Screw feeder for steel preparation

A screw feeder, steel technology, applied in conveyor objects, cleaning devices, loading/unloading, etc., can solve the problems of reduced output, smaller pitch of screw blades, slowed output speed of screw feeder, etc. The effect of slowing down the output speed and preventing it from flying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

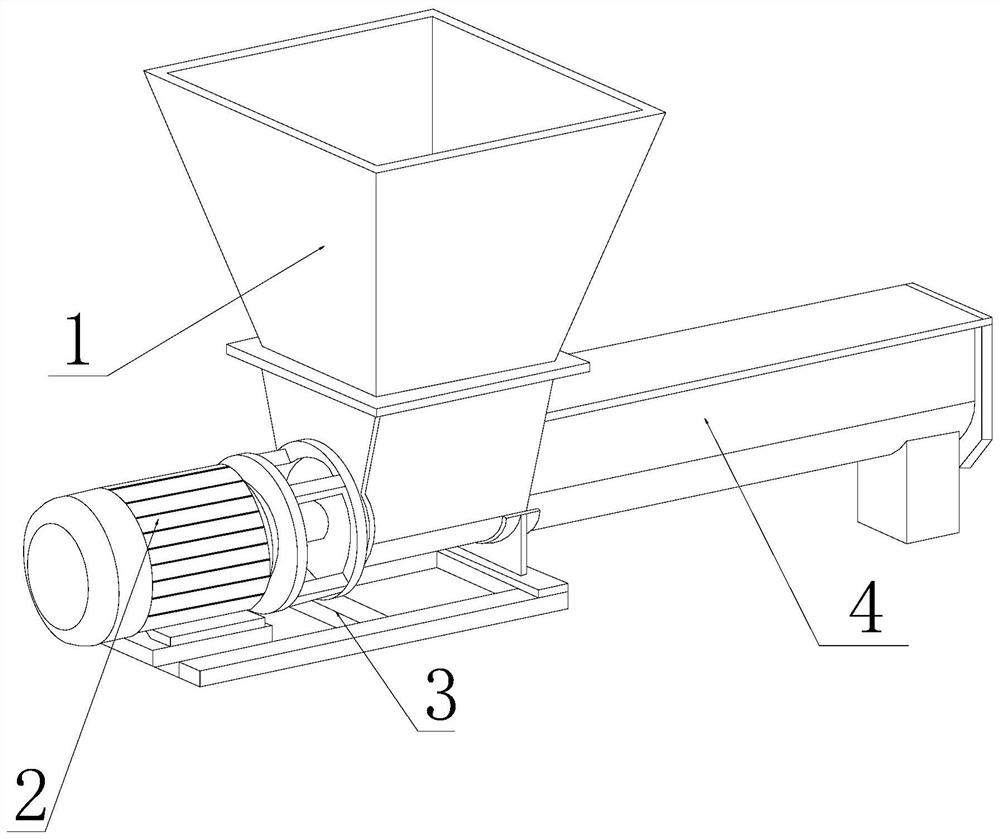

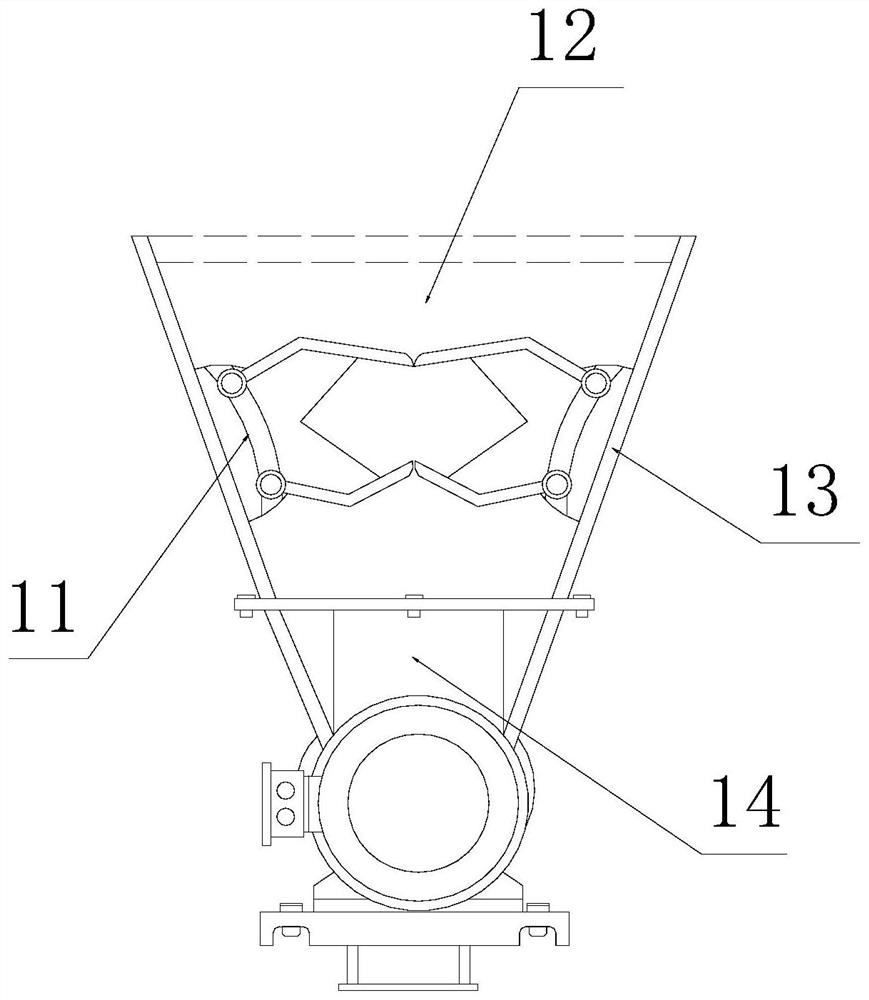

[0030] as attached figure 1 to attach Figure 5 Shown:

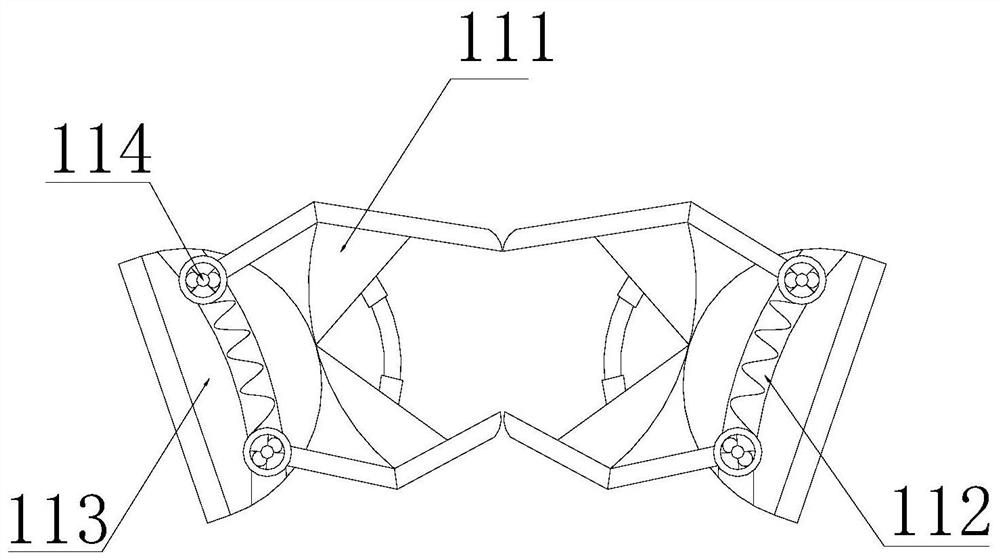

[0031] Its structure includes a lower hopper 1, a driving machine 2, a support platform 3, and a conveying pipe 4. The lower end of the lower hopper 1 is welded to the top of the surface of the conveying pipe 4, and the top of the conveying pipe 4 is fixed to the surface of the driving machine 2 by bolts. The lower end of the driving machine 2 is embedded and connected with the surface of the support platform 3, and the upper end of the support platform 3 is integrally matched with the lower hopper 1. The lower hopper 1 includes a dust-proof baffle 11, a movable cavity 12, an inner hopper wall 13, and a feeding mouth 14, the end of the dust-proof baffle 11 is embedded and connected with the surface of the inner bucket wall 13, the inner side of the inner bucket wall 13 is movably matched with the inside of the movable chamber 12, and the lower end of the movable chamber 12 is in clearance fit with the top end of the mat...

Embodiment 2

[0038] as attached Figure 6 to attach Figure 9 Shown:

[0039] Wherein, the conveying pipe 4 includes a spiral blade 41, a discharge port 42, a conveying cavity wall 43, and a driving rotating rod 44. end and the inner wall of the conveying chamber wall 43 in a clearance fit, the lower surface of the top end of the conveying chamber wall 43 is integrally embedded and connected with the discharge port 42, the surface of the spiral blade 41 is movably matched with the surface of the conveying chamber wall 43, and the center of the spiral blade 41 It is embedded and connected with the surface of the driving rotating rod 44, and its surface is in active cooperation with the surface of the conveying chamber wall 43. Among them, the spiral blade 41 is beneficial to cooperate with the transportation of steel raw materials, and the driving rotating rod 44 drives it to rotate as a whole to reach the top. After that, it is discharged from the discharge port 42.

[0040] Wherein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com