Concentrated transportation device of stem-shaped crop harvesting machine

A collection and transportation, rod-shaped technology, applied in the field of collection and transportation devices of rod-shaped crop harvesters, can solve the problems that crops are easy to fly out of the bucket, easy to hit the suspension, and the hanging bucket is easy to bring down the crops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, introduce rod-shaped crop collecting and transporting device of the present invention (taking the collection of sugarcane as example):

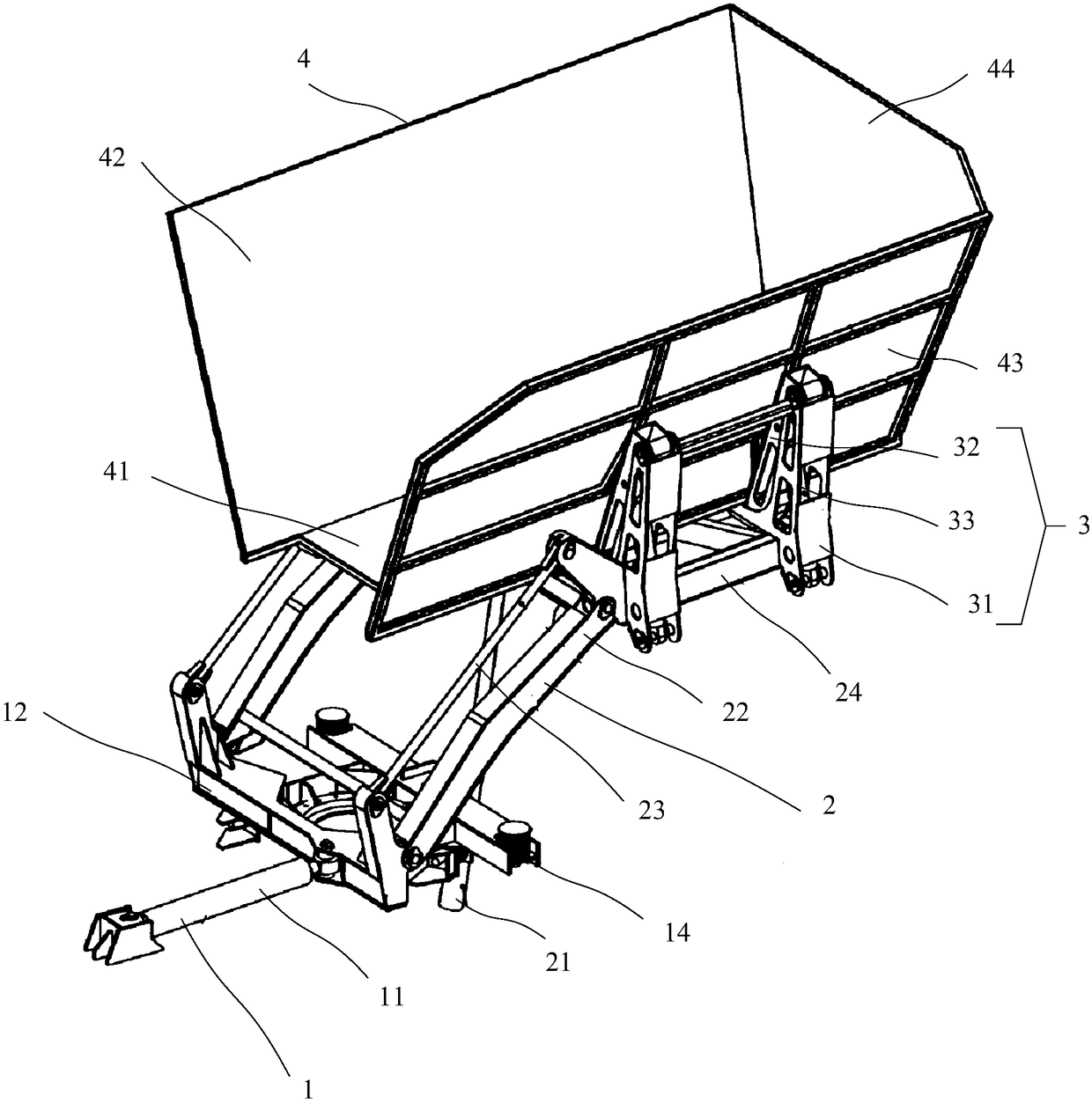

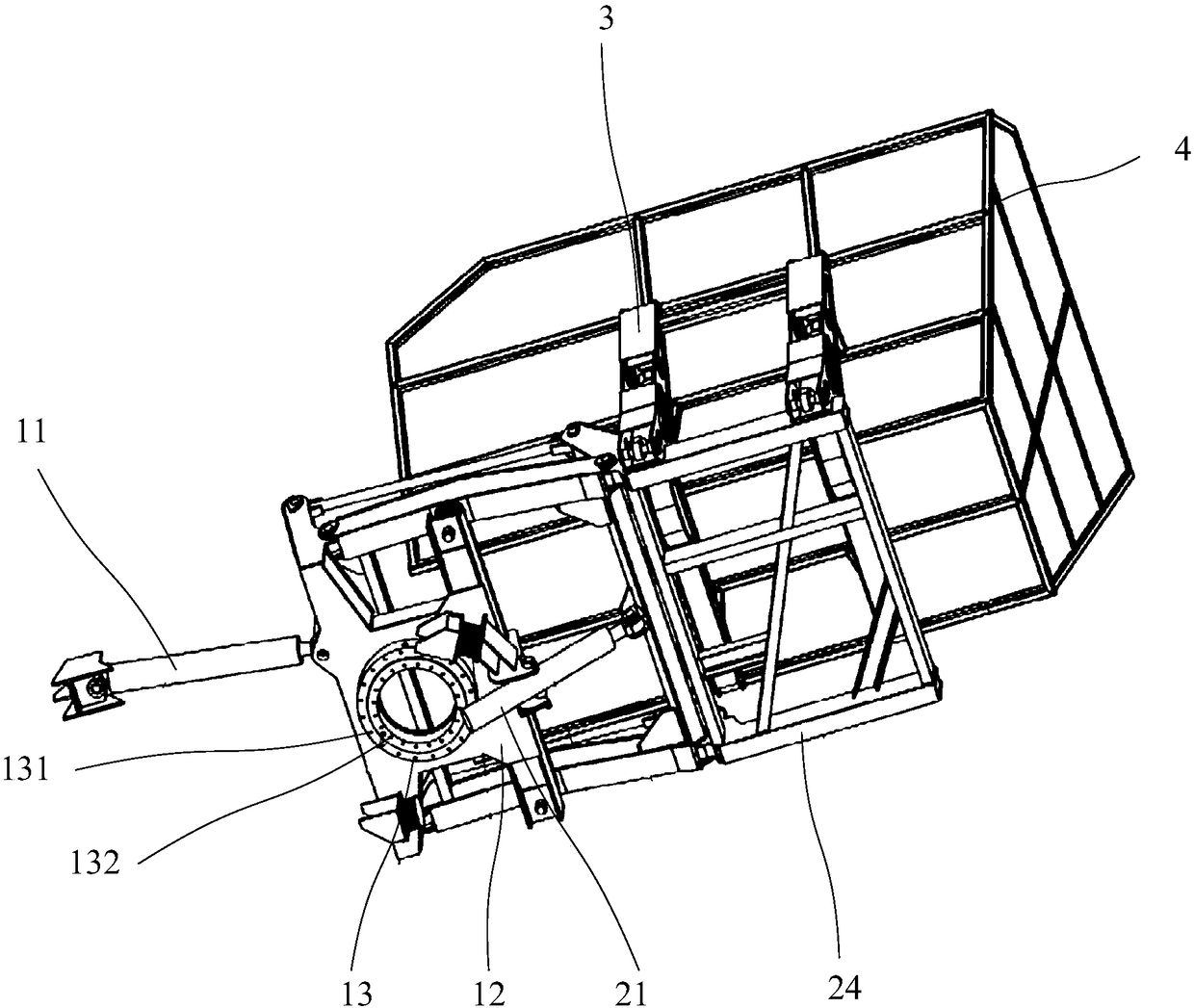

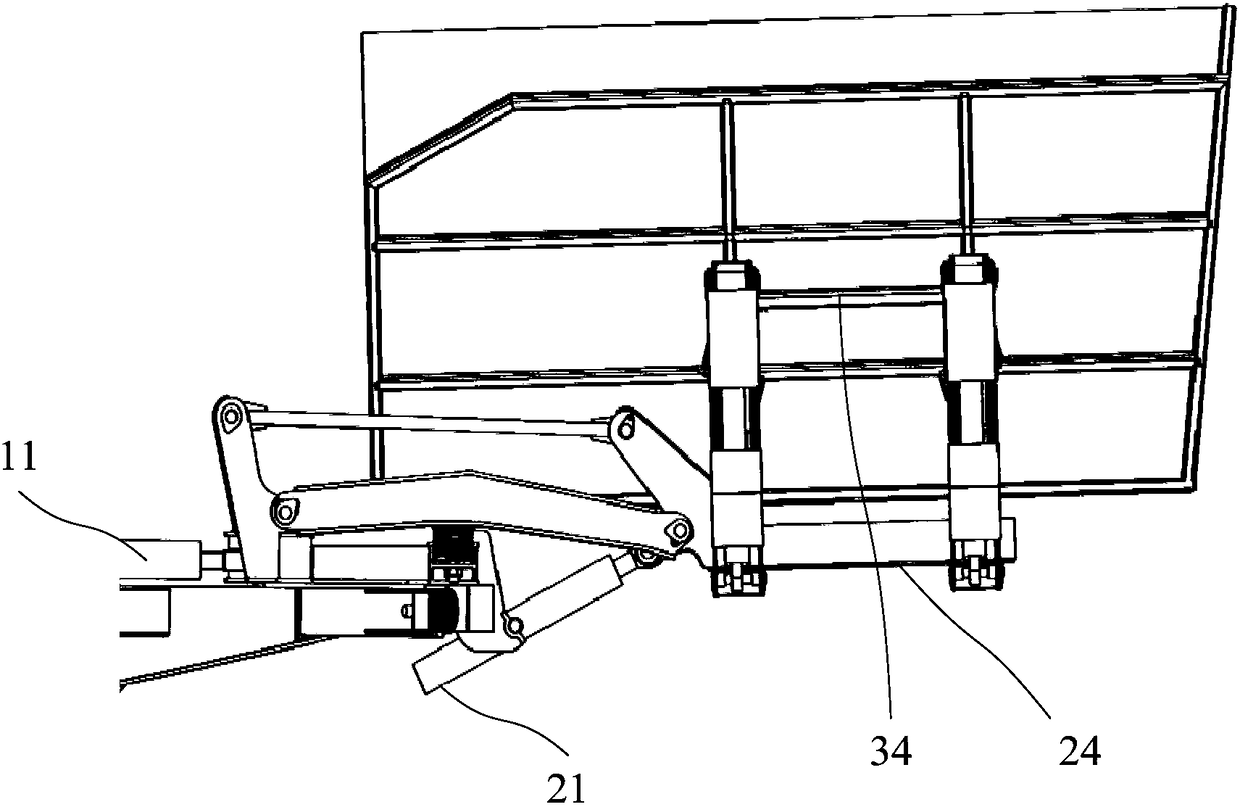

[0015] Such as figure 1 , figure 2 and image 3 As shown, it is a rod-shaped crop gathering device provided by the present invention, which includes a rotary structure 1, a support jacking structure 2, a dump structure 3 and a hopper assembly 4, and the rotary structure 1 and the support jacking structure 2 It is movably connected, the dump structure 3 is connected with the supporting jacking structure 2 , and the hopper assembly 4 is connected with the dump structure 3 .

[0016] The slewing structure 1 includes a slewing drive device 11, a slewing chassis 12, a slewing support structure 13 and a disc spring shock absorber 14, the slewing drive structure 11 is movably connected with the slewing chassis 12, and the disc spring shock The seat 14 is arranged on the rotary chassis 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com