A kind of magnesium alloy profile multi-directional repeated extrusion deformation processing device and processing method

A technology of repeated extrusion and processing methods, applied in the direction of metal extrusion dies, etc., to achieve the effects of uniform strain, avoiding stress concentration, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

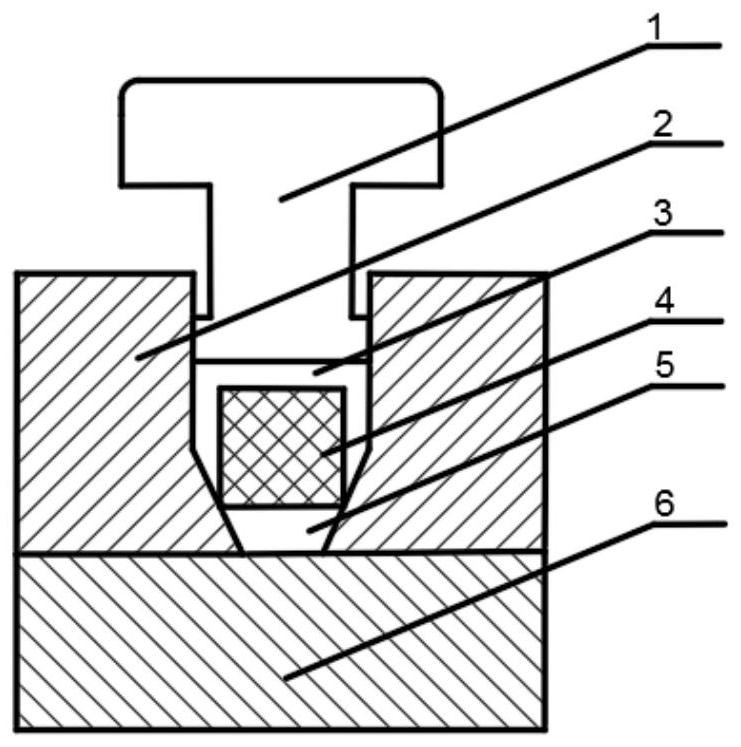

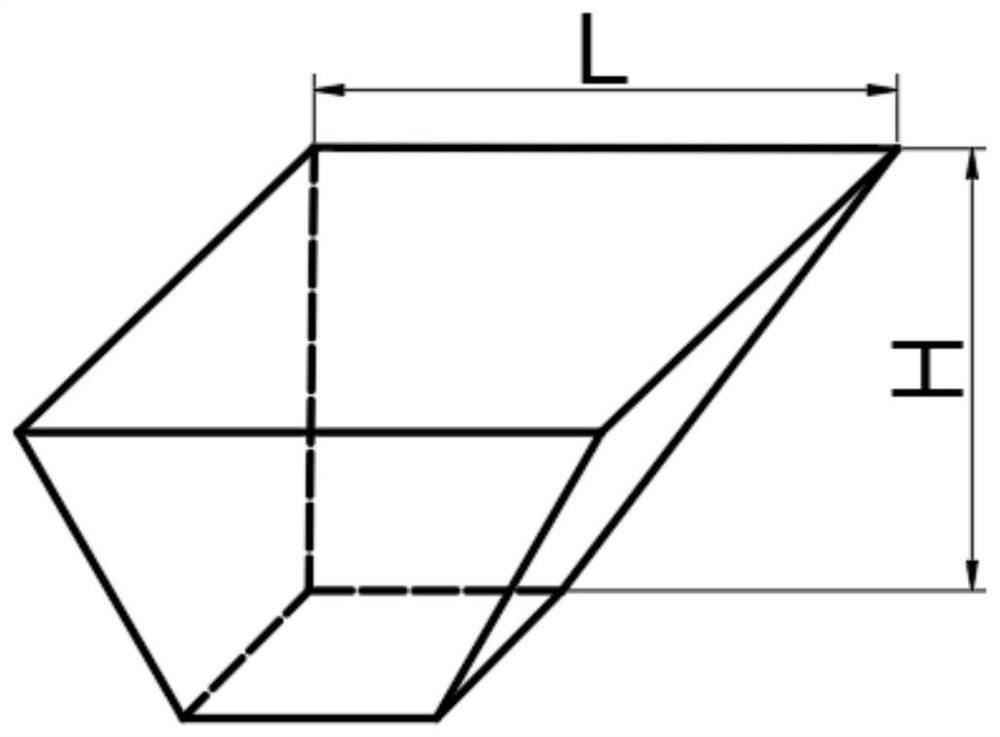

[0033] A multi-directional repeated extrusion deformation processing device for magnesium alloy profiles, including a punch 1, an upper die 2 and a lower die 6, the upper die 2 is provided with a die cavity, and the die cavity is formed by the punch. The channel 3 and the extrusion channel 5 are formed. The punch channel 3 is in the shape of a cuboid, the extrusion channel 5 is in the shape of an inverted regular quadrangular prism, and the upper die 2 and the lower die 6 are connected and combined by screws and pins. into a concave mold, the punch 1 is arranged in the punch channel 3, and is matched with the punch channel 3; The height H of the quadrangular platform of the cavity, the four edges of the quadrangular platform are inclined upward, and are provided with rounded corners of 1mm.

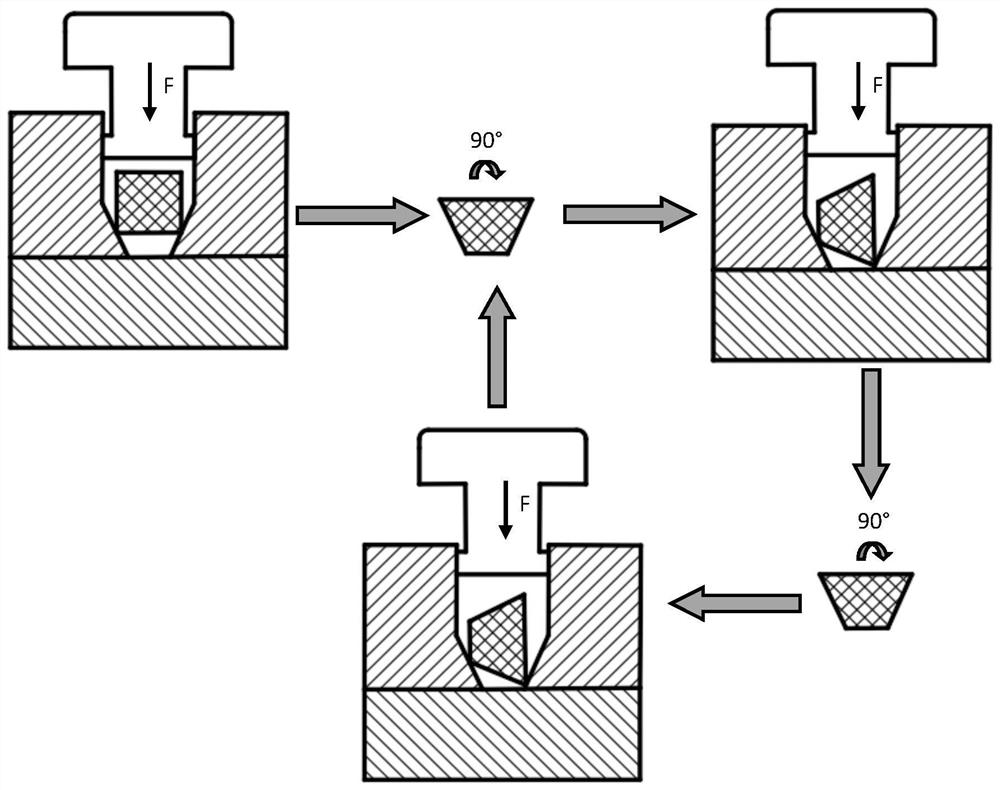

[0034] The method for multi-directional repeated extrusion deformation processing of magnesium alloy profiles adopts the above-mentioned multi-directional repeated extrusion deformation p...

Embodiment 2

[0047] A multi-directional repeated extrusion deformation processing device for magnesium alloy profiles, including a punch 1, an upper die 2 and a lower die 6, the upper die 2 is provided with a die cavity, and the die cavity is formed by the punch. The channel 3 and the extrusion channel 5 are composed, the punch channel 3 is in the shape of a cuboid, the extrusion channel 5 is in the shape of an inverted regular quadrangle, and the upper die 2 and the lower die 6 are connected and combined by screws and pins. into a concave mold, the punch 1 is arranged in the punch channel 3, and is matched with the punch channel 3; The height H of the quadrangular platform of the cavity is set, and the four edges of the quadrangular platform are inclined upward, and are provided with rounded corners of 1.5 mm.

[0048] The method for multi-directional repeated extrusion deformation processing of magnesium alloy profiles adopts the above-mentioned multi-directional repeated extrusion defor...

Embodiment 3

[0061] A multi-directional repeated extrusion deformation processing device for magnesium alloy profiles, including a punch 1, an upper die 2 and a lower die 6, the upper die 2 is provided with a die cavity, and the die cavity is formed by the punch. The channel 3 and the extrusion channel 5 are composed, the punch channel 3 is in the shape of a cuboid, the extrusion channel 5 is in the shape of an inverted regular quadrangle, and the upper die 2 and the lower die 6 are connected and combined by screws and pins. into a concave mold, the punch 1 is arranged in the punch channel 3, and is matched with the punch channel 3; The height H of the four-sided platform of the cavity is set, and the four edges of the four-sided platform are inclined upward and provided with rounded corners of 2mm.

[0062] The method for multi-directional repeated extrusion deformation processing of magnesium alloy profiles adopts the above-mentioned multi-directional repeated extrusion deformation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com