Seat armrest support structure

A technology of armrest support and seat frame, which is applied in the direction of armrests, vehicle seats, special positions of vehicles, etc., and can solve problems such as safety problems, fracture of rotating shafts or guide pillars, etc., to ensure safe use, avoid damage, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

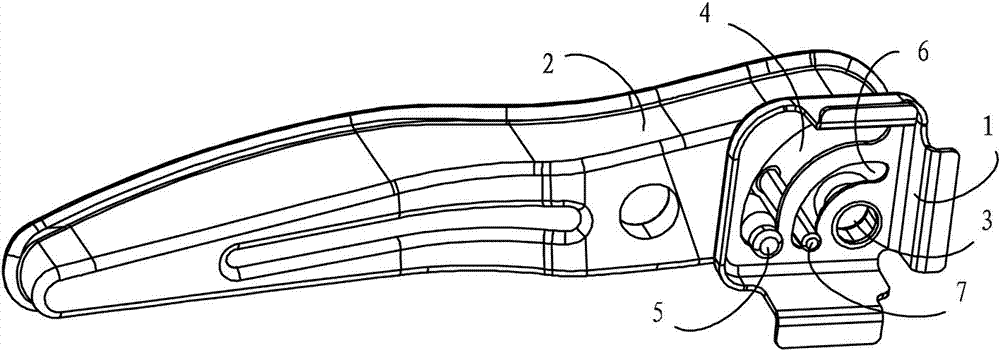

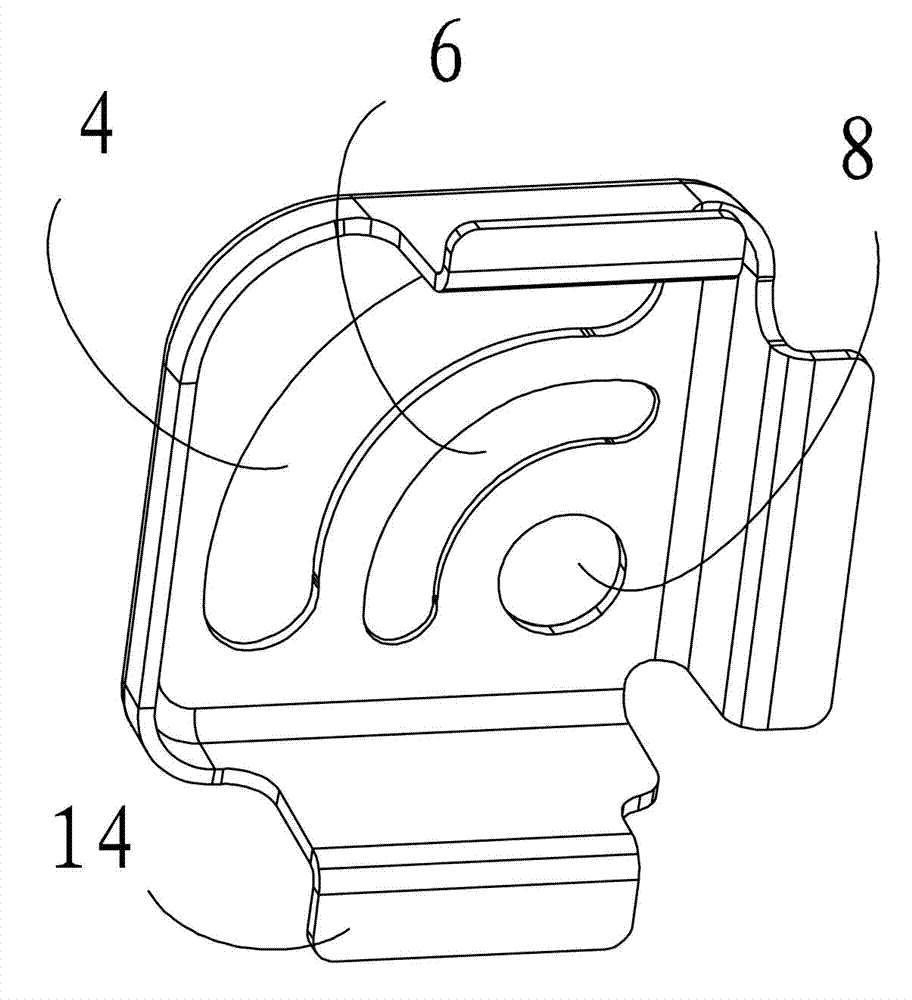

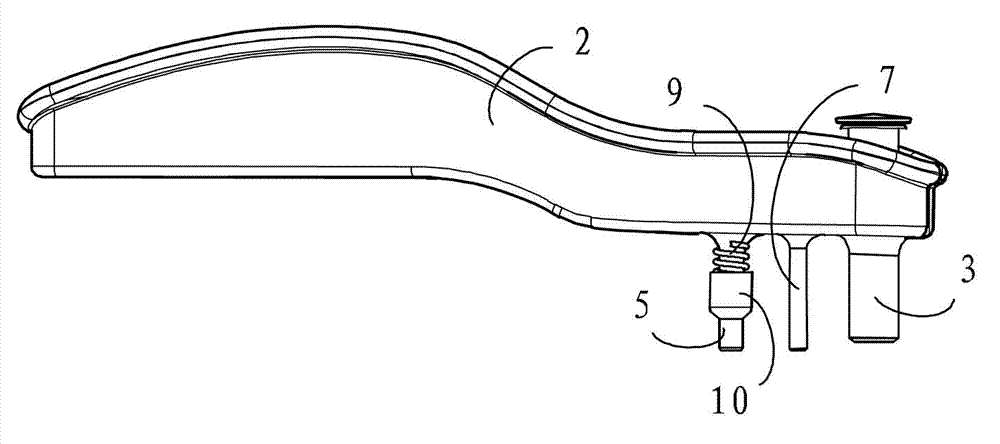

[0027] This embodiment relates to a seat armrest bracket structure, which consists of Figure 1 to Figure 3 As shown, it includes a mounting bracket 1 that is fixedly connected to the seat frame not shown in the figure, and is rotatably connected to the mounting bracket through a connecting shaft 3 arranged at one end thereof and a shaft mounting hole 8 on the mounting bracket 1. The handrail 2 on 1 is provided with the circular arc groove 4 and the second circular arc groove 6 arranged at intervals with the rotation center of the handrail 2 as the center of the circle on the mounting bracket 1, and the circular arc groove 4 inserted into the handrail 2 is respectively arranged on the armrest 2. and the second guide post 5 and the second guide post 7 sliding along the arc slot 4 and the second arc slot 6 when the handrail 2 rotates around its center of rotation. An elastic support mechanism is also provided on the side of the mounting bracket 1 facing the armrest 2 on the guid...

Embodiment 2

[0034] This embodiment relates to a seat armrest support structure, which has substantially the same structure as the seat armrest support structure in Embodiment 1, the difference is that Figure 8 As shown in , in this embodiment, the elastic support mechanism is arranged on the guide post 5 on the side of the mounting bracket 1 facing away from the handrail 2. At this time, in order to reduce the structural length of the guide post 5, the shaft of the support sleeve 10 can be The length is slightly shortened, and a support nut 16 is installed at the end of the guide post 5, and a second spring 17 is arranged between the support nut 16 and the support sleeve 10. After the armrest 2 is connected to the mounting bracket 1, it passes through the second The installation pretightening force of the two springs 17 pushes the support sleeve 10 so that the tapered end 13 of the support sleeve 10 is embedded in the arc groove 4 . In this embodiment, the movement process of the support...

Embodiment 3

[0036] This embodiment relates to a seat armrest support structure, which has substantially the same structure as the seat armrest support structure in Embodiment 1, the difference is that Figure 9 As shown in , it is provided with elastic supporting mechanisms on both sides of the mounting bracket 1 on the guide post 5 . A support nut 16 is installed at the end of the guide post 5 located at the side of the mounting bracket 1 facing away from the handrail 2, and between the support nut 16 and the mounting bracket 1 is a support sleeve 10 sleeved on the side of the guide post 5, for Reduce the structural length of the guide post 5, the axial length of the support sleeve 10 on this side is also slightly shortened, and a second spring 17 is also arranged between the support nut 16 and the support sleeve 10 on this side, and is connected to the armrest 2. After being installed on the bracket 1, under the promotion of the installation pre-tightening force of the first spring 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com