Push-out type ice cube tray structure and refrigerator with push-out type ice cube tray structure

An ice-making tray and ejecting technology, which is applied to ice-making, ice-making, household refrigerators, etc., can solve the problems of inconvenient way of flipping and taking ice, ice cubes flying out, ice-making tray damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

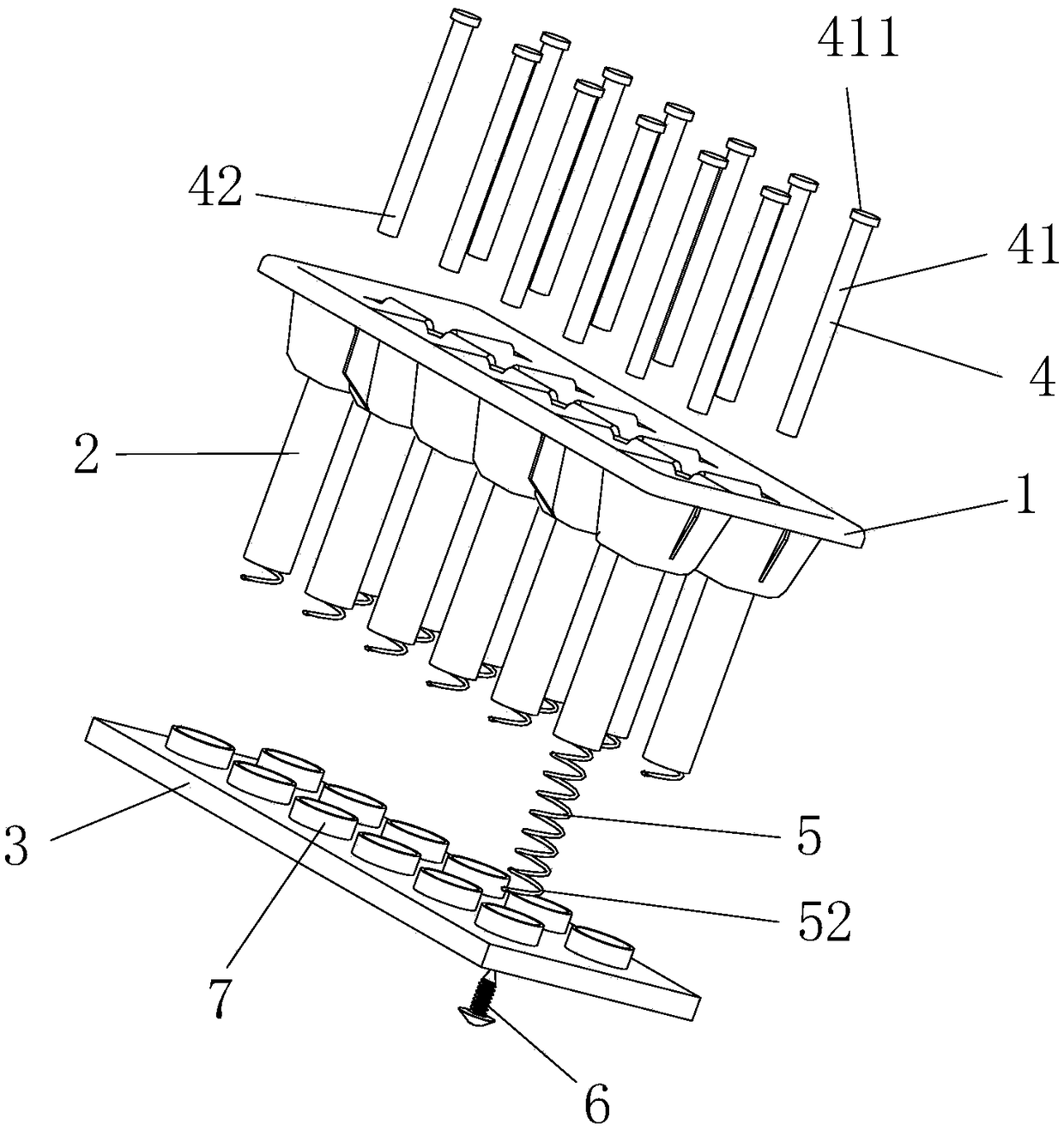

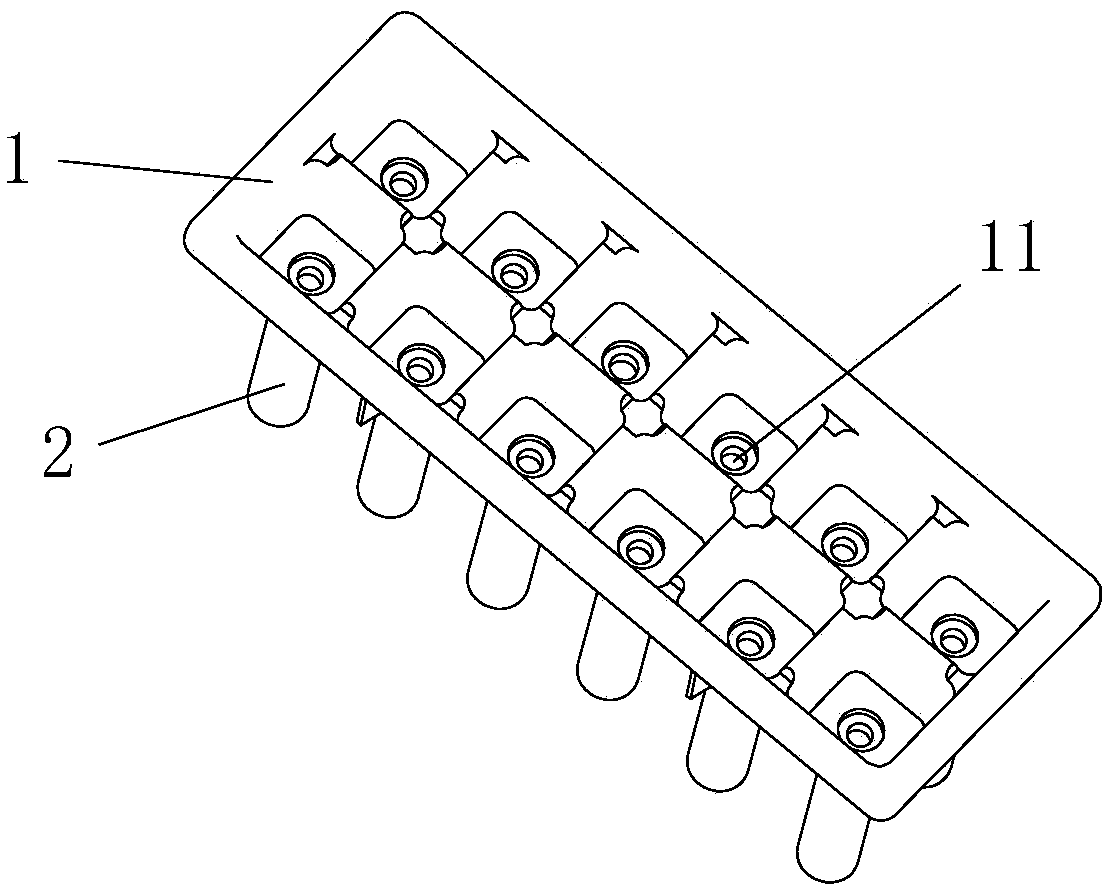

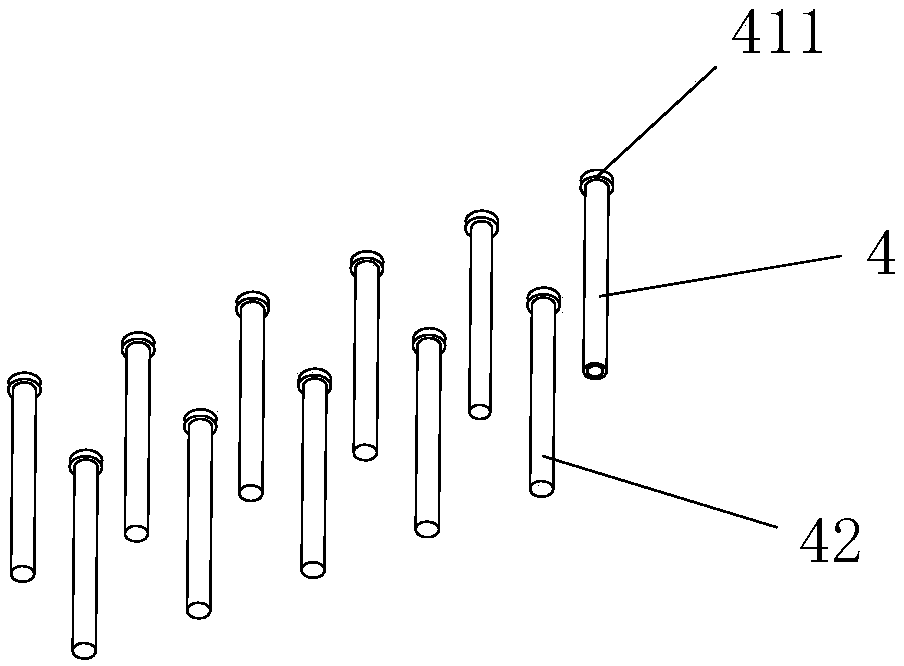

[0027] Such as Figure 1 to Figure 4 As shown, the figure schematically shows that the ejection ice-making tray structure includes an ice-making tray 1, a cylinder body 2, a bottom plate 3, an ejection member 4, and an elastic support member 5.

[0028] In the embodiment of the present application, a through hole 11 is configured on the bottom wall of the ice-making tray 1, and a cylindrical body 2 extending downward is configured on the edge of the through hole 11. It should be noted that the inner diameter of the through hole 11 is smaller than the inner diameter of the cylinder 2, so that the upper end of the cylinder 2 will be constructed with a shielding portion (constituted by the bottom wall of the ice tray 1), which is equivalent to The upper cover plate is arranged above the cylinder 2 and has a through hole.

[0029] The shape of the bottom plate 3 is not only limited to the rectangle shown in the figure, but can also be adjusted accordingly according to actual needs, su...

Embodiment 2

[0050] This embodiment is basically the same as Embodiment 1. For brevity of description, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1:

[0051] According to the second aspect of the present application, there is also provided a refrigerator (not shown in the figure), including a freezing chamber and a refrigerating chamber, and further including the above-mentioned top-out ice tray structure provided in the freezing chamber.

[0052] In summary, by forming a through hole 11 on the bottom wall of the ice making tray 1, the above-mentioned cylinder 2 is configured on the edge of the through hole 11, and by installing the ejection member 4 in the cylinder 2, At the same time, the upper end of the ejection member 4 is made to block the through hole 11 to prevent water leakage during ice making. The lower end of the ejection member 4 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com