Extrusion forming mould for annular ribs of magnesium alloy shell parts

An extrusion forming and magnesium alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems such as the quality of the ring bars cannot meet the requirements, the rib filling is not enough, and the adaptability is not good, so as to reduce energy consumption, high production efficiency, Easy to operate and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is specifically illustrated by specific embodiments.

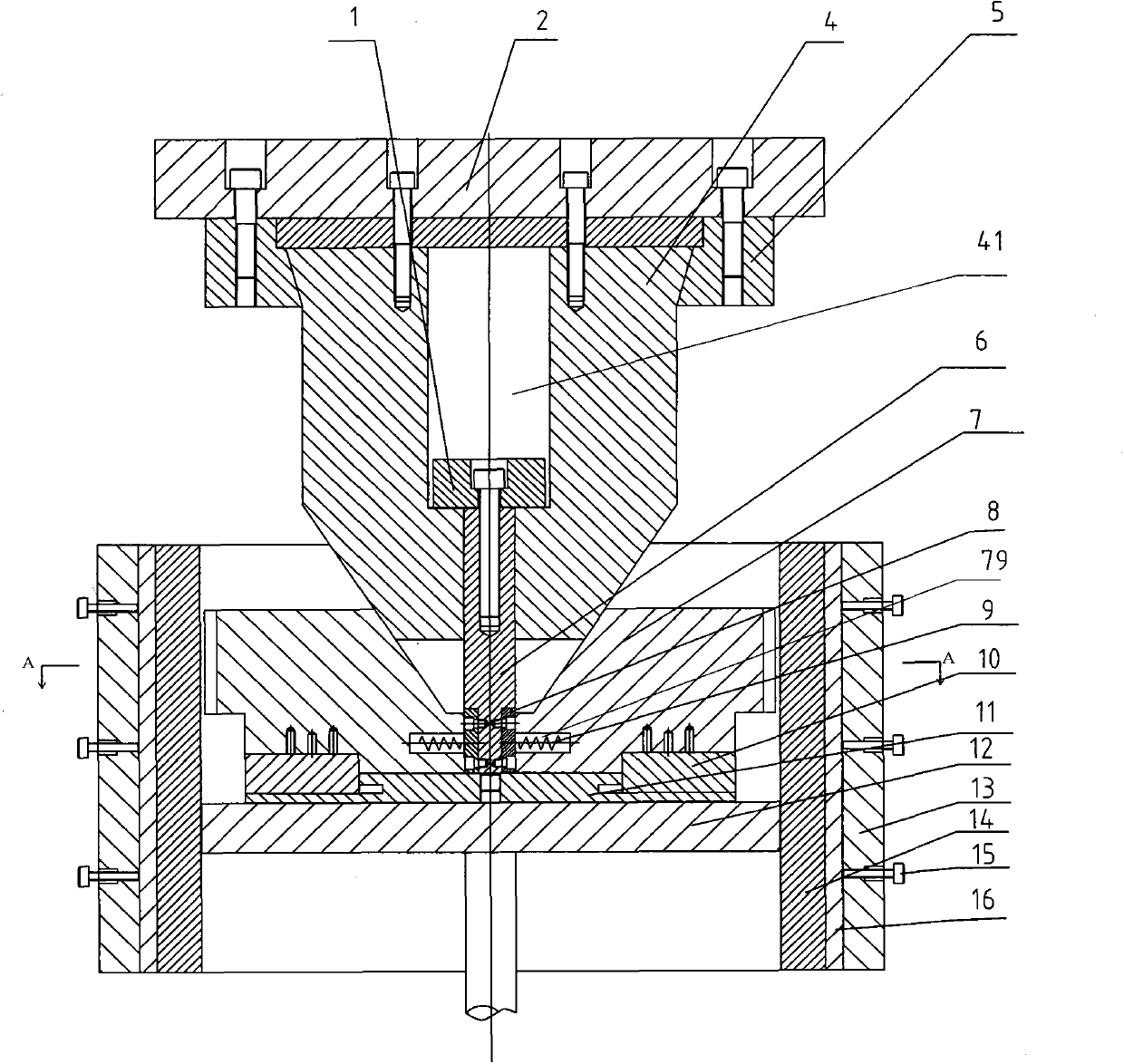

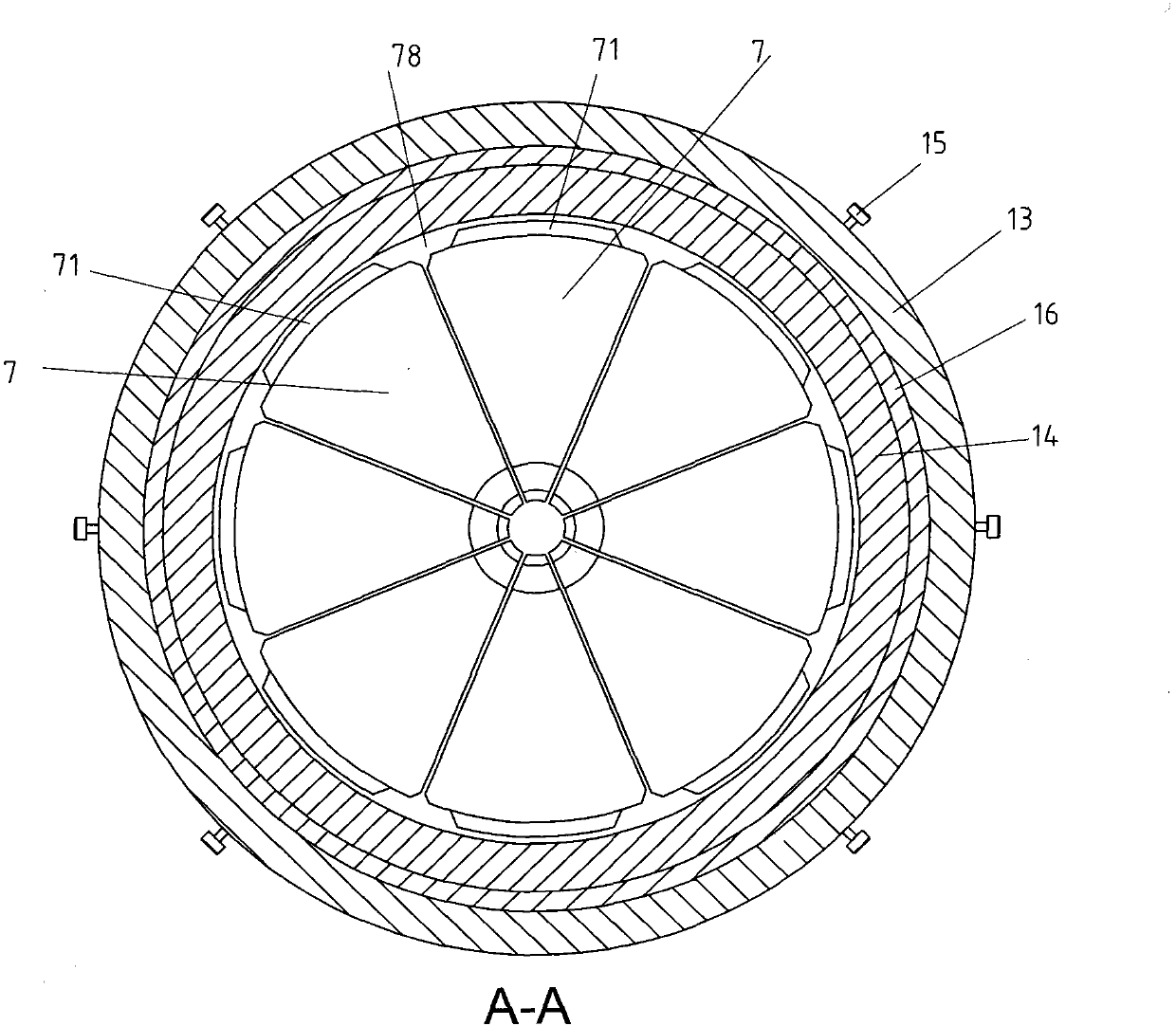

[0029] Such as figure 1 , figure 2 As shown, a mold for extrusion forming of ring ribs of magnesium alloy shell parts mainly includes an upper template 2, a mandrel 4, a split punch pull rod 6, a pull rod fixing plate 1, a tension spring 9, and a split punch 7 , punch sliding guide rail 10, split punch sliding bottom plate 11, supporting plate 12, cylindrical die 13, the head of the mandrel 4 is tapered, and the tail is fixed on the upper template 2 through the punch fixing plate 5 The mandrel 4 has a central hole 41 in the axial direction, and one end of the split punch pull rod 6 is inserted into the central hole 41. The central hole 41 of the mandrel 4 is a stepped hole with a larger diameter in the upper section and a smaller diameter in the lower section. , the upper end of split punch pull rod 6 passes through the lower part of the center hole 41 and is fixed to the tie rod fixing plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com