Patents

Literature

33results about How to "Avoid flying out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

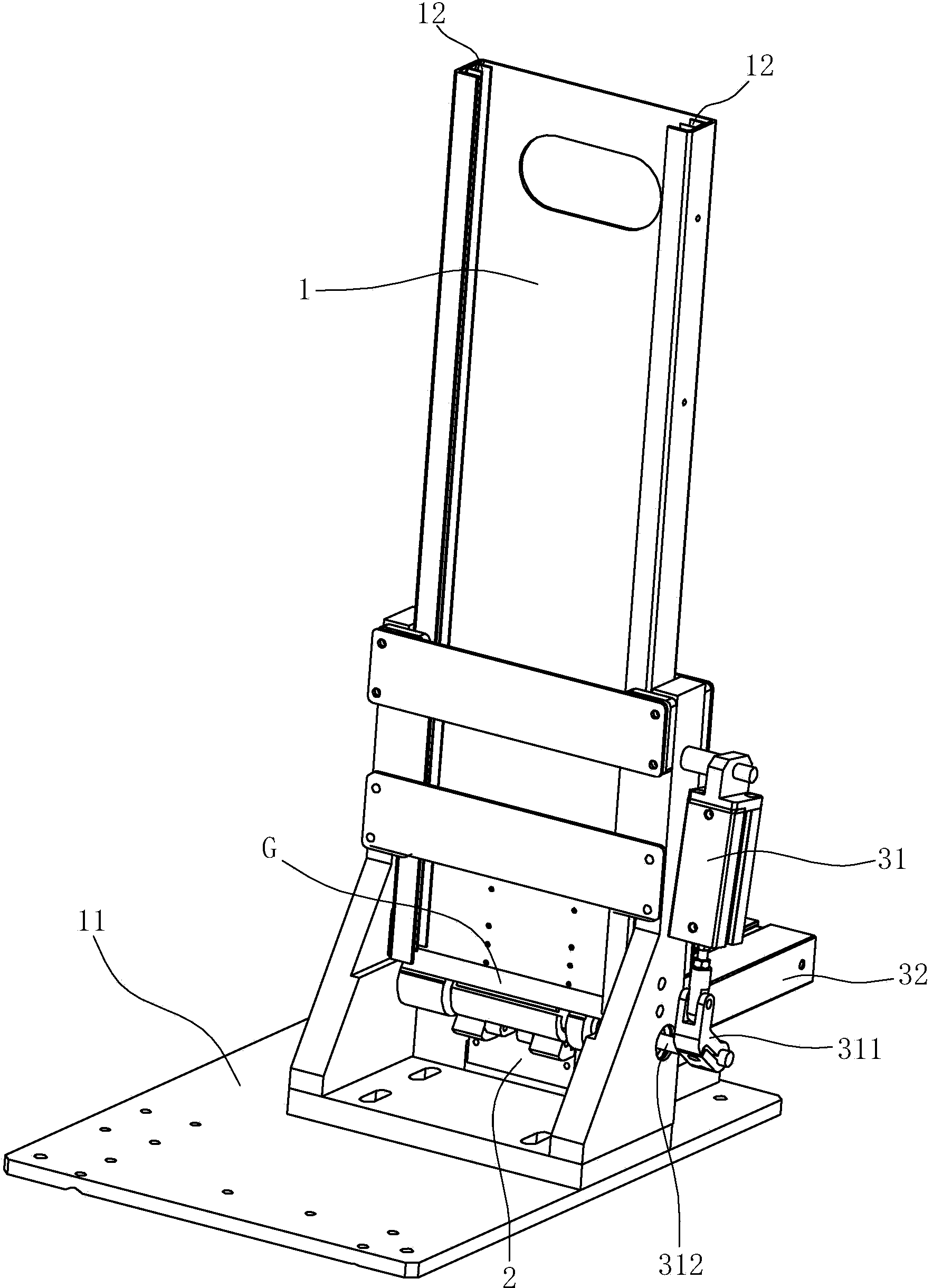

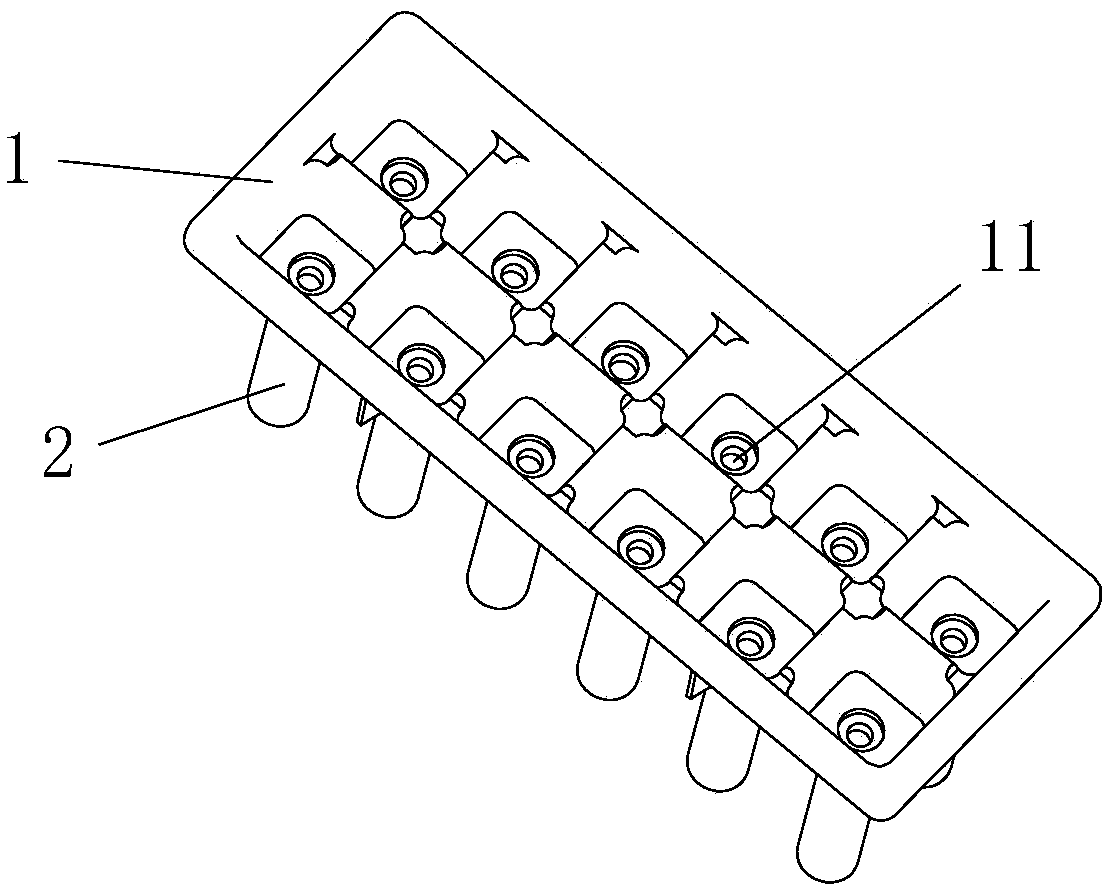

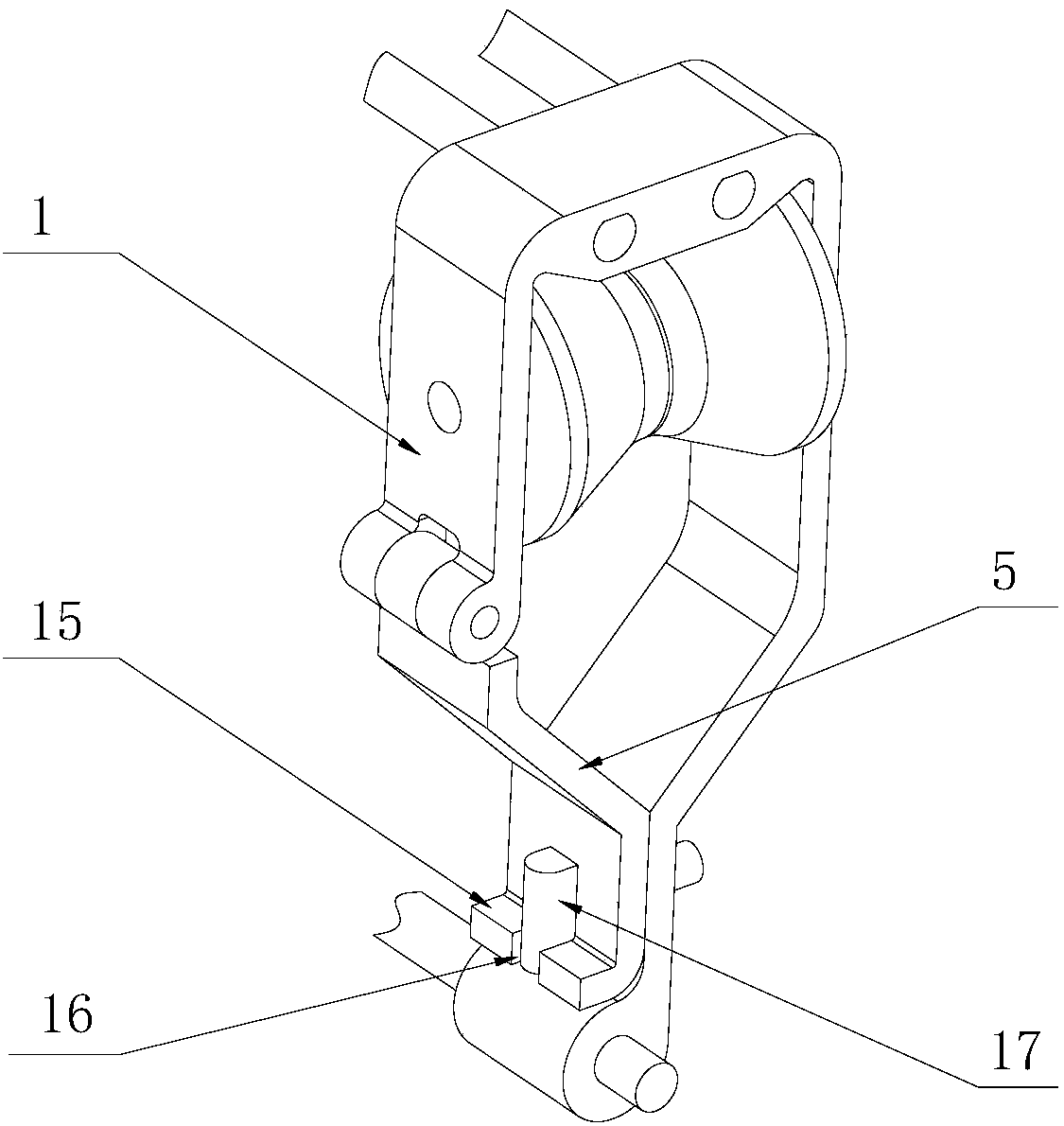

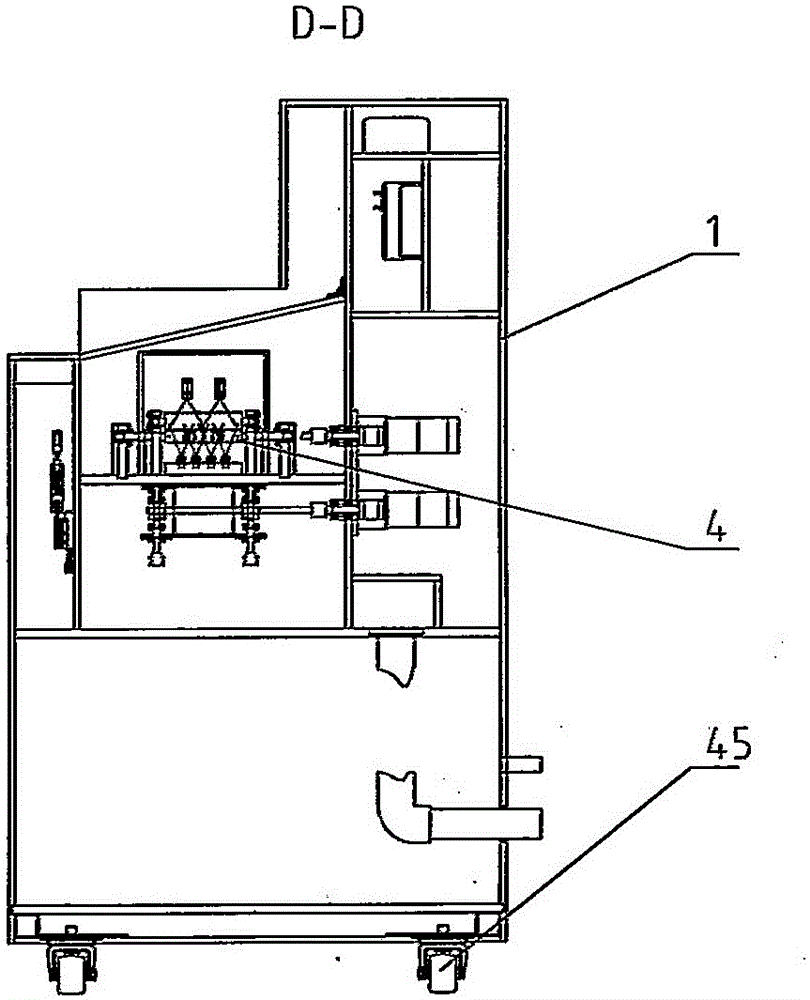

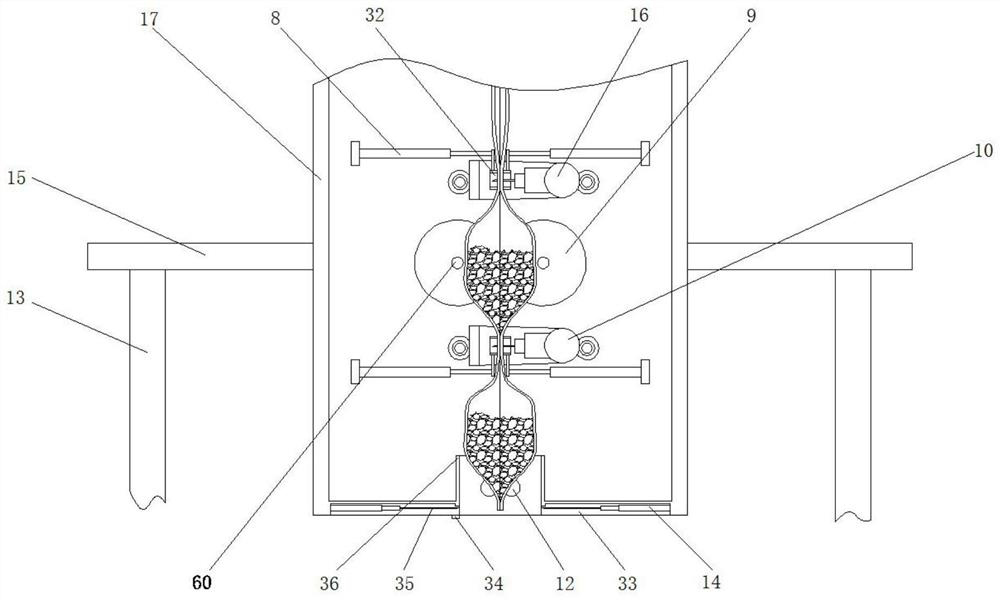

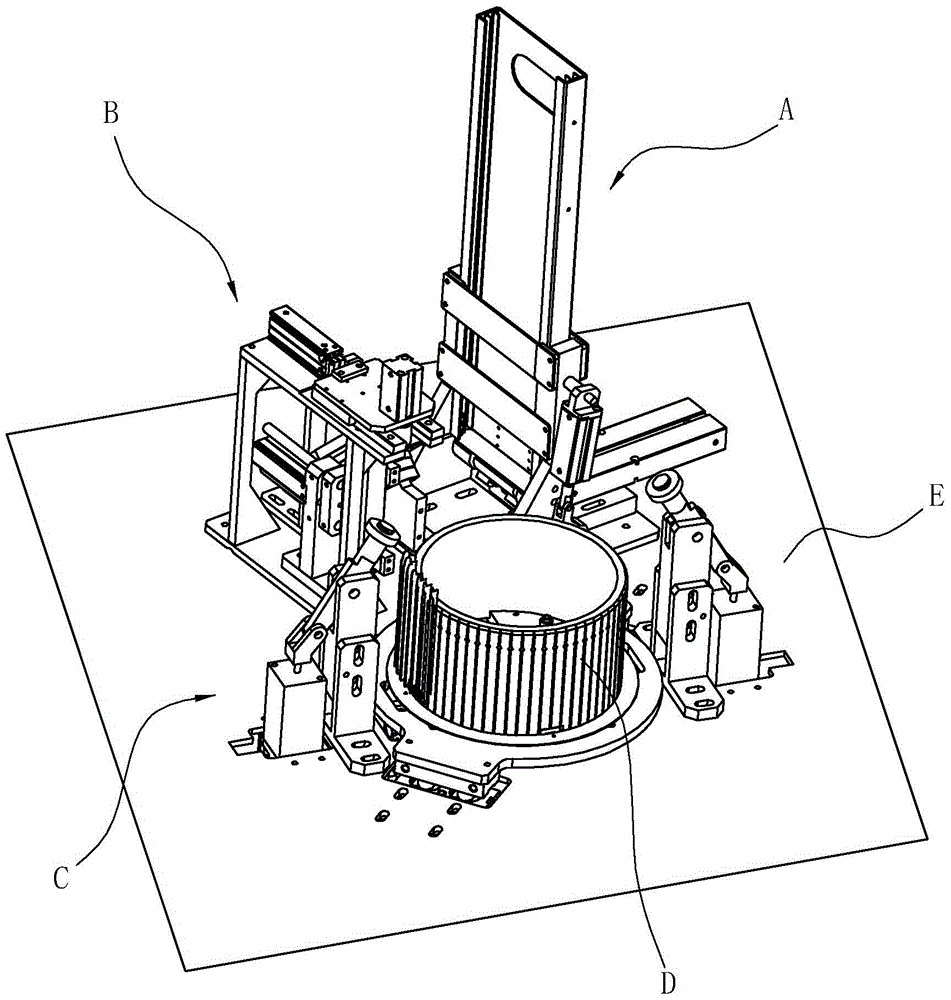

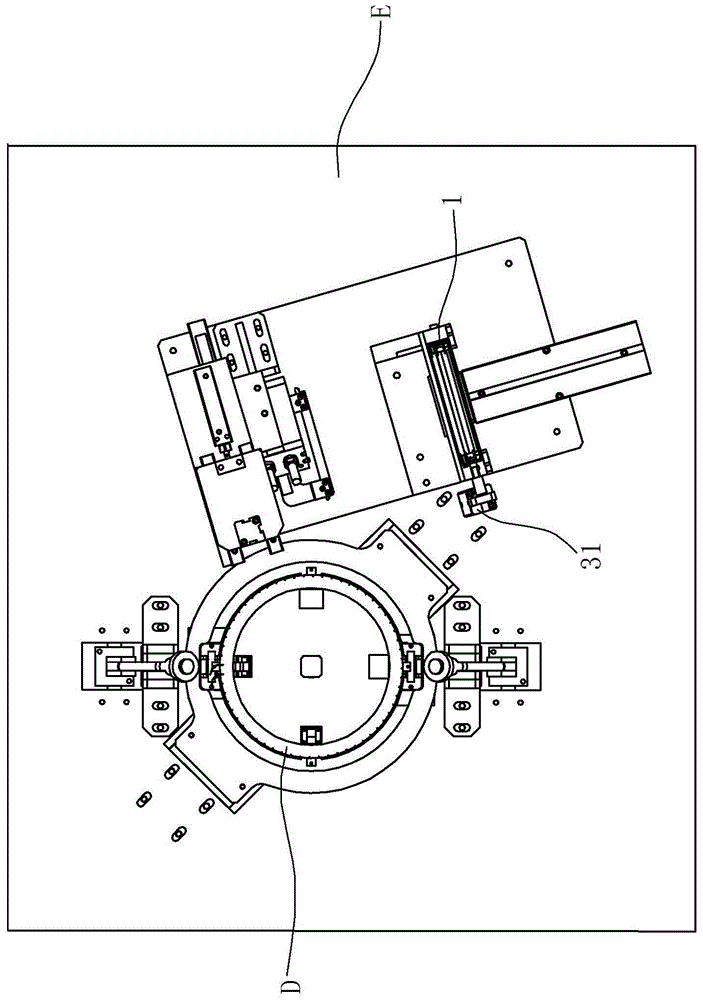

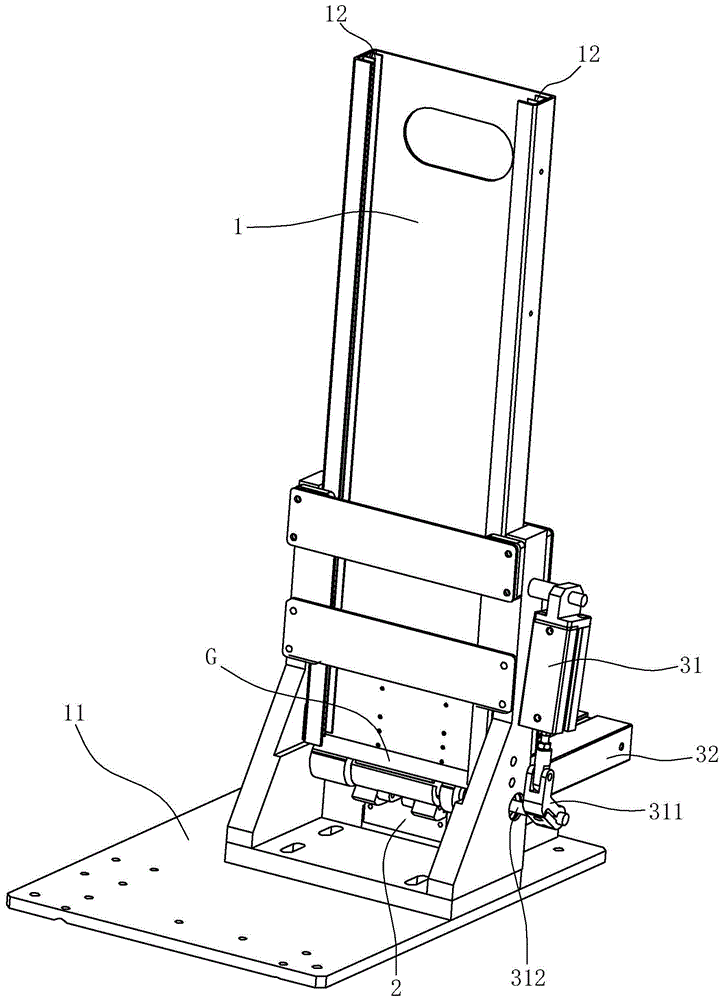

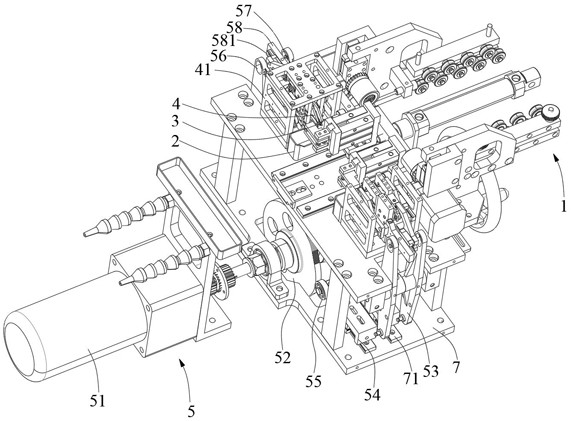

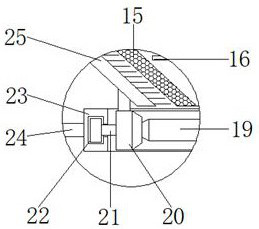

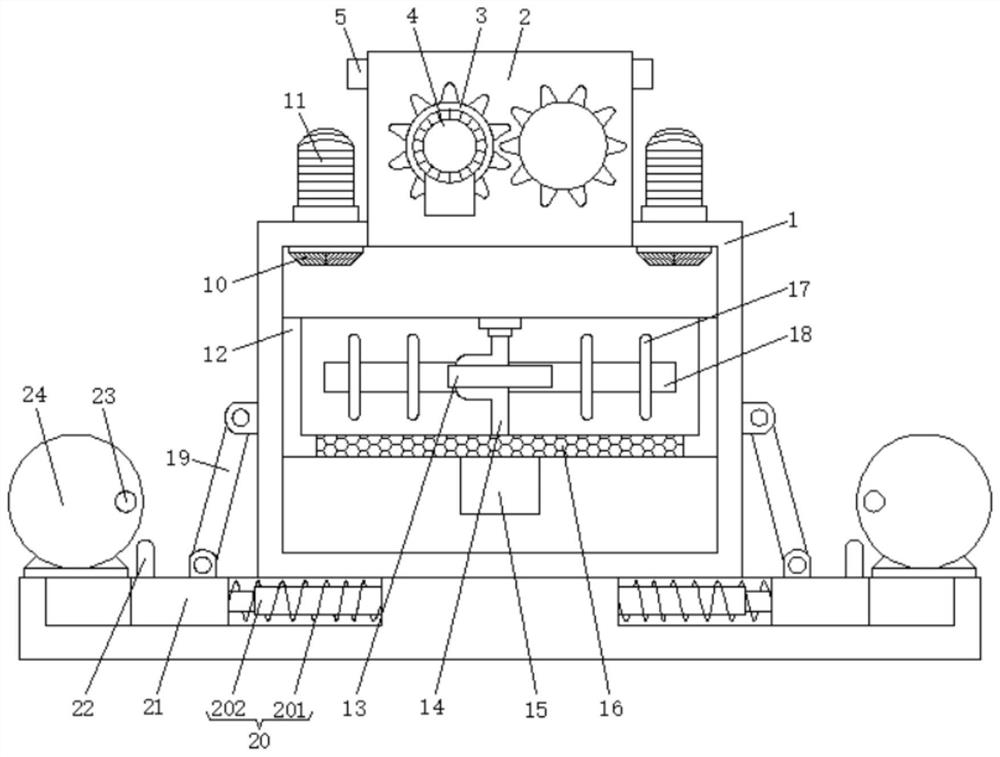

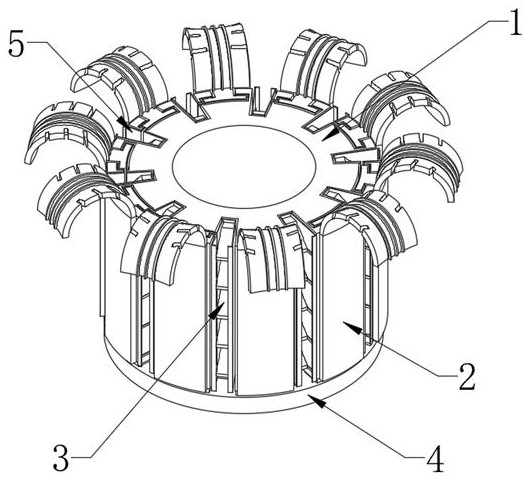

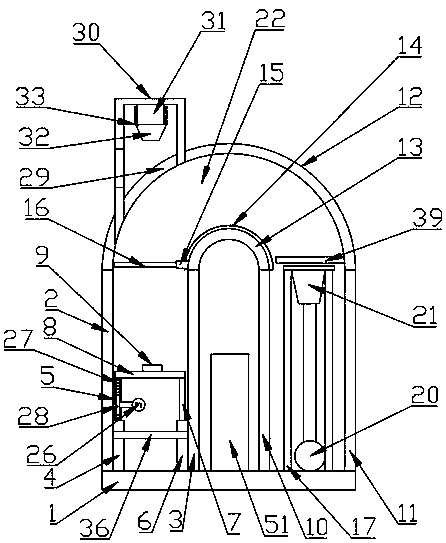

Feeding device of impeller insertion sheet

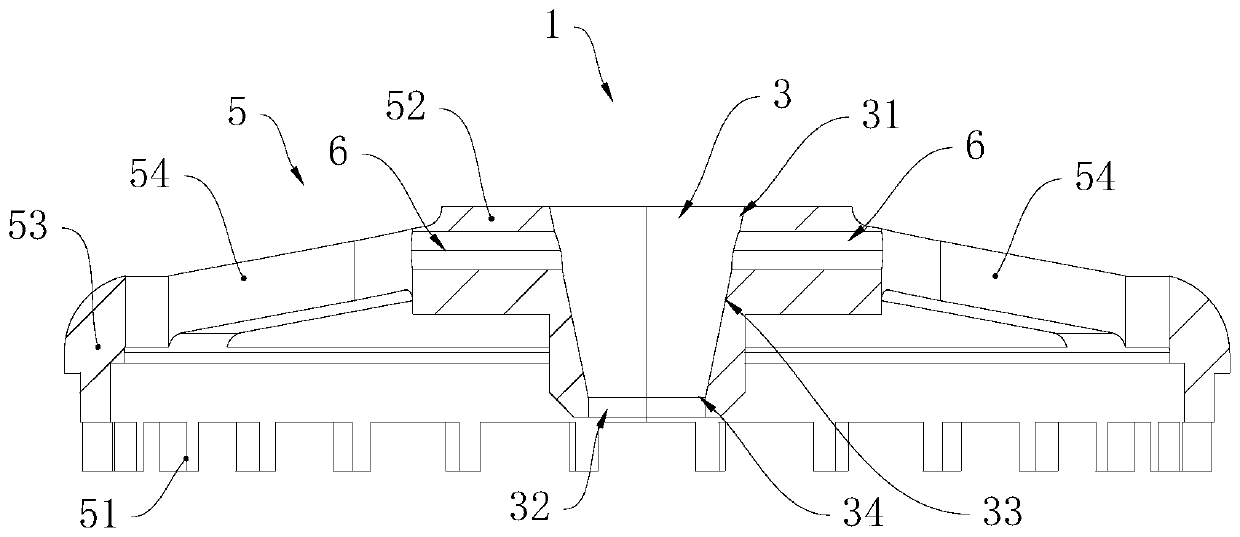

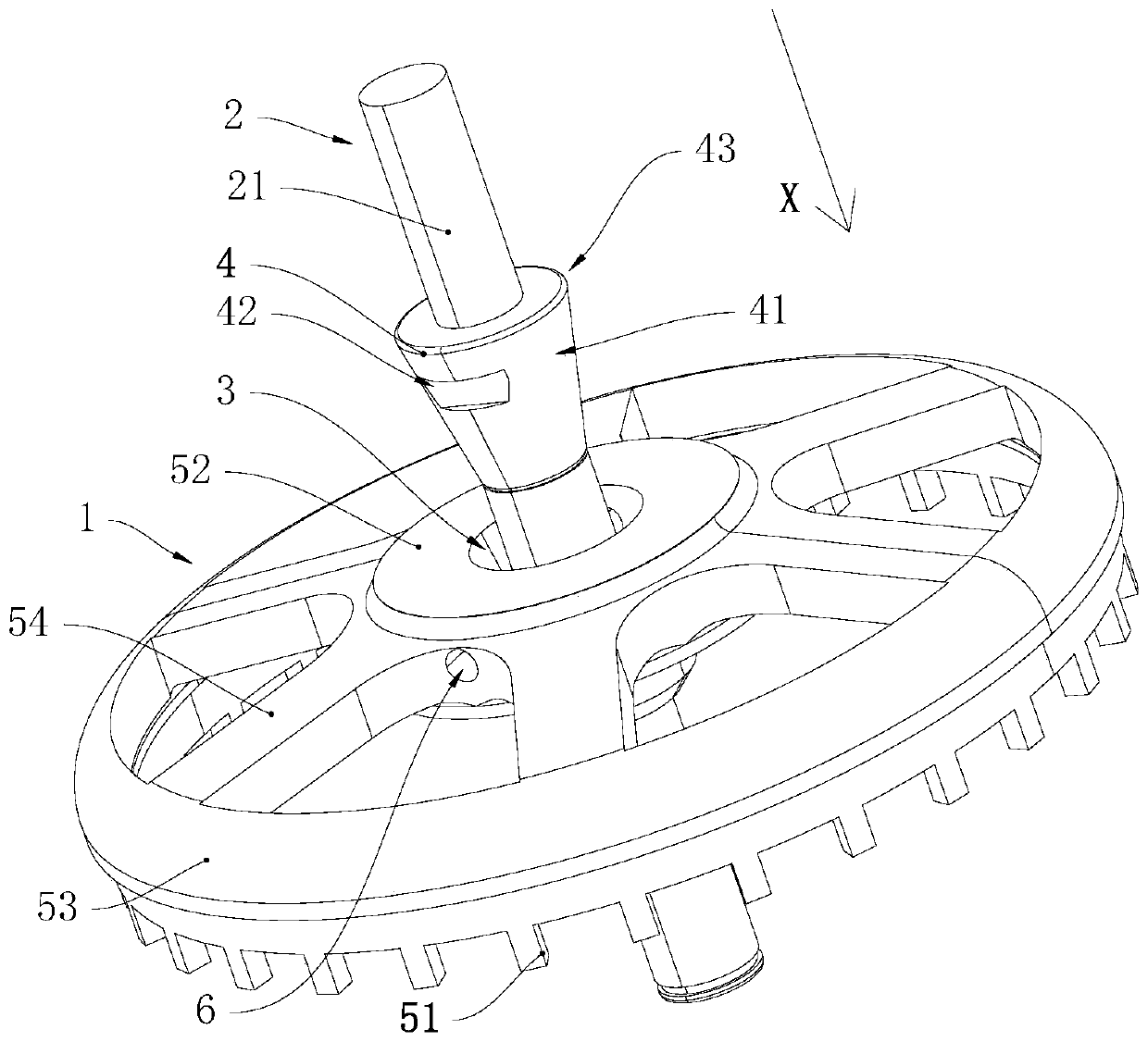

The invention discloses a feeding device of an impeller insertion sheet, which comprises a feeding hole and a discharge hole. The feeding device of the impeller insertion sheet is characterized by further comprising a material box and a first drive mechanism capable of driving an impeller to pull away from the material box, wherein the first drive mechanism comprises a first cylinder, a connecting rod, a rotating shaft, a second cylinder and a push block; the two ends of the connecting rod are respectively connected with a piston rod of the first cylinder and one end of the rotating shaft; the piston of the first cylinder is movably hinged to one end of the connecting rod; one end of the rotating shaft is fixedly connected with the other end of the connecting rod; the rotating shaft is arranged on the lower part of the discharge hole of the material box; the rotating shaft includes a circular arc surface adaptive to the profile of the impeller; the push block is located below the rotating shaft and includes a arc surface guide platform adaptive to the profile of the impeller; the piston rod of the second cylinder is connected with the push block. The feeding device of the impeller insertion sheet has the advantages of guaranteeing that one impeller can be taken out per each time as a rotary impeller taking mode is adopted, the impeller material taking precision is improved, automatic conveying of the impeller is realized, the automatic operation degree is improved, and the stability and reliability of the impeller in the material feeding process are guaranteed.

Owner:嘉兴市朗盛机械有限公司

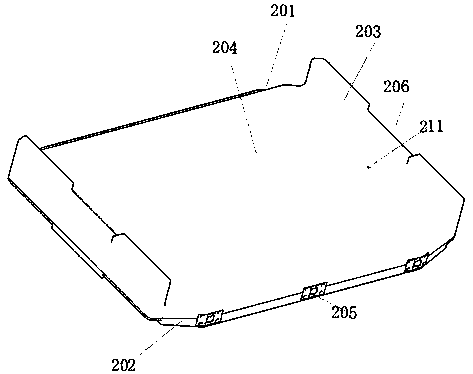

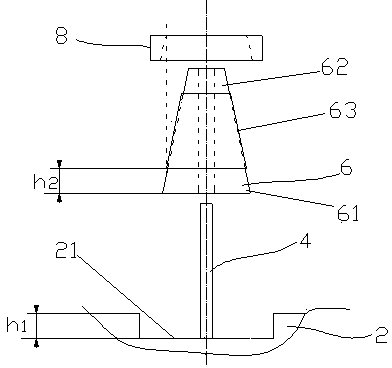

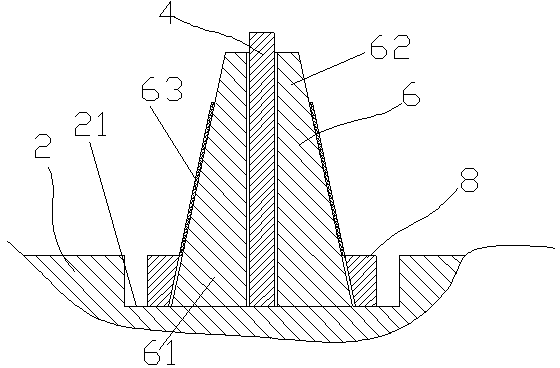

Push-out type ice cube tray structure and refrigerator with push-out type ice cube tray structure

InactiveCN108981253AStable supportEscape smoothlyLighting and heating apparatusIce productionMarine engineeringRefrigerated temperature

The invention relates to the technical field of household appliance manufacturing and discloses a push-out type ice cube tray structure and a refrigerator with the push-out type ice cube tray structure. The push-out type ice cube tray structure comprises an ice cube tray, a base plate, a push-out part and an elastic support part, wherein a through hole is formed on a bottom wall of the ice cube tray; a barrel which extends downward is constructed on an edge of the through hole; the push-out part is arranged in the barrel; the through hole is plugged by the upper end of the push-out part; the lower end of the push-out part is fixedly connected with the base plate; the elastic support part is arranged between the barrel and the push-out part and is used for keeping the lower end of the barrel under a free suspending state; a first end of the elastic support part is resisted against the bottom wall of the ice cube tray; a second end of the elastic support part is resisted against the baseplate. The push-out type ice cube tray structure has the advantage that ice can be conveniently and quickly taken off.

Owner:HUBEI MIDEA REFRIGERATOR CO LTD

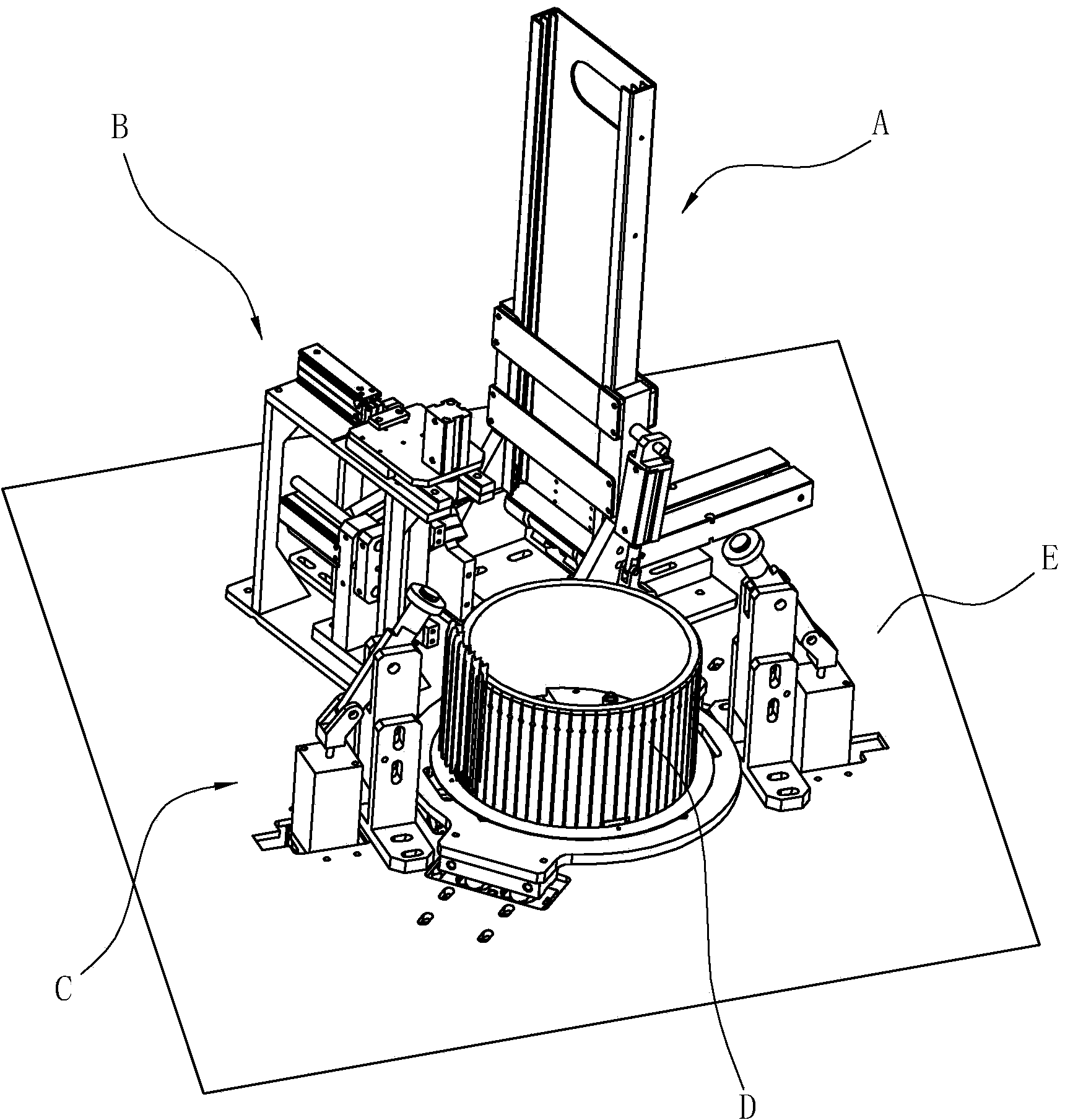

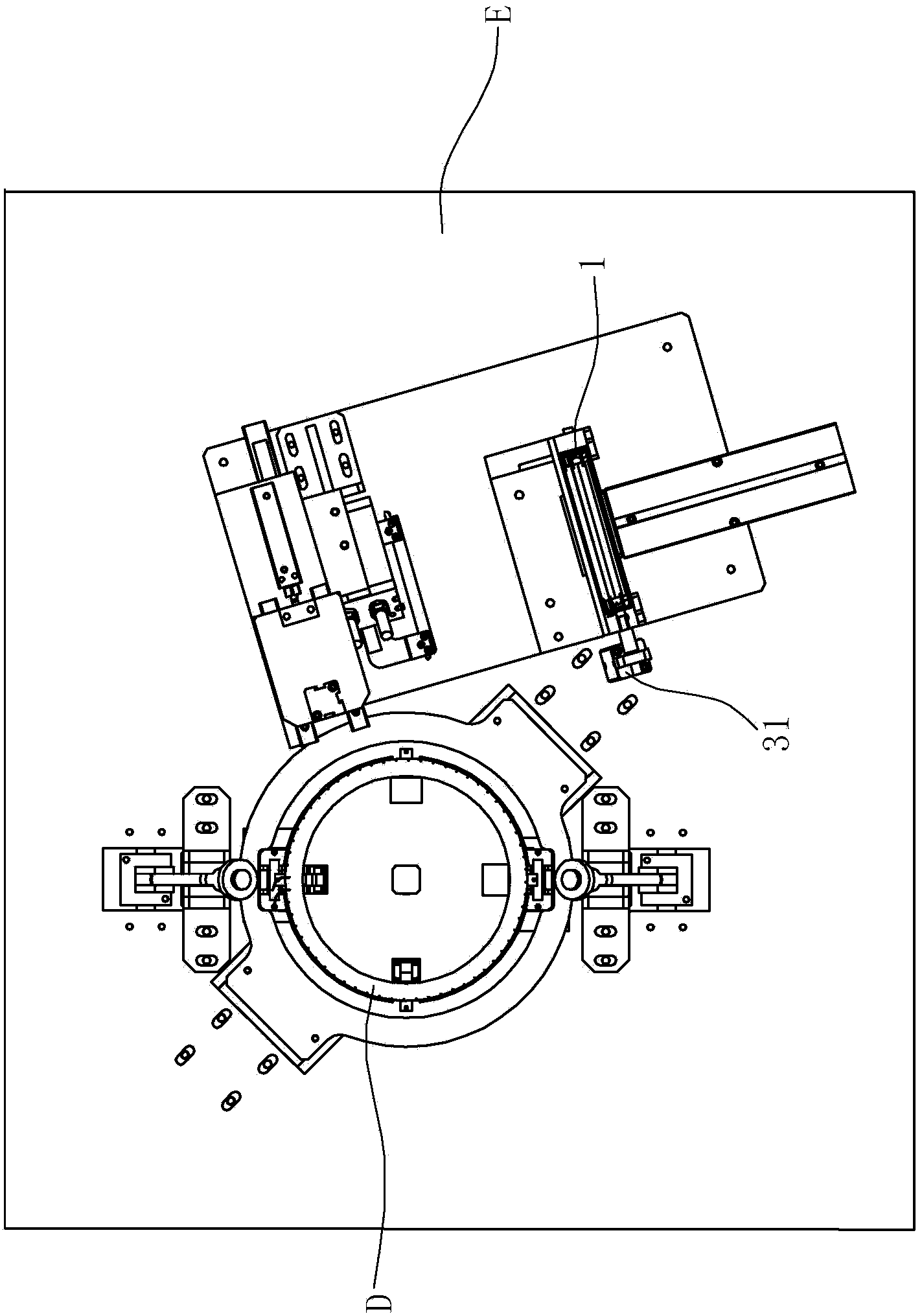

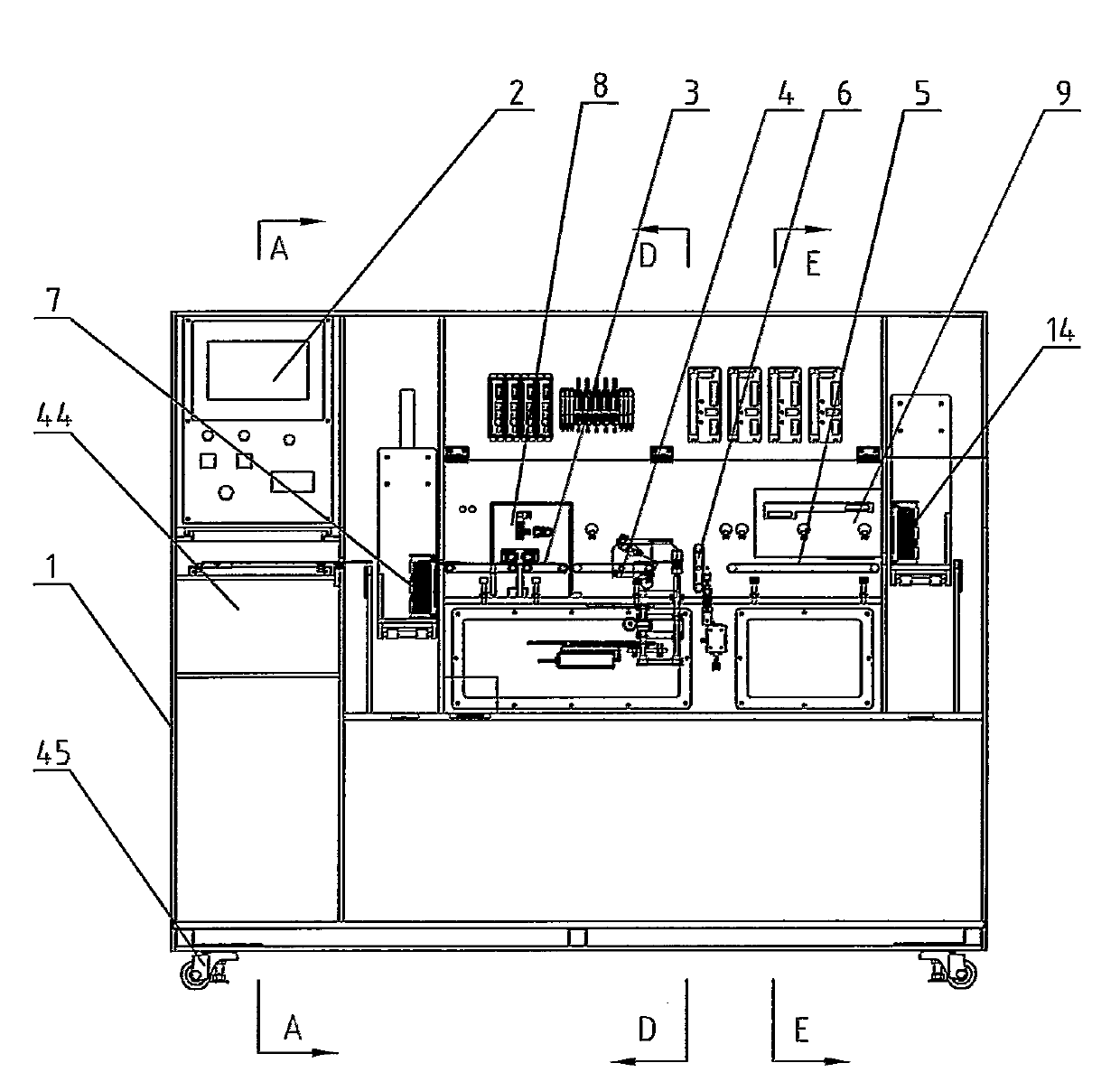

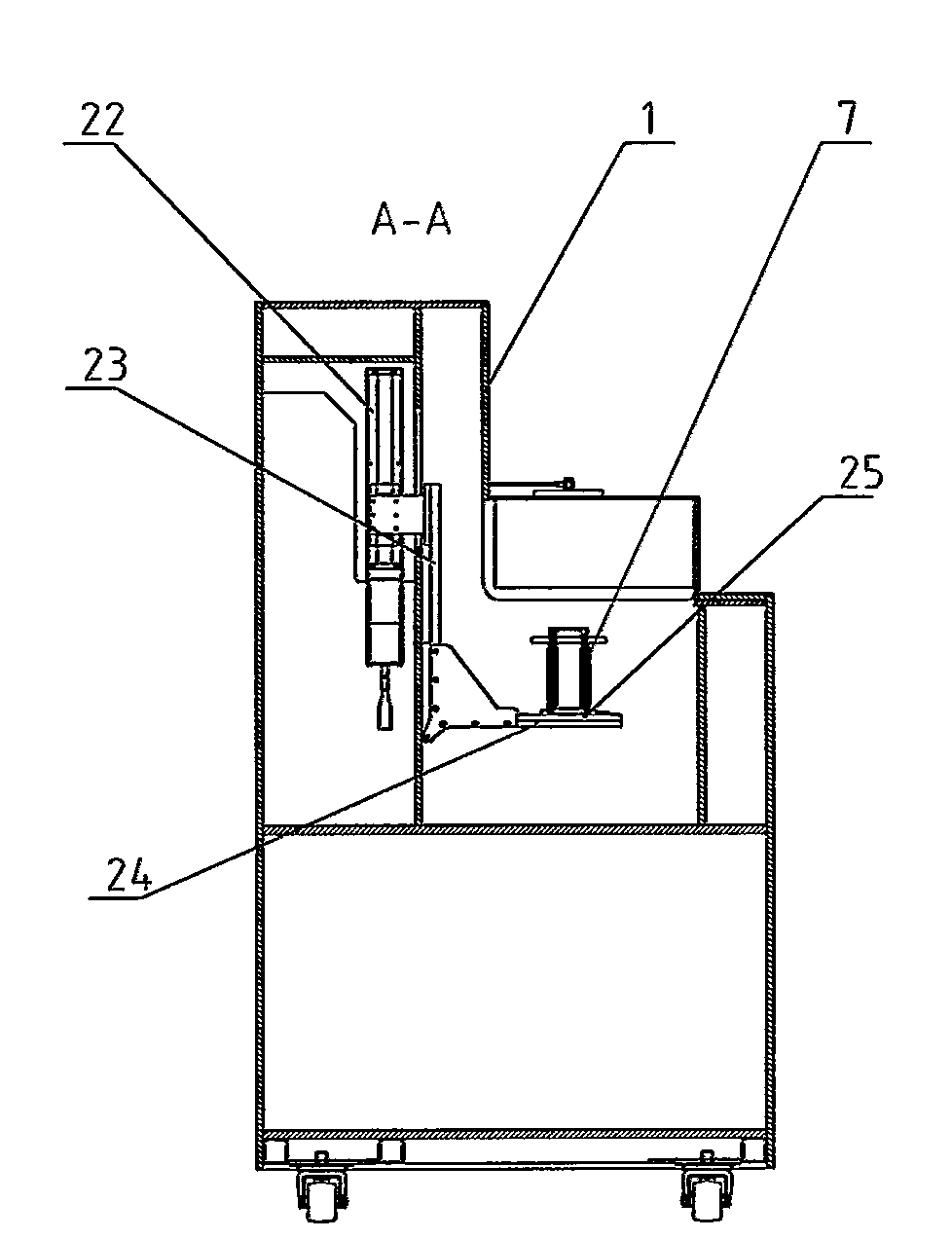

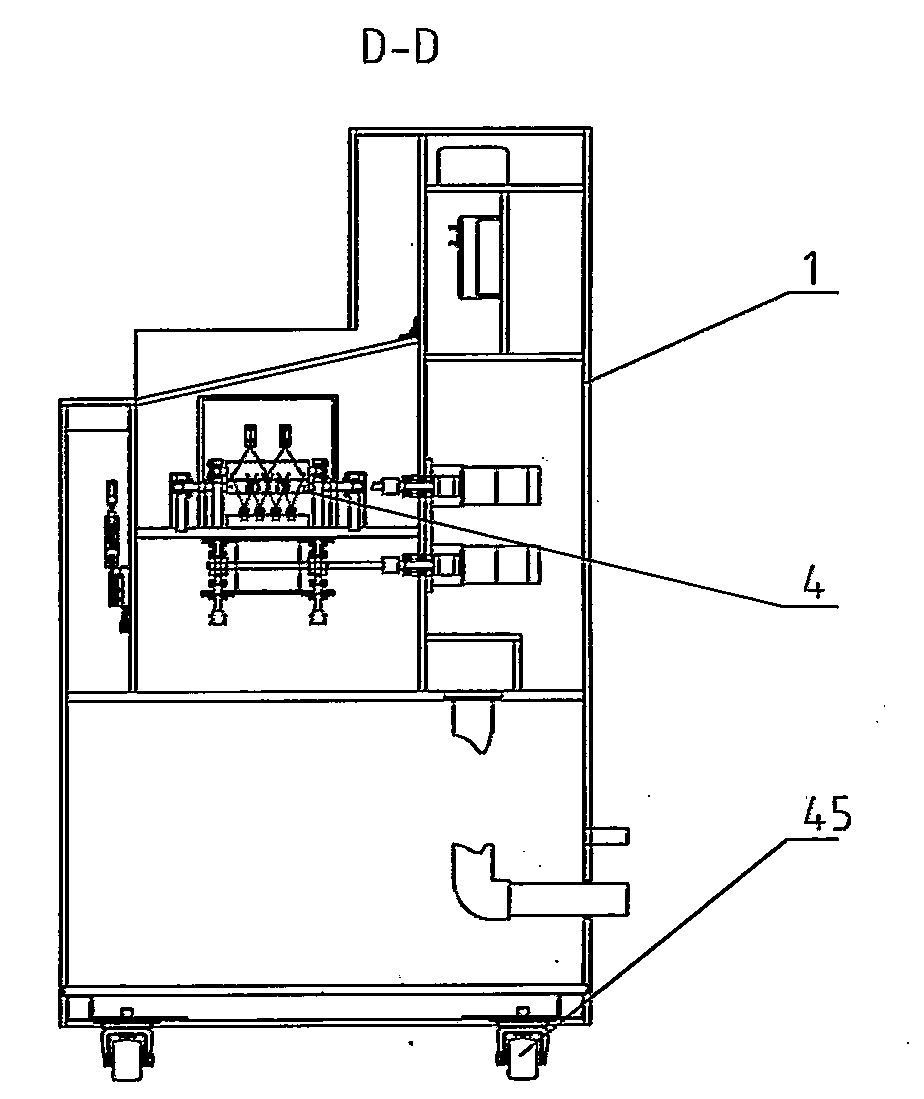

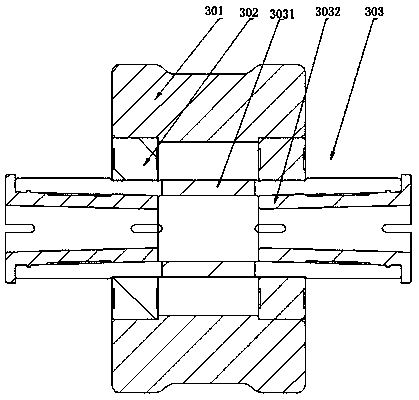

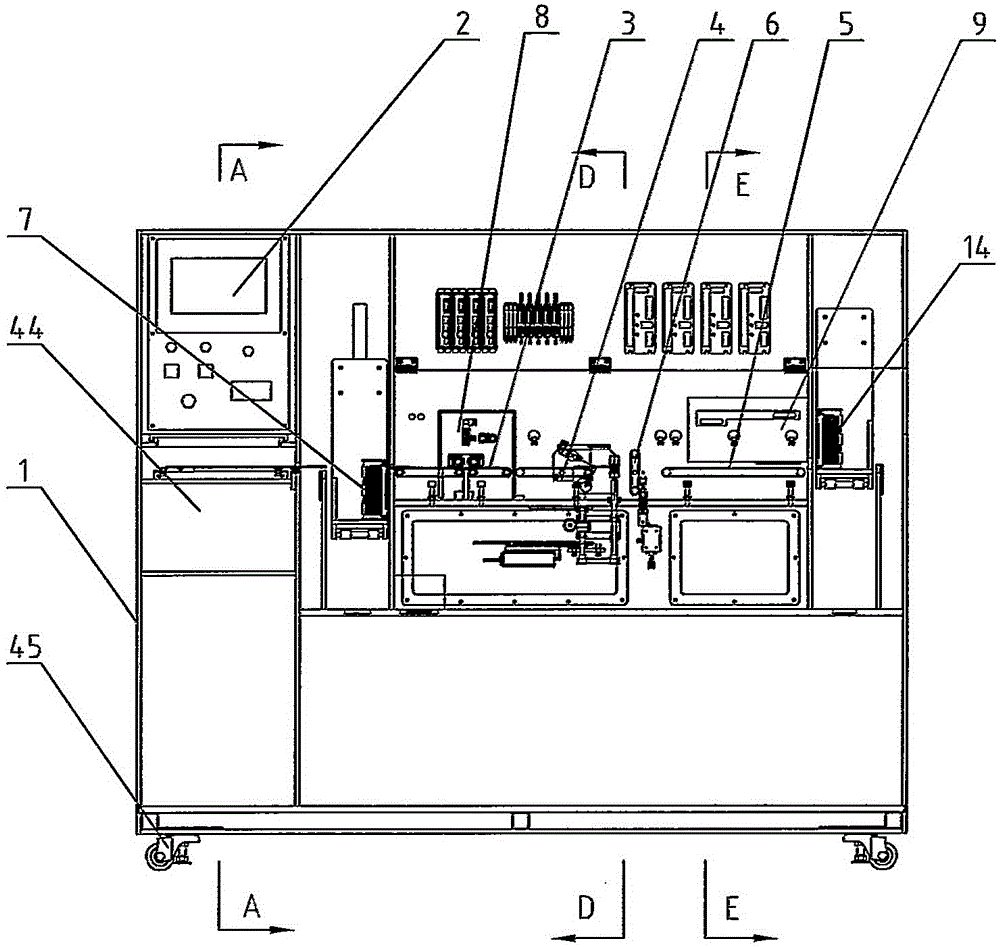

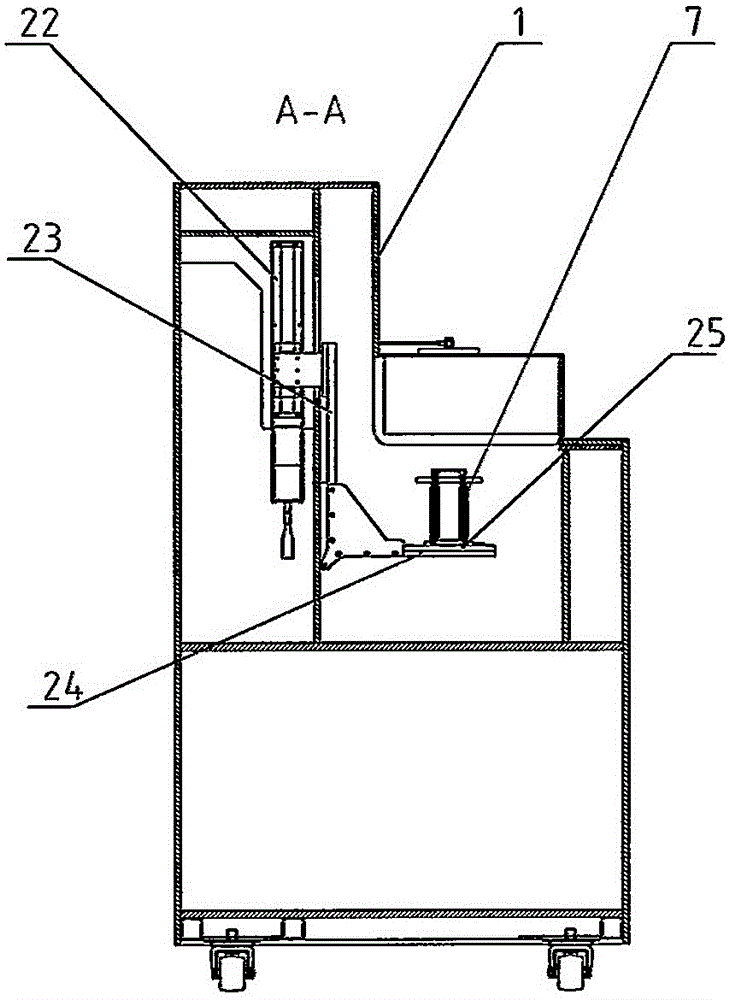

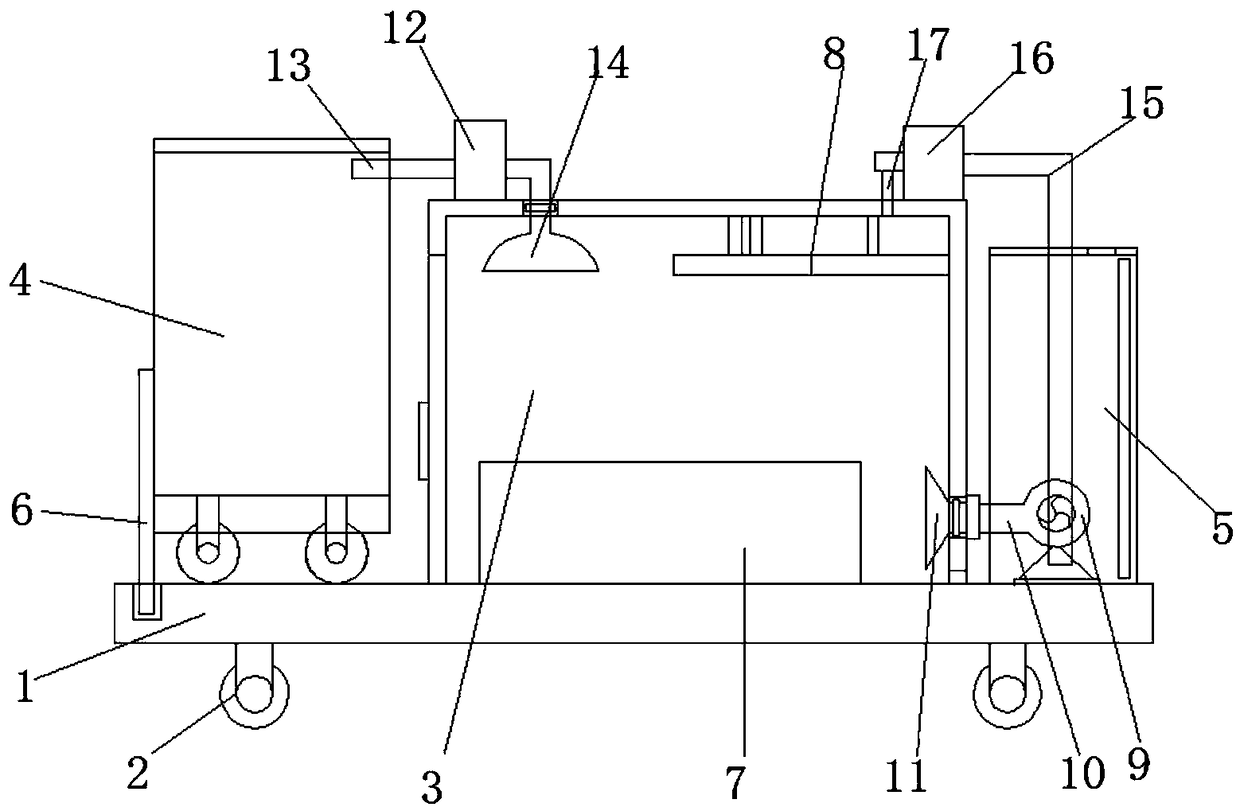

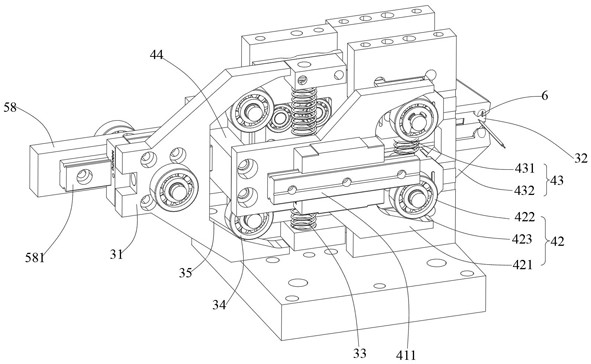

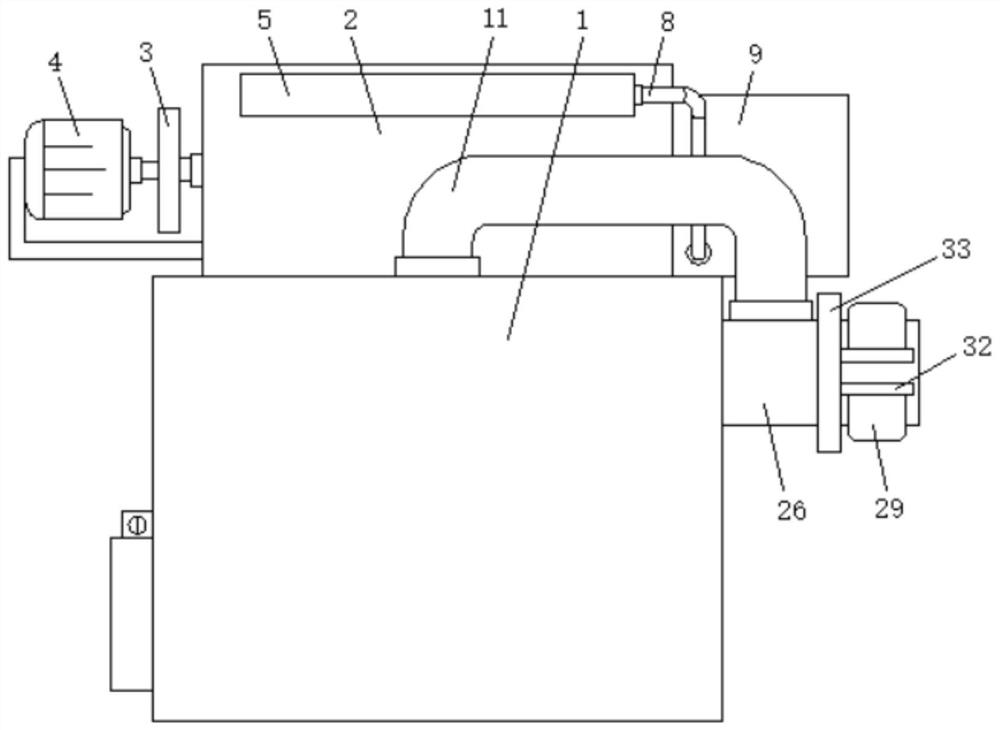

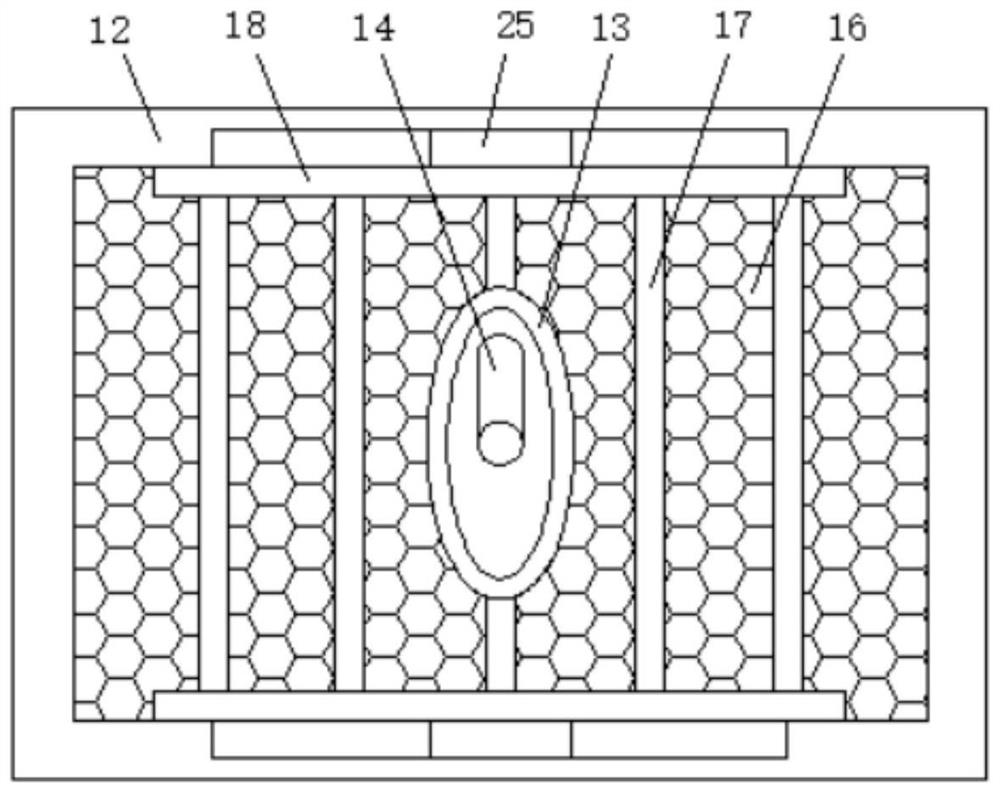

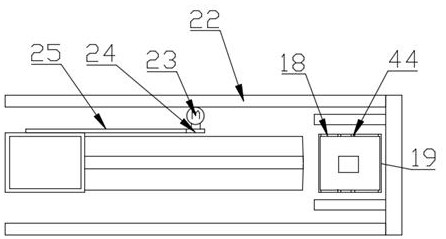

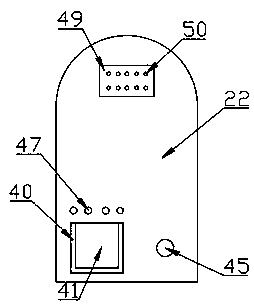

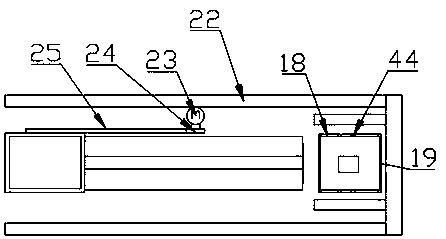

Two-sided scrubbing unit for wafers

ActiveCN103008301AAchieve all-round scrubbingImprove scrubbing effectCleaning using toolsCleaning using liquidsMechanical engineeringSmall particles

A two-sided scrubbing unit for wafers is provided with a two-sided scrubbing device located at the tail end of a two-sided scrubbing section conveying mechanism. The two-sided scrubbing device comprises a scrubbing support, two brushes capable spraying liquid from inside, two scrubbing shaft components which synchronously rotate, and a driving component driving the scrubbing shaft components to rotate. The scrubbing shaft components are rotatably borne on the scrubbing support which is mounted on a frame, and the two brushes are sleeved on the corresponding scrubbing shaft components respectively and are located on two sides of a wafer to be detected respectively. The two-sided scrubbing unit further comprises a wafer rotation driving device for driving the wafer located in the two-sided scrubbing device to rotate, an unloading device, and a discharge device for pushing the wafer on the scrubbing section conveying mechanism to a discharge wafer box. The two-sided scrubbing unit for wafers is high in automation, the front and reverse sides of the wafer are scrubbed simultaneously, scrubbing is effectively, removing small particles smaller than 0.3 micrometers in diameter is evidently effective, the problem that other devices fail to clean is solved, the high requirement for cleanness of the surface of the wafer is guaranteed effectively, and the high requirement that number of particles which are 0.3 micrometers in diameter and have surface cleanness of the 2-inch wafer is not more than 30 is met.

Owner:常州科沛达清洗技术股份有限公司

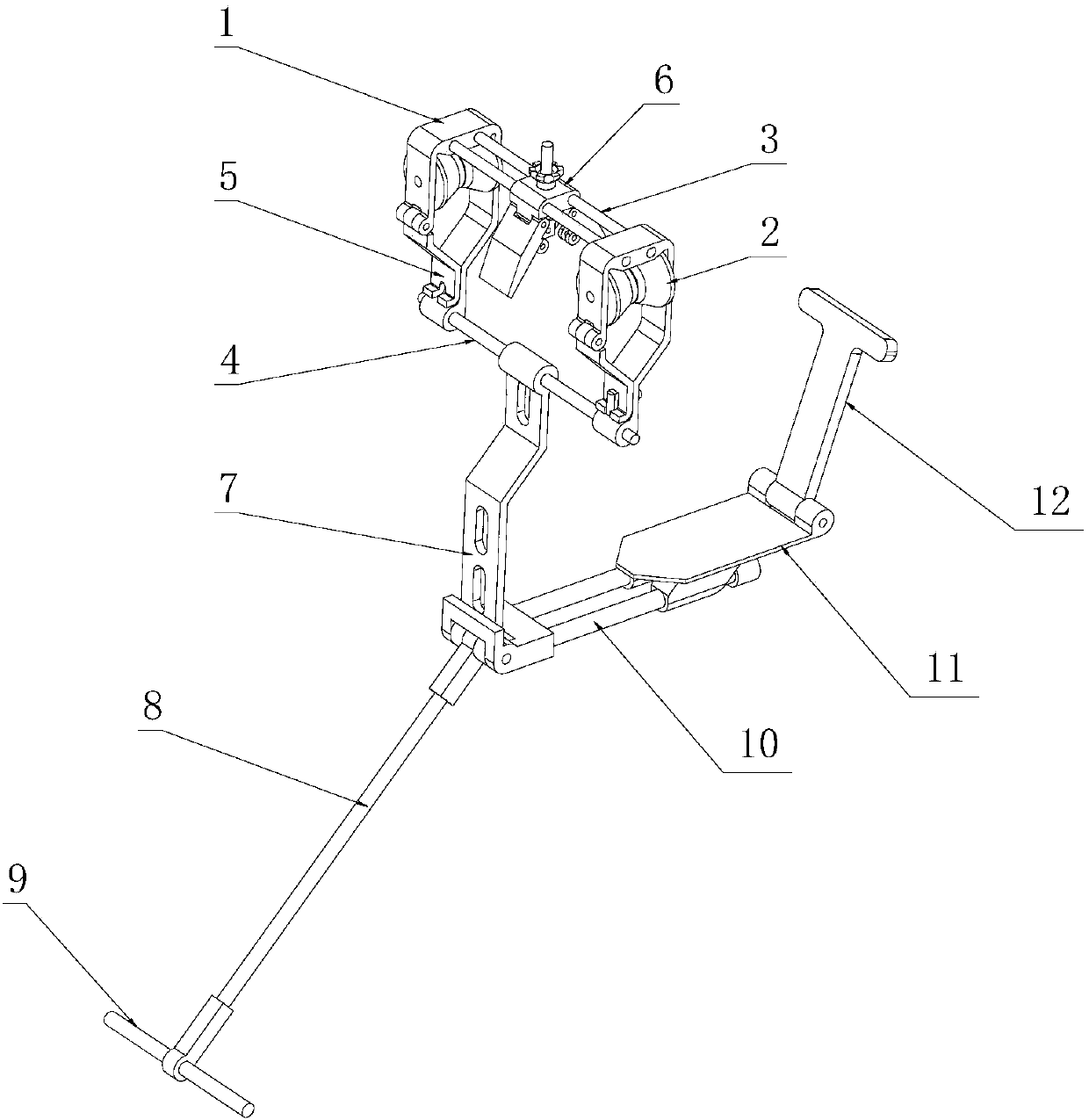

Steep-slope differential self-locking ground wire flying car

ActiveCN107919634AAvoid flying outEnsure personal safetyApparatus for overhead lines/cablesStructural engineeringMechanical engineering

The invention discloses a steep-slope differential self-locking ground wire flying car, which comprises wheel seat frames, V-shaped groove road wheels, an upper connecting rod, a lower connecting rod,safety buckles, a differential brake, a seat linkage plate, a pedal connecting rod, a pedal rod, a telescopic seat frame, a seat and a folding seat backrest, wherein the wheel seat frames, the road wheels and the safety buckles are symmetrically distributed at two ends of the upper connecting rod and the lower connecting rod; the differential brake is arranged on the upper connecting rod; the upper end of the seat linkage plate is hinged with the middle of the lower connecting rod and the lower end is coaxially hinged with the upper end of the pedal connecting rod and a fixed end of the telescopic seat frame; the pedal rod is fixed at the lower end of the pedal connecting rod; the seat is arranged at a movable end of the telescopic seat frame; and the folding seat backrest is arranged onthe seat. According to the ground wire flying car, the speed is effectively controlled through the differential brake to form differential protection; the condition that operating personnel fly out due to the fact that a pulling rope is suddenly pulled off is avoided to ensure the personal safety of the operating personnel; and the steep-slope differential self-locking ground wire flying car conforms to the ergonomic structure to improve the work efficiency of the operating personnel.

Owner:GUANGZHOU BUREAU CSG EHV POWER TRANSMISSION

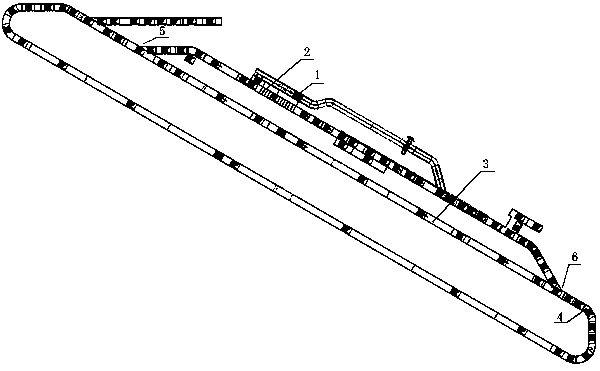

Airport luggage high-speed conveying and sorting system

ActiveCN109160251AImprove stabilityEnsure safetyConveyor partsMechanical conveyorsLogistics managementEngineering

The invention belongs to the civil aviation logistics application field, and particularly relates to an airport luggage high-speed conveying and sorting system. The system comprises a track part, a dynamic sorting device and a luggage high-speed conveying tray; the luggage high-speed conveying tray is used for conveying the luggage on the track part, and the dynamic sorting device is used for carrying out high-speed sorting on the luggage; the track part comprises a straight track, a turning conveyor, at least one section of rapid shunting conveying device and at least one section of rapid confluence conveying device; and a supporting wheel device capable of realizing rapid dismounting and mounting is arranged on the track part. According to the system, high-speed conveying and sorting ofthe airport luggage can be realized; and the whole system is rearranged, a conveying part and a luggage sorting part in the system are mainly improved, so that the speed of conveying the luggage of the whole system can be up to 10 m / s, the stability of the luggage sorting part in the system during tipping is improved, so that the safety and stability when the luggage is conveyed and tipped can beguaranteed on the premise that the system guarantees that the luggage can be conveyed at a high speed.

Owner:CIVIL AVIATION LOGISTICS TECH

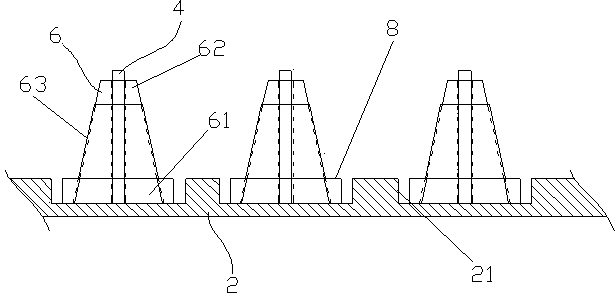

Stable yarn frame for spinning

The invention relates to a stable yarn frame for spinning. The stable yarn frame comprises a tabular base and a plurality of yarn uprights. The sequentially arrayed yarn uprights are vertically arranged on the base and are used for sleeving yarn bobbins. Each yarn bobbin is in the shape of a circular truncated cone with big end down. The bottom of each yarn bobbin has a bare portion with a certain height. The stable yarn frame is characterized in that grooves are formed in positions, corresponding to the yarn uprights, of the base; the uprights are arranged in the corresponding grooves of the base; the diameter of each cylindrical groove is larger than the outer diameter of the bottom of each yarn bobbin. Through the grooves, good limiting and protecting effects to the yarn bobbins jumping in a certain height range during rotating are achieved, and the situation that the yarn bobbins fly from the yarn uprights directly due to high-speed rotation is avoided; the grooves are easy to process, increased cost is low, and influences on normal mounting and demounting of the yarn bobbins are not caused.

Owner:WUJIANG JIUMEI MICROFIBER WEAVING

Wafer double-sided scrubbing machine

ActiveCN103008301BAchieve all-round scrubbingAvoid secondary pollutionCleaning using toolsCleaning using liquidsMicrometerEngineering

A two-sided scrubbing unit for wafers is provided with a two-sided scrubbing device located at the tail end of a two-sided scrubbing section conveying mechanism. The two-sided scrubbing device comprises a scrubbing support, two brushes capable spraying liquid from inside, two scrubbing shaft components which synchronously rotate, and a driving component driving the scrubbing shaft components to rotate. The scrubbing shaft components are rotatably borne on the scrubbing support which is mounted on a frame, and the two brushes are sleeved on the corresponding scrubbing shaft components respectively and are located on two sides of a wafer to be detected respectively. The two-sided scrubbing unit further comprises a wafer rotation driving device for driving the wafer located in the two-sided scrubbing device to rotate, an unloading device, and a discharge device for pushing the wafer on the scrubbing section conveying mechanism to a discharge wafer box. The two-sided scrubbing unit for wafers is high in automation, the front and reverse sides of the wafer are scrubbed simultaneously, scrubbing is effectively, removing small particles smaller than 0.3 micrometers in diameter is evidently effective, the problem that other devices fail to clean is solved, the high requirement for cleanness of the surface of the wafer is guaranteed effectively, and the high requirement that number of particles which are 0.3 micrometers in diameter and have surface cleanness of the 2-inch wafer is not more than 30 is met.

Owner:常州科沛达清洗技术股份有限公司

Cleaning device for textile machine

InactiveCN108787686AWork cleanConvenience to workSpraying apparatusDirt cleaningWater sprayWaste management

The invention discloses a cleaning device for a textile machine. The cleaning device comprises a baseplate, wherein universal wheels are symmetrically arranged at the bottom end of the baseplate; a tank body, a collecting tank and a water tank are arranged at the top end of the baseplate; the tank body is positioned between the collecting tank and the water tank; a baffle plate positioned on one side of the collecting tank is arranged at the top end of the baseplate; a textile machine body is arranged inside the tank body; a water spraying mechanism is arranged at the inner top end of the tankbody; a draught fan positioned on one side of the water tank is arranged on the baseplate; an air pipe penetrating through the side wall of the tank body is arranged at one end of the draught fan; anair vent positioned inside the tank body is arranged at one end of the air pipe; a suction pump is arranged on one side of the top end of the tank body; a transmission pipe is arranged on the suctionpump; and one end of the transmission pipe penetrates through the side wall of the collecting tank and extends into the collecting tank. The cleaning device has the following beneficial effects: theefficiency of textile machine body cleaning with water can be effectively improved; the textile machine body can be further cleaned; convenience can be brought to the work of the textile machine body;meanwhile, the service life of the textile machine body can be prolonged; and the cost can be effectively reduced.

Owner:芜湖瀚德信息科技有限公司

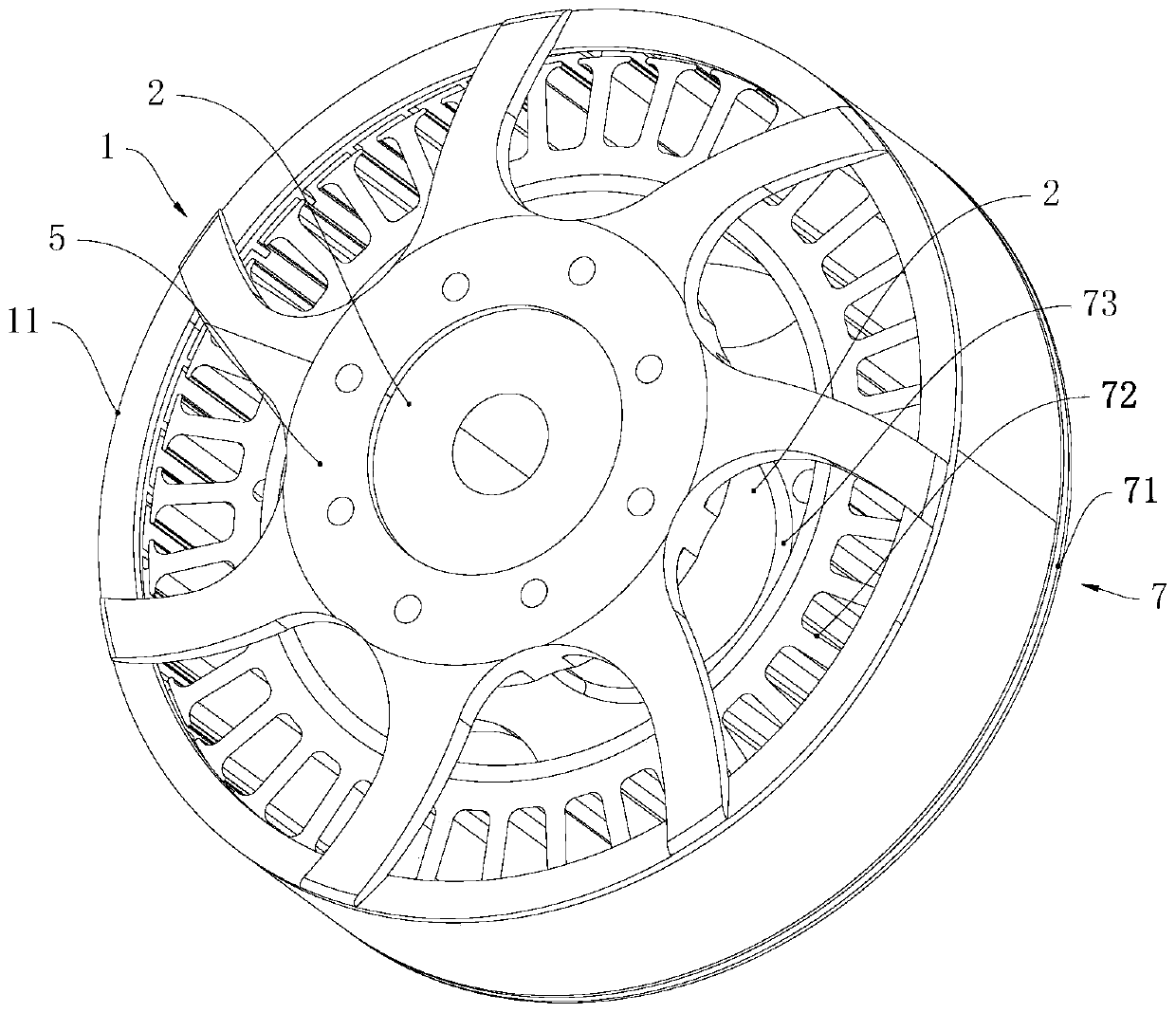

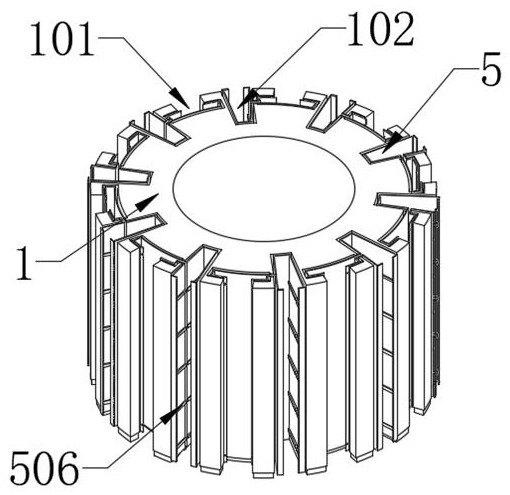

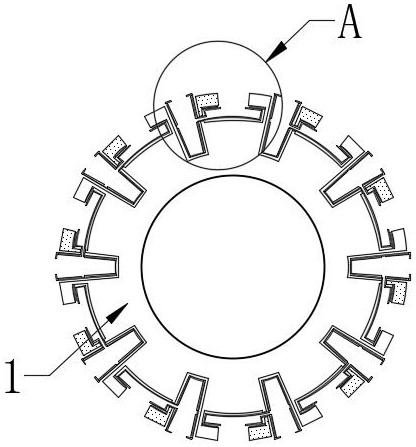

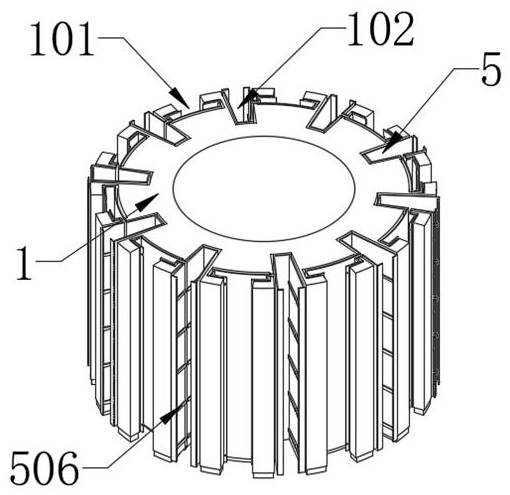

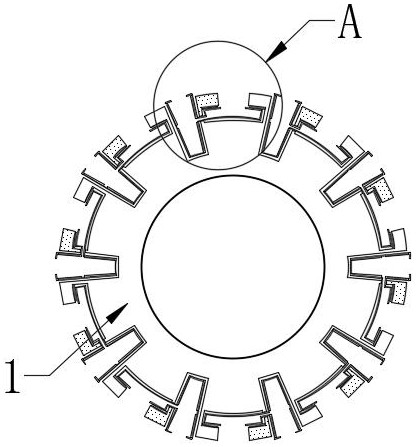

Brushless motor and unmanned aerial vehicle

PendingCN110676976AAvoid flying outAvoid swinging situationsMagnetic circuit rotating partsMechanical energy handlingBrushless motorsUncrewed vehicle

The invention provides a brushless motor and an unmanned aerial vehicle. The unmanned aerial vehicle comprises the brushless motor; the brushless motor comprises a stator, a rotor and a connecting shaft; the rotor rotates relative to the stator; the connecting shaft is connected with the stator; a mounting through groove is formed in the rotor; the mounting through groove comprises a guide section; the cross section of the guide section is trapezoidal; the connecting shaft comprises a connecting shaft body and a guide block; the guide block is arranged on the periphery of the connecting shaftbody; the connecting shaft body is cylindrical; a conical surface is arranged at the outer side wall of the guide block; the guide block is arranged in the guide section in an interference manner; andthe radial width of the outer end part of the guide block is greater than that of the inner end part of the guide section. With the above structure adopted, by the adoption of the structure, under the guiding effect of the guiding section, the situation that the connecting shaft is pressed to deviate or incline is avoided, so that the scrapping of the rotor and the swing of the motor are avoided;and therefore, a propeller connected with the rotor rotates more stably, the rotor cannot be disengaged from the connecting shaft in the high-speed rotating process of the rotor, and the situation that the rotor flies out is avoided.

Owner:SANGAIR TECH

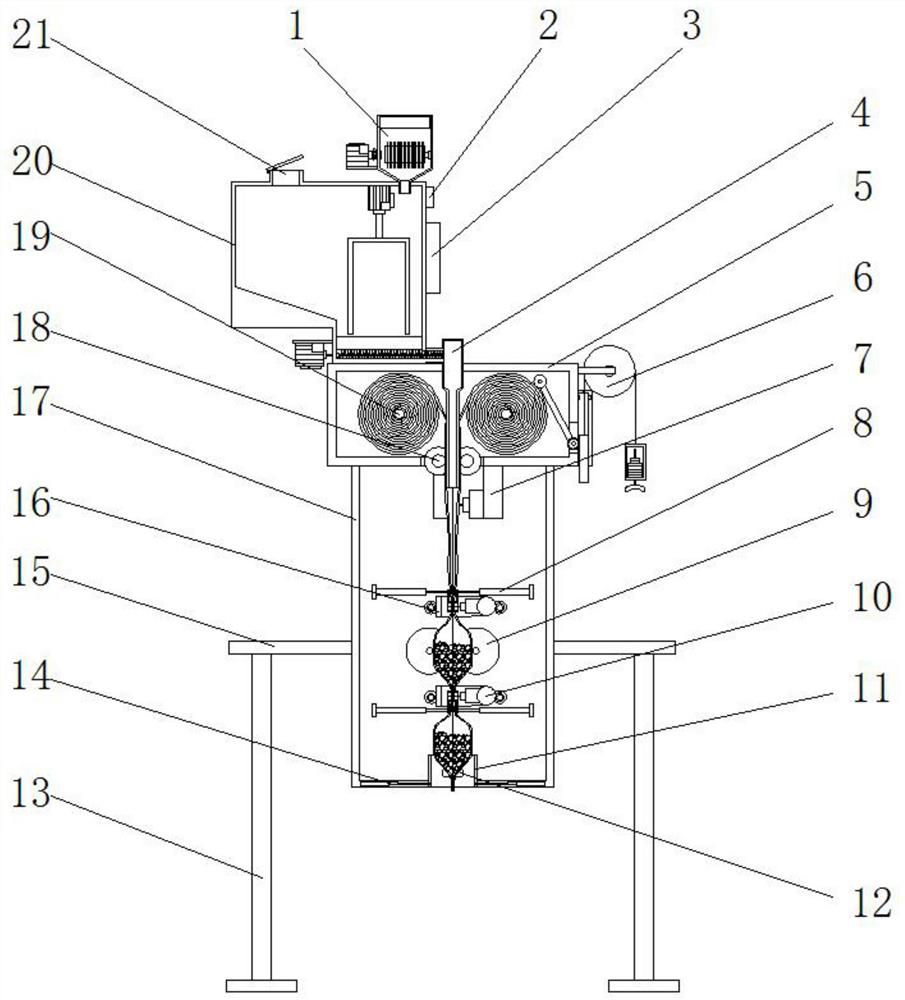

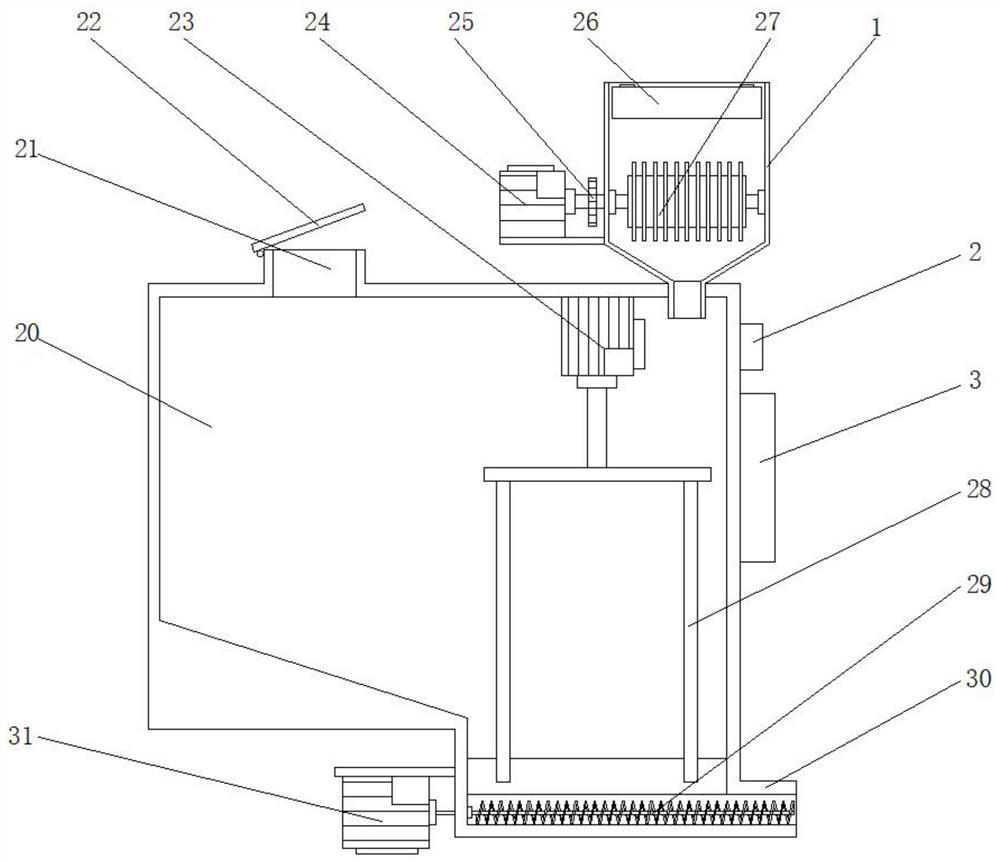

Automatic mixing production device for wormwood salt bags

PendingCN112206149AEasy to crushEasy to mix and storeDevices for heating/cooling reflex pointsWork-feeding meansElectric machineryProcess engineering

The invention discloses an automatic mixing production device for wormwood salt bags. The automatic mixing production device comprises a shell, wherein a fixed disc is welded on the outer side wall ofthe shell; a pair of supporting columns are symmetrically welded at the bottom of the fixed disc; a cloth bag storage box is welded at the top of the shell; an opening communicating with the inner part of the shell is formed in the bottom of the cloth bag storage box. According to the automatic mixing production device disclosed by the invention, a material mixing box is arranged and a crushing box is mounted at the top of the material mixing box, so that wormwood is conveniently and efficiently crushed by utilizing the crushing box; a protection plate hinged to the top end of the crushing box can realize the effects of increasing the sealing performance of an opening end part of the crushing box and preventing the wormwood from flying out in a crushing process; the protection plate is matched with a feeding opening in the material mixing box, so that raw materials needed by the wormwood salt bags are conveniently and efficiently mixed and stored; the raw materials are efficiently andautomatically produced and utilized by a supply device; and a stirring shaft driven by a motor V in the material mixing box can also be used for mixing the added raw materials, so that the mixing efficiency and the mixing effect are increased and the mixing uniformity of the raw materials is improved.

Owner:广州中医药大学深圳医院

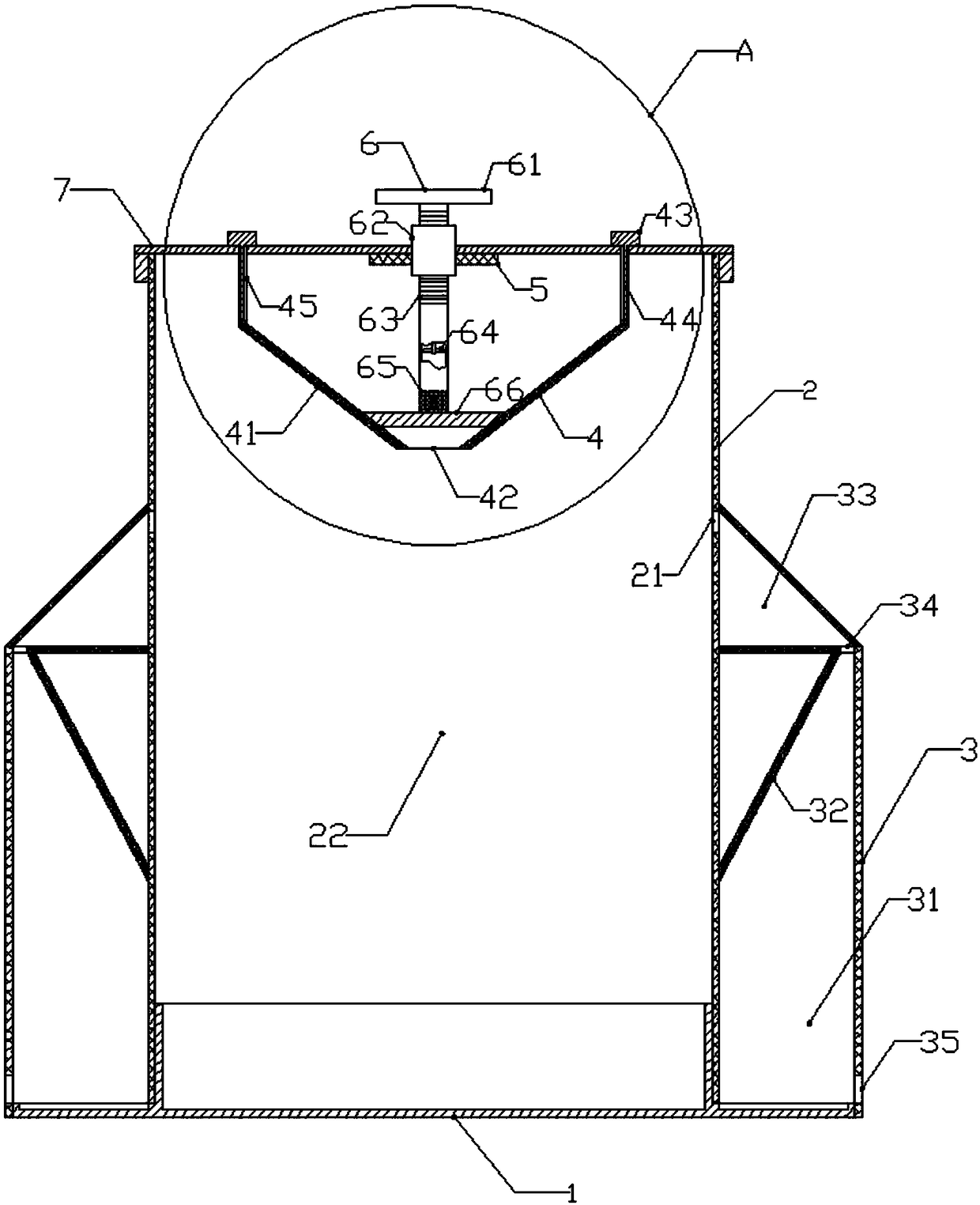

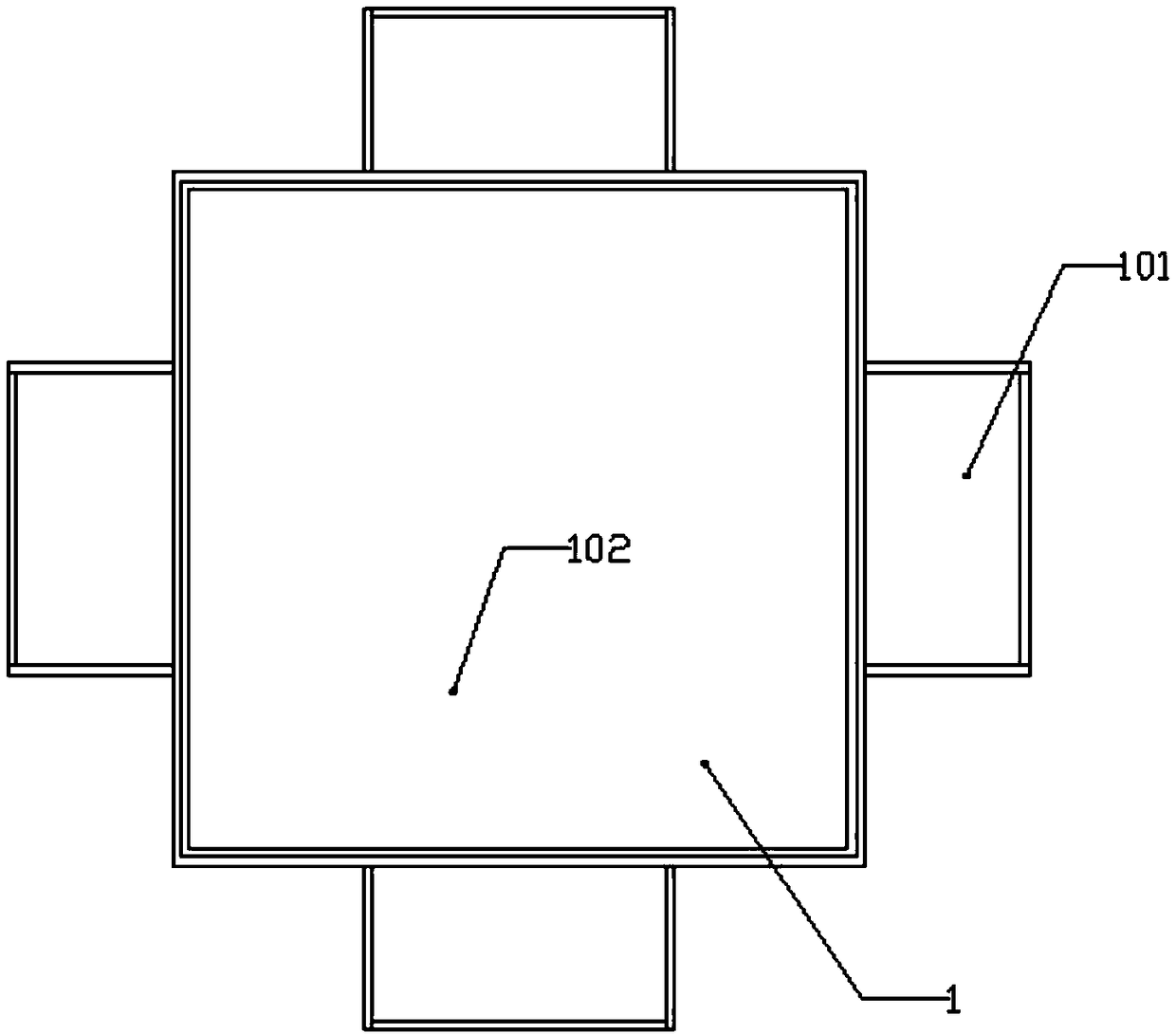

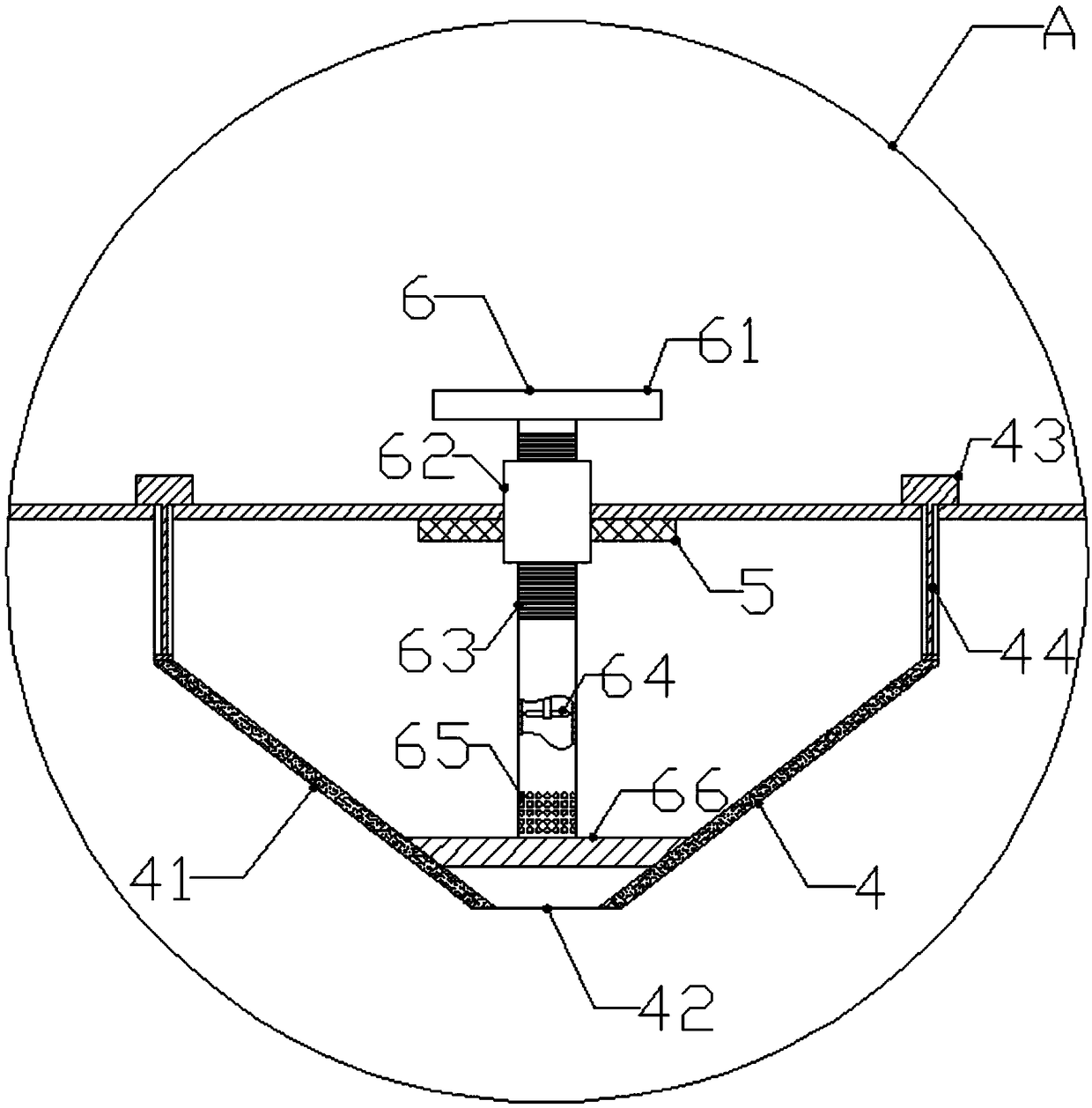

Plastic concrete diaphragm wall seepage failure gradient quality detection test device

ActiveCN113218836AAvoid flying outLower resistanceNuclear energy generationPermeability/surface area analysisStructural engineeringPlastic property

The invention discloses a plastic concrete diaphragm wall seepage failure gradient quality detection test device which comprises a base body, a placement groove is formed in the upper end of the base body, a wall body is arranged in the placement groove, a test groove is formed in the upper end of the wall body, a water pump is arranged at the upper end of the base body, and the water inlet end of the water pump communicates with a liquid inlet pipe. The water outlet end of the water pump is communicated with a transmission pipe, a sealing plug is installed at a notch of the test groove, the end, away from the water pump, of the transmission pipe penetrates through the sealing plug and extends into the test groove, and an external power source is installed at the upper end of the base body. According to the device, the notch of the test groove can be completely sealed and fixed in the plastic concrete diaphragm wall seepage failure gradient quality detection test process, the sealing plug cannot be popped out, meanwhile, an alarm can be automatically given when leakage occurs, and manual observation is not needed.

Owner:宁夏同润华盛建设工程有限公司

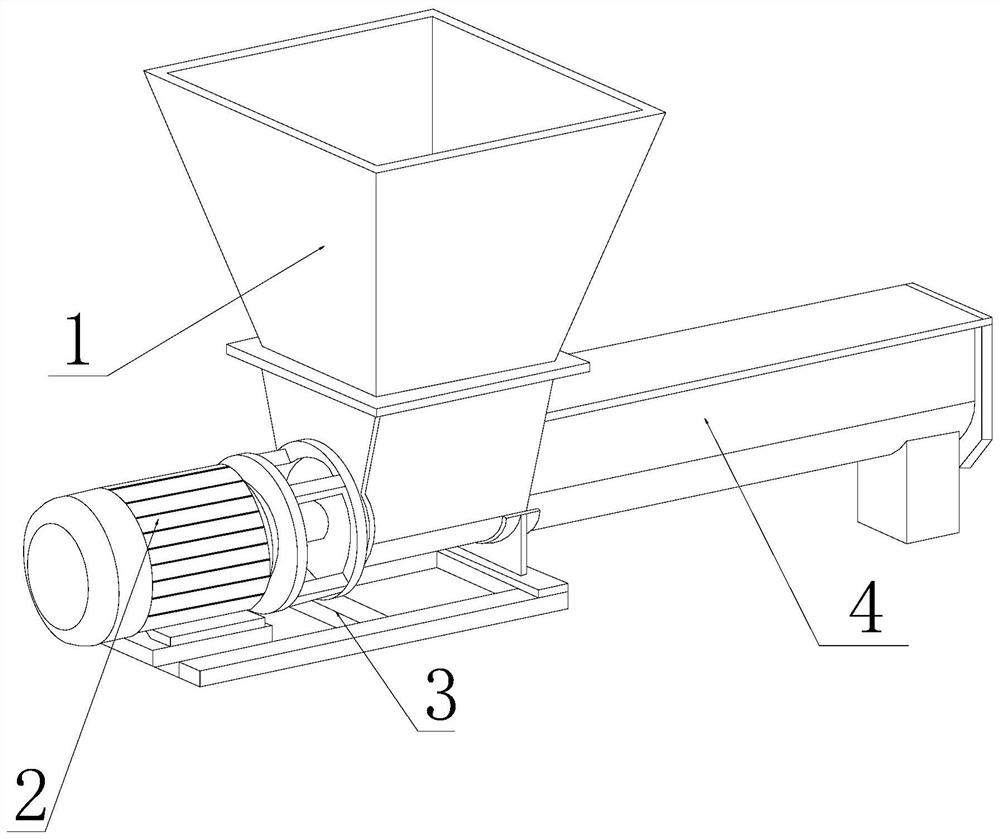

Screw feeder for steel preparation

PendingCN113264328AAvoid flying outReduced output slows downCleaningPackagingStructural engineeringManufacturing engineering

The invention discloses a screw feeder for steel preparation. The screw feeder structurally comprises a discharging hopper, a driving machine, a supporting table and a conveying pipe, wherein the lower end of the discharging hopper is welded to the top end of the surface of the conveying pipe, the top end of the conveying pipe is fixed to the surface of the driving machine through bolts, the lower end of the driving machine is fixedly connected to the surface of the supporting table in an embedded manner, and the upper end of the supporting table is in overall clearance fit with the discharging hopper; and the discharging hopper comprises a dustproof baffle, a movable cavity, an inner hopper wall and a feeding port. According to the screw feeder, a spiral blade is driven by a driving rotating rod, scraping plates slide in clamping grooves fixedly embedded in the surface of a block body through rotating centrifugal force, the scraping plates are matched with the surface of an external sliding rail to slide, coal adhering to the surface of the block body is vibrated and shaken off through sliding of the block body, and then the wall of an inner cavity is scraped through scraping strips under throwing-out of centrifugal force, so that the coal adhering to the wall of the inner cavity is effectively scraped, and the problems that the output speed of the spiral feeder is reduced and the output quantity is reduced due to coal assistance of the wall of the inner cavity are solved.

Owner:许雯雯

A hook type commutator

ActiveCN114039255BExtended service lifeGuaranteed insulation performanceRotary current collectorElectric machineryStructural engineering

The invention discloses a hook-type commutator, which relates to the technical field of motor accessories, and includes an inner sleeve and a commutator piece. There are multiple commutator pieces, and each side of the commutator piece close to the inner sleeve is fixedly connected with a locking block , a plurality of slots are fixed on the outer peripheral wall of the inner sleeve, a separation slot is fixed between two adjacent slots, a cleaning component is movable in the separation slot, and a through hole is fixed between the separation slot and the slot. The bottom of the inner sleeve is fixedly connected with a fixed ring, the top of the fixed ring is abutted and connected with the bottom of the commutator piece, and a ferrule assembly is embedded and connected between the outer wall of the block and the inner wall of the slot, and the other end of the ferrule assembly is inserted into the separation groove through the through hole Among them, the other end of the ferrule assembly is located between the separation groove and the cleaning assembly. The commutator piece of the present invention is installed stably, can process carbon powder in time, prevents the carbon powder from passing through the commutator piece, and improves the stability of the motor.

Owner:浙江科固电器有限公司

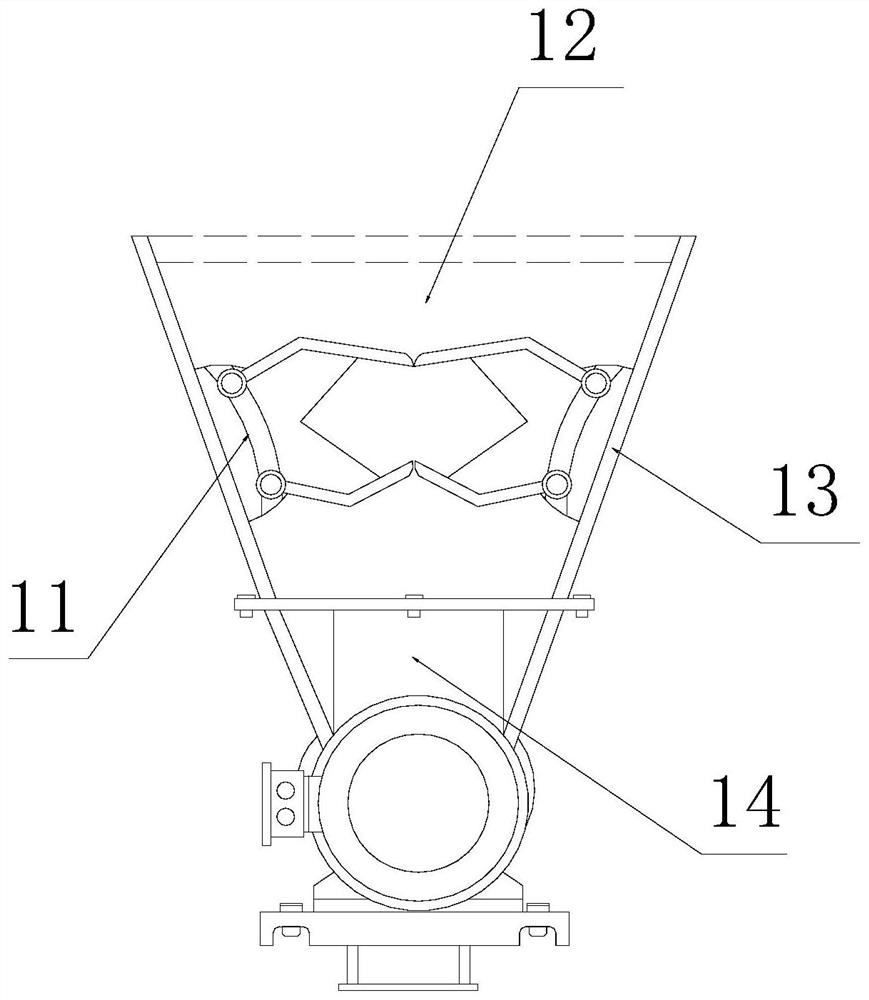

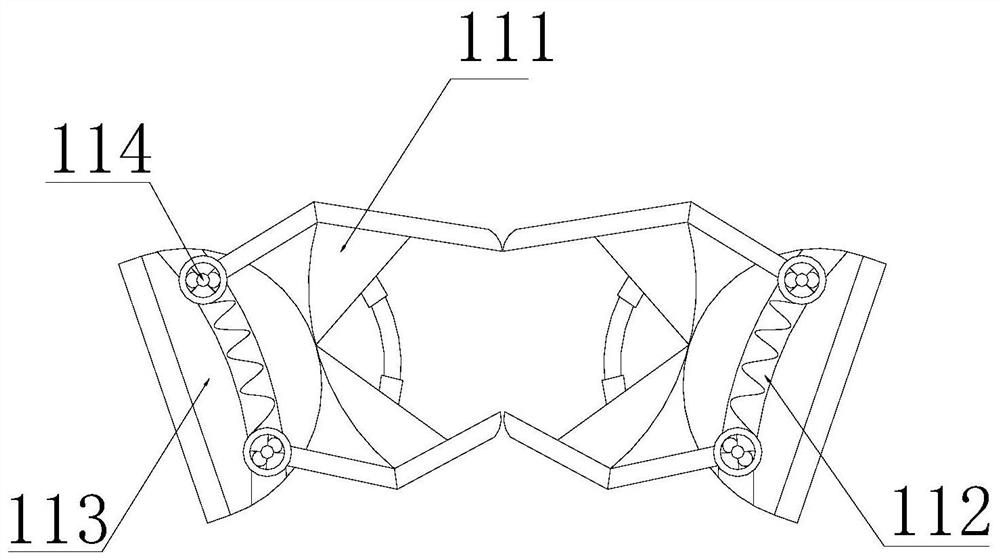

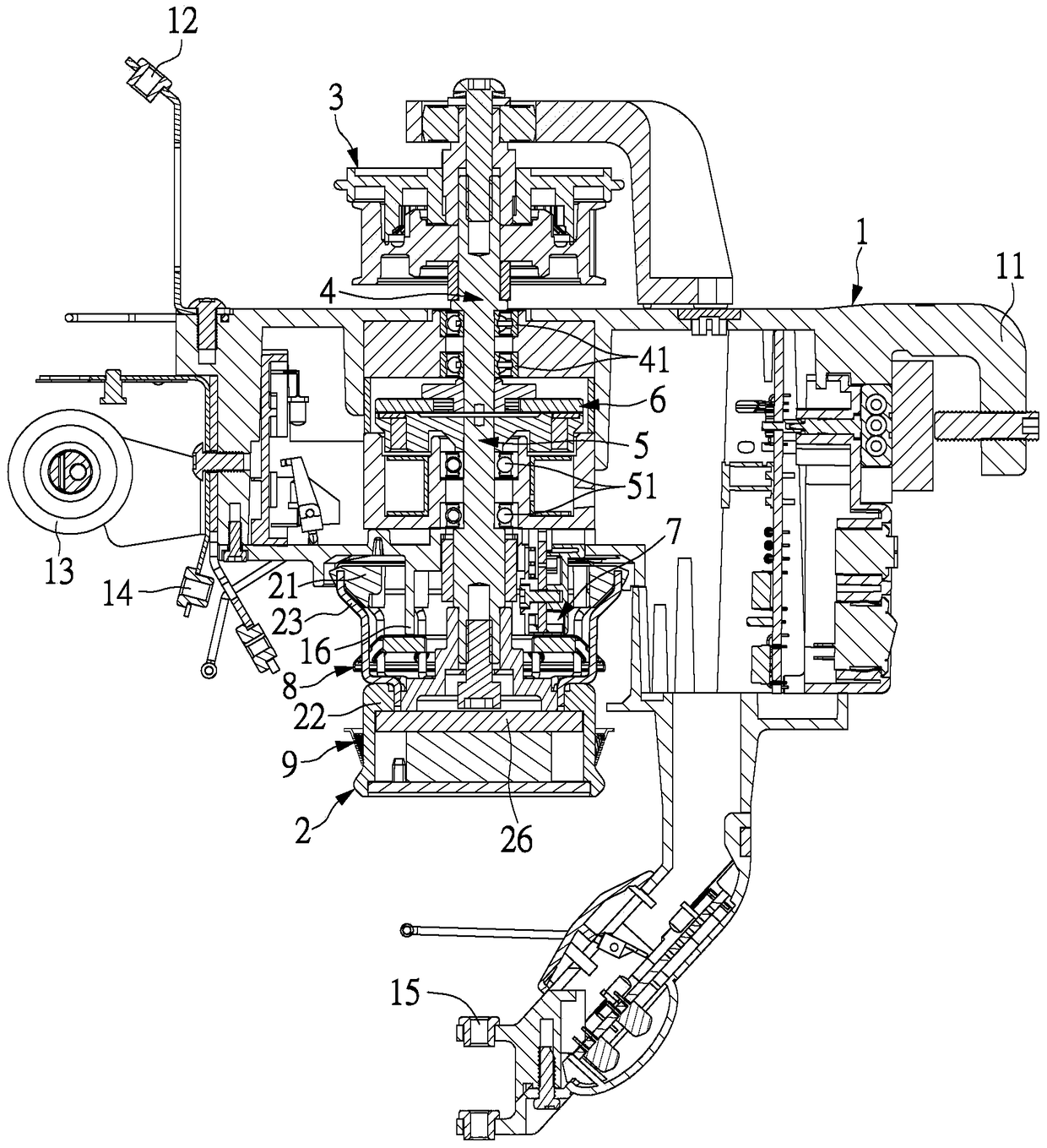

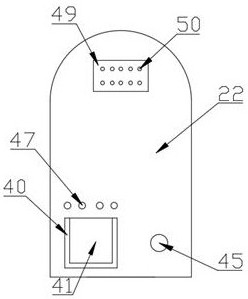

A feeding device for impeller inserts

The invention discloses a feeding device of an impeller insertion sheet, which comprises a feeding hole and a discharge hole. The feeding device of the impeller insertion sheet is characterized by further comprising a material box and a first drive mechanism capable of driving an impeller to pull away from the material box, wherein the first drive mechanism comprises a first cylinder, a connecting rod, a rotating shaft, a second cylinder and a push block; the two ends of the connecting rod are respectively connected with a piston rod of the first cylinder and one end of the rotating shaft; the piston of the first cylinder is movably hinged to one end of the connecting rod; one end of the rotating shaft is fixedly connected with the other end of the connecting rod; the rotating shaft is arranged on the lower part of the discharge hole of the material box; the rotating shaft includes a circular arc surface adaptive to the profile of the impeller; the push block is located below the rotating shaft and includes a arc surface guide platform adaptive to the profile of the impeller; the piston rod of the second cylinder is connected with the push block. The feeding device of the impeller insertion sheet has the advantages of guaranteeing that one impeller can be taken out per each time as a rotary impeller taking mode is adopted, the impeller material taking precision is improved, automatic conveying of the impeller is realized, the automatic operation degree is improved, and the stability and reliability of the impeller in the material feeding process are guaranteed.

Owner:嘉兴市朗盛机械有限公司

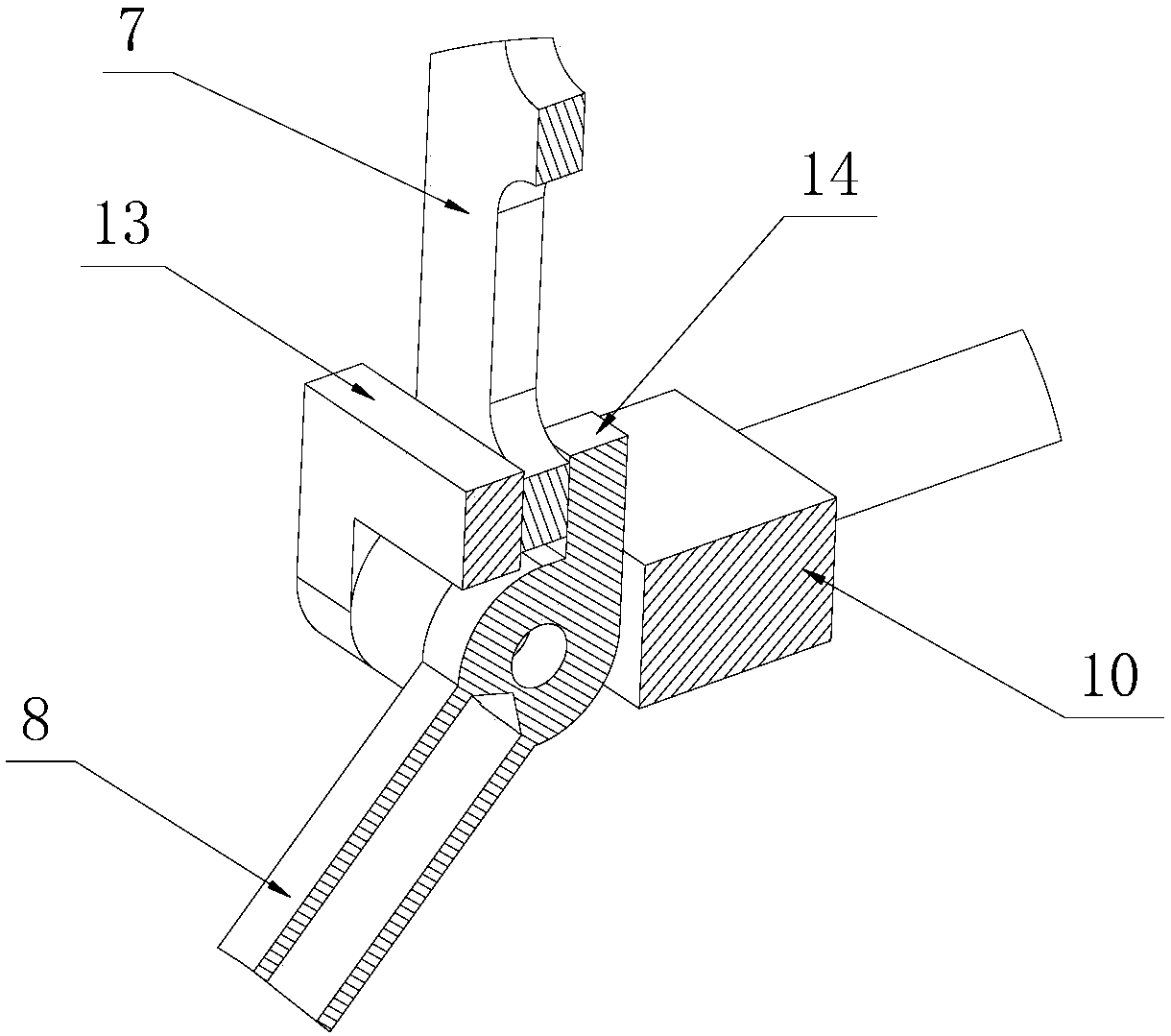

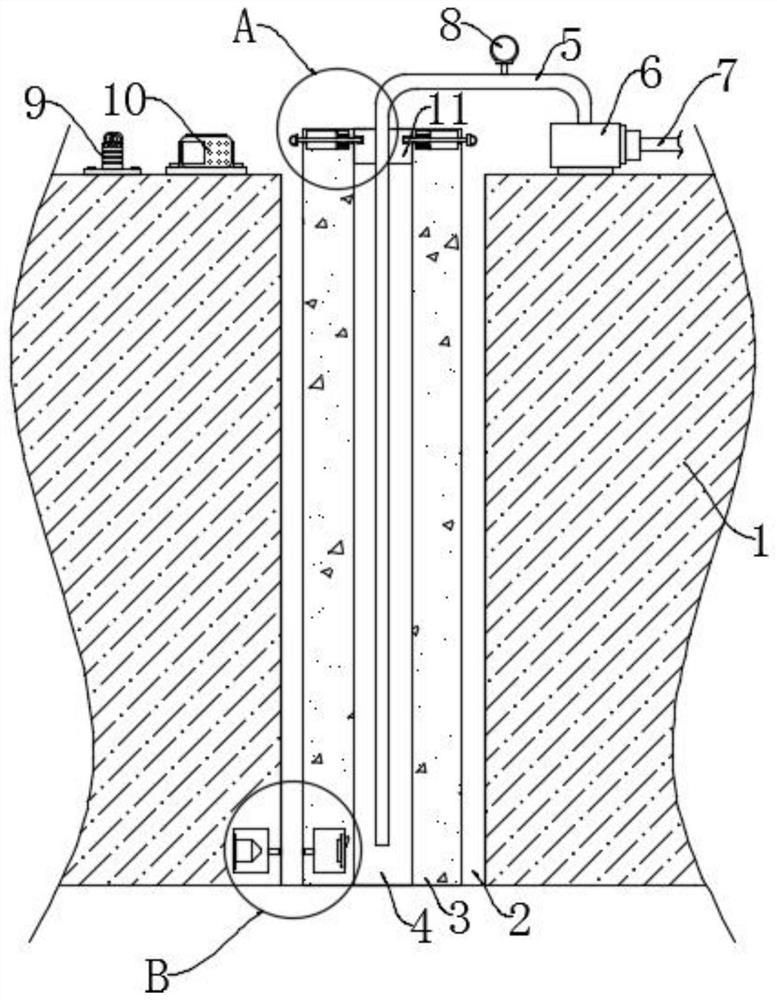

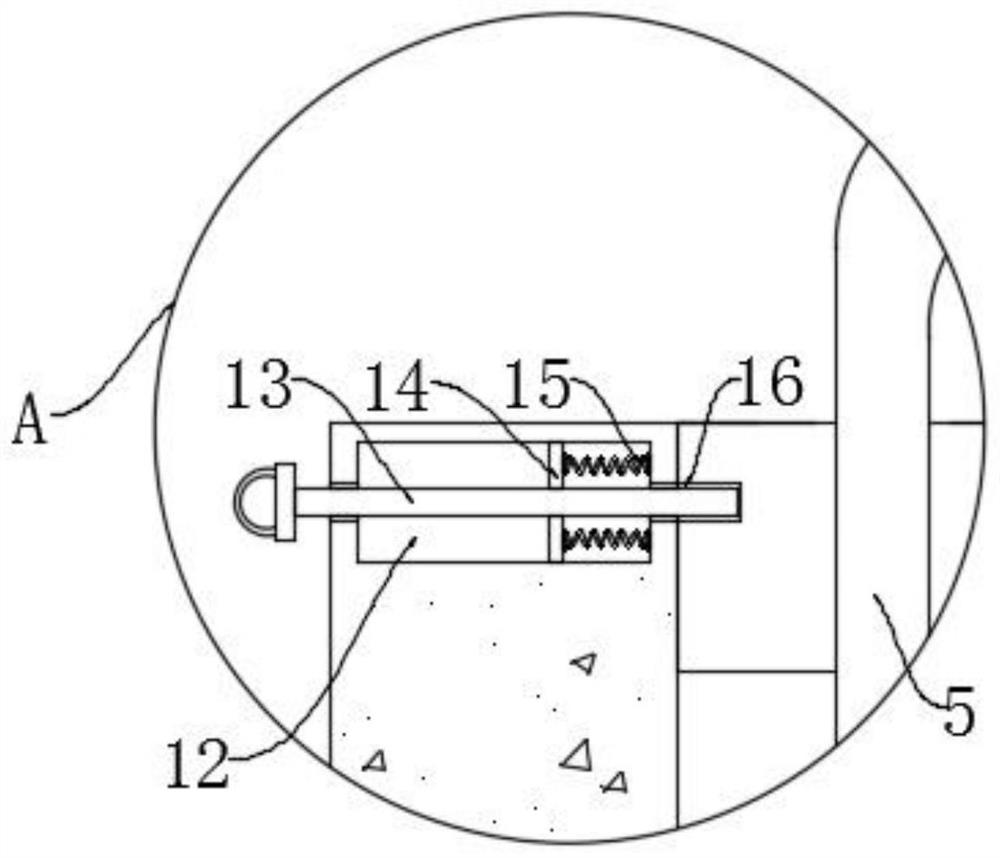

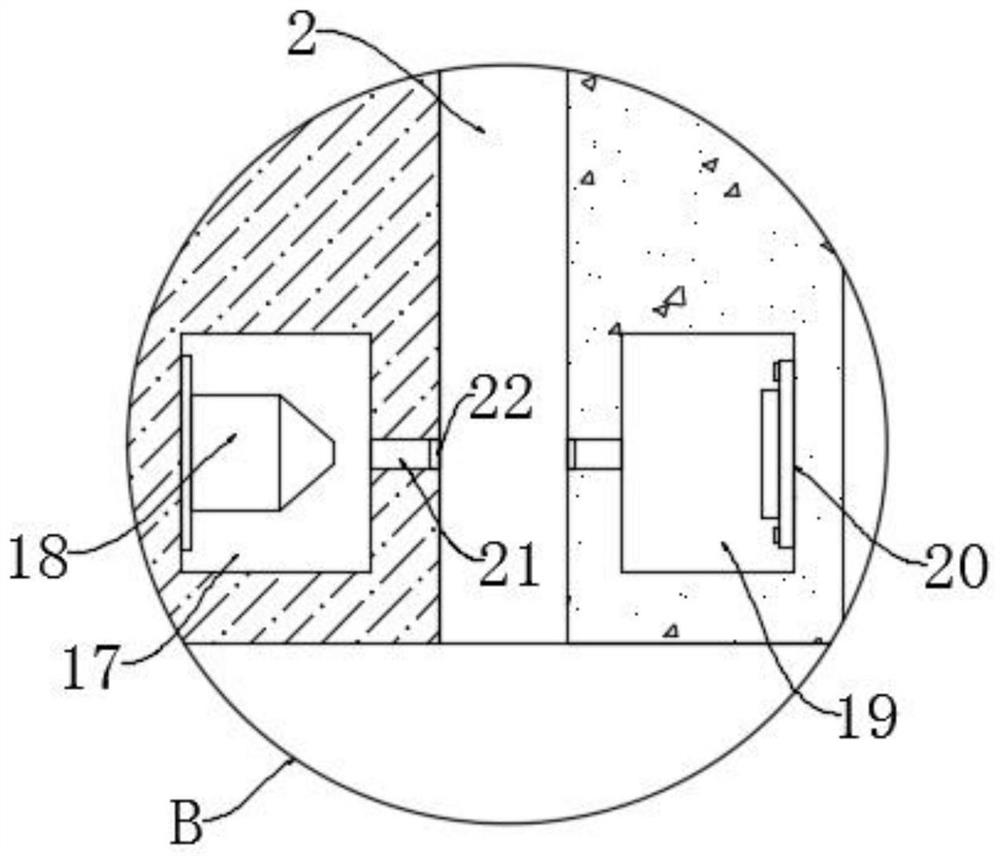

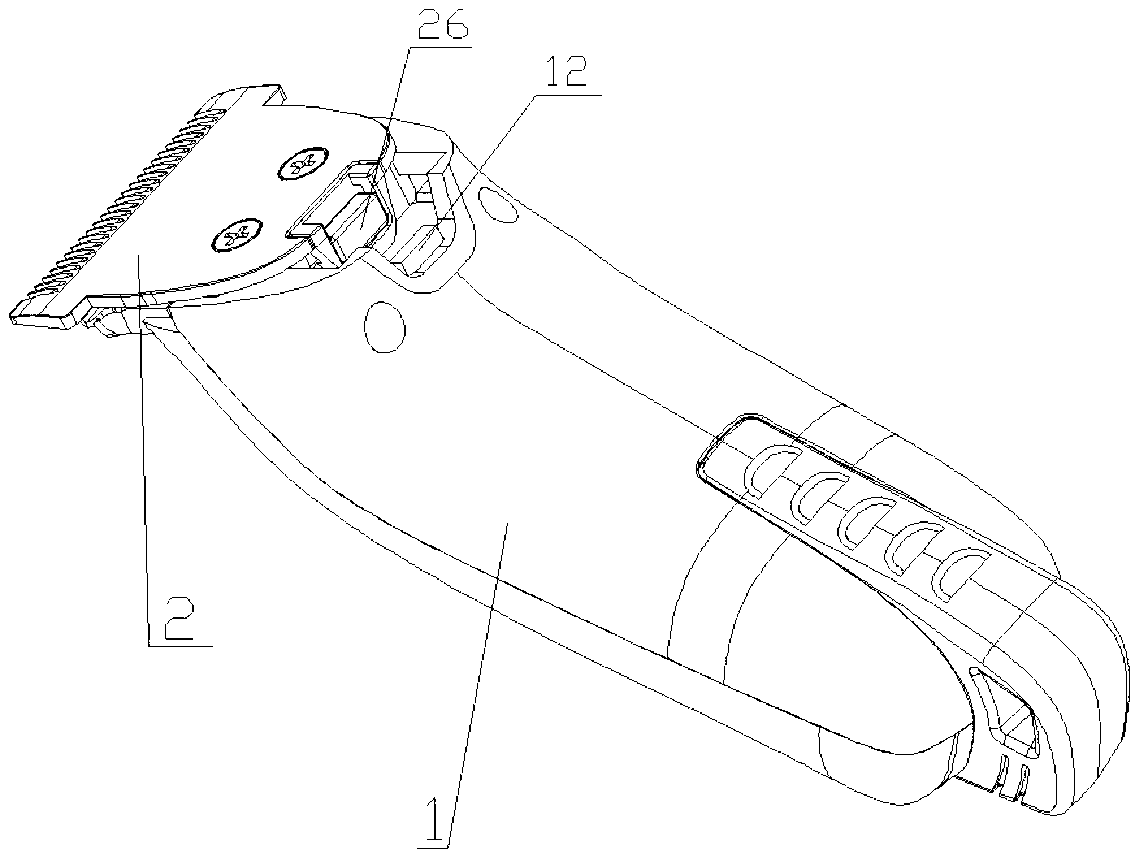

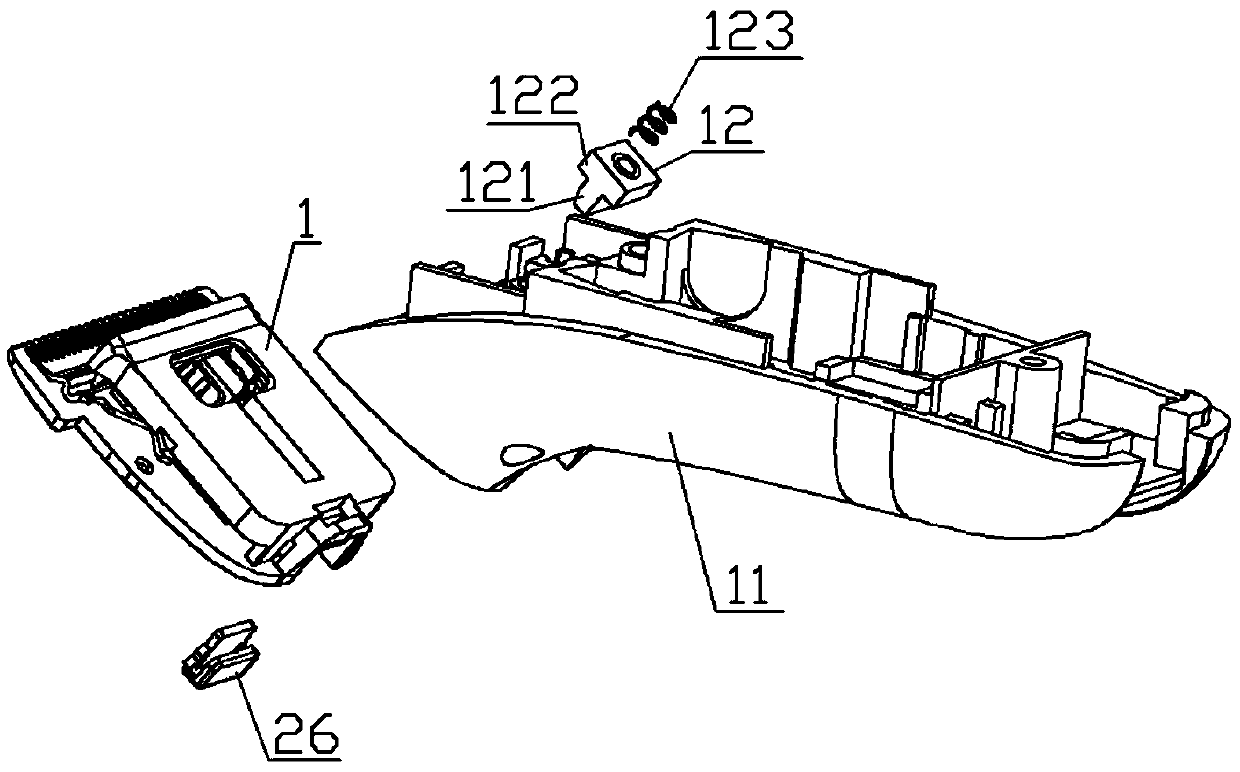

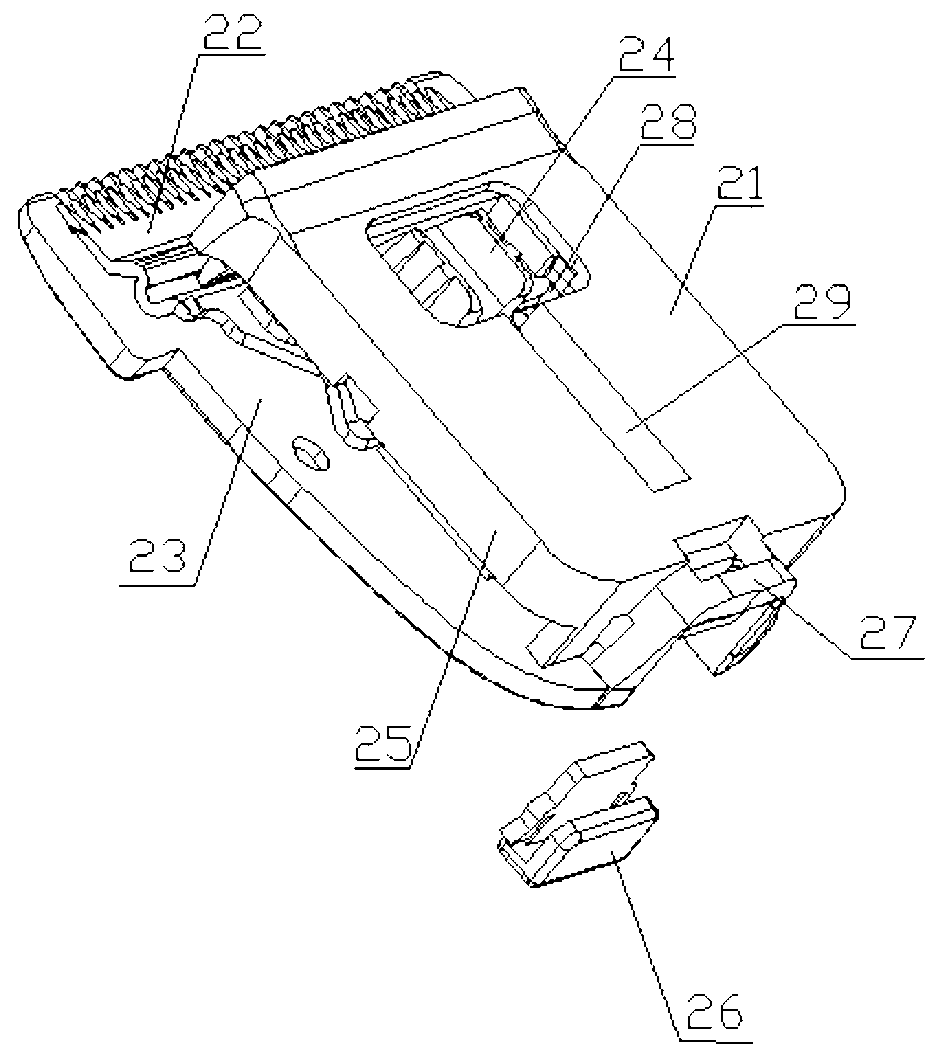

Clipper with locking device and detachable clipper head

ActiveCN102990683AEasy to disassembleEasy to moveMetal working apparatusTool bitReciprocating motion

The invention provides a clipper with a locking device and a detachable clipper head. The clipper comprises a machine body and a clipper head component which is detachably connected with the end of the machine body, wherein the clipper head component comprises a clipper head bracket provided with a cavity, a fixed blade which is fixedly connected with the clipper head bracket and is used as the outer surface of the clipper head component, a movable blade which is arranged in the cavity of the clipper head bracket and a moving part which is fixedly connected with the movable blade and drives the movable blade to carry out reciprocating motion relative to the fixed blade, the fixed blade and the movable blade are respectively provided with a blade tooth edge, the blade tooth edge of the fixed blade and the blade tooth edge of the movable blade tightly cling to each other to form a shearing surface, a strip block is arranged at each of two opposite side edges of the clipper head bracket, a groove matched with each strip block is formed at each of the two inner sides at the end of the machine body, each strip block is arranged in each groove, and an elastic lock block is arranged at the end of the machine body and is used for locking the clipper head component. The clipper has a simple structure, is easy to operate, is high in safety and is very comfortable in usage experience.

Owner:SPECIALIFE ZHUHAI

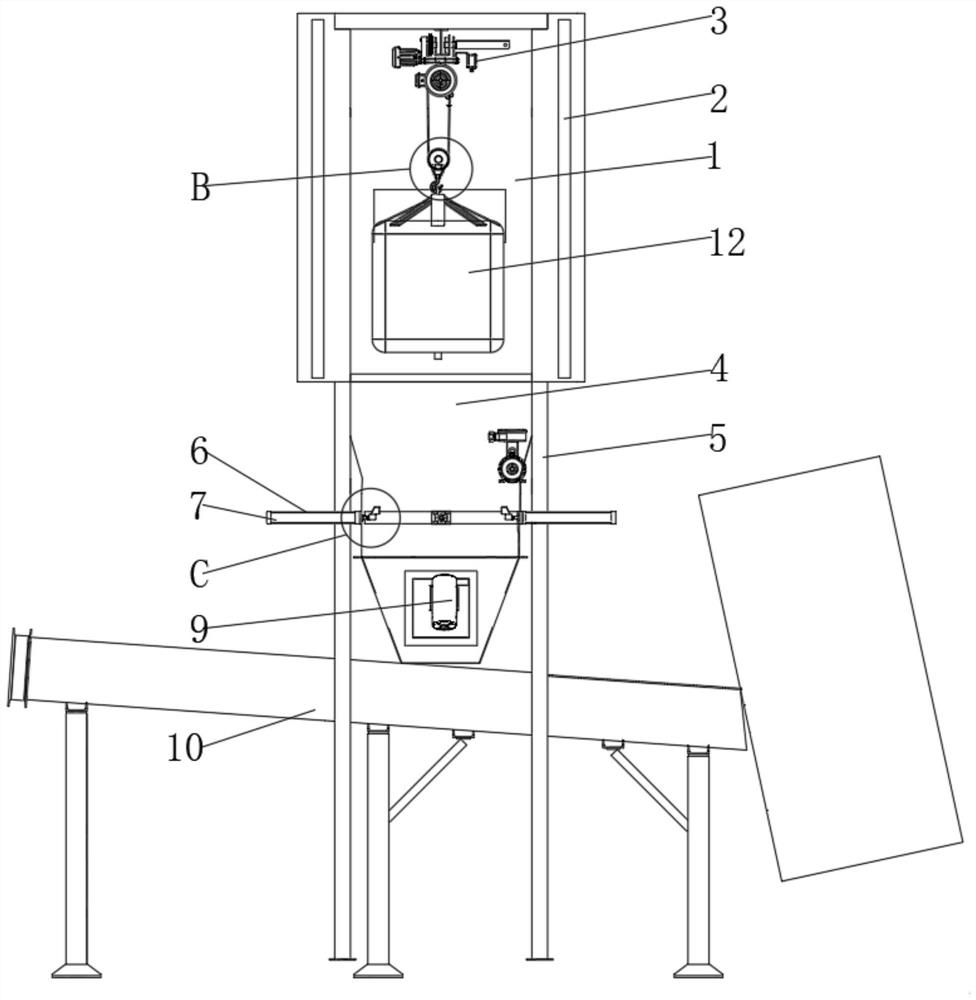

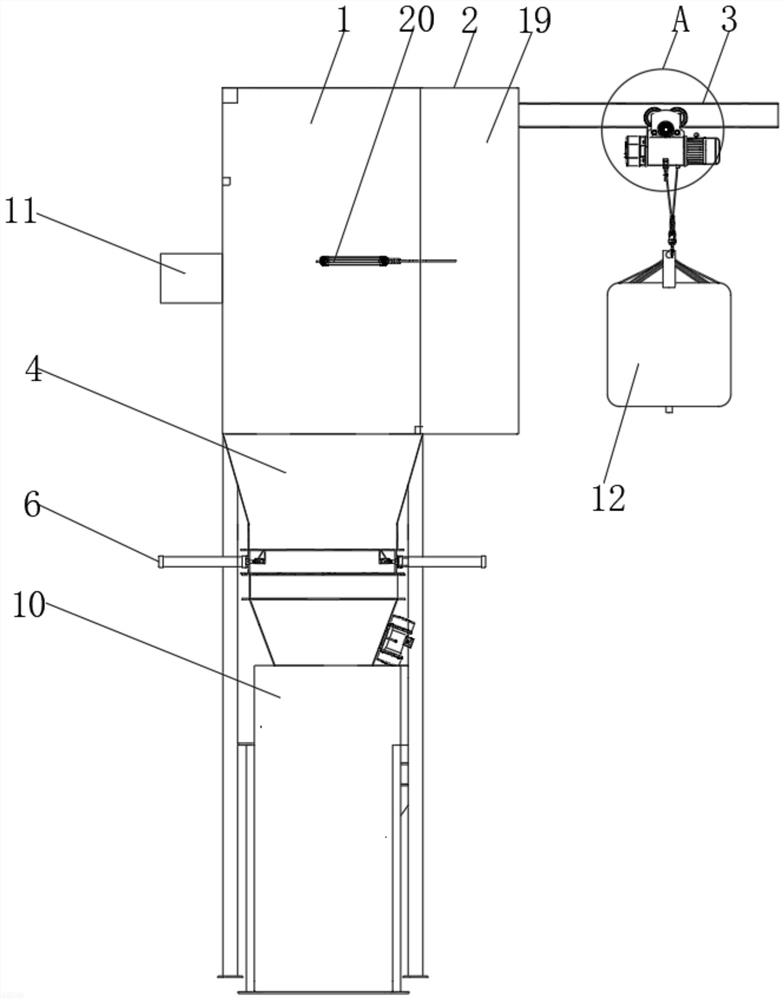

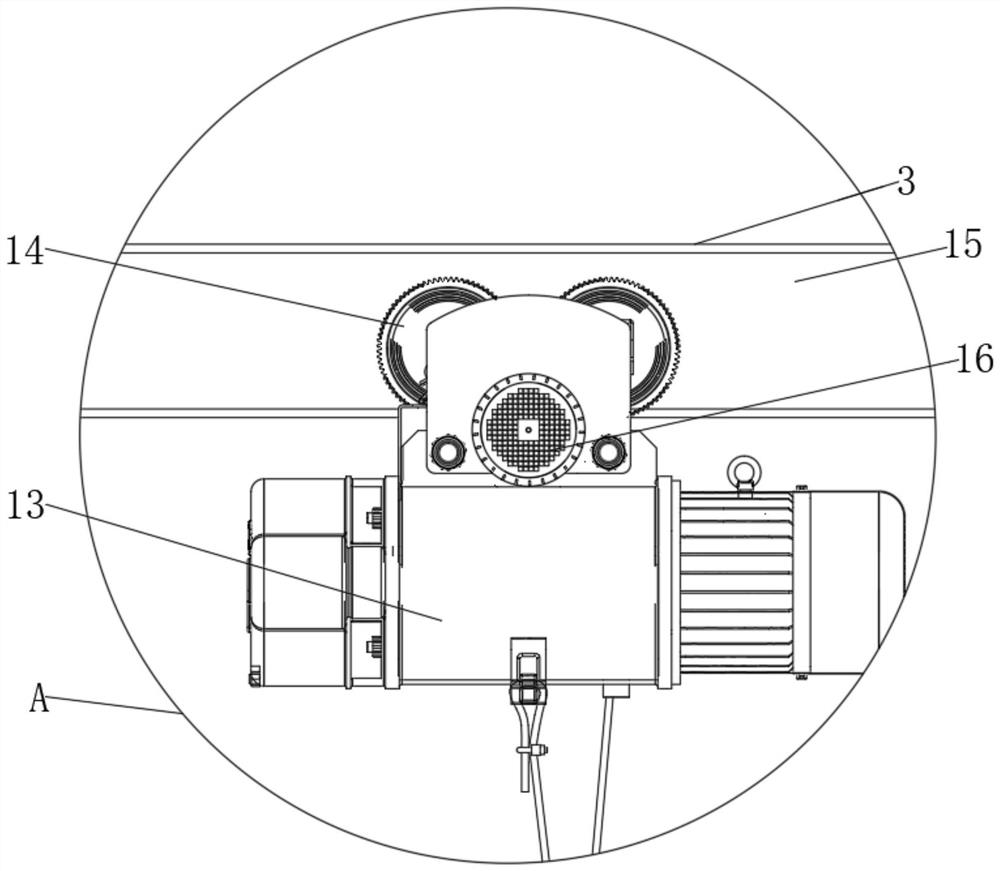

Activated carbon feeding dust-free bag breaking system

PendingCN114084451AAvoid flying outLoading/unloadingUnpacking by cuttingActivated carbonElectrical and Electronics engineering

The invention belongs to the technical field of activated carbon, and particularly relates to an activated carbon feeding dust-free bag breaking system which comprises a storage box, supporting frames are installed at the two ends of the bottom of the storage box, an automatic door sealing device is installed at one end of each supporting frame, and a lifting device is installed in the middle of the front surface of each supporting frame. Each lifting device comprises an electric hoist; The bag body is moved to the feeding box below the storage box through the lifting device, when the bag body is moved to a shearing bag breaking device in the feeding box, the bag body is cut open through the shearing bag breaking device, and then materials in the bag body fall to a resistance propelling device from the bottom of the feeding box under the action of gravity and are conveyed to production equipment through the resistance propelling device. The bag body can be conveniently cut, materials in the bag body can be conveniently poured out, and when the bag body enters the storage box, the storage box can be sealed through an automatic door sealing device, so that the situation that dust flies out when the materials are poured into the bag body can be avoided.

Owner:QINGDAO GUANBAOLIN ACTIVATED CARBON CO LTD

A wire stripping machine for cables

ActiveCN113783142BEasy to peelAvoid Situations That Affect PeelingApparatus for cutting/splicing cablesApparatus for removing/armouring cablesEngineeringControl theory

The invention relates to the technical field of cables, in particular to a wire stripping machine for cables, comprising: a waste box, the waste box is located below the output end of the conveying mechanism; a slitting mechanism, the slitting mechanism is installed at the output end of the conveying mechanism, and The cutting mechanism is used to cut the cable; the stripping mechanism is used to cut off the insulation layer of the cut cable end and separate it from the cable; the driving mechanism is used to drive the slitting mechanism and the stripping mechanism to work simultaneously; the cross-cutting mechanism , the cross-cutting mechanism is in an inverted "U" shape, and the two ends of the cross-cutting mechanism pass through the two side walls of the cutting position of the stripping mechanism, and the heights of the two ends of the cross-cutting mechanism are different; the cross-cutting mechanism follows the stripping mechanism to cut off the cable end When removing the insulation layer of the head, one end of the cross-cutting mechanism retracts to the inside of the stripping mechanism, and the other end of the cross-cutting mechanism is inserted into the insulation layer of the cable; when the stripping mechanism is separated from the cable, the retracted end of the cross-cutting mechanism rebounds to push Drop and insert the insulation at the other end of the crosscutting mechanism.

Owner:常州市生生线缆有限公司

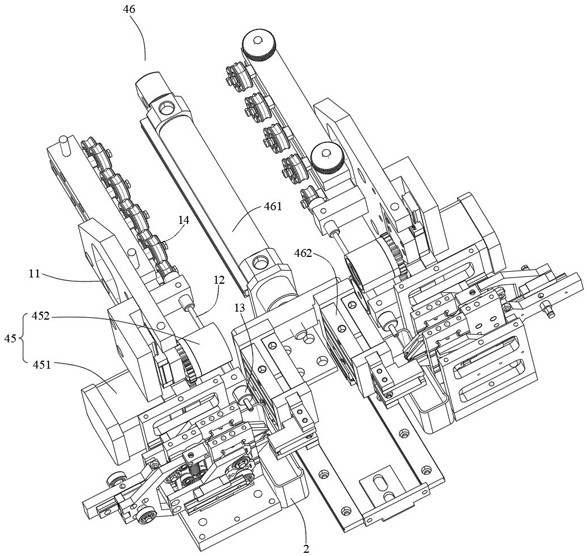

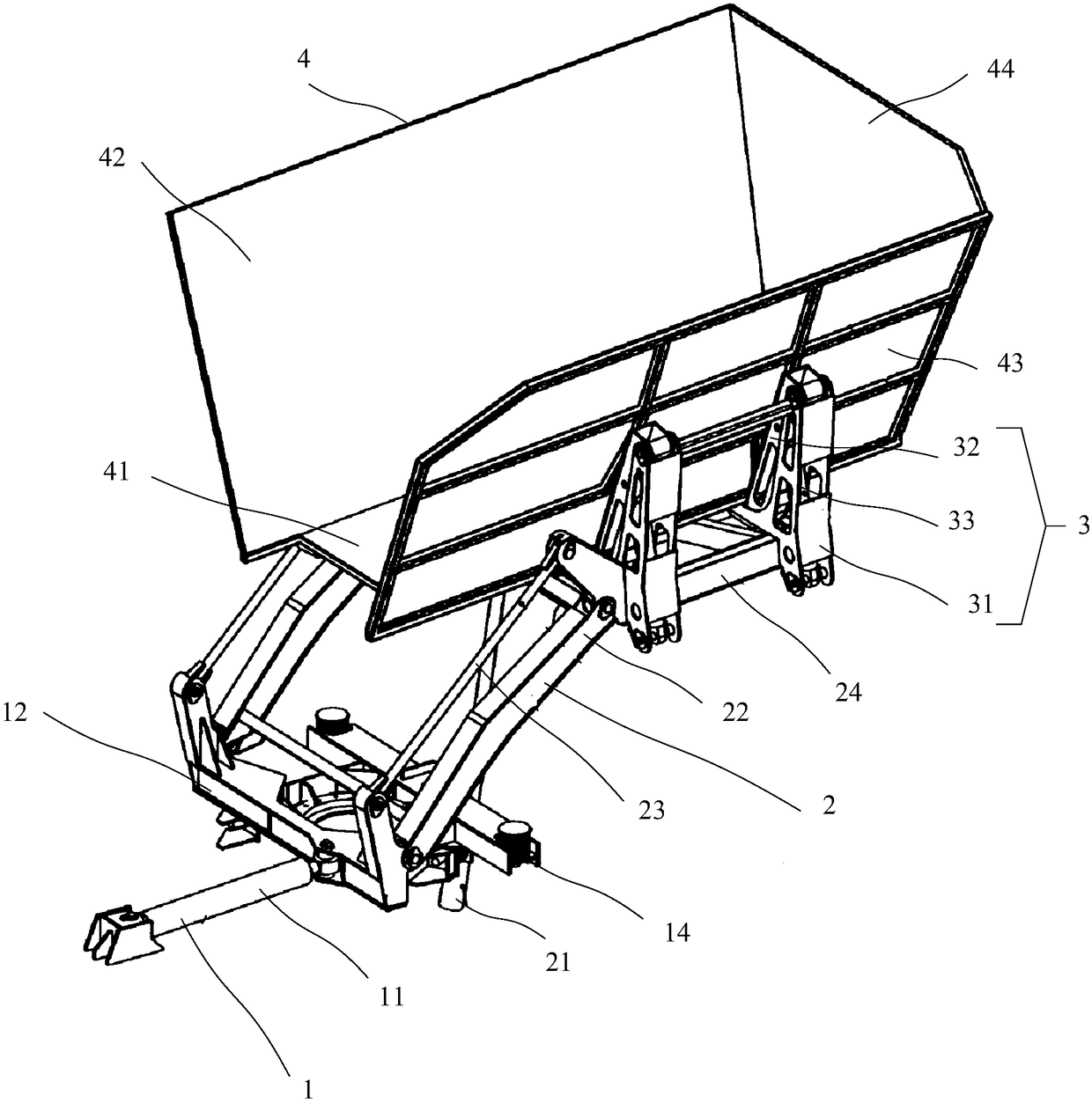

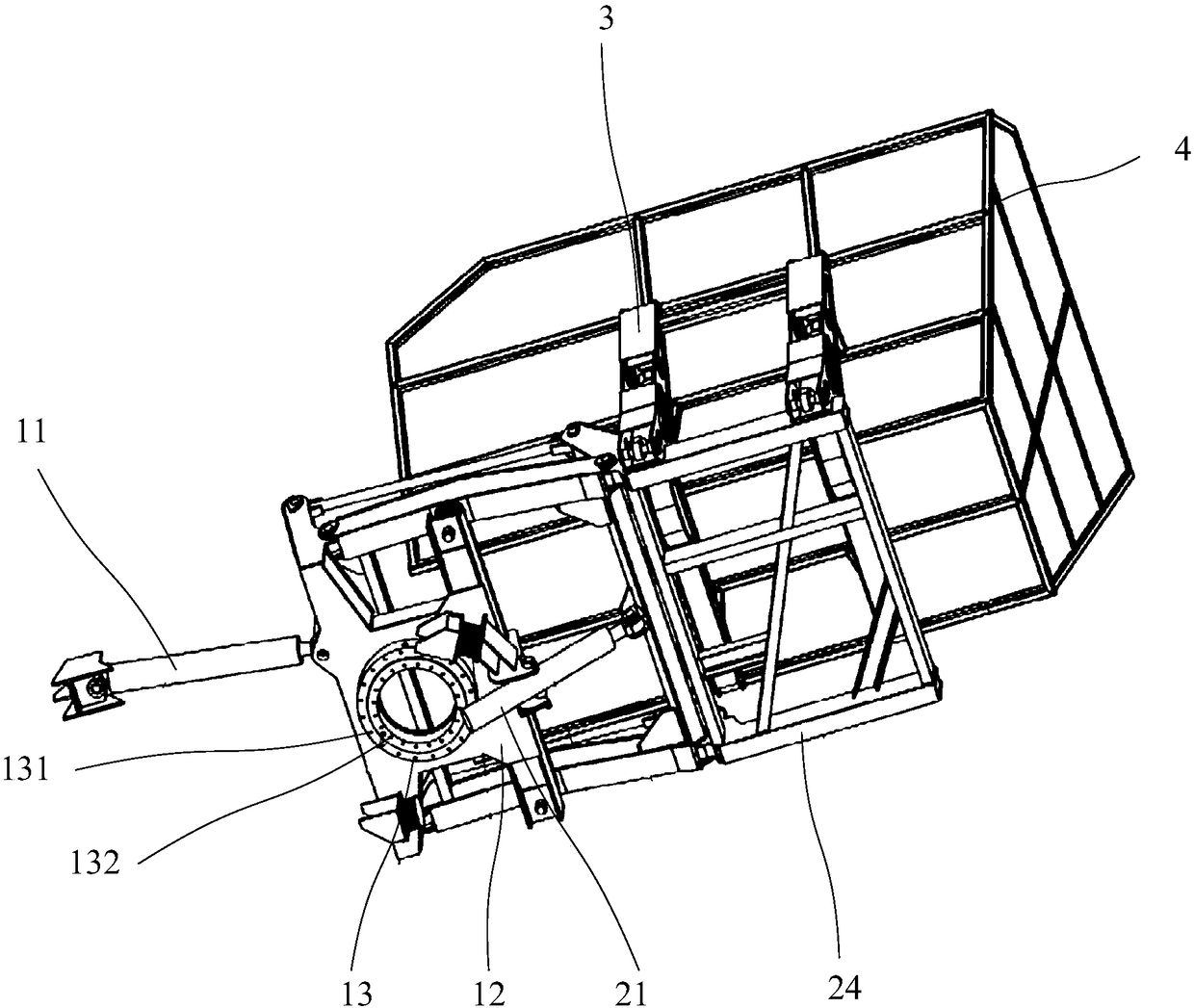

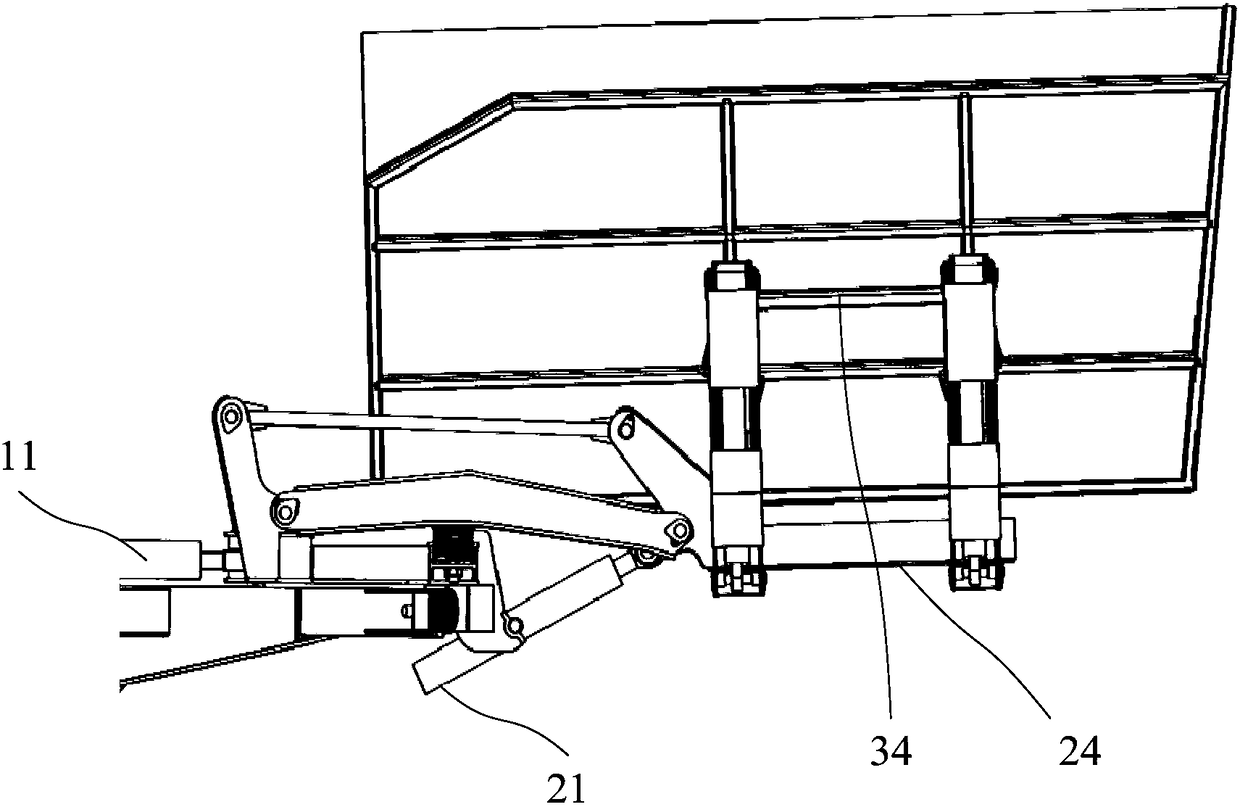

Concentrated transportation device of stem-shaped crop harvesting machine

PendingCN108394732AConvenient and flexible usePrevent crushingConveyorsLarge containersTransport engineeringTurning radius

The invention relates to a concentrated transportation device of a stem-shaped crop harvesting machine. The concentrated transportation device comprises a rotation structure, a supporting and jackingstructure, a tipping bucket structure and a hopper assembly; the supporting and jacking structure is movably connected with the rotation structure; the tipping bucket structure is connected with the supporting and jacking structure; the hopper assembly is connected with the tipping bucket structure; the rotation structure comprises a rotation driving device, a rotation underframe and a rotation supporting device; the supporting and jacking structure comprises a lifting oil cylinder, lifting arms, drawbars and a hopper underframe; and one end of the lifting oil cylinder is hinged with the hopper underframe. The stem-shaped crop concentrated transportation device is convenient and flexible to use; the material unloading direction is selected freely; no wheels are arranged below the hopper, so that the situation that tires run over and injure ribbings and roots of crops is avoided; when the complete stem-shaped crop concentrated transportation device makes a turn during operation, the hopper is lifted to a certain height, so that too large turn radius is avoided, and the hopper allows the crops beside to fall; and in general, the stem-shaped crop concentrated transportation device canadapt to complicated stem collection operation better.

Owner:湖北国拓重工科技有限责任公司

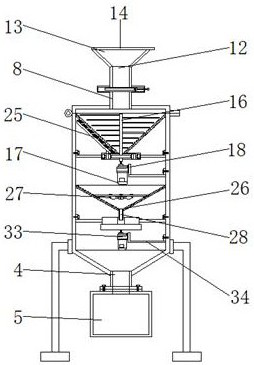

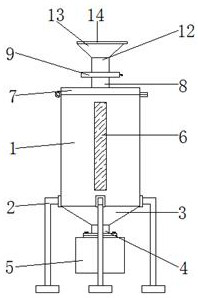

Anti-blocking dust removal device for closed grinding machine

InactiveCN112718105AAvoid flying outReduce overflowSievingScreeningDust controlStructural engineering

The invention discloses an anti-blocking dust removal device for a closed grinding machine. The device comprises a grinding box body, supporting legs are correspondingly welded to four corners of the bottom of the grinding box body, a discharging hopper is welded to the inner wall of the bottom of the grinding box body, the inner wall of the bottom of the discharging hopper communicates with a first discharging pipe, a collecting cloth bag is fixed to the bottom of the first discharging pipe through screws, a sealing cover is hinged to the top of the grinding box body, a first feeding pipe communicates with the center of the top of the sealing cover, a partition chamber communicates with the top of the first feeding pipe, and a partition plate is installed in the partition chamber. According to the device, when raw materials are injected, the device is separated through the partition plate, the raw materials are stored in a second feeding pipe firstly, then the partition plate is shifted to inject the raw materials into the grinding box body, therefore, the raw materials are added step by step, the situation that dust flies out in the feeding process of a feeding port in the past can be avoided, and overflow of dust is greatly reduced.

Owner:安徽维盛智能装备有限公司

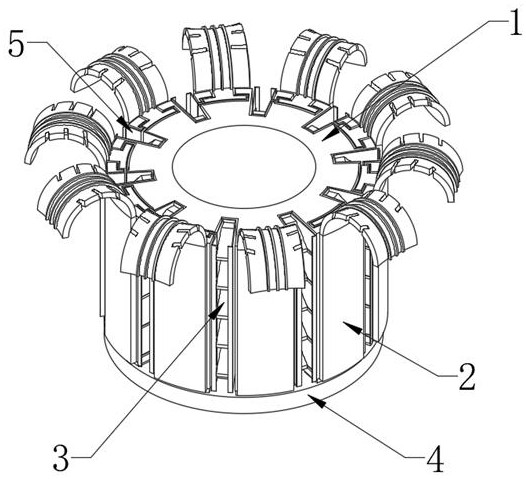

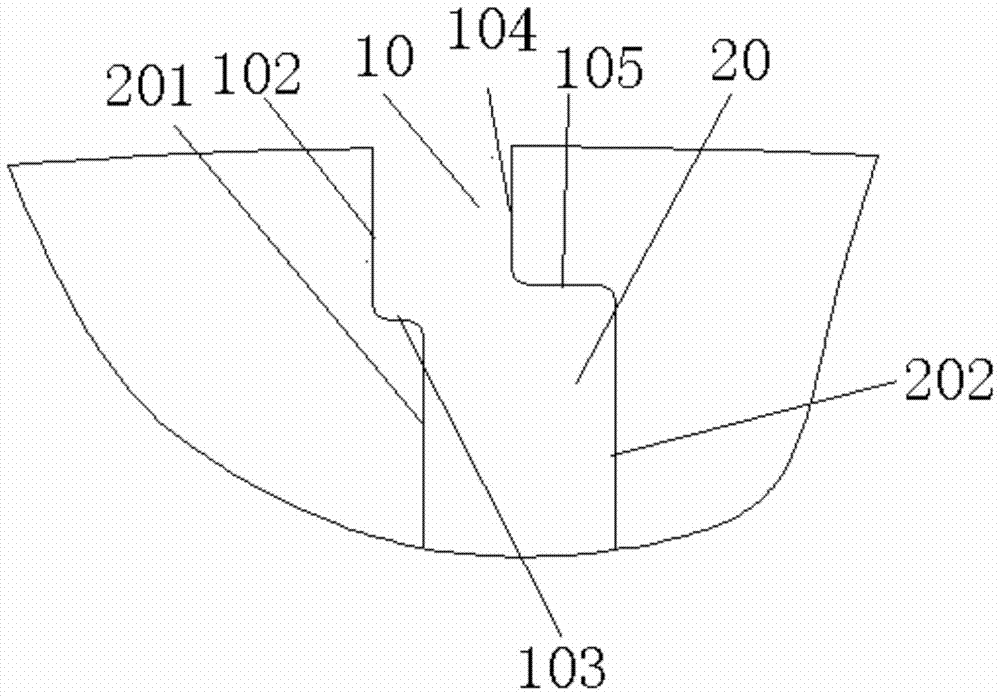

Rotor punching of high-speed motor and its design method

ActiveCN105119407BHigh mechanical strengthAvoid flying outMagnetic circuit rotating partsManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a rotor stamping of a high-speed motor and a design method thereof. The rotor stamping of the high-speed motor includes a body, and the body is provided with a plurality of notch structures, and the notch structure has a notch and a guide bar groove , one side of the guide bar groove is provided with a first limiting edge, the other side of the guide bar groove is provided with a second limiting edge, one side of the notch has a first notch edge, the The other side of the notch has a second notch side, the first notch side and the first limiting side and the second notch side and the second limiting side are all in an offset structure, and the first notch side and the first limiting side The offset direction between the first limit sides is the same as the offset direction between the second notch side and the second limit side, and the first notch side is connected to the first limit side through the first lateral movement side, The second notch side is connected with the second limiting side through the second traversing side. The invention can improve the mechanical strength of the notch, ensure the leakage reactance of the rotor punch, avoid the deformation of the notch and cause the guide bar to fly out, and reduce the design difficulty of the high-speed motor rotor punch.

Owner:NEW UNITED RAIL TRANSIT TECH

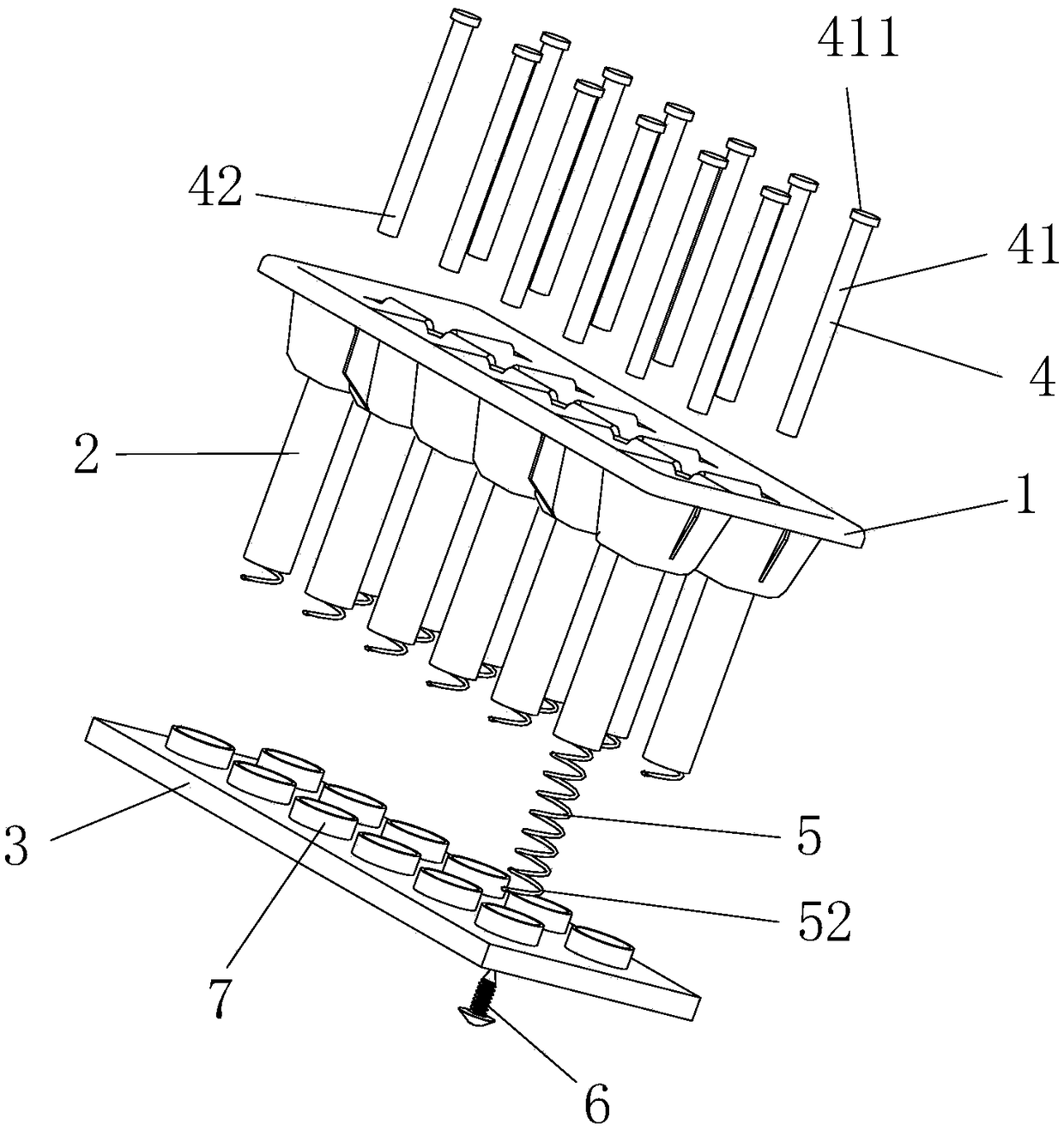

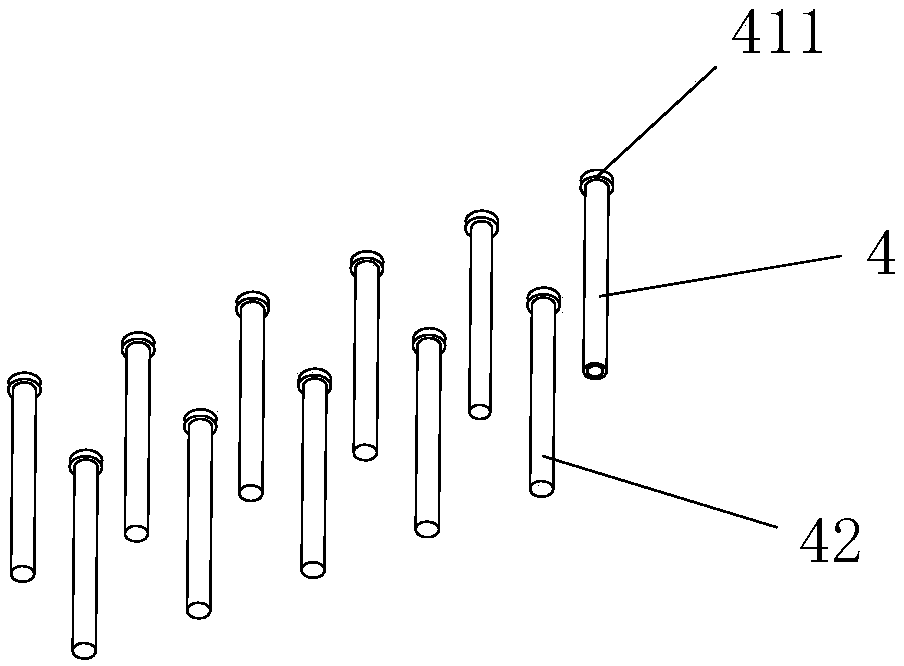

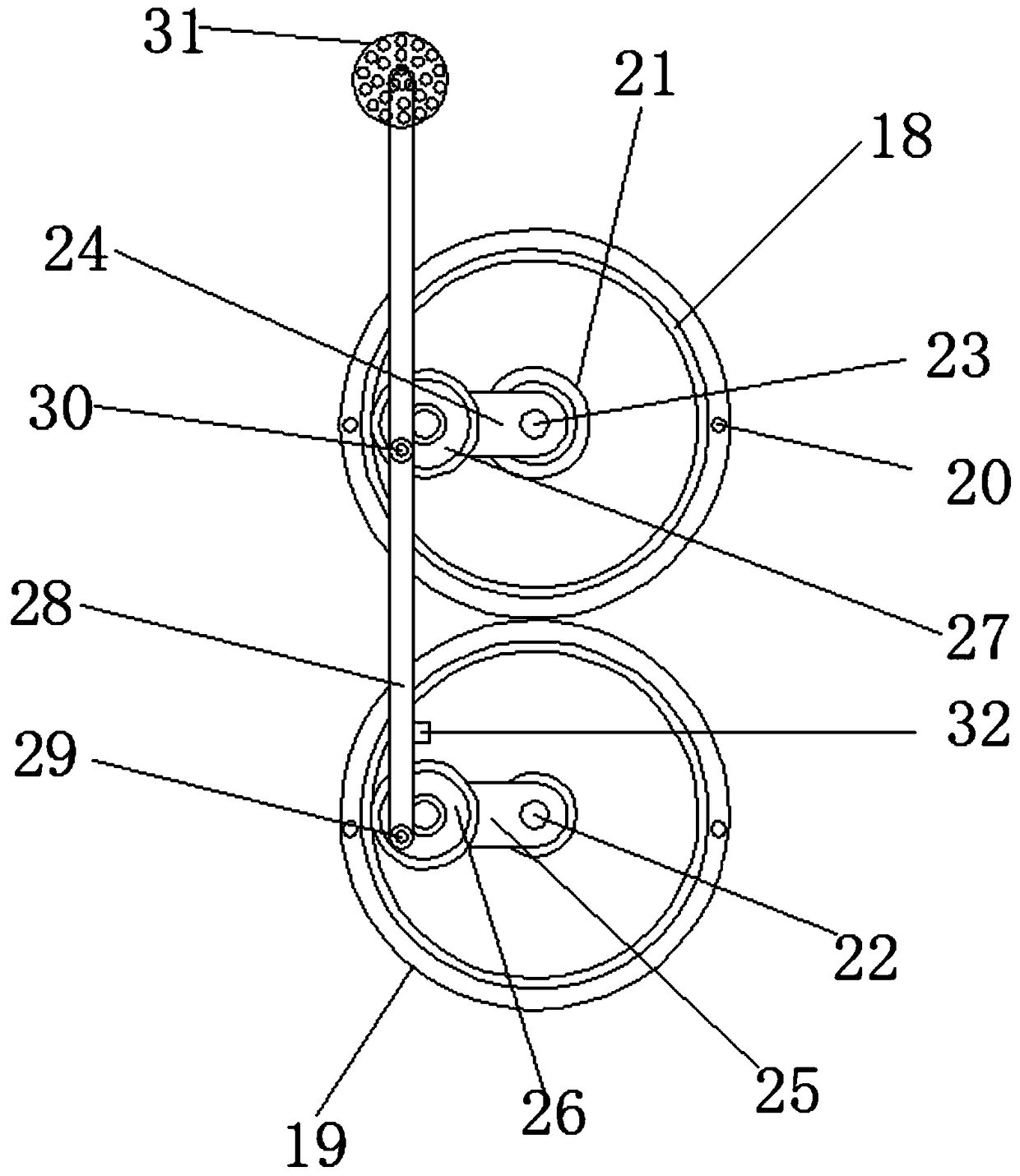

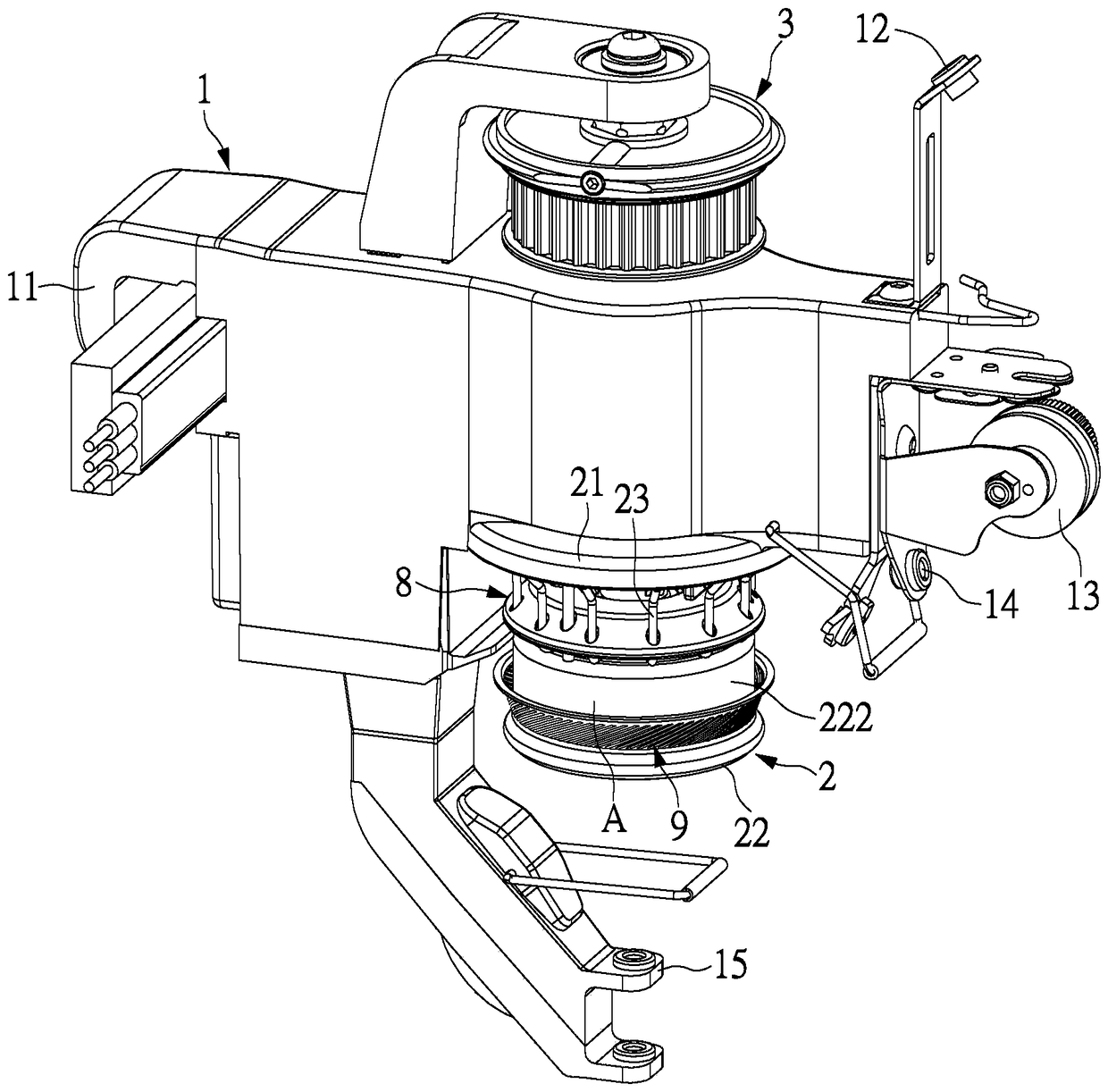

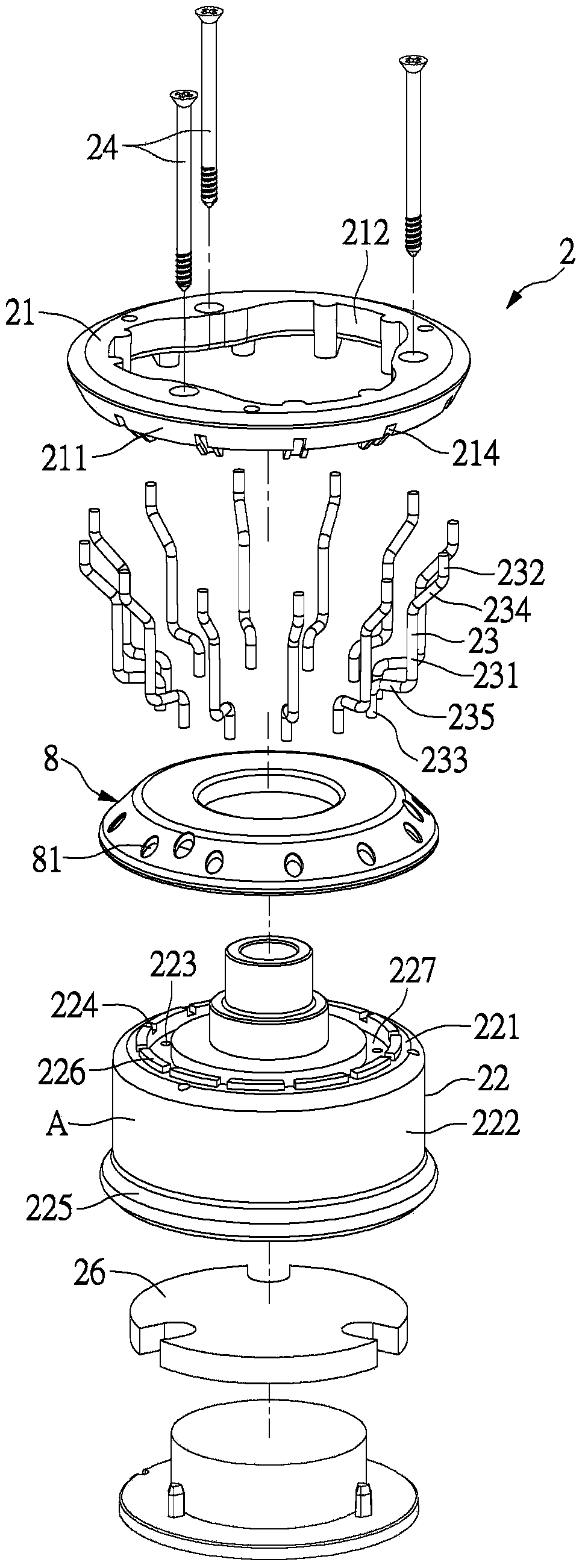

Yarn feeding device, yarn storage wheel of yarn feeding device and assembly method thereof

InactiveCN105420906BThe second jack is exposedWill not be exposedCrochetingWeft knittingYarnMan-hour

The invention discloses a yarn conveying device, a yarn storage wheel of the yarn conveying device and an assembling method of the yarn storage wheel. The yarn storage wheel of the yarn conveying device comprises an upper wheel body, a lower wheel body and multiple yarn storage nails, multiple first insertion holes are formed in the upper wheel body at intervals, the lower wheel body is provided with a top plate and a side wall, the side wall is connected to the outer edge of the top plate and extends downward, a thread winding surface is formed at the outer edge of the side wall, multiple second insertion holes are formed in the top plate at intervals, each yarn storage nail is provided with a rod body, an upper end portion and a lower end portion, the upper end portion of each yarn storage nail is arranged in the corresponding first insertion hole of the upper wheel body in an inserted mode, and the lower end portion of each yarn storage nail is arranged in the corresponding second insertion hole of the lower wheel body in an inserted mode. By means of the yarn conveying device, the yarn storage wheel of the yarn conveying device and the assembling method of the yarn storage wheel, trouble in the production inspection process can be omitted, so that man-hours are saved, and production cost is lowered.

Owner:TIEN YANG KNITTING MACHINERY

Construction waste treatment device with dust diffusion prevention function

PendingCN113522421AImprove classification effectReduce leakageUsing liquid separation agentDirt cleaningRefuse DisposalsWater tanks

The invention discloses a construction waste treatment device with a dust diffusion prevention function, and belongs to the technical field of construction waste treatment equipment. The construction waste treatment device comprises a shell, a crushing box and a water tank, wherein the crushing box is fixedly installed on the upper surface of the shell and communicated with the shell, two crushing rollers are rotationally connected into the crushing box, and one end of each crushing roller penetrates through the front face of the crushing box and is fixedly connected with a gear. According to the construction waste treatment device, a first sliding block and a connecting rod are arranged, the first sliding block can drive one end of the connecting rod to move when moving left and right, the other end of the connecting rod can drive a collecting box to shake up and down, and therefore waste in the collecting box can be screened; and impurities small in size can fall off the collecting box through the arrangement of leakage holes, so that waste classification is realized; and through the arrangement of a stirring plate, when the stirring plate moves leftwards and rightwards, the waste in the collecting box can be driven to shake, so that the position of the waste can be continuously changed, and the waste classification effect is improved.

Owner:袁安友

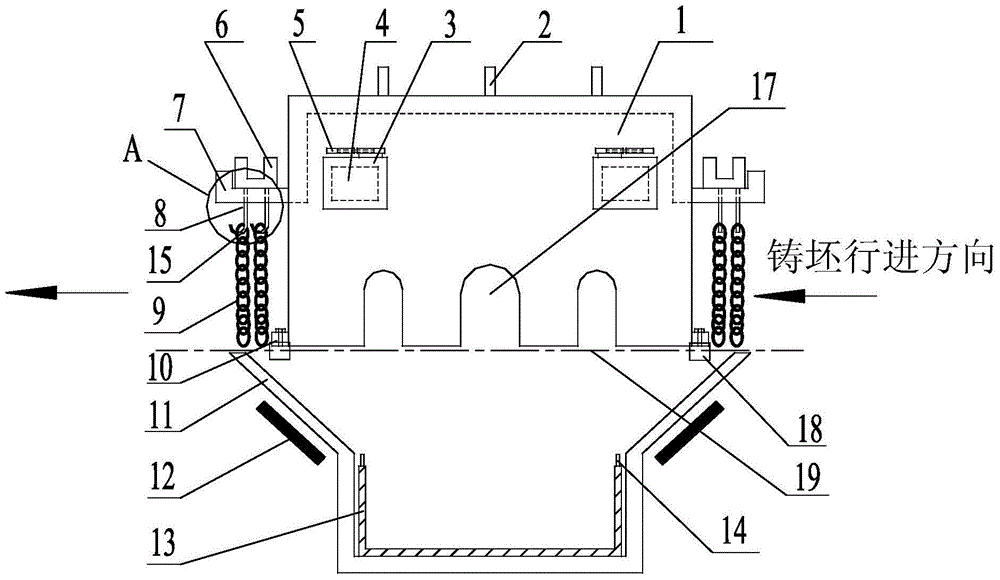

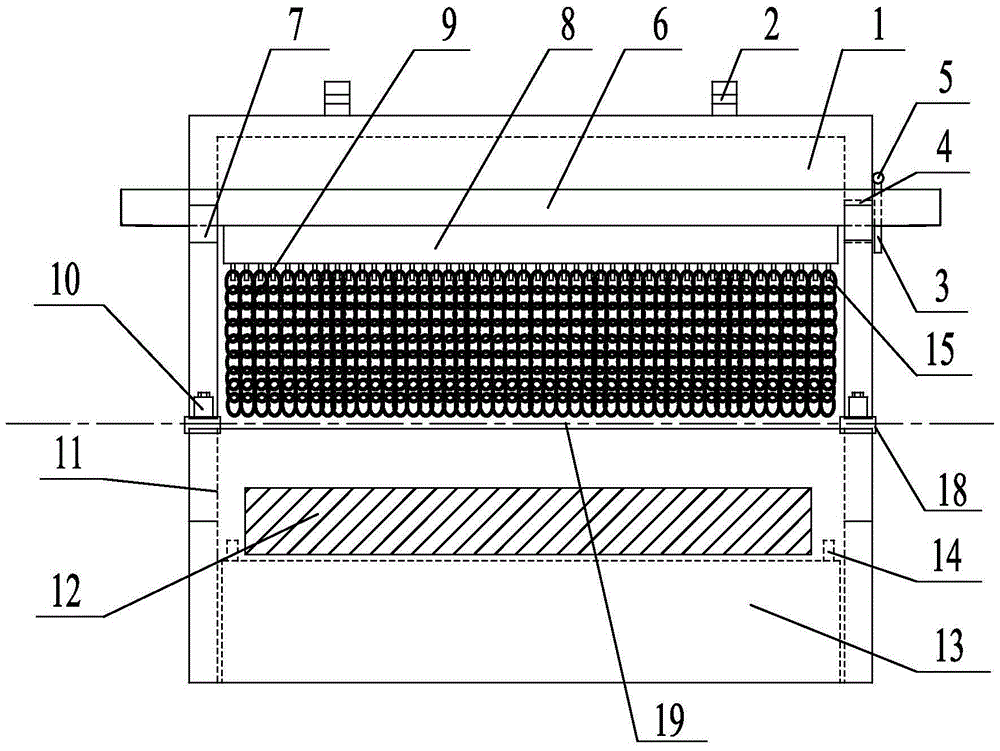

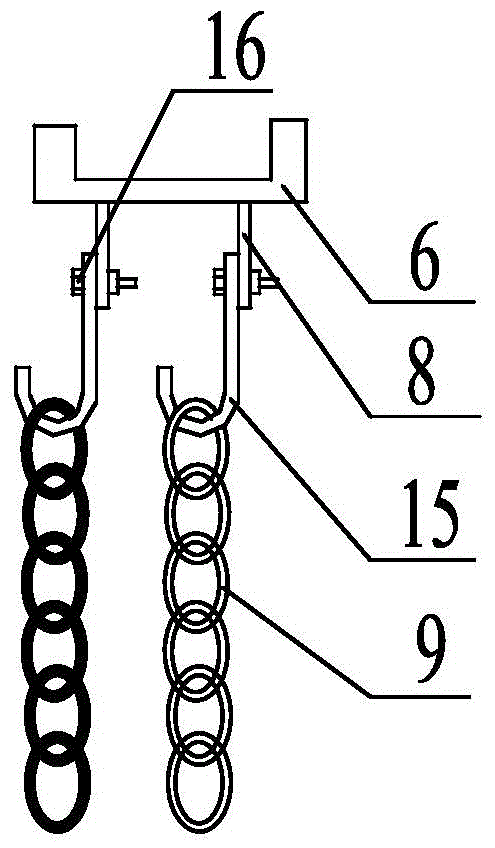

Deburring machine dust cover

The invention discloses a dustproof cover of a deburring machine. The dustproof cover comprises a protection cover with an opening in the bottom. The protection cover is fixed to foundations through positioning bases. Supporting frames are fixed to the two sides of the casting blank input end of the protection cover and the two sides of the casting blank output end of the protection cover respectively. A U-shaped rod is placed on the supporting frames on the two sides of the casting blank input end of the protection cover. A U-shaped rod is placed on the supporting frames on the two sides of the casting blank output end of the protection cover as well. A plurality of hanging chains are arranged at the bottom end of each U-shaped rod. A diversion tank is arranged below the protection cover and is located below a casting blank roll gang. Electromagnetic plates are arranged on the side walls of the diversion tank. A hopper is arranged at the bottom of the diversion tank. Installation holes matched with a roll of the casting blank roll gang are formed in the bottoms of the two sides of the protection cover. A closed area is formed in the slab deburring area through the protection cover and other devices, multiple layers of whole curtains are composed of hooks and hanging chains, and collision caused to the protection cover after casting blanks deform is avoided.

Owner:武汉钢铁有限公司

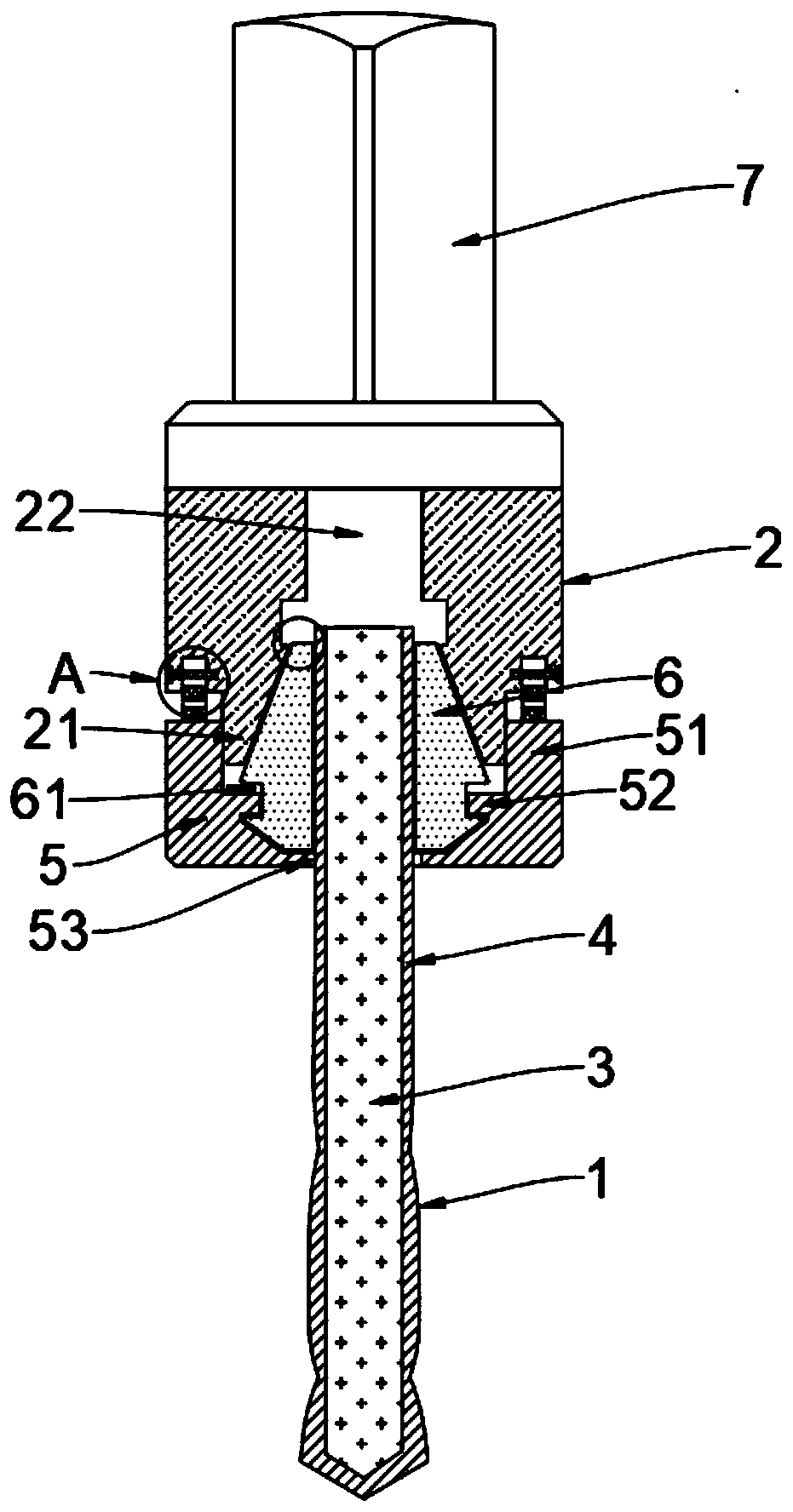

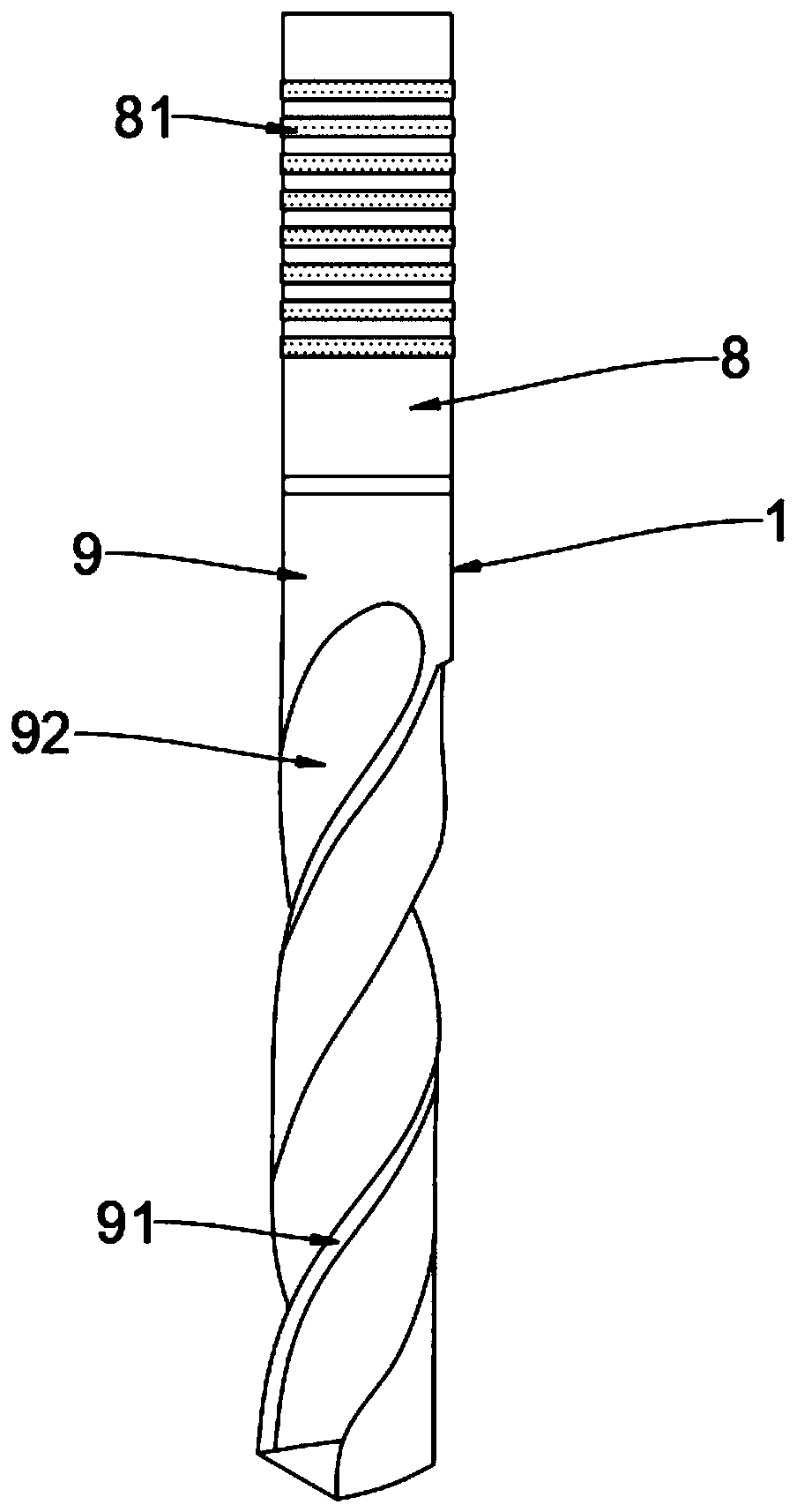

High-strength welding hard industrial cutter

InactiveCN110202186AImprove bindingHigh strengthTransportation and packagingWorkpiecesAlloyEngineering

The invention discloses a high-strength welding hard industrial cutter, relates to the technical field of hard industrial cutters, and solves the problems of easy fall and collapse of the cutter caused by easy reduction of the bonding degree between hard alloys and a tool bit main body due to multi-place welding of only welding the hard alloys on a tool point of the cutter and two sides of a cutting part in a three-piece welding method generally adopted by a traditional hard industrial cutter. A connecting body is arranged at the lower end of a shank; an empty groove is formed in the shank; amovable groove is formed under the empty groove; fixed grooves are arranged on the two sides of the movable groove; T-shaped thread holes are formed in one sides of the fixed grooves; second thread holes are formed in the other sides of the fixed grooves; a spring chuck is mounted in the movable groove; a locking groove is formed in the spring chuck; a limiting groove is arranged at the external under the spring chuck; a nut sleeve is mounted under the spring chuck; and a tool bit is mounted in the locking groove.

Owner:SUZHOU MAIKAFU IND TECH CO LTD

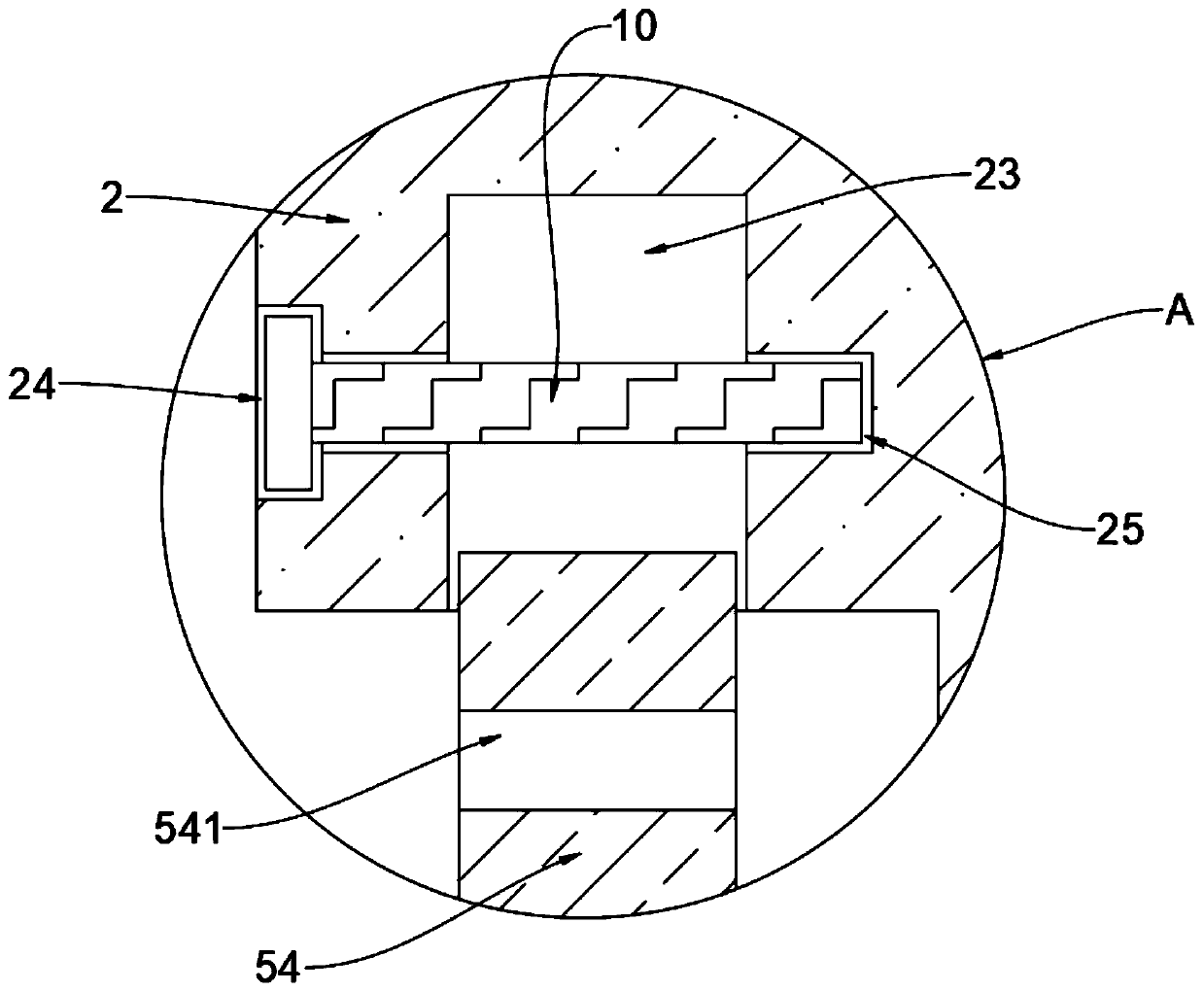

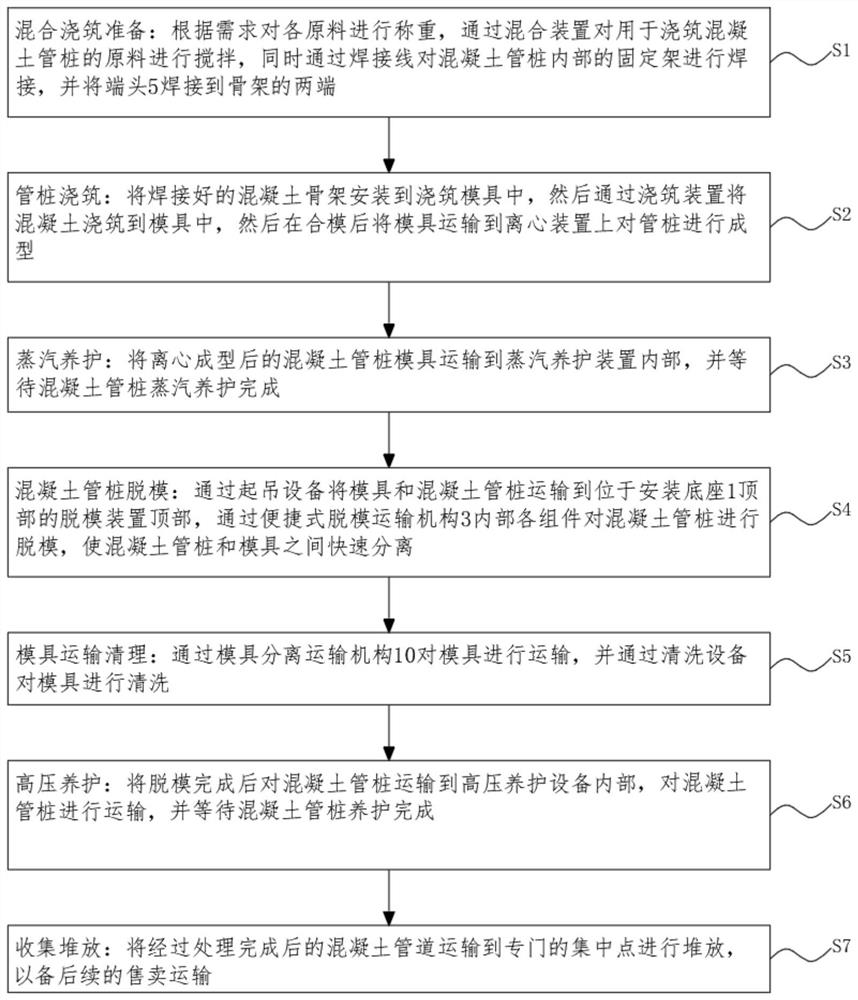

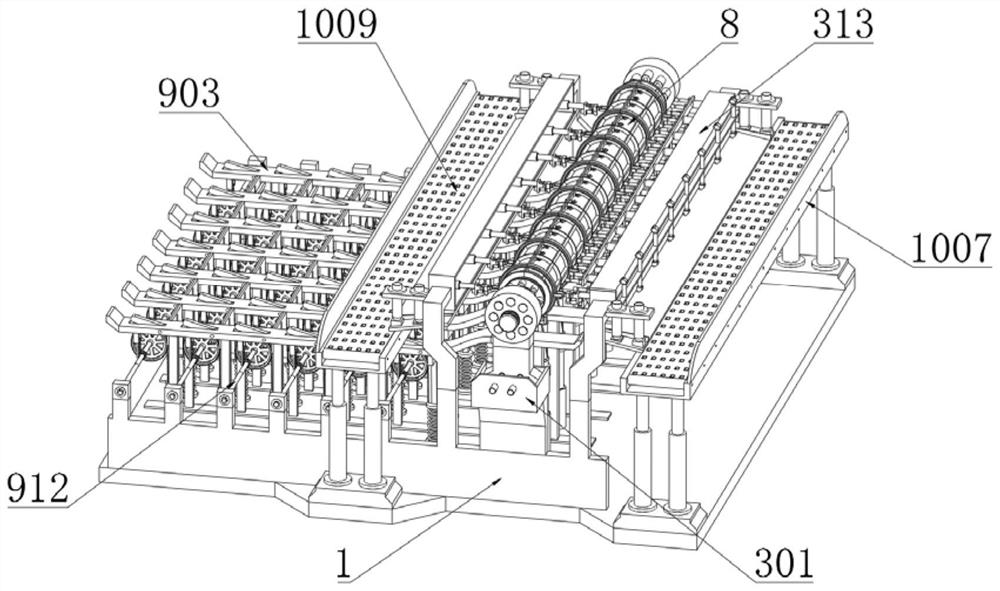

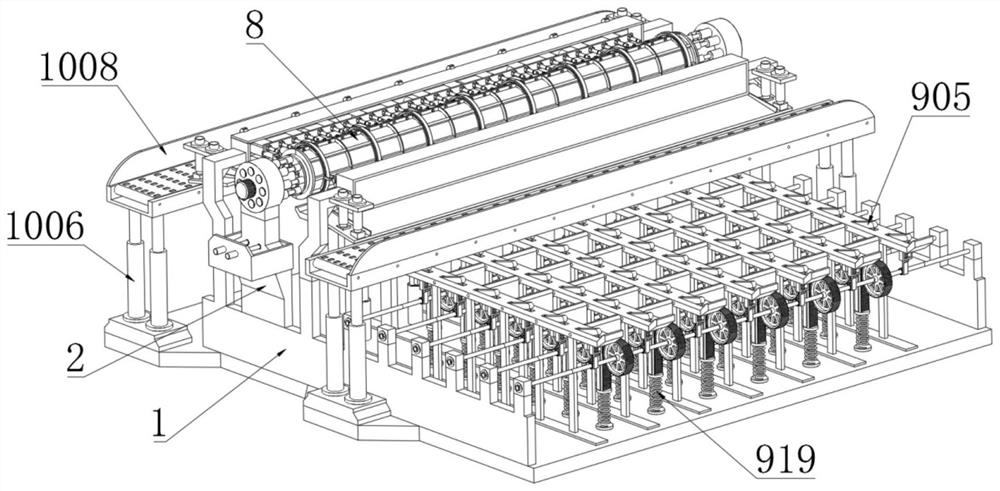

Concrete pipe pile production method facilitating demolding

ActiveCN113183308AScientific and reasonable structureEasy to useShaping reinforcementsAuxillary shaping apparatusArchitectural engineeringStructural engineering

The invention discloses a concrete pipe pile production method facilitating demolding. The concrete pipe pile production method comprises the following steps that S1, mixing and pouring preparation is conducted, specifically, raw materials are weighed according to requirements, the raw materials for pouring a concrete pipe pile are stirred through a mixing device, meanwhile, a fixing frame in the concrete pipe pile is welded through a welding line, and ends are welded to the two ends of a framework; and S2, pipe pile pouring is conducted, specifically, the welded concrete framework is installed in a pouring mold, then concrete is poured into the mold through a pouring device, and after mold closing, the mold is conveyed to a centrifugal device to conduct forming on the pipe pile. Through cooperation of components in a convenient demolding and transporting mechanism, automatic demolding of the concrete pipe pile is achieved, the demolding efficiency of the concrete pipe pile is improved, meanwhile, the whole demolding process of the concrete pipe pile is concentrated in one area, then the transporting process of the mold and the pipe pile in the demolding process is omitted, the demolding process of the pipe pile is quicker and more convenient, and the production efficiency of the pipe pile is improved.

Owner:西安北望建材有限公司

Hook-type commutator

ActiveCN114039255AGuaranteed insulationExtended service lifeRotary current collectorElectric machineryEngineering

The invention discloses a hook-type commutator, which relates to the technical field of motor accessorie. The hook-type commutator comprises an inner sleeve and a plurality of commutator segments, one side, close to the inner sleeve, of each commutator segment is fixedly connected with a clamping block, the peripheral wall of the inner sleeve is fixedly provided with a plurality of clamping grooves, and a separation groove is fixedly arranged between every two adjacent clamping grooves. A cleaning assembly is movably arranged in the separation groove, a through hole is fixedly formed between the separation groove and the clamping groove, a fixing ring is fixedly connected to the lower portion of the inner sleeve, the top of the fixing ring abuts against the bottom of the commutator segment, a clamping sleeve assembly is connected between the outer wall of the clamping block and the inner wall of the clamping groove in an embedded mode, the other end of the clamping sleeve assembly is inserted into the separation groove through the through hole and the other end of theclamping sleeve assembly is located between theseparation groove and the cleaning assembly. The commutator segments are installed stably, carbon powder can be processed in time, the commutator segments are prevented from being conducted by the carbon powder, and the stability of the motor is improved.

Owner:浙江科固电器有限公司

A kind of dustbin for automatic vacuum packing

The invention discloses an automatic vacuum packing dustbin. The automatic vacuum packing dustbin comprises a rectangular plate I, and the upper surface of the rectangular plate I is provided with a clamping device; the clamping device is composed of a rectangular plate II, a rectangular plate III, a guide cylinder I, a lifting column I, a guide cylinder II, a lifting column II, a rectangular frame I and an electric clamping plate, wherein the rectangular plate II is provided with a moving device; the moving device is composed of a rectangular plate IV, a rectangular plate V, a curved plate I,a curved plate II, a semicircular guide rail, a slider and a rectangular frame II; the right of the upper surface of the rectangular plate I is provided with a vacuumizing device, which is composed of a short rectangular plate I, two short rectangular plates II, a short rectangular plate III, a vacuumizing pump and a rectangular funnel. The automatic vacuum packing dustbin has the advantages of being simple in structure and high in practicality.

Owner:王新期

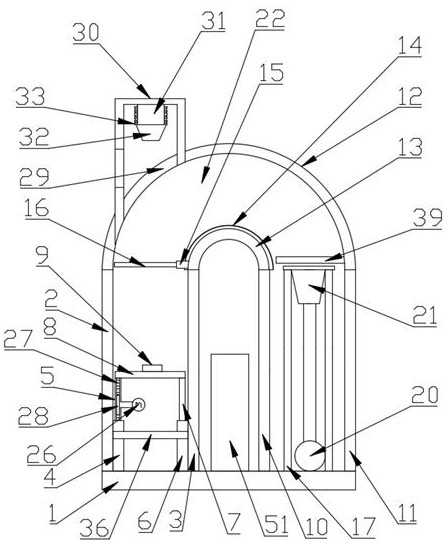

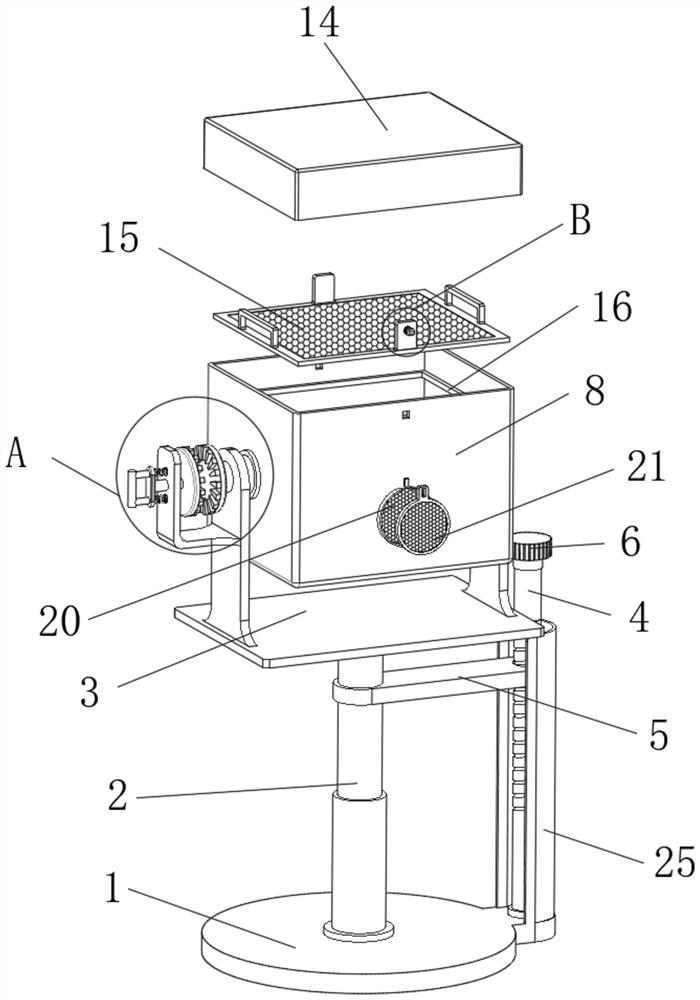

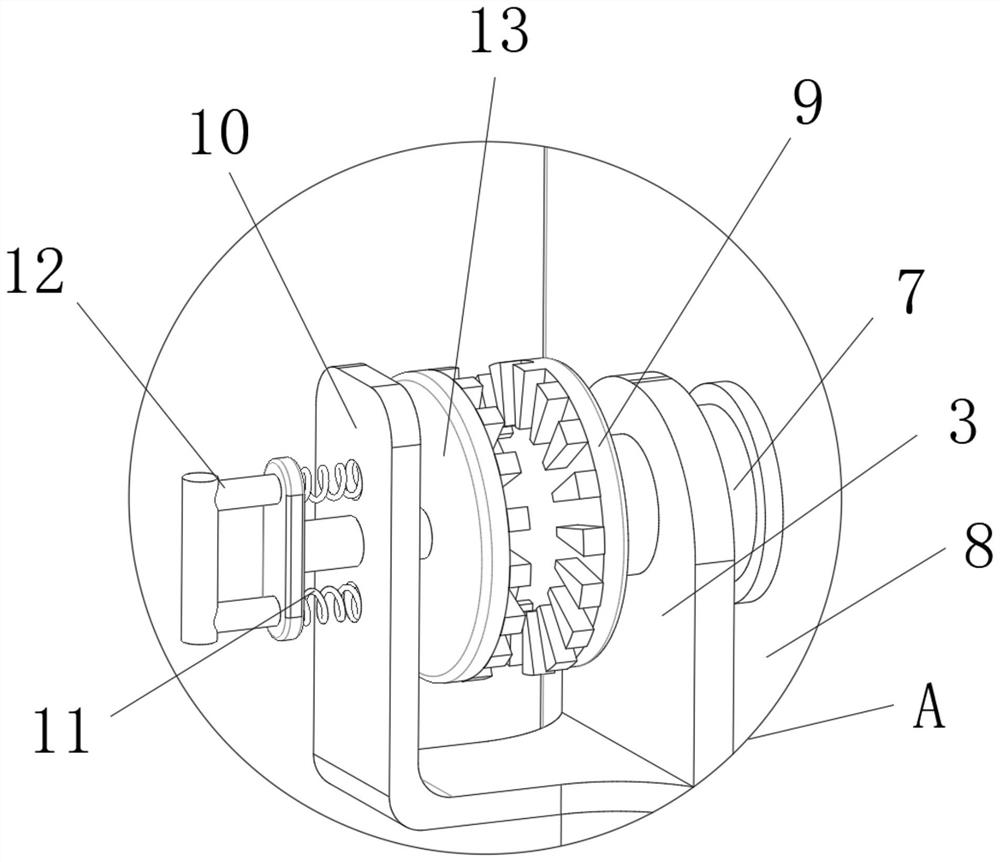

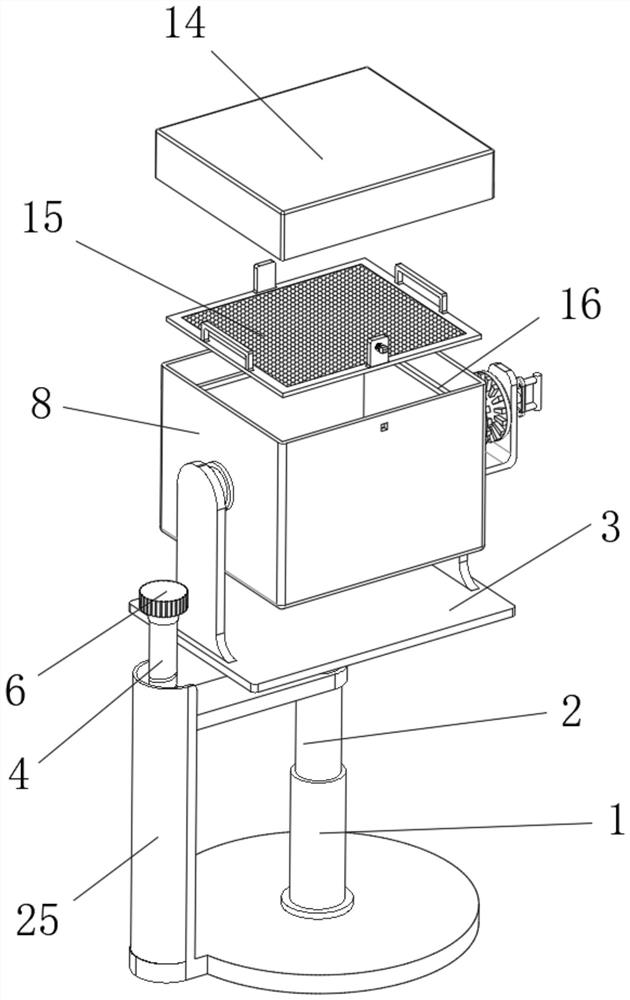

Fly catcher

PendingCN109315369ASimple structureImprove capture efficiencyInsect catchers and killersTrappingEngineering

The invention discloses a fly catcher, and relates to the technical field of fly catching. The fly catcher comprises a base, a body and a cover body. The base is provided with a first box and a secondbox annularly arrayed at the periphery of the first box; a first cavity is formed inside the body, and a trapping device is annularly arrayed outside the body; the lower end of the first cavity is matched with the upper end of the first box, and the lower end of the trapping device is matched with the upper end of the second box; the trapping device comprises a first trapping cavity and a secondtrapping cavity, a first trapping opening is formed in the bottom of the first trapping cavity, and the first trapping opening is formed in the outer side of the second box; the second trapping cavityis formed in the upper end of the first trapping cavity, and the second trapping cavity is provided with a second trapping opening and a third trapping opening; the second trapping cavity and the first trapping cavity are communicated through the second trapping opening, and the second trapping cavity and the first cavity are communicated through the third trapping opening. The fly catcher is simple and effective in structure, and high in catching efficiency and can sufficiently utilize caught flies to produce food needed by animals.

Owner:李勇军

Bee feeding box facilitating observation of bee state and use method thereof

ActiveCN114831053AImprove practicalityEasy to operateAgriculture and animal husbandary industryBeehivesStructural engineeringMechanical engineering

The invention provides a bee raising box facilitating observation of bee states and a using method thereof, and relates to the technical field of bee raising boxes, the bee raising box comprises a base, a lifting rod is slidably arranged in the base, a frame body is fixedly mounted at the top end of the lifting rod, a threaded rod is rotatably arranged on one side of the base, and a connecting block is rotatably arranged on the surface of the threaded rod; the connecting blocks are fixedly connected with the lifting rods, rotating rods are rotationally arranged between the frame bodies, an acrylic box is fixedly connected between the rotating rods, a fluted disc a is fixedly installed at one end of each rotating rod, and a rectangular block is fixedly installed on one side of each frame body. By arranging the base, the lifting rod, the frame body, the threaded rod, the connecting block, the rotating rod, the acrylic box, a fluted disc a, a rectangular block, a tension spring, a pull rod, a fluted disc b and an upper cover, researchers of different heights can watch the conditions of bees in the acrylic box by adjusting the height and angle of the acrylic box, and the practicability of the acrylic box is improved.

Owner:山西农业大学园艺学院

Automatic vacuum packing dustbin

The invention discloses an automatic vacuum packing dustbin. The automatic vacuum packing dustbin comprises a rectangular plate I, and the upper surface of the rectangular plate I is provided with a clamping device; the clamping device is composed of a rectangular plate II, a rectangular plate III, a guide cylinder I, a lifting column I, a guide cylinder II, a lifting column II, a rectangular frame I and an electric clamping plate, wherein the rectangular plate II is provided with a moving device; the moving device is composed of a rectangular plate IV, a rectangular plate V, a curved plate I,a curved plate II, a semicircular guide rail, a slider and a rectangular frame II; the right of the upper surface of the rectangular plate I is provided with a vacuumizing device, which is composed of a short rectangular plate I, two short rectangular plates II, a short rectangular plate III, a vacuumizing pump and a rectangular funnel. The automatic vacuum packing dustbin has the advantages of being simple in structure and high in practicality.

Owner:王新期

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com