Mechanism for separating plastic products from slide blocks on four sides

A technology for plastic products and sliders, which is applied in the field of molds with inverted buckles on the inside and outside of plastic products, can solve the problems of reduced production efficiency, large matching size, weak strength and easy breakage, etc., to improve production efficiency and simplify the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

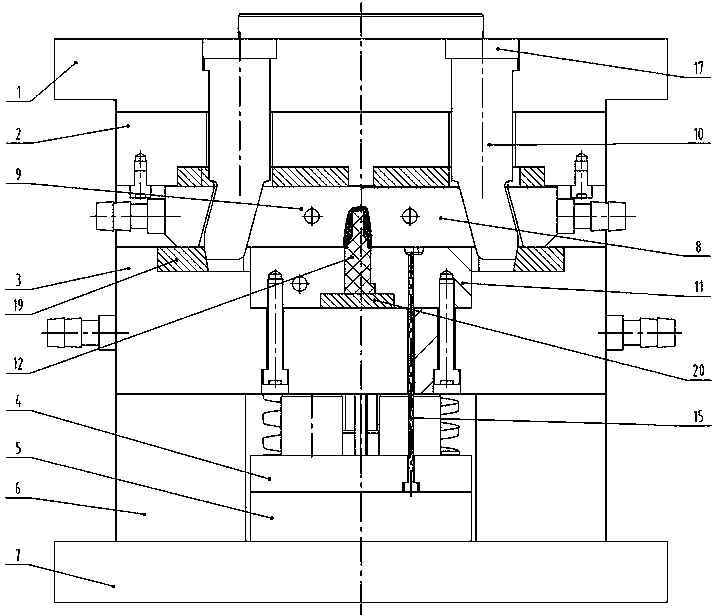

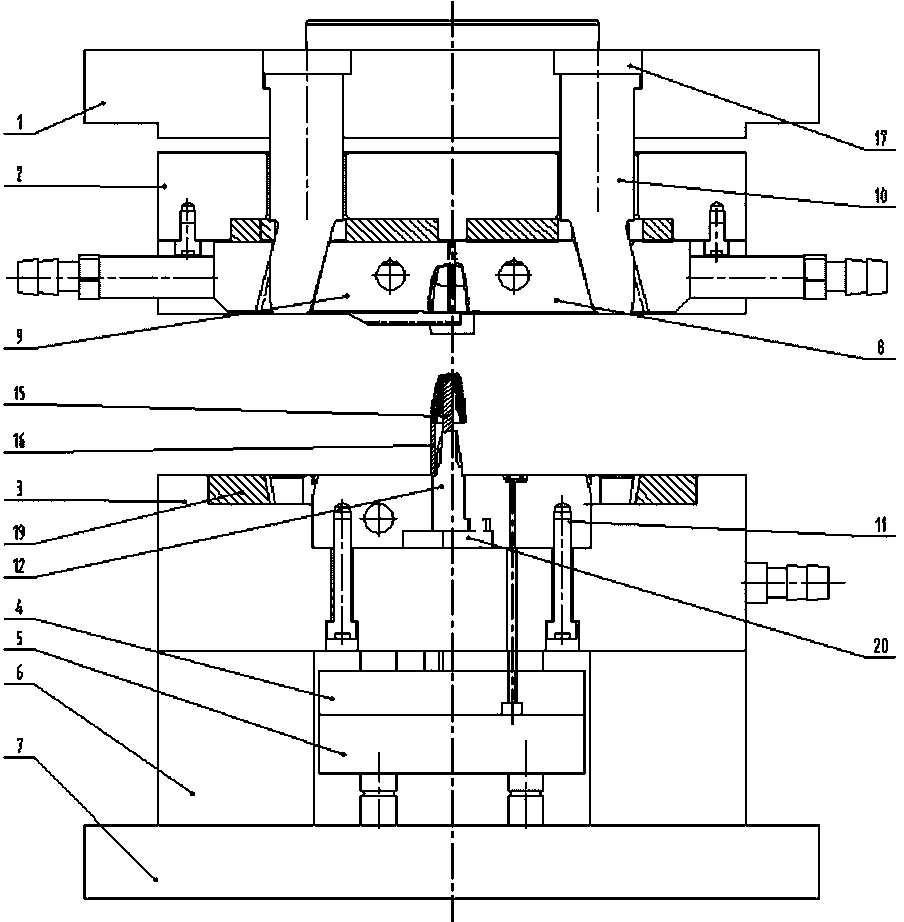

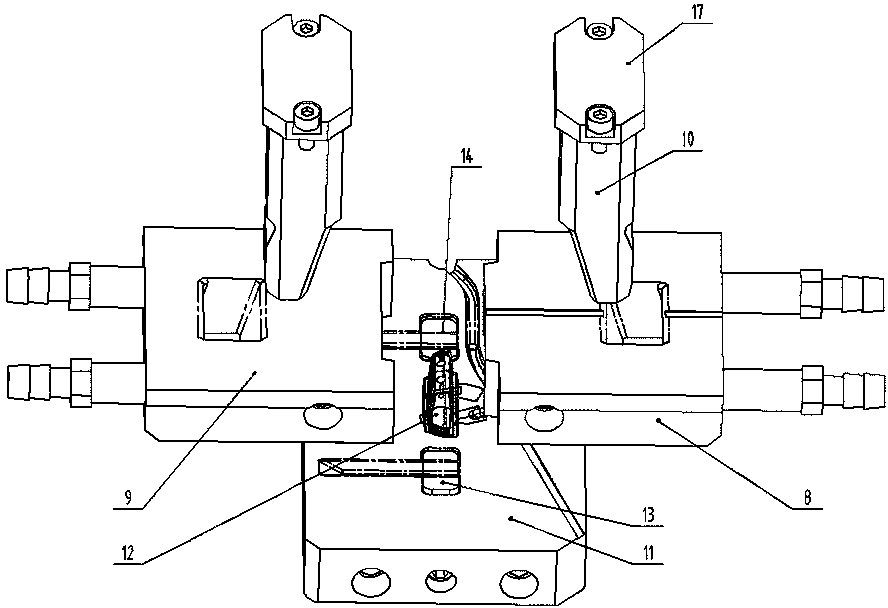

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0019] Assembly of the mold: the wedge 10 is embedded in the fixed mold base plate 1, the bolt is threaded with the fixed mold base plate 1 through the pressure plate A17, the fixed mold slider A8 and the fixed mold slider B9 are placed in the slider groove of the fixed mold plate 2, and the pressure plate B18 is installed on both sides of the fixed mold slider A8 and the fixed mold slider B9, and the two sides of the fixed mold slider B9 are in contact with them to limit the surface. The bolt is threaded with the fixed template 2 through the pressure plate 18, and the wedge 10 passes through the fixed mold slider A8 and the fixed mold slider. B9 is in contact with the wedge limit 19 surface, the movable mold insert 12, the movable mold inner drawing slider A13 and the movable mold inner drawing slider B14 are embedded in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com