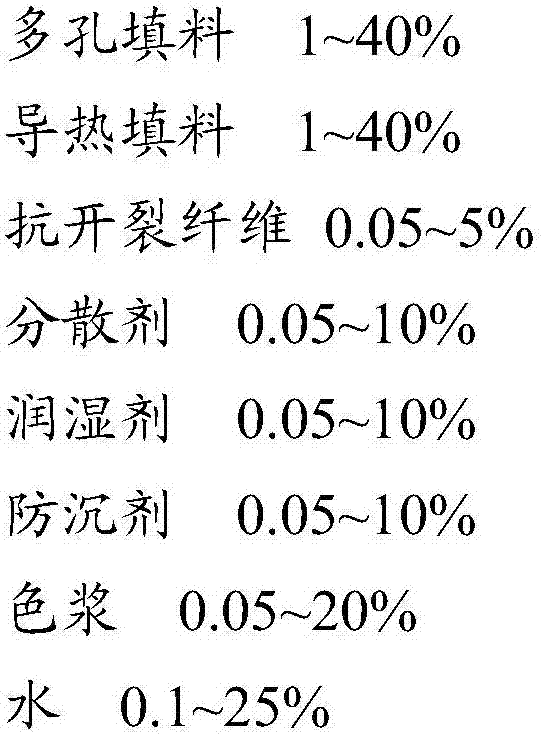

[0041] In the present invention, there is no special limitation on the preparation method of the high-temperature bakeable water-based coating, and the method for preparing the composition well known to those skilled in the art can be used. In the present invention, the preparation of the high-temperature bakeable water-based paint preferably includes the following steps: mixing quick-drying emulsion, common filler, thermally conductive filler, porous filler, anti-cracking fiber, dispersant, wetting agent, anti-sedimentation agent, colorant slurry, mixed with water to obtain a water-based paint that can be baked at a high temperature.

[0042] The present invention preferably mixes the quick-drying emulsion with a dispersant, a wetting agent, an anti-sedimentation agent and a color paste to obtain a mixed material; then the mixed material is mixed with a common filler, a thermally conductive filler and a porous filler to obtain a slurry; finally the The slurry is mixed with wa...

Embodiment 1

[0092] Raw materials include the following components in mass content: quick-drying emulsion 40% (solid content 42%), filler 45%, porous filler 10%, polypropylene fiber 0.3%, dispersant 2.4%, wetting agent 0.3%, anti-sedimentation Agent 1.0%, pigment 0.5%, thickener 0.25%, defoamer 0.25%, water 0%;

[0093] in,

[0094] Quick-drying emulsion: 20g of styrene-butadiene emulsion with a Tg of 20°C, 10g of water-based epoxy resin, and 10g of water-based polyurethane resin;

[0095] Ordinary filler: 35g of talc powder with a particle size of 325 mesh, 10g of mica powder with a particle size of 400 mesh;

[0096] Porous filler: 5g of zeolite powder with a porosity of 30% and a particle size of 200 mesh, 5g of a molecular sieve with a porosity of 45% and a particle size of 200 mesh;

[0097] Thermally conductive filler: silicon carbide 15g,

[0098] Polypropylene fiber 0.3g, length 3mm;

[0099] Dispersant Tego 760W 2.5g;

[0100] Wetting agent Tego 245 0.3g;

[0101] Anti-settl...

Embodiment 2

[0109] Raw materials include the following components in mass content: 35% of quick-drying emulsion (solid content 45%), 28.7% of common filler, 15% of thermally conductive filler, 15% of porous filler, 0.3% of polyacrylonitrile fiber, 3% of dispersant, wetting Agent 1.0%, anti-settling agent 0.8%, pigment 0.5%, thickener 0.35%, defoamer 0.35%, water 0%;

[0110] in,

[0111] Quick drying lotion: T g 15g of tertiary vinegar emulsion at 20°C, T g 10g of polyvinyl acetate emulsion at 50°C, T g 10g of chlorine partial emulsion at -10°C;

[0112] Filler: 18.7g of calcium carbonate with a particle size of 325 mesh, 10g of mica powder with a particle size of 100 mesh;

[0113] Thermally conductive filler: 15g of thermally conductive graphite with a particle size of 400 mesh;

[0114] Polyacrylonitrile fiber 0.3g, length 3mm;

[0115] Porous filler: 15g of diatomite with a porosity of 40% and a particle size of 400 mesh;

[0116] Dispersant Tego 750W 3g;

[0117] Wetting agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com