Rotor punching of high-speed motor and its design method

A technology of rotor punching and high-speed motor, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. The problem of strip flying out and notch stress increase can achieve the effect of high mechanical strength of notch, reducing design difficulty and excellent electromagnetic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

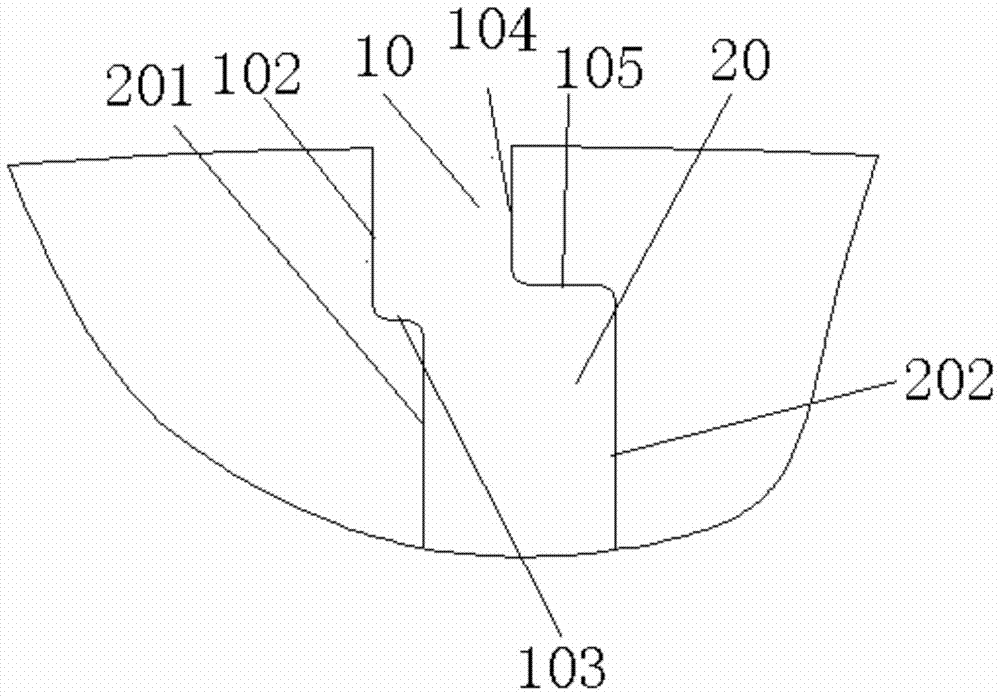

[0024] Such as figure 1 As shown, a rotor punch of a high-speed motor, which includes a body, the body is provided with a plurality of notch structures, the notch structure has a notch 10 and a guide bar groove 20, the guide bar groove 20 One side is provided with a first limiting edge 201, the other side of the guide groove 20 is provided with a second limiting edge 202, one side of the notch 10 has a first notch edge 102, and the notch The other side of 10 has a second notch side 104, the first notch side 102 and the first limiting side 201 and the second notch side 104 and the second limiting side 202 are all in an offset structure, and the first The offset direction between the notch side 102 and the first limiting side 201 is the same as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com