Flexible steel pads for multi-point forming

A multi-point forming and steel pad technology, which is applied in the field of mechanical engineering, can solve the problems of forming accuracy and reduce sheet forming accuracy, and achieve the effect of dispersing concentrated loads, suppressing wrinkles and indentations, and improving continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific content and implementation of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

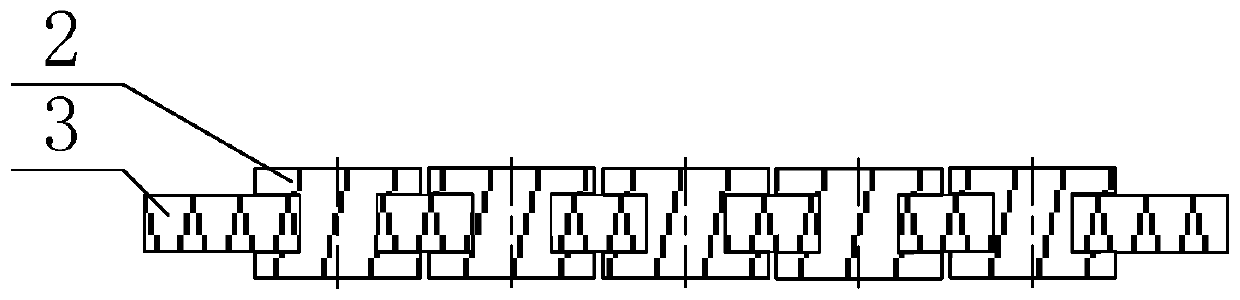

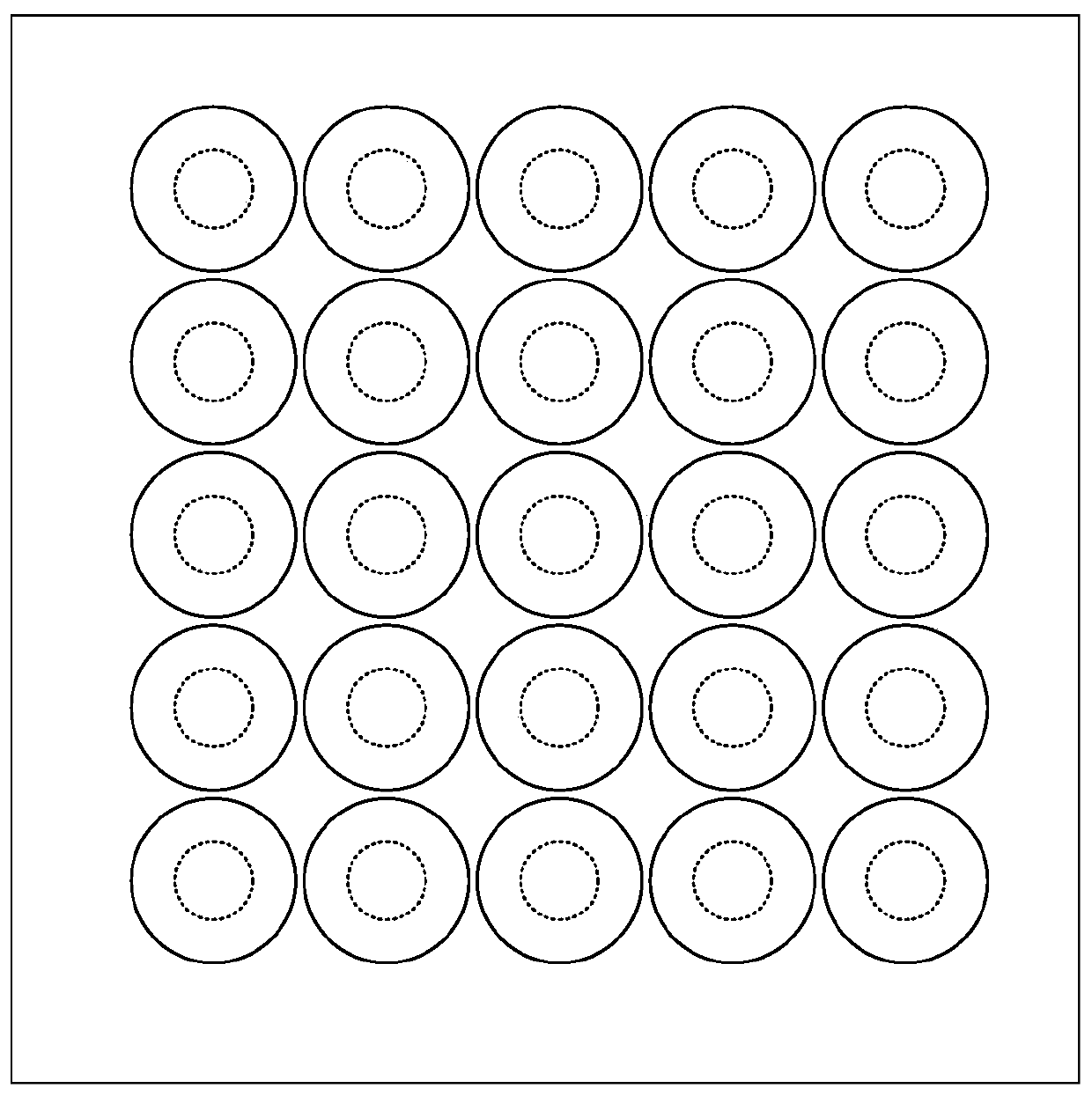

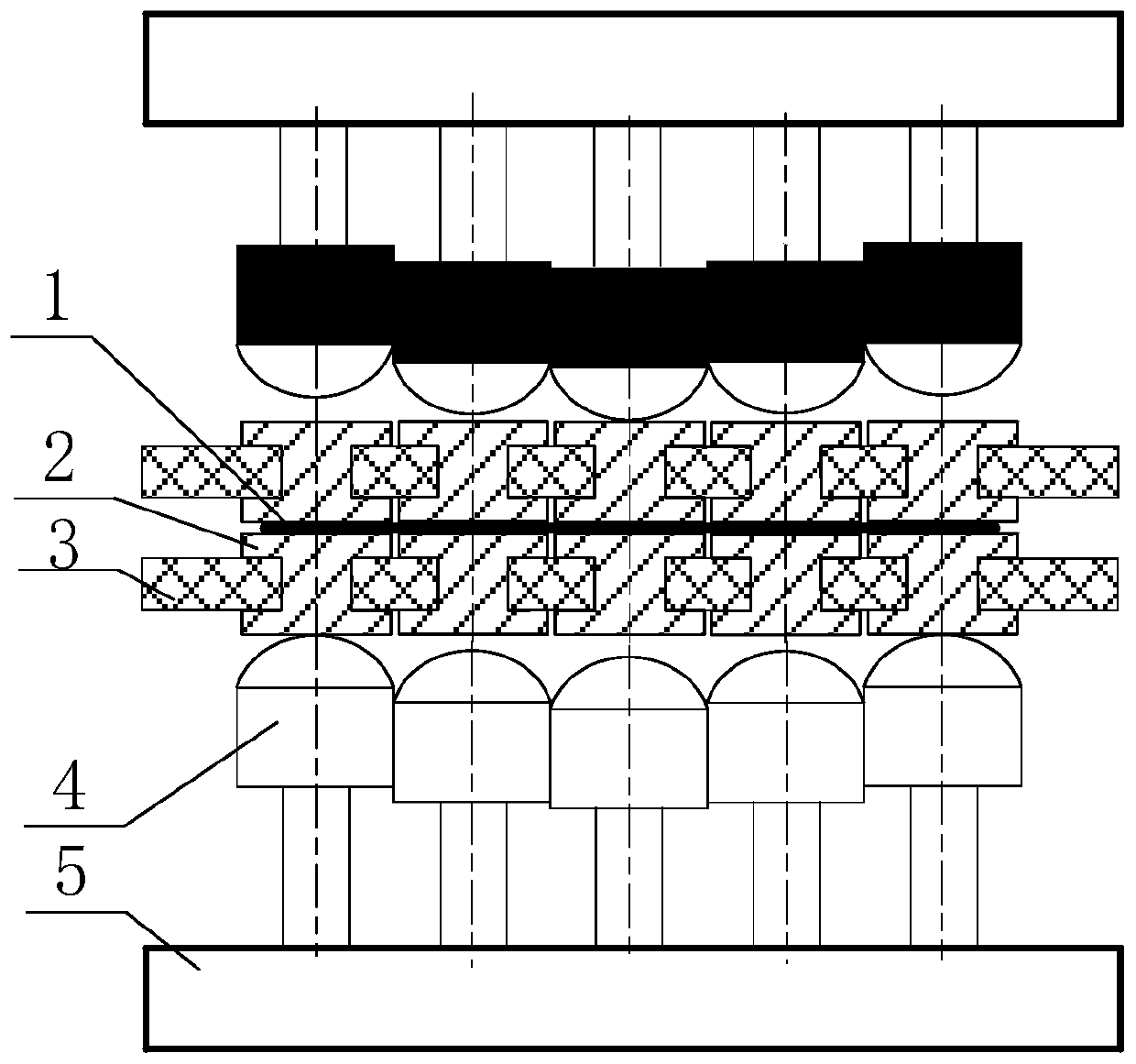

[0027] A flexible steel pad for multi-point forming is mainly composed of an I-shaped steel pad 2 and a polyurethane plate with holes 3, and a plurality of I-shaped steel pads 2 and the polyurethane plate with holes 3 are assembled into one body. Before forming, the upper and lower basic unit 4 of the multi-point forming device is adjusted to a specified height according to the CAD digital model of the formed part. When forming, the basic unit 4 of the upper mold and the unit fixing plate 5 move downward, and the steel pad 2 rotates with the deformation of the plate, converting the vertical compressive stress applied by the basic unit 4 into a compressive stress perpendicular to the plate, so that the plate Deformation is produced while suppressing the occurrence of creasing and wrinkles. The integrated structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com