Manufacturing method of composite material pressure container

A technology for pressure vessels and composite materials, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of reducing the overall performance of composite materials and aggravating fiber fracture, so as to maintain stable mechanical properties and reduce fiber fracture rate , the effect of reducing the deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take the 20MPA aluminum-lined carbon fiber full-wound high-pressure gas cylinder as an example. The aluminum lining material is 6061 aluminum alloy, the shape is cylindrical, and the capacity is 120L, 110L and 80 liters. After the lining is heat-treated according to the predetermined plan, the measured Poisson's ratio μ=0.32 and elastic modulus E=70.25GPa.

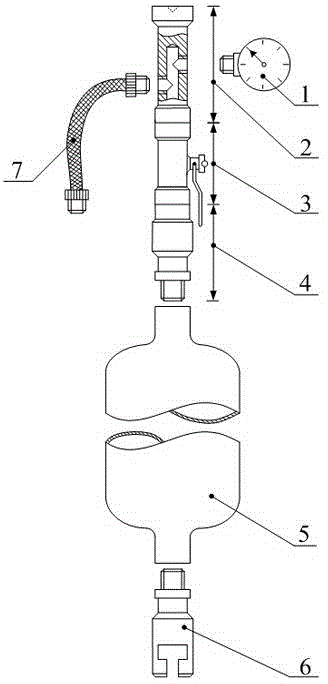

[0049] Take the wall thickness t=4.5mm uniformly, and the inner diameter R=167mm. It is calculated that the cure shrinkage of the composite material (carbon fiber + epoxy resin) with a glue content of 25% is close to 0.18%, and considering the winding tension of the filaments, the strain ε in formula (3) is taken as 0.2%. Combining formula (1) and formula (2) to solve, it can be obtained that the air should be pre-washed into the aluminum lining to 2.535MPa before winding processing, and the actual value is P 0=2.54MPa. After the inner lining completes the machining process, the frocks 1, 2, 3, 4, 7, etc. in the a...

Embodiment 2

[0051] Take the 35MPA aluminum-lined carbon fiber full-wound high-pressure gas cylinder as an example, with a capacity of 110L and a cylindrical structure of 6061 aluminum alloy. Take wall thickness t=5.0mm, inner diameter R=154mm. Similarly, using the same aluminum alloy heat treatment system, the glue content of the composite material is still 25%, and the curing shrinkage rate is also 0.18%. The actual strain ε in formula (3) is 0.2%. After solving the same formula, it can be obtained that the air should be pre-flushed into the aluminum liner to 3.179MPa before winding processing, and the actual value of P 0 =3.18MPa. After completing the scheduled winding and curing processes, the self-tightening operation is also performed. Compared with the same gas cylinder without stamping operation, the self-tightening pressure of 3MPA is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com