Concrete pipe pile production method facilitating demolding

A technology of concrete pipe piles and production methods, which is applied in the direction of reinforcement molding, ceramic molding machines, manufacturing tools, etc., and can solve the problems of reducing the production efficiency of concrete pipe piles, increasing the labor intensity of operators, and reducing the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

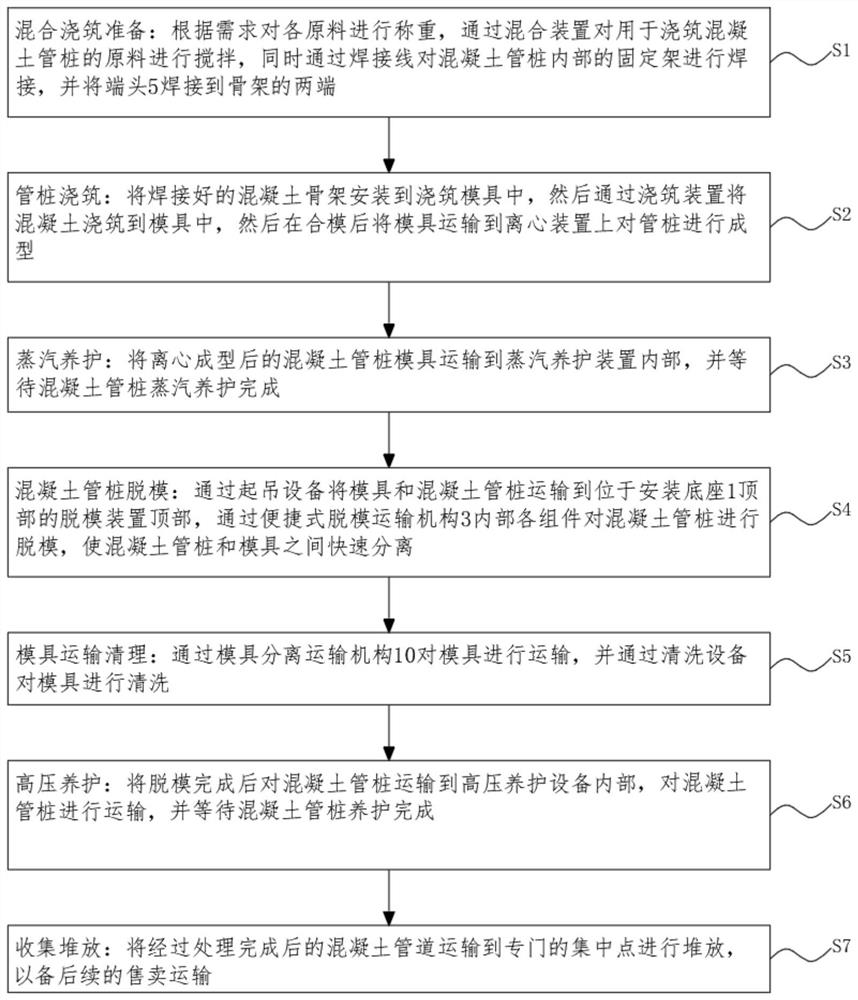

[0051] Example: such as Figure 1-12 As shown, the present invention provides a kind of technical scheme, a kind of concrete pipe pile production method that is convenient to demoulding, it is characterized in that, comprises the following steps;

[0052] S1. Preparation for mixing and pouring: Weigh each raw material according to the requirements, mix the raw materials for pouring concrete pipe piles through the mixing device, and weld the fixing frame inside the concrete pipe piles through the welding line, and connect the ends 5 Welded to both ends of the skeleton;

[0053] S2. Pipe pile pouring: Install the welded concrete skeleton into the pouring mold, then pour concrete into the mold through the pouring device, and then transport the mold to the centrifugal device to form the pipe pile after the mold is closed;

[0054] S3. Steam curing: transport the centrifugally formed concrete pipe pile mold to the interior of the steam curing device, and wait for the steam curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com