Activated carbon feeding dust-free bag breaking system

A technology of activated carbon and package breaking, which is applied in the directions of packaging, transportation and packaging, loading/unloading, etc., and can solve the problems of staff inconvenience and dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

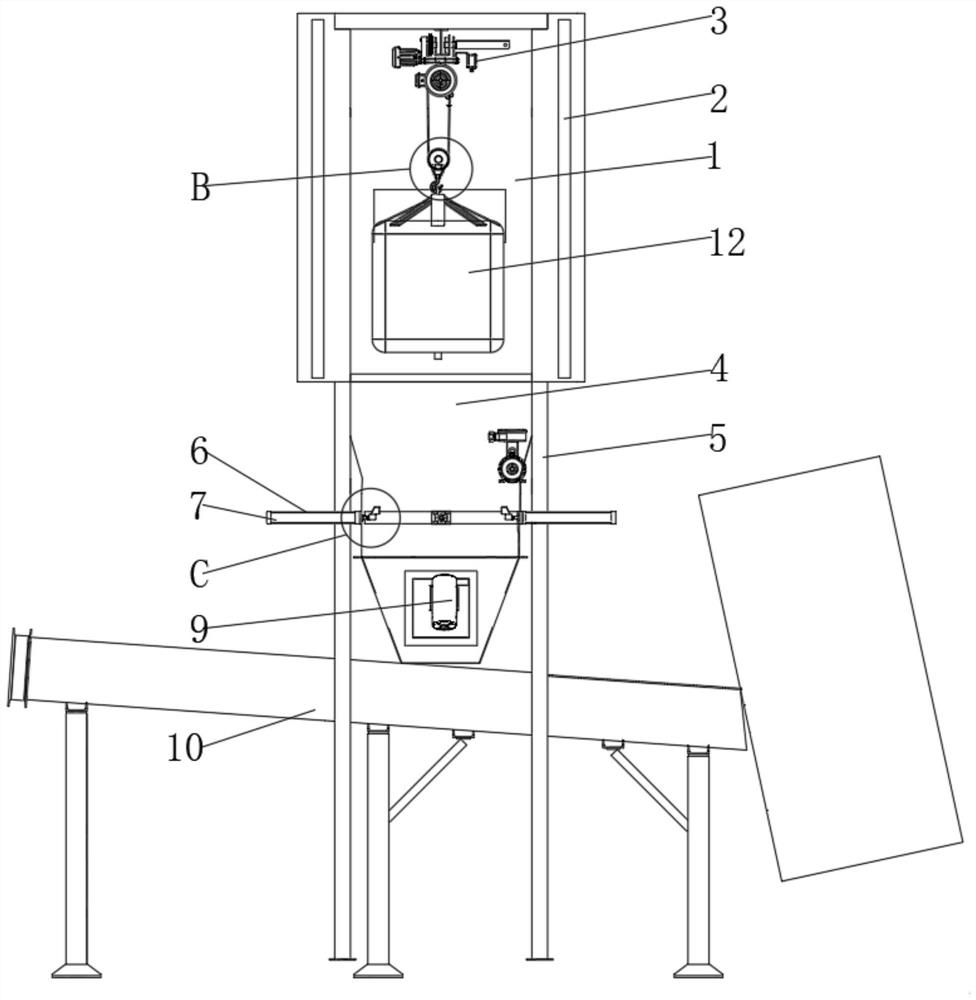

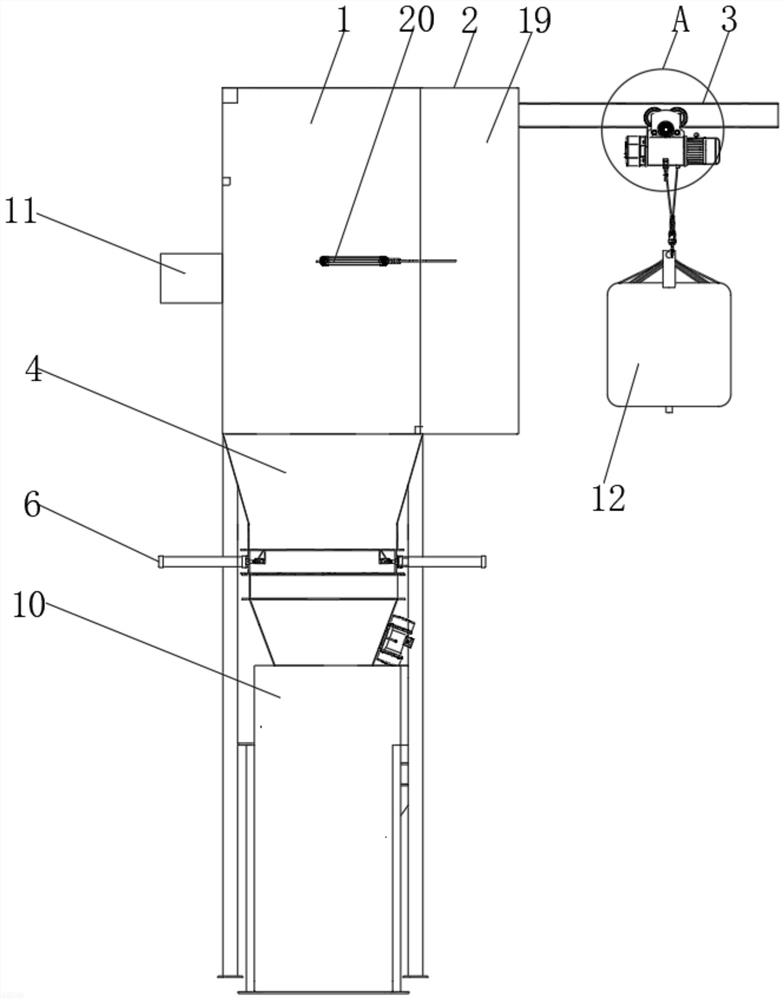

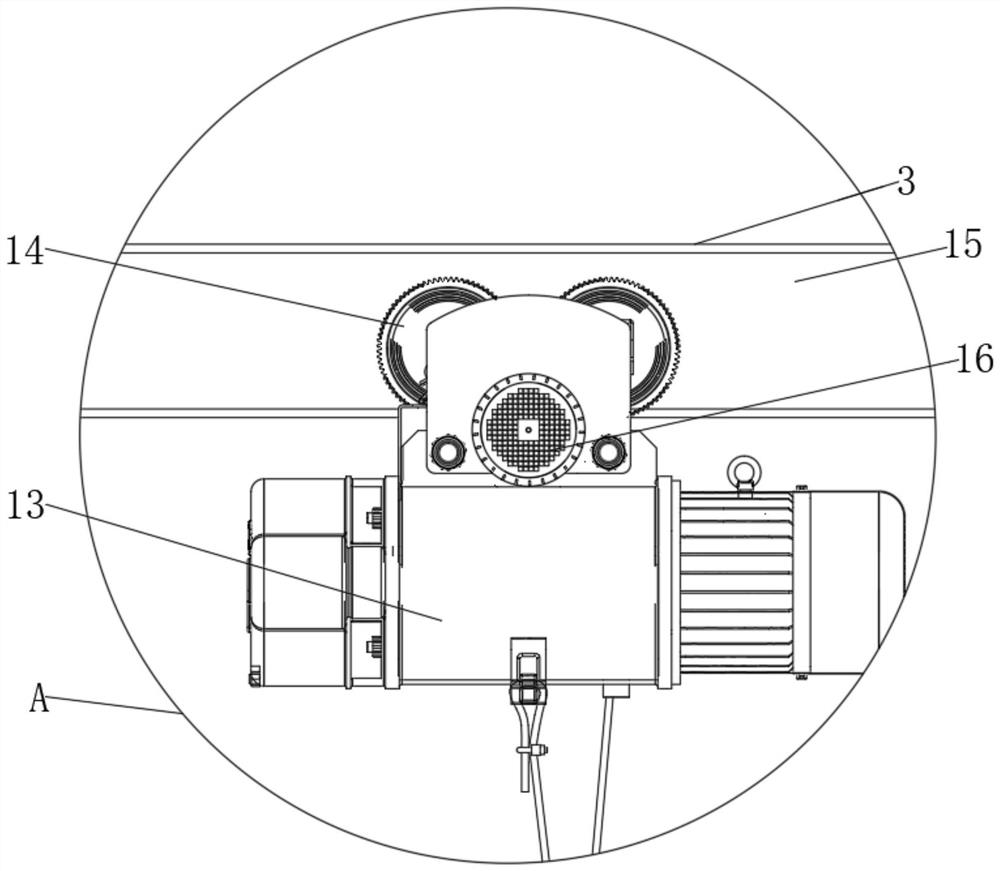

[0022] see Figure 1-5 , the present invention provides a technical solution: a dust-free bag breaking system for activated carbon feeding, including a storage box 1, a support frame 5 is installed at both ends of the bottom of the storage box 1, and an automatic door is installed at one end of the support frame 5. Device 2, a lifting device 3 is installed at the middle position of the front surface of the support frame 5, and the lifting device 3 includes an electric hoist 13, a travel gear 14, a slide rail 15, a motor 16, a pulley 17 and a hook lock 18, wherein the inside of the lifting device 3 Slide rail 15 is installed above, and the rear surface of slide rail 15 extends to the inside of storage box 1, and the two ends of slide rail 15 are equipped with travel gear 14, and the end of travel gear 14 away from slide rail 15 is equipped with motor 16, and motor 16 An electric hoist 13 is installed at the bottom of the electric hoist 13, a pulley 17 is wound around the wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com