Brushless motor and unmanned aerial vehicle

A technology of brushless motors and connecting shafts, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of voltage deviation or skew, motor swing, propeller rotation instability, etc., to avoid scrapping, avoid motor swing, The effect of rotation stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

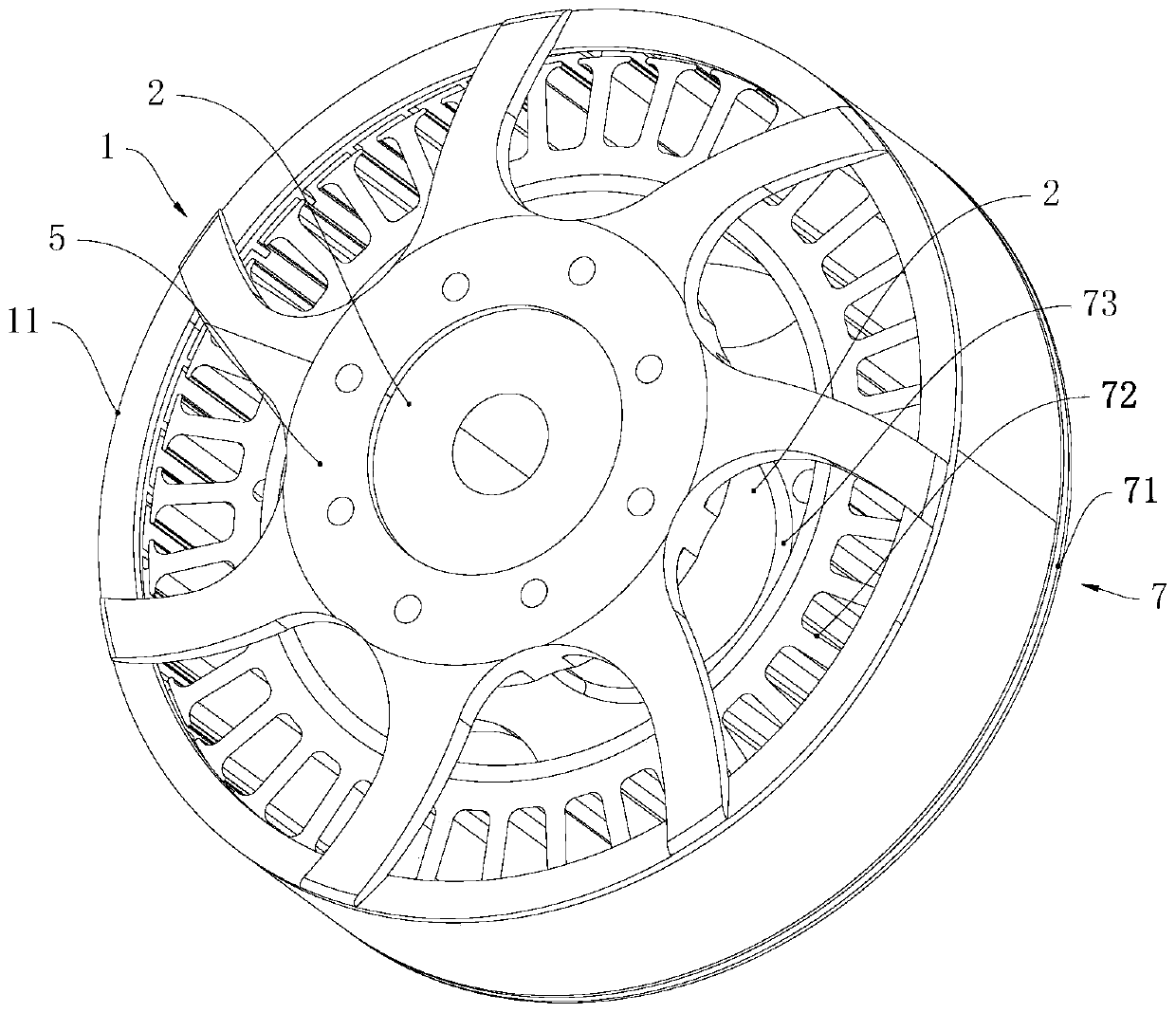

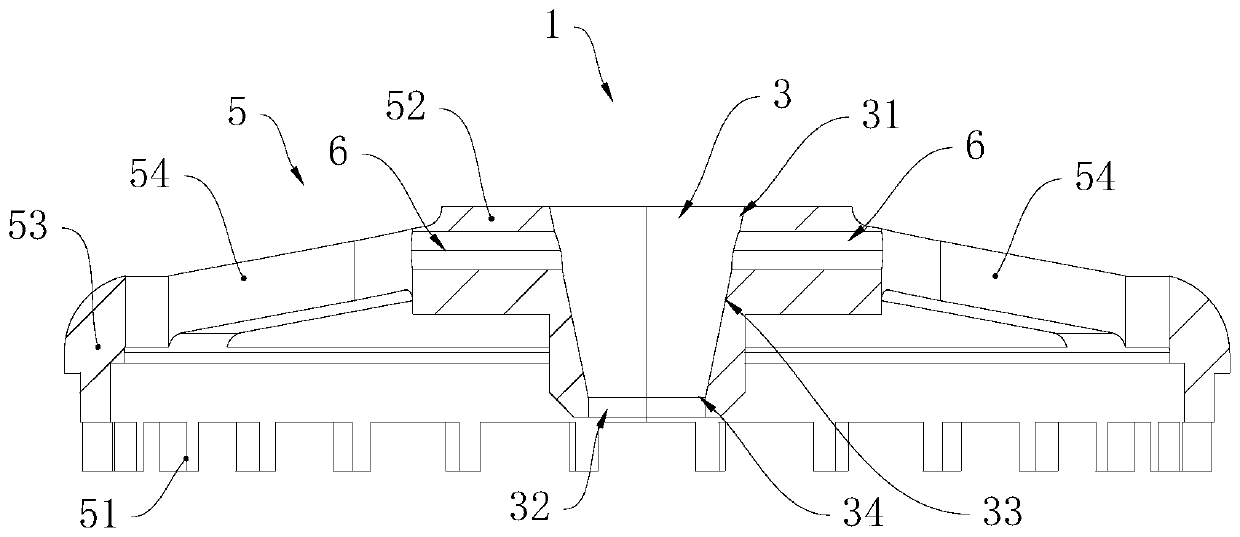

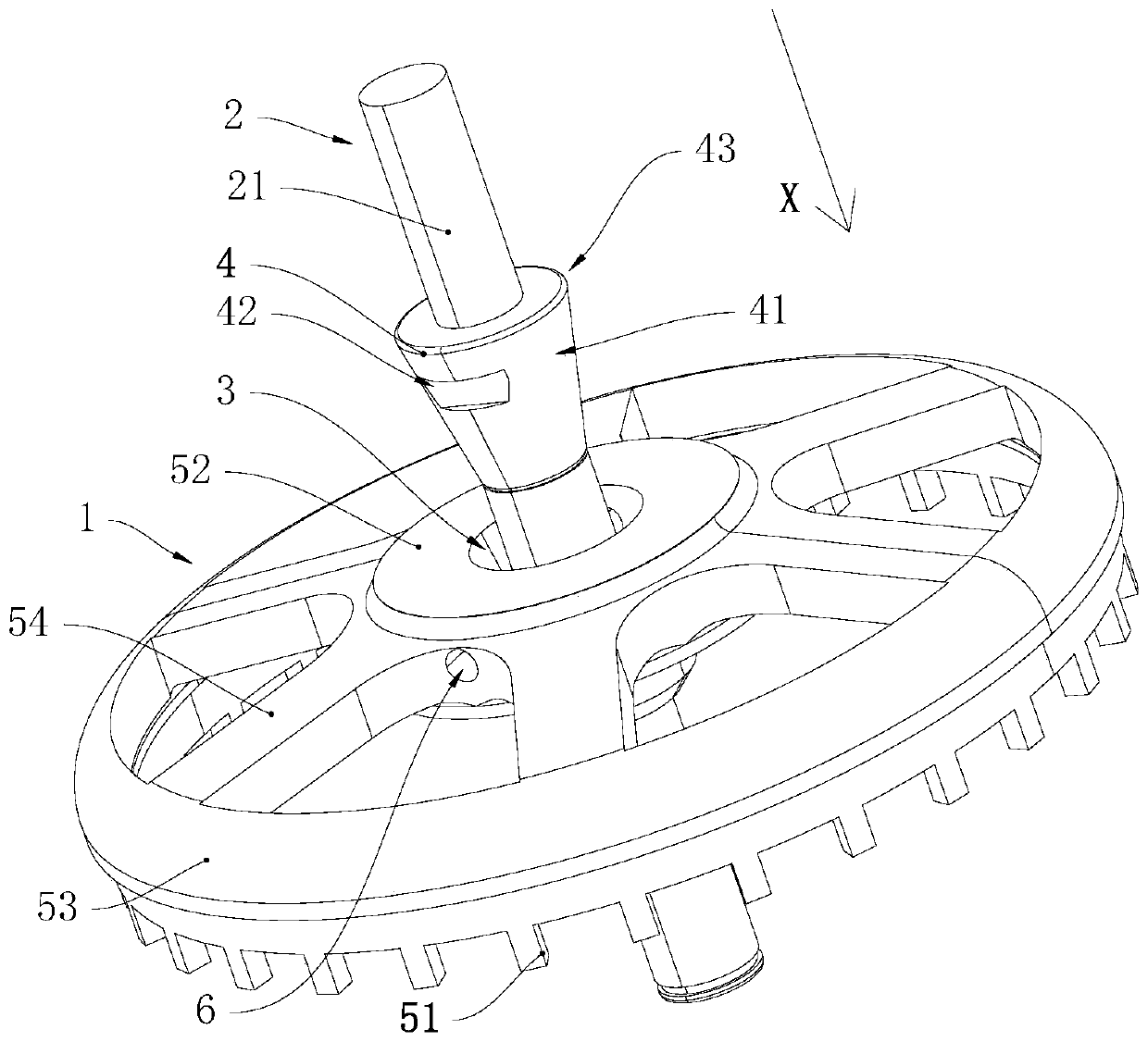

[0030] see figure 1 , The brushless motor includes a stator 7, a rotor 1 and a connecting shaft 2, and the rotor 1 rotates relative to the stator 7. The stator 7 includes a bearing seat 71, a silicon steel sheet 72 and a bearing 73. The bearing seat 71 supports a silicon steel sheet 72, and the bearing seat 71 supports a bearing 73. The silicon steel sheet 72 is provided with a coil; the connecting shaft 2 is arranged in the bearing 73. The rotor 1 includes a back cover 5, a casing 11 and a magnetic sheet. The magnetic sheet is evenly arranged on the inner peripheral wall of the casing 11. The casing 11 is arranged along the edge of the bearing seat 71. The magnetic sheet is arranged on the periphery of the silicon steel sheet 72. The back cover 5 is provided with a plurality of raised strips, and one raised strip is arranged between two adjacent magnetic pieces. In this embodiment, the raised strip is arranged on the side of the back cover 5 facing the stator 7 .

[0031] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com