Deburring machine dust cover

A technology of deburring machine and dust cover, which is applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of quality influence of casting billet, unsafe equipment maintenance and environmental pollution, etc., so as to shorten the maintenance period. The effect of working time, avoiding dust leakage, and simple hook replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

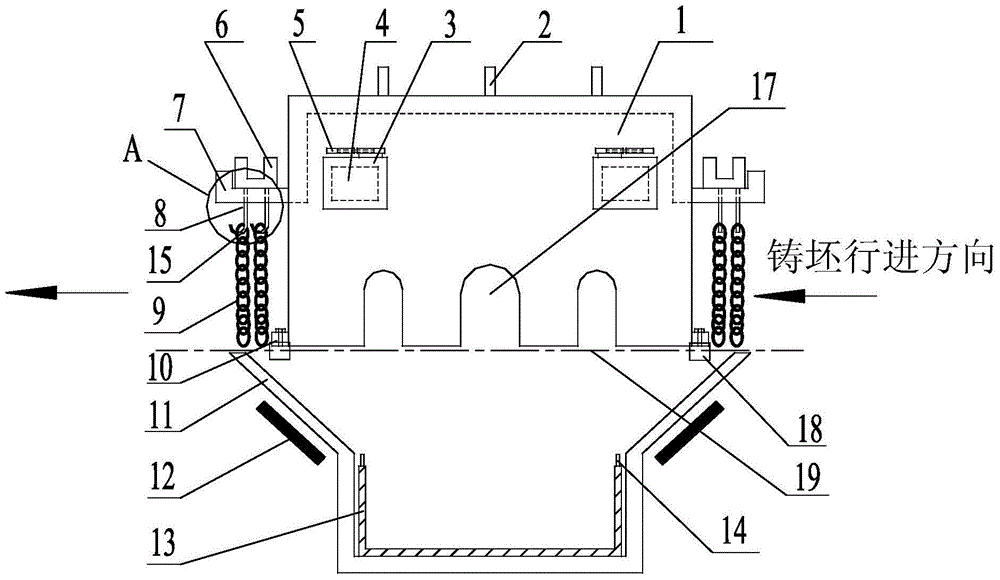

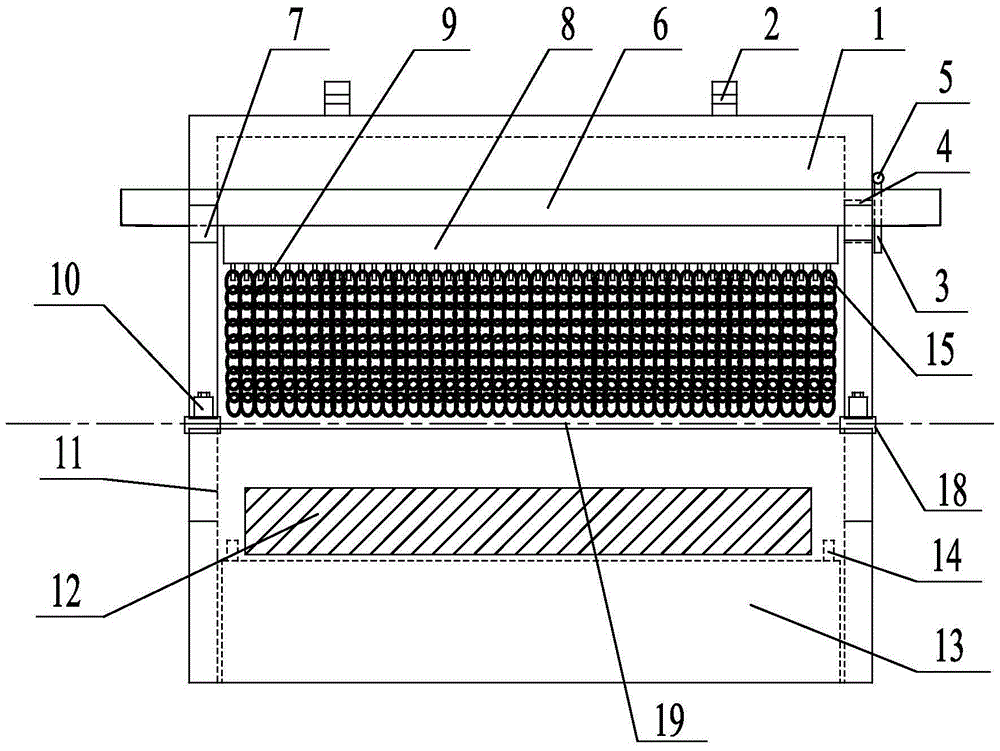

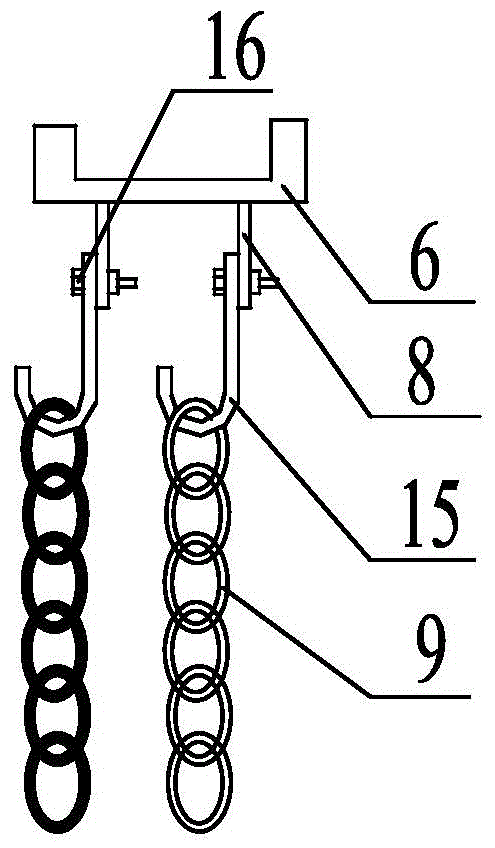

[0032] Such as Figure 1~3 The shown deburring machine dust cover includes a protective cover 1 with an opening at the bottom (the protective cover 1 is composed of five steel plates, and the bottom is in an open state), and the protective cover 1 is fixed on the foundation 18 through a positioning seat 10. Both sides of the slab input end of the protective cover 1 and both sides of the slab output end are fixed with support frames 7, and concave rods 6 are placed on the support frames 7 on both sides of the slab input end of the protective cover 1, and the protective cover 1 Concave rods 6 are also placed on the support frames 7 on both sides of the output end of the slab. The bottom ends of the above two concave rods 6 are provided with a plurality of hanging chains 9, and a diversion groove is provided under the protective cover 1. 11 (a div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com