Mold and method for producing open-mouthed concrete box

A concrete and mold technology, which is applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems that the accuracy of the error size of the geometric shape of the box is difficult to control, the mold can only produce the same, and the production efficiency is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the features of the technical solution more clearly, the present invention will be further elaborated below.

[0021] (1) Assemble the mould, the steps are as follows:

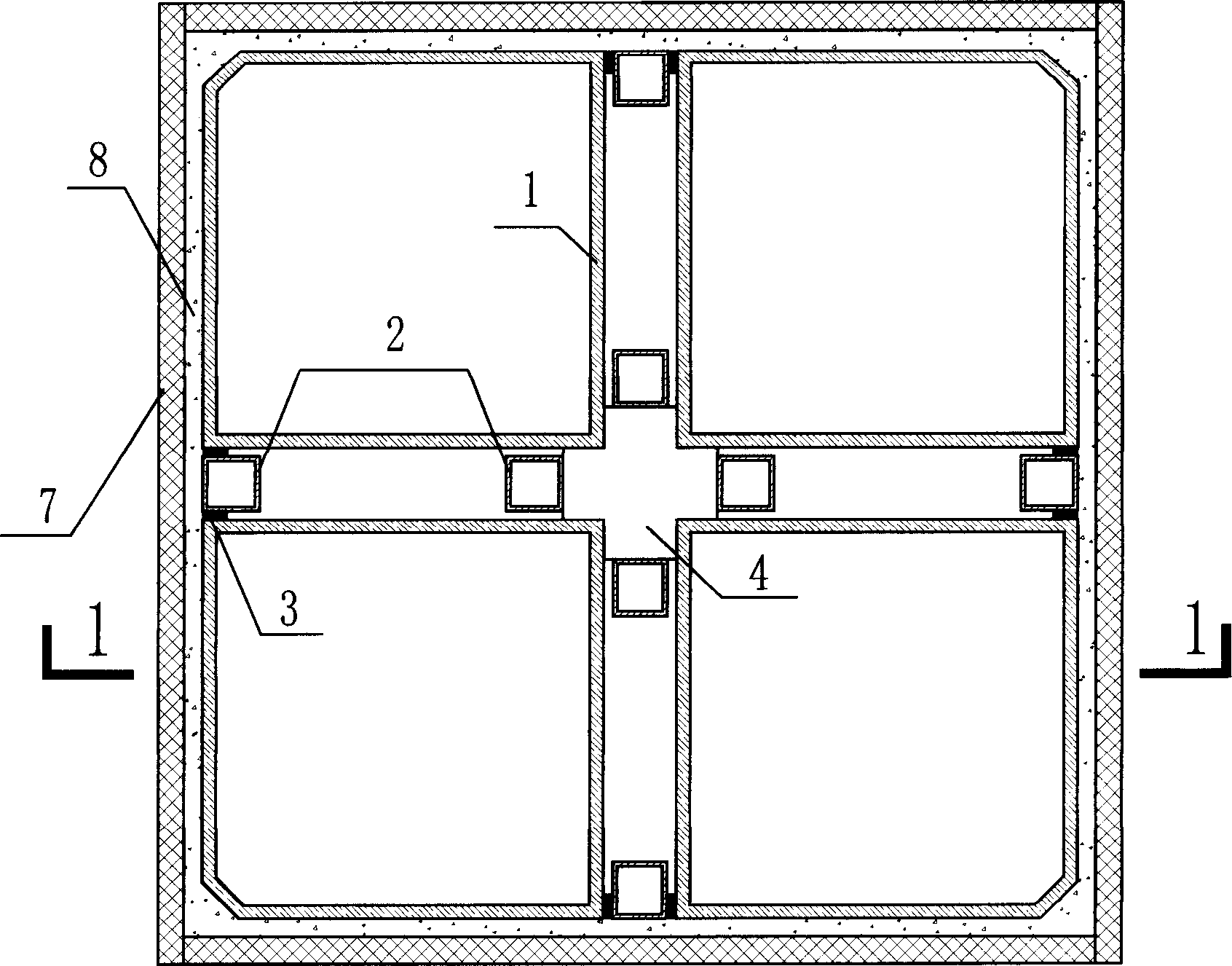

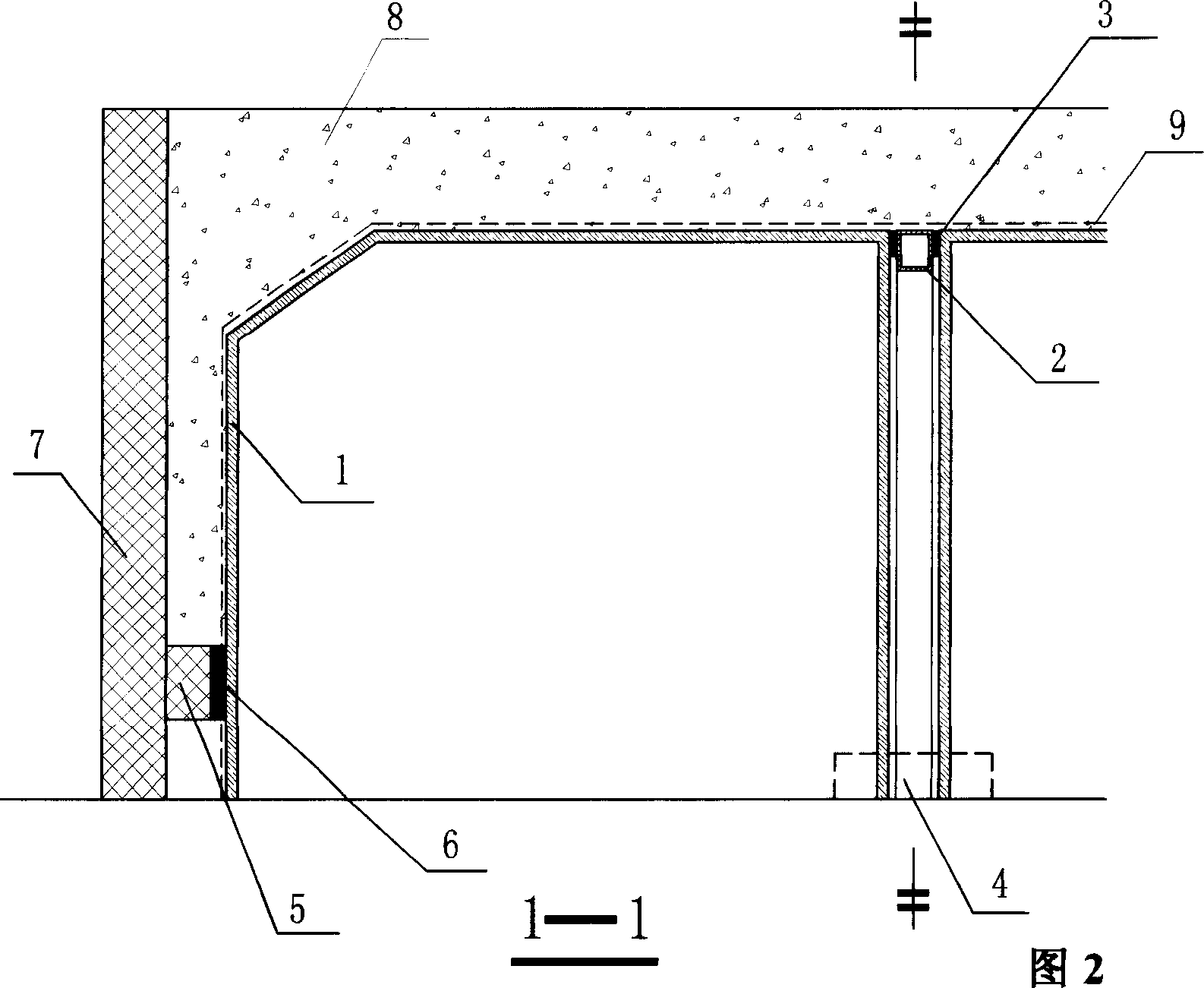

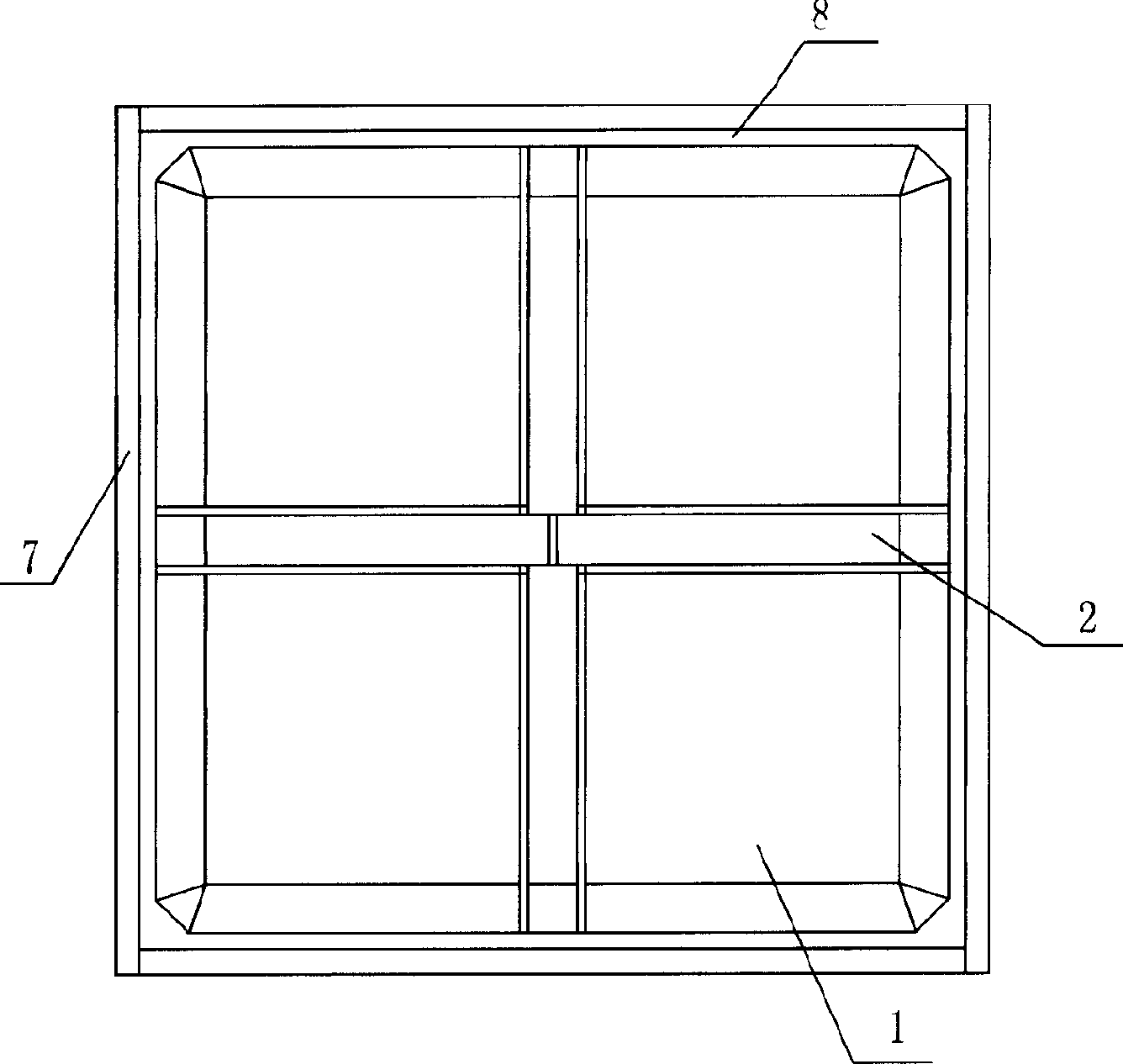

[0022] (1) Put all parts of the inner mold, the inner mold shell 1, the bracket 2, and the cross insert 4 in place, and put the inner lining 9 on it.

[0023] (2) Four mold pieces 7 are connected together on the periphery of the inner mold, and now the whole inner mold forms a whole by the extruding action of the elastic rubber strip on the outer mold piece, like this, the whole mold assembly has just been completed.

[0024] Note: Bolts, return pins for building steel formwork, or special connectors can be used to connect the four outer formwork pieces. The dimensional accuracy and geometric shape accuracy of the concrete box can be well controlled by the connections between the four outer formwork pieces.

[0025] (2) Concrete is poured in the mould, and cured to make it reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com