High-strength welding hard industrial cutter

A welding type, high-strength technology, applied in manufacturing tools, drilling tool accessories, metal processing equipment, etc., can solve the problems of tool falling off, collapse, reducing the bonding degree of cemented carbide and tool head body, etc., to improve the tightening The effect of high strength, extended service life, and simple and convenient fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

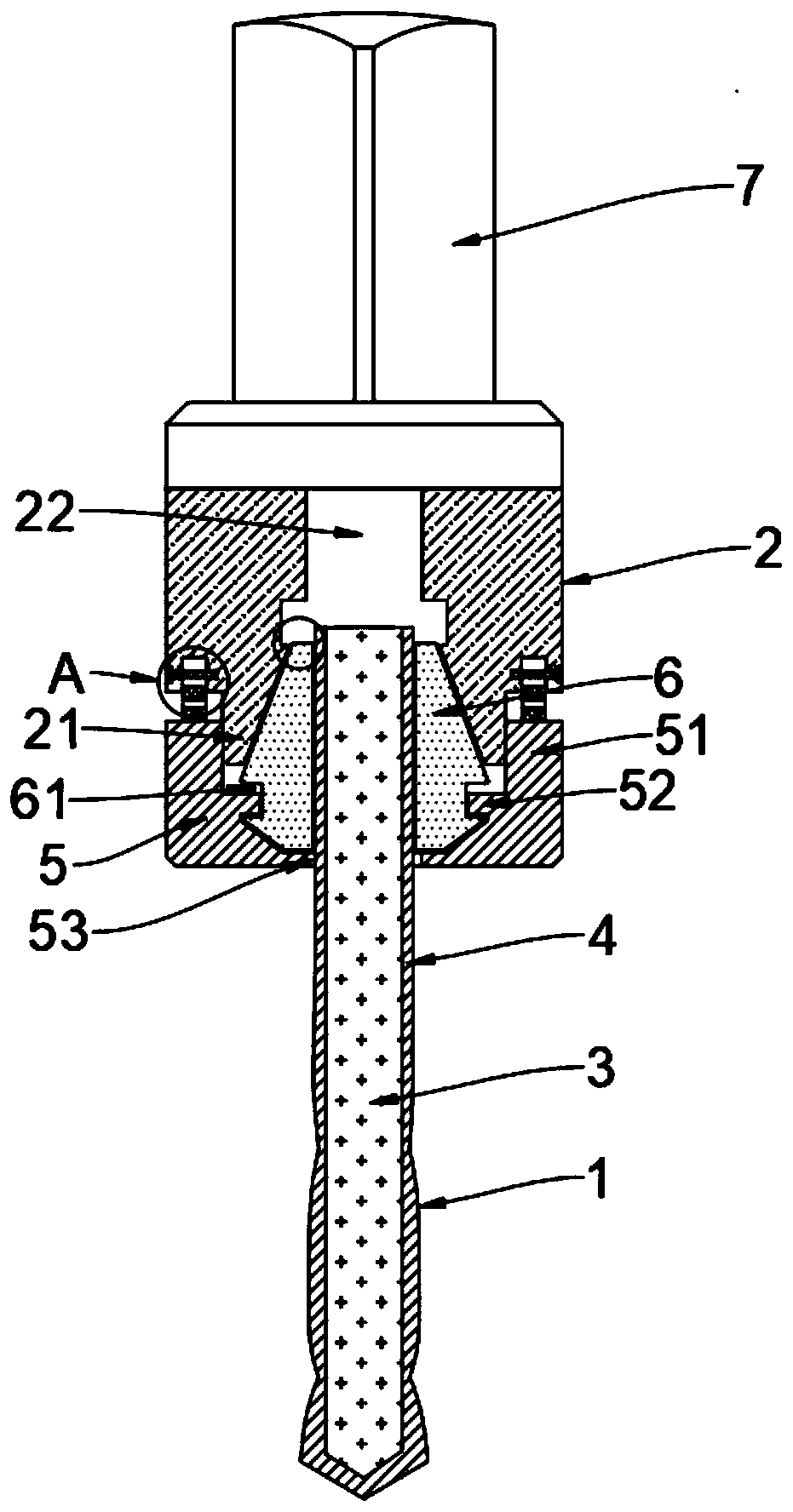

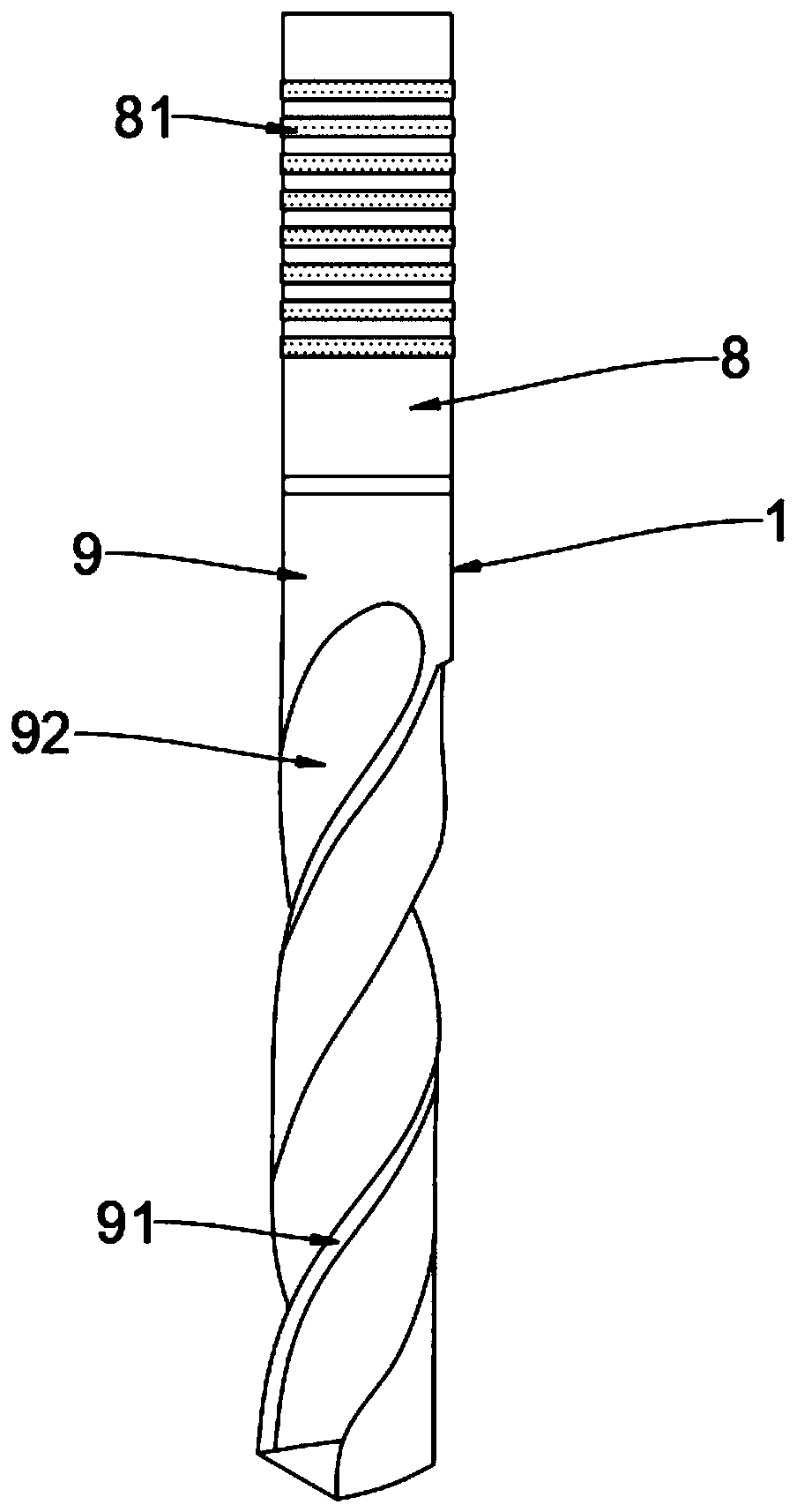

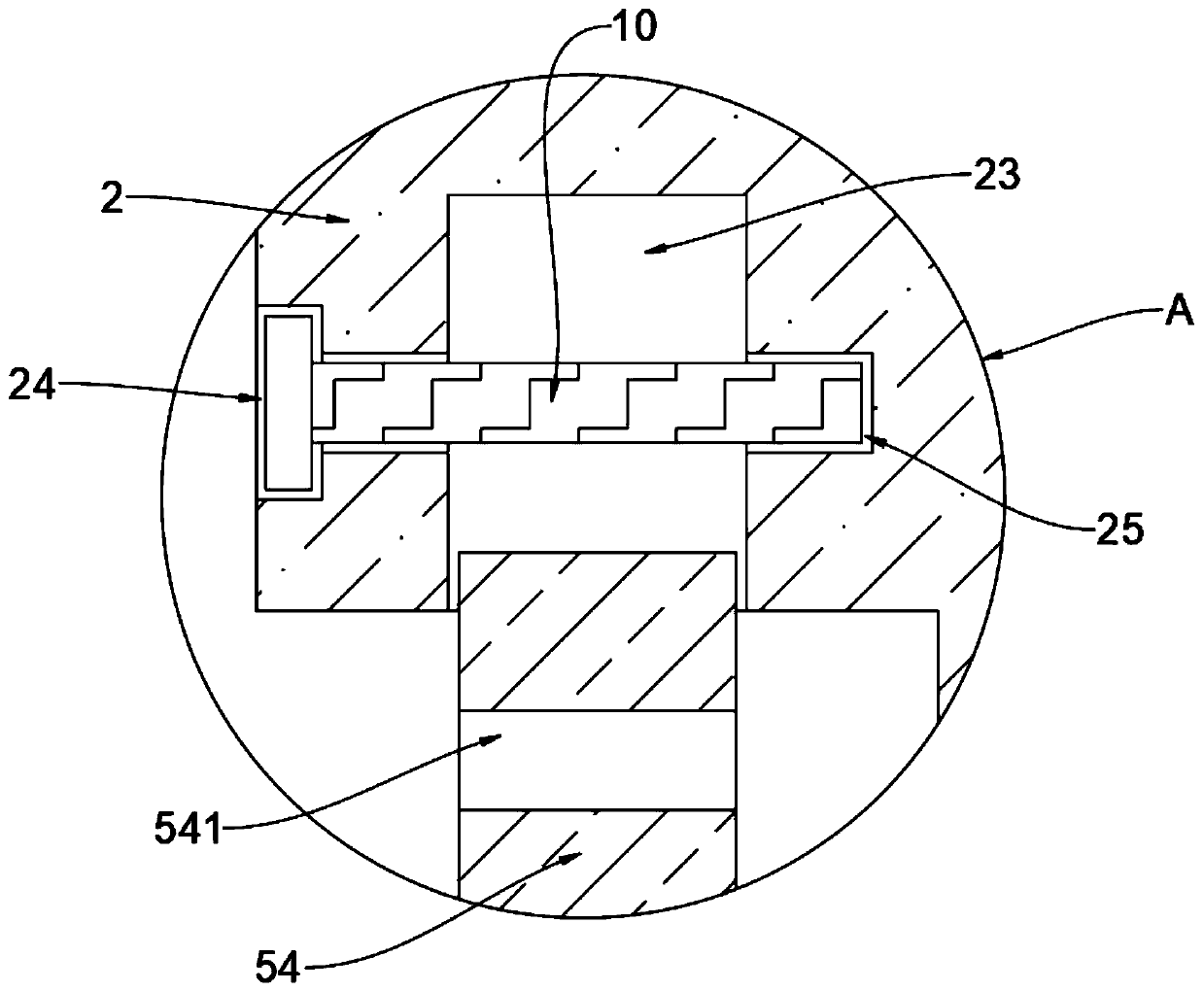

[0021] see Figure 1-4 , an embodiment provided by the present invention: a high-strength welded hard industrial tool, including a handle 2, the lower end of the handle 2 is provided with a connecting body 21, and the outside is provided with threads, and the connecting body 21 and the handle 2 One-piece structure, good integrity, not easy to break, the inside of knife handle 2 is provided with empty groove 22, and the bottom of empty groove 22 is provided with moving groove 26, and the both sides of moving groove 26 is provided with fixing groove 23, and one side of fixing groove 23 One side is provided with a T-shaped threaded hole 24, and the other side of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com