Patents

Literature

33results about How to "Automatic sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

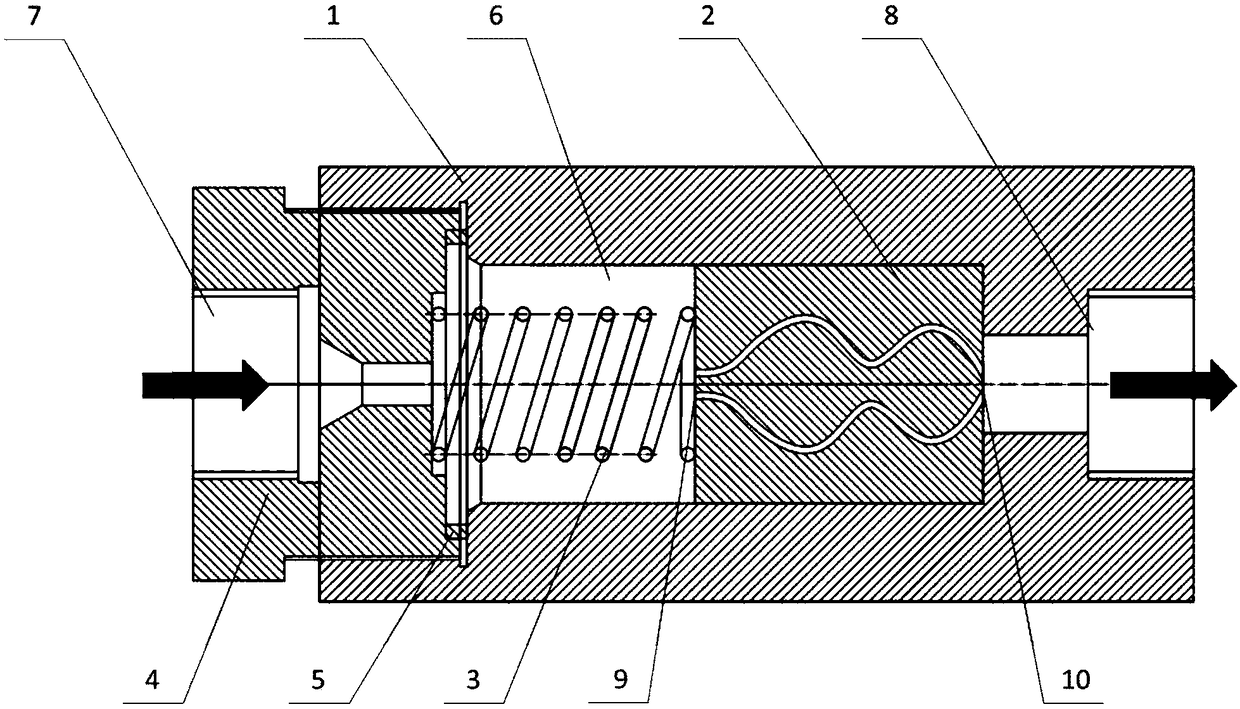

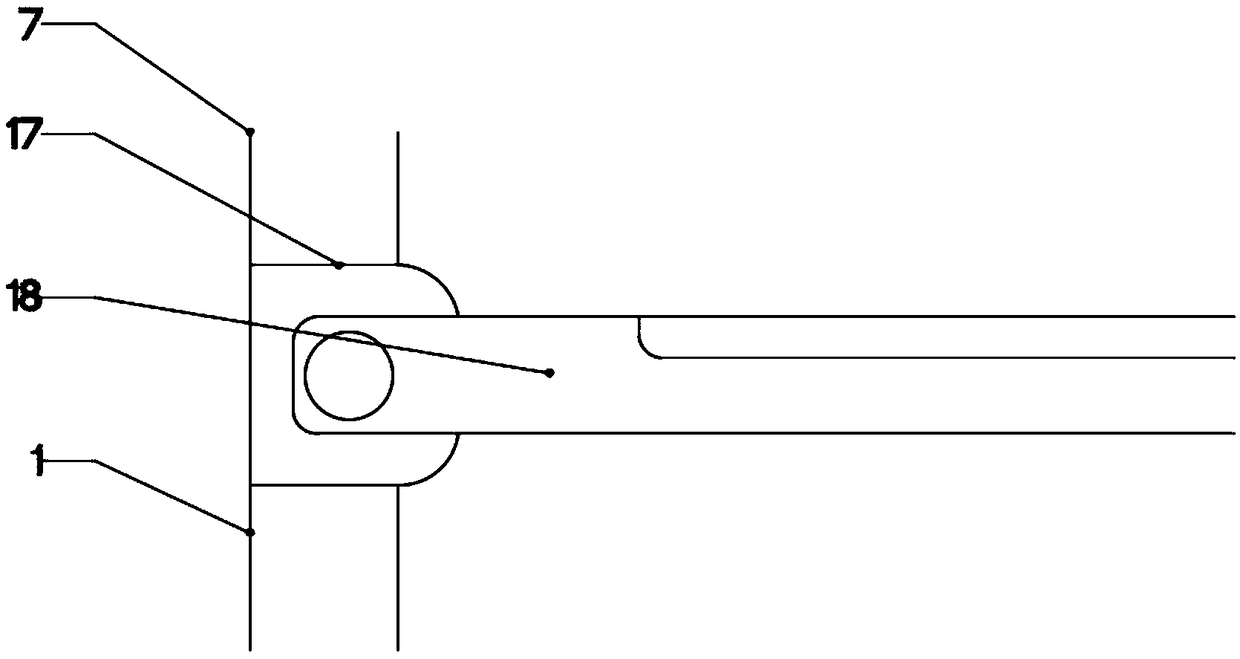

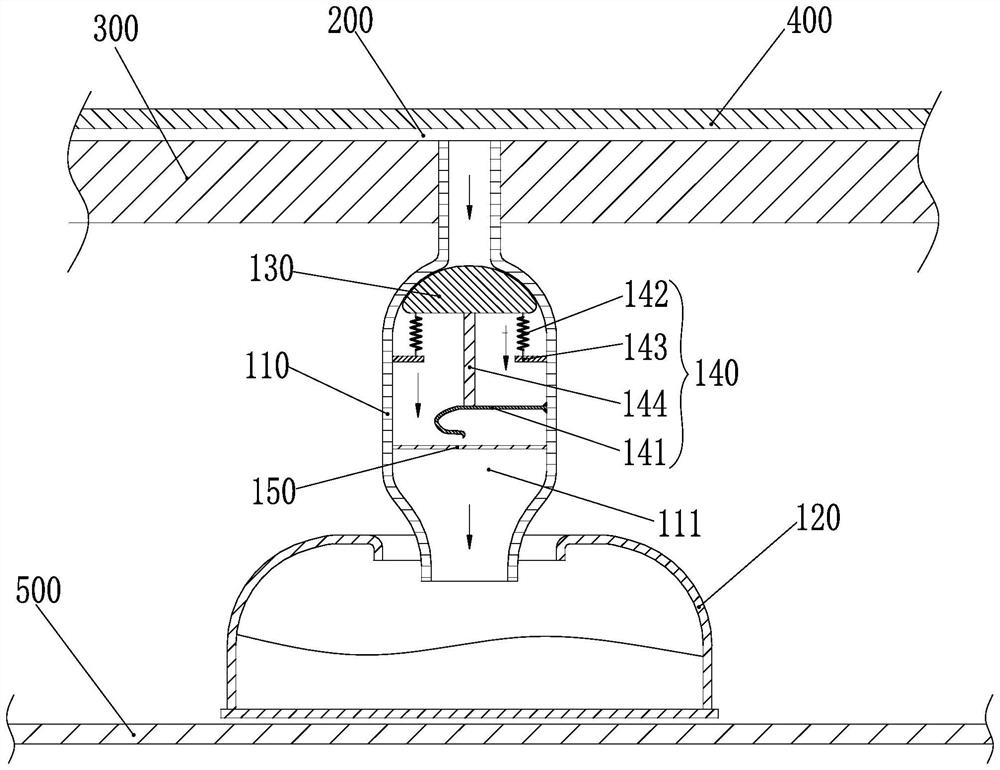

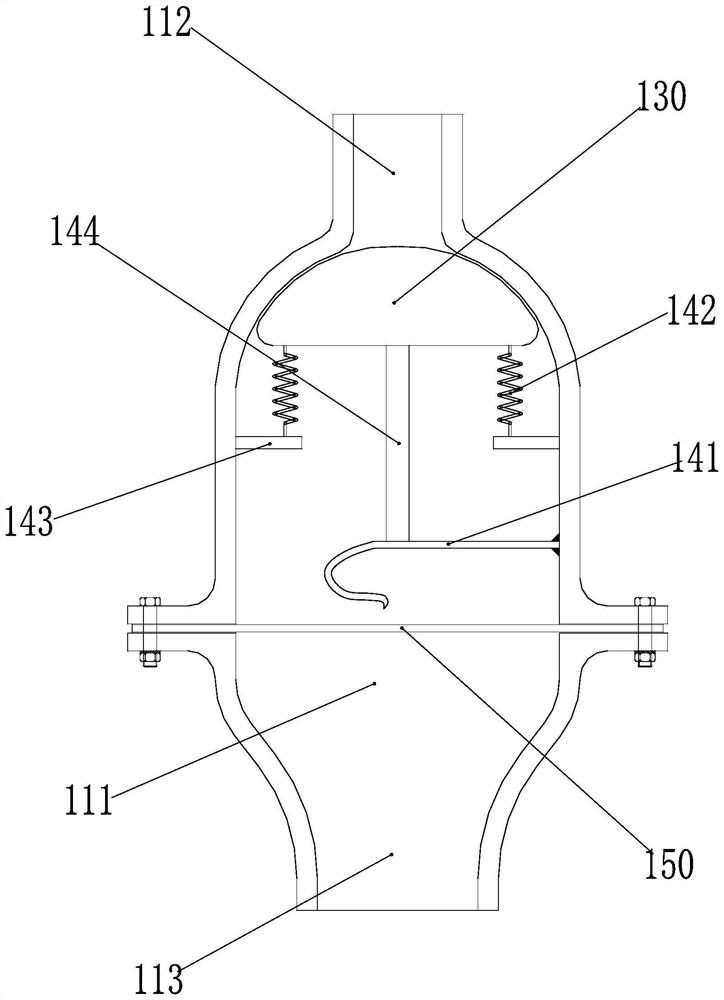

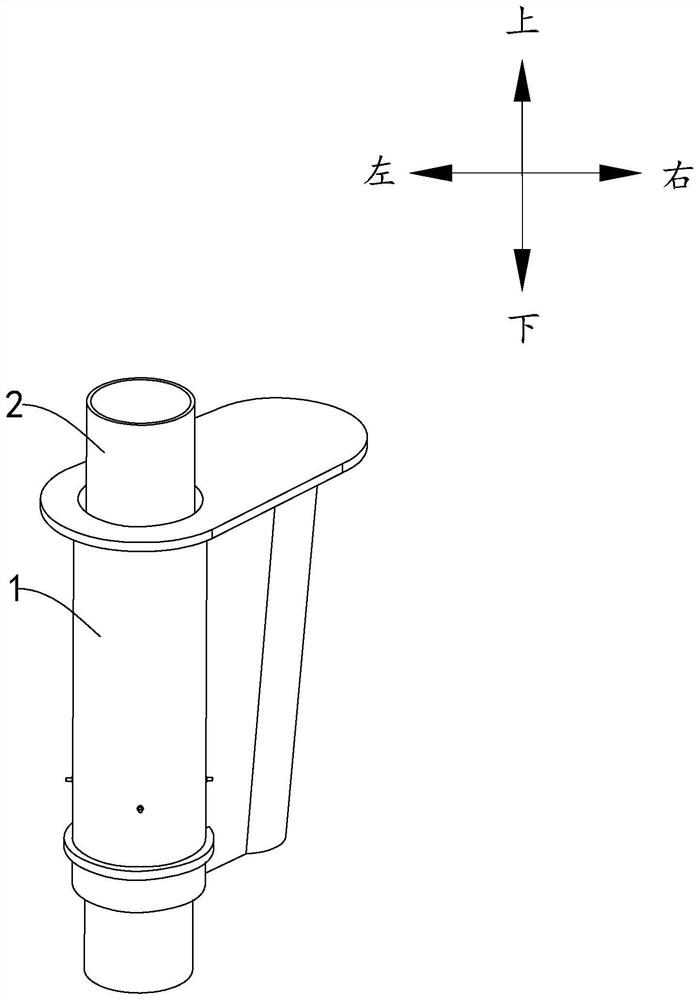

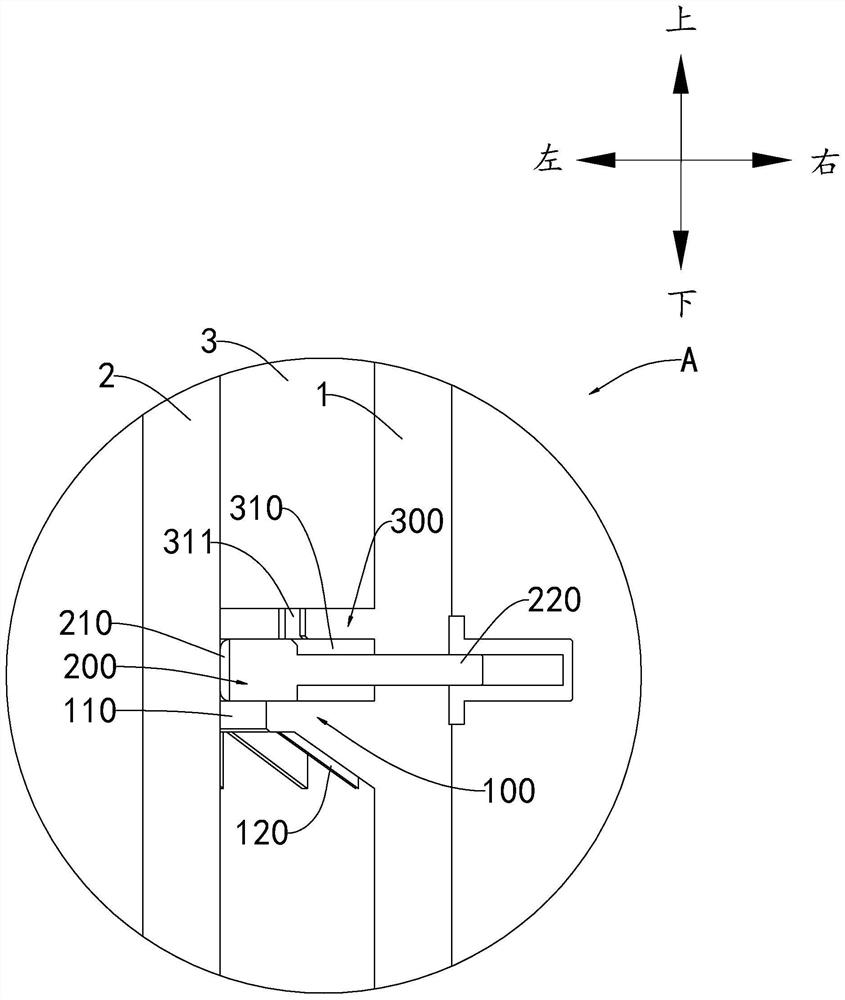

High-pressure jet-flow nozzle and high-pressure jet-flow crushing device using same

PendingCN109351443ASolve technical problemsSolve problems prone to damageGrain treatmentsElastic componentJet flow

The invention relates to a high-pressure jet-flow nozzle and a high-pressure jet-flow crushing device using the same. An elastic component is arranged between a jet-flow channel component and a sealing cover of the high-pressure jet-flow nozzle, and the jet-flow channel component is fixed to a shell. In addition, a buffering cavity is formed by a space used for accommodating the elastic component.Assembling of the high-pressure jet-flow nozzle can be simplified, and damage to the jet-flow channel component is avoided in the assembling process; sealing between the jet-flow channel component and the shell can be automatically achieved by means of the pressure generated by a high-pressure pump; the capacity can be conveniently improved; pressure fluctuation can be reduced through the buffering cavity, so that the crushing effect is improved, and particle size distribution of materials is decreased; and meanwhile, the impact of pressure fluctuation on the jet-flow channel component is reduced, and the damage risk of the jet-flow channel component is lowered.

Owner:北京协同创新食品科技有限公司

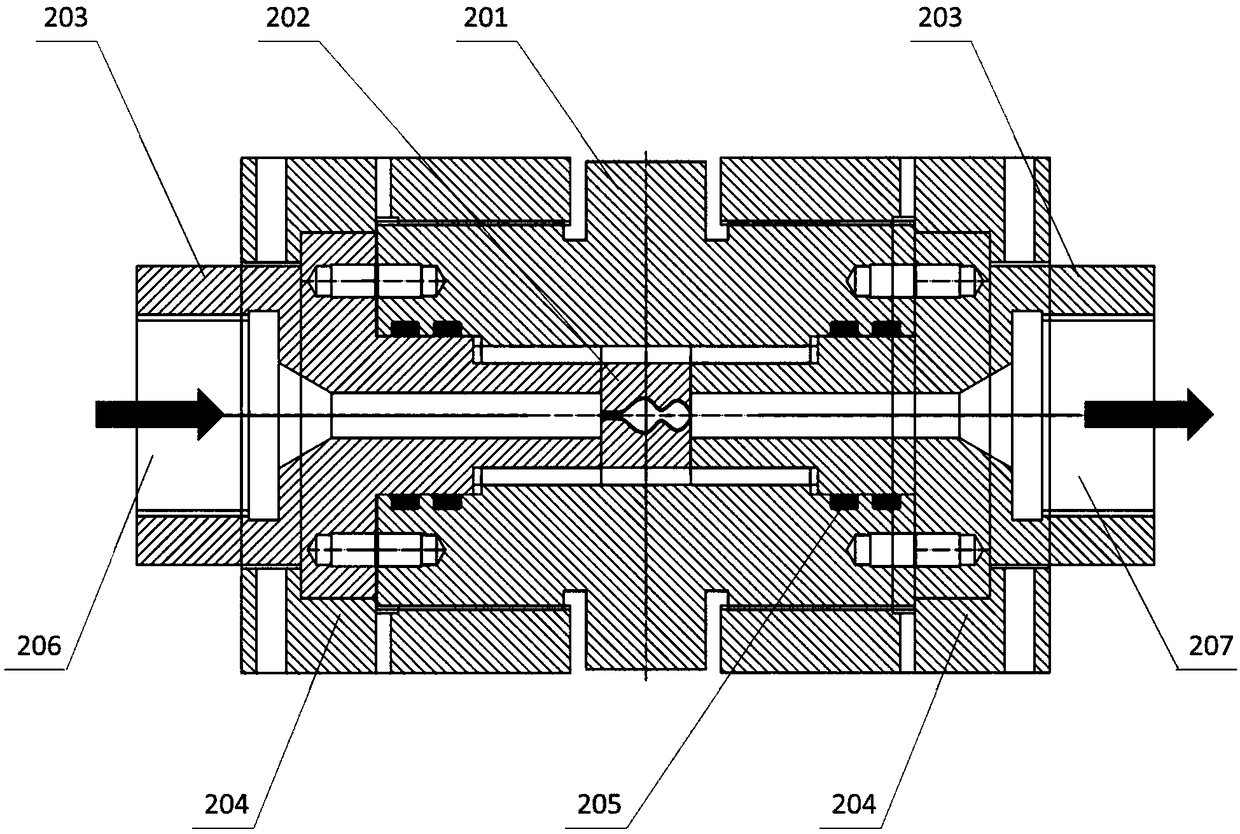

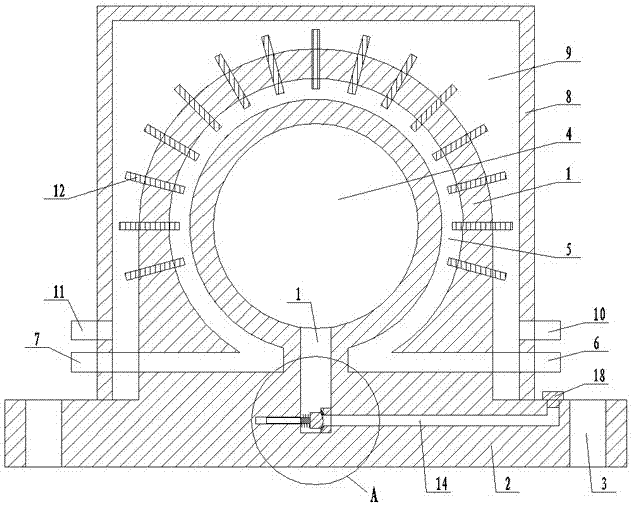

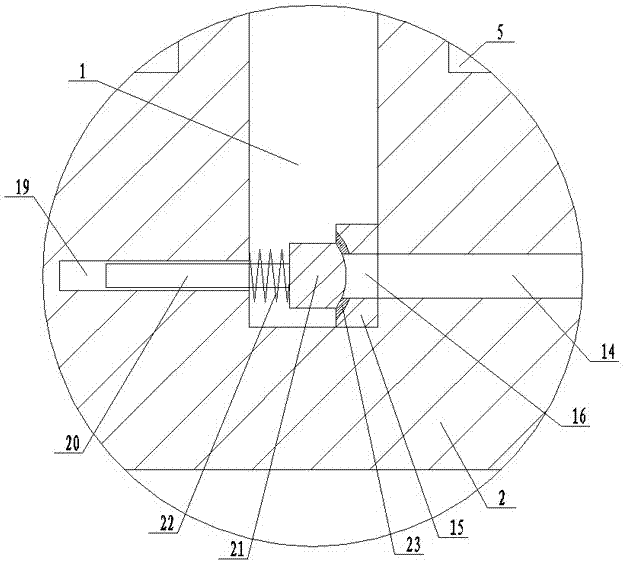

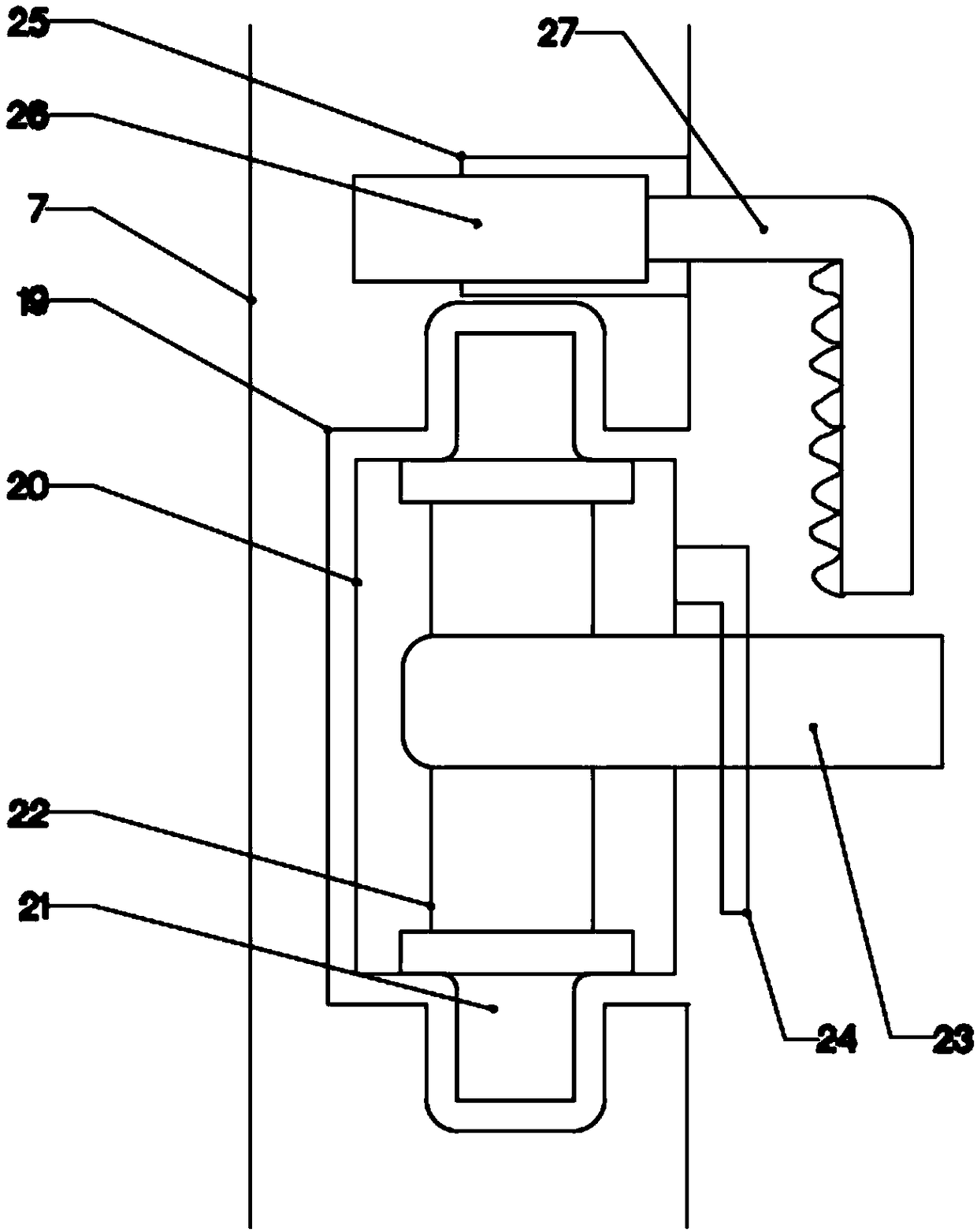

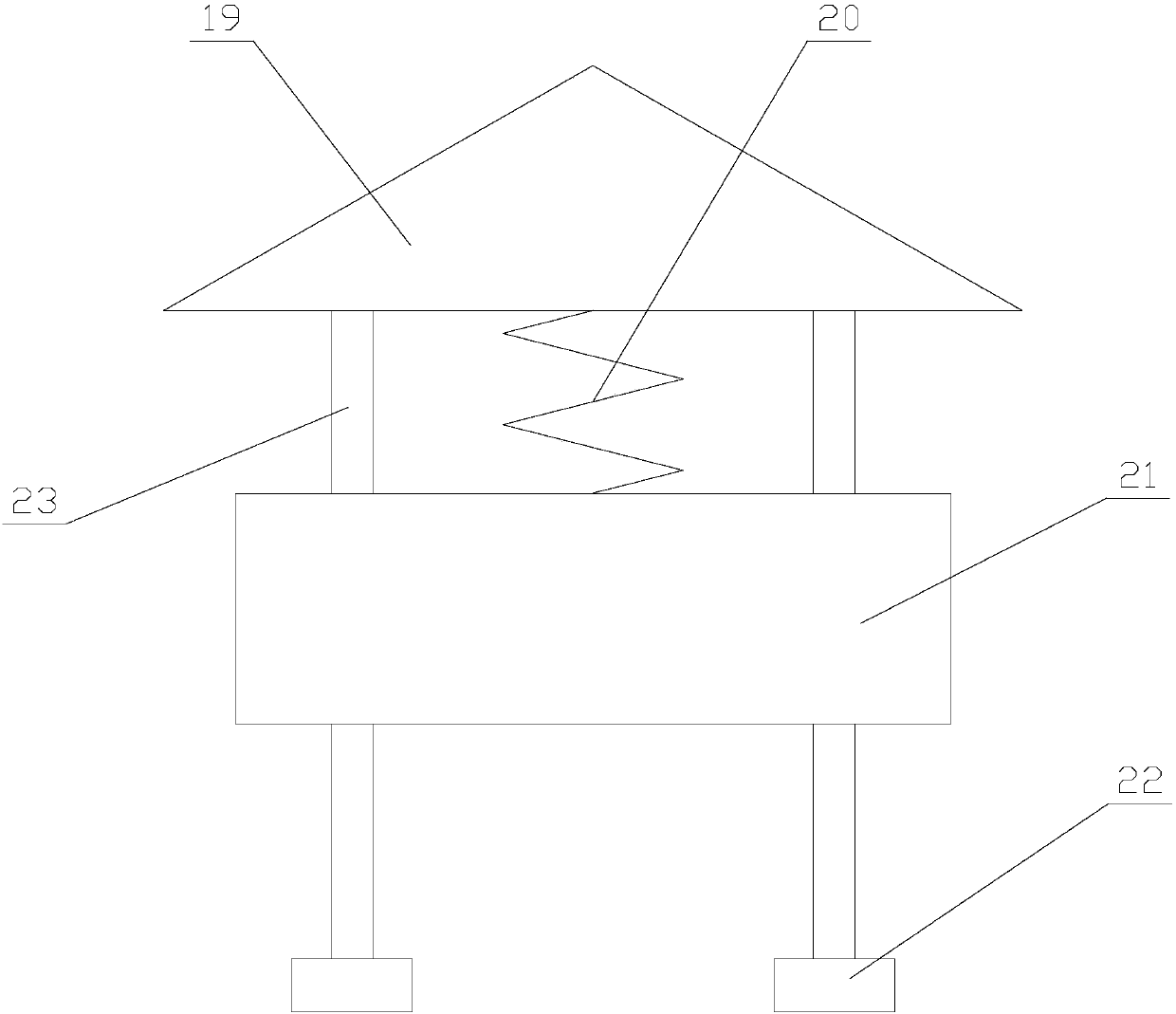

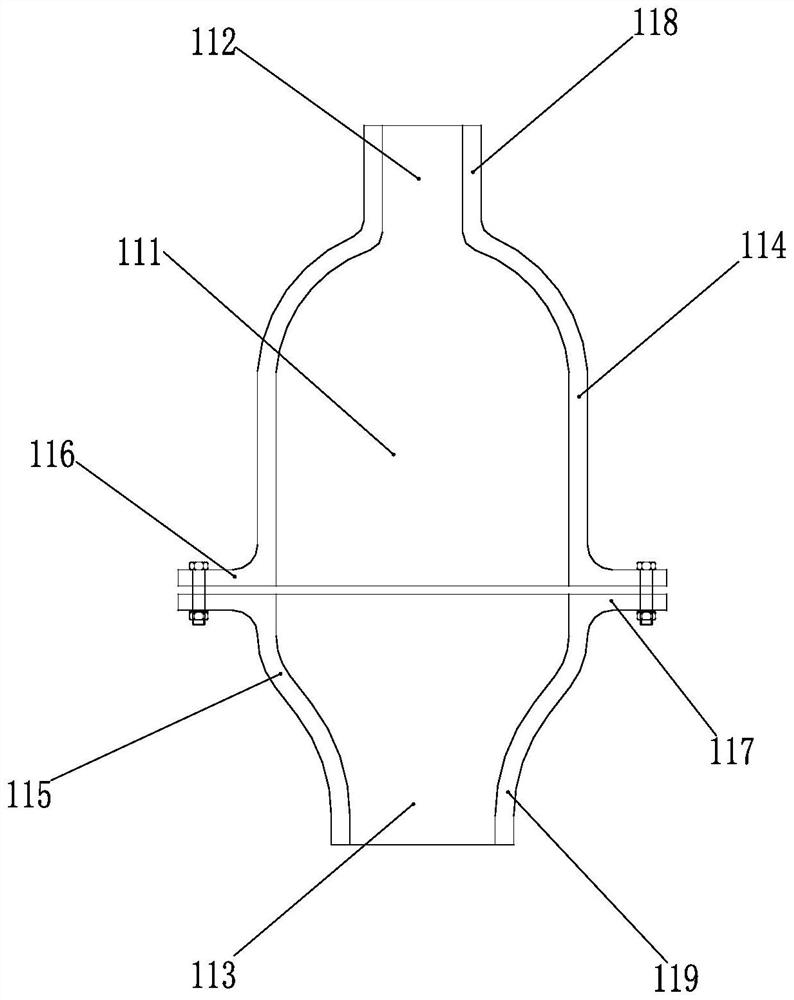

Sealed bearing seat

InactiveCN107575489AGuaranteed uptimeExtended service lifeBearing coolingBearing unit rigid supportEngineeringOmega

The invention discloses a sealed bearing seat which comprises a bearing seat body and a mounting base arranged at the lower end of the bearing seat body, wherein fixing holes are symmetrically arranged on two sides of the mounting base; a bearing sealing-mounting cavity and an omega-shaped cooling water cavity are arranged in the bearing seat body; the outer side of the bearing sealing-mounting cavity is coated with the omega-shaped cooling water cavity; a water inlet communicating with the omega-shaped cooling water cavity mutually is arranged on one side of the lower end of the bearing seatbody; a water outlet communicating with the omega-shaped cooling water cavity mutually is arranged on the other side of the lower end of the bearing seat body; an outer sheath is arranged on the mounting base on the outer side of the bearing seat body; a cooling air cavity is arranged between the outer sheath and the bearing seat body; an air inlet communicating with the cooling air cavity mutually is arranged on one side of the lower end of the outer sheath; and an air outlet communicating with the cooling air cavity mutually is arranged on the other side of the lower end of the outer sheath.

Owner:盐城恒发精密齿轮有限公司

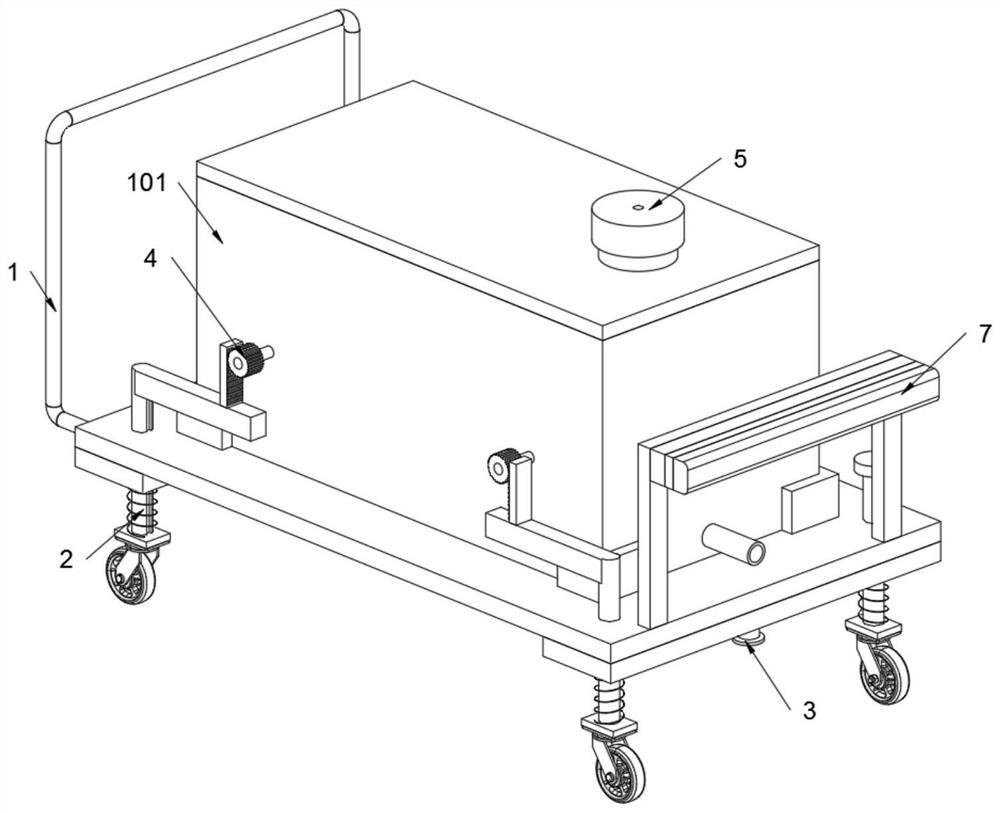

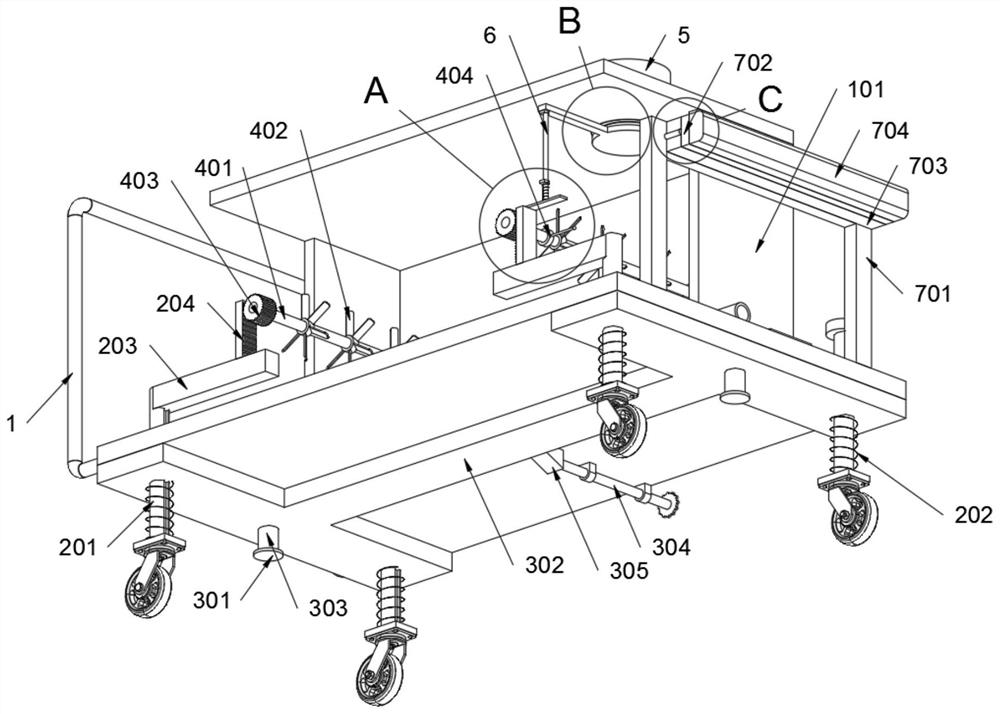

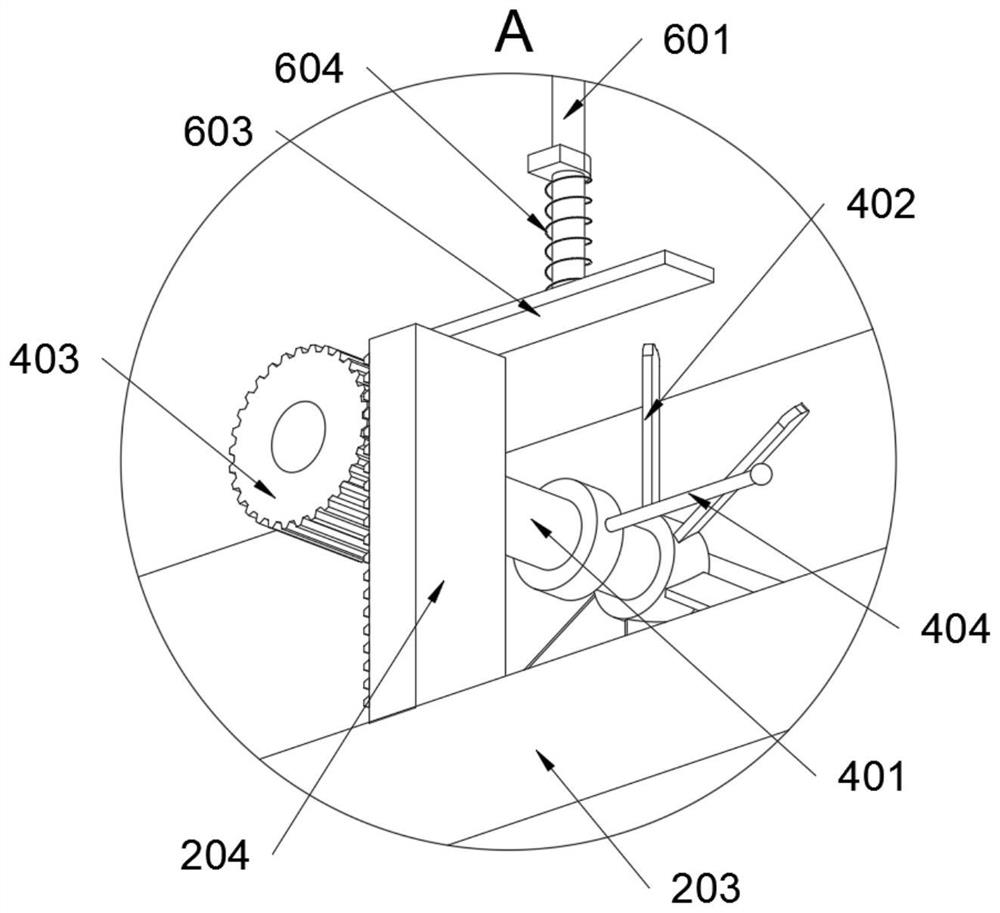

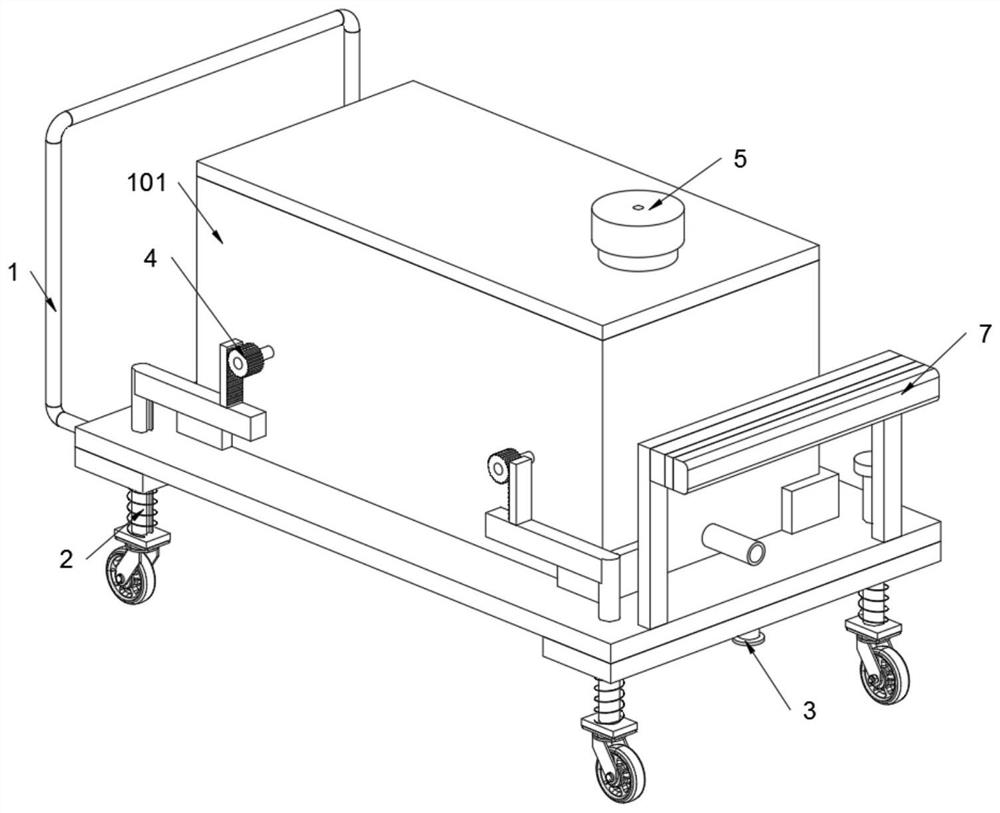

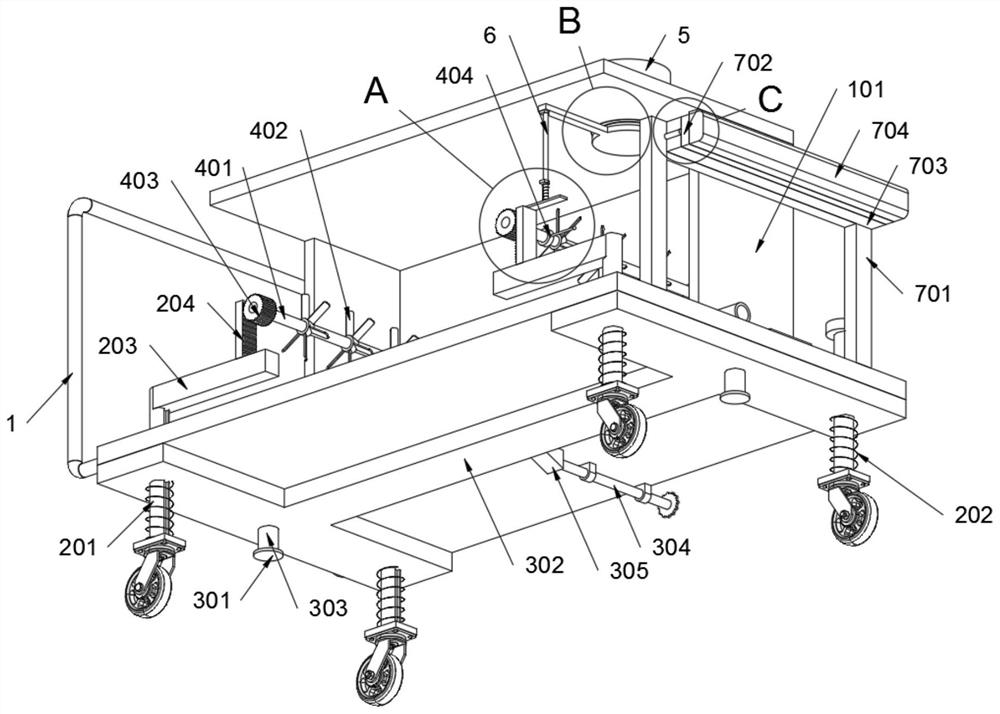

Special chemical product transportation device with three-stage protection mechanism

ActiveCN111619628AReduce wearRealize synchronous regulationShaking/oscillating/vibrating mixersSledge wheelsReciprocating motionControl engineering

The invention provides a special chemical product transportation device with a three-stage protection mechanism, relates to the field of chemical raw material transportation, and solves the problems that unpowered mixing of liquid in a liquid storage barrel cannot be driven in a linkage manner through up-and-down buffering of a buffer wheel, diversified sealing structure cooperation cannot be achieved to achieve improvement of the sealing effect, and linkage cannot be achieved to achieve improvement of the sealing effect while unpowered mixing is conducted. The special chemical product transportation device with the three-stage protection mechanism comprises a transportation vehicle main body, a sealing block and a stress plate, wherein a liquid storage barrel is fixedly placed on the transportation vehicle main body. Secondly, the distance from the stress plate to a rotating shaft is less than the length of a poke rod, when the poke rod rotates along with the rotating shaft, a columnar sliding rod and a sealing plate are in an up-down reciprocating motion state under the poke of the poke rod, and a sponge cushion is in an extrusion state under the extrusion of the sealing plate, so that the sealing between the sealing block and the columnar pipe is realized, and the liquid splashing caused by the following shaking of the liquid storage barrel is prevented.

Owner:SHANGHAI DINGMING CONTAINER STORAGE & TRANSPORTATION CO LTD

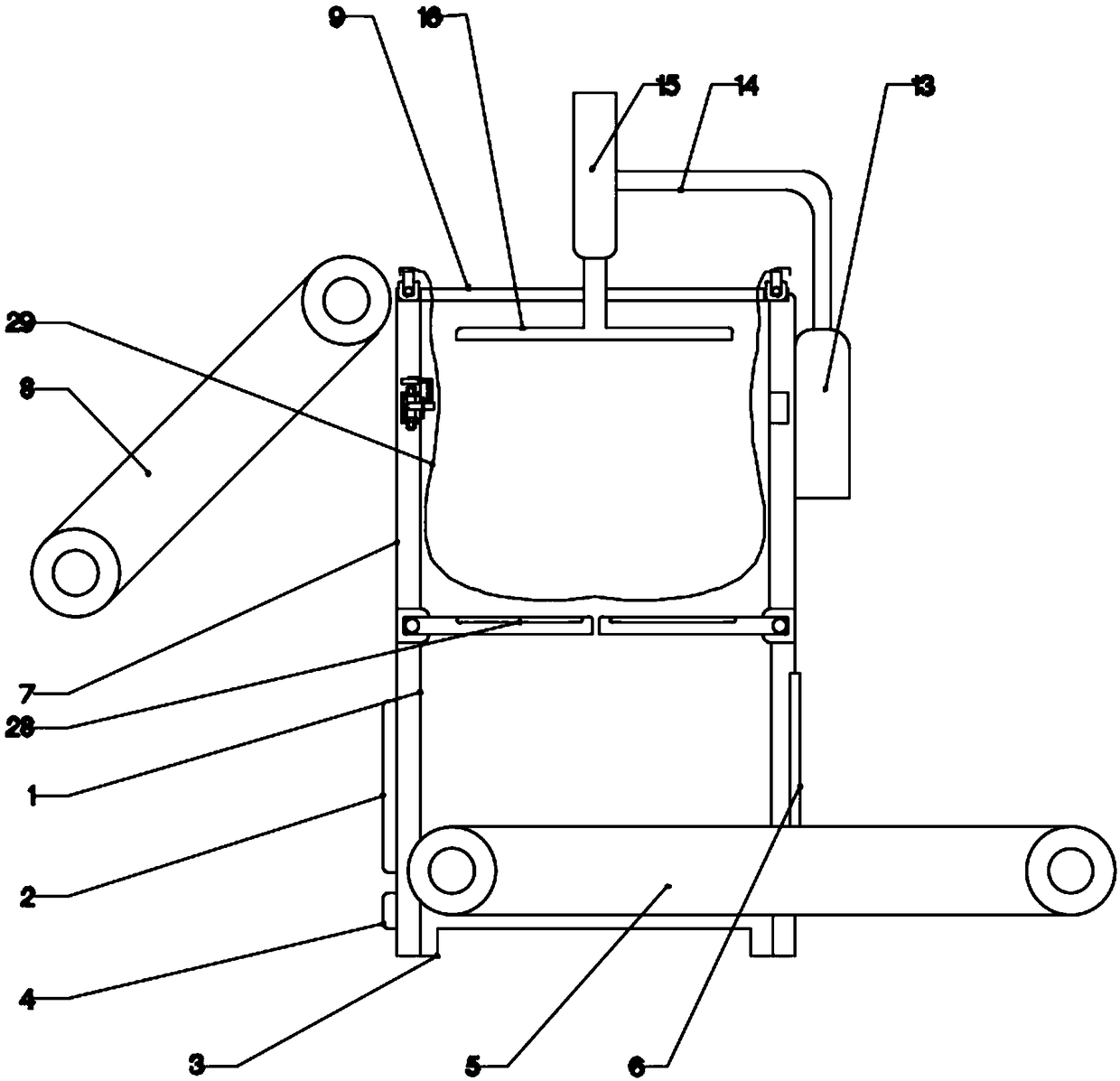

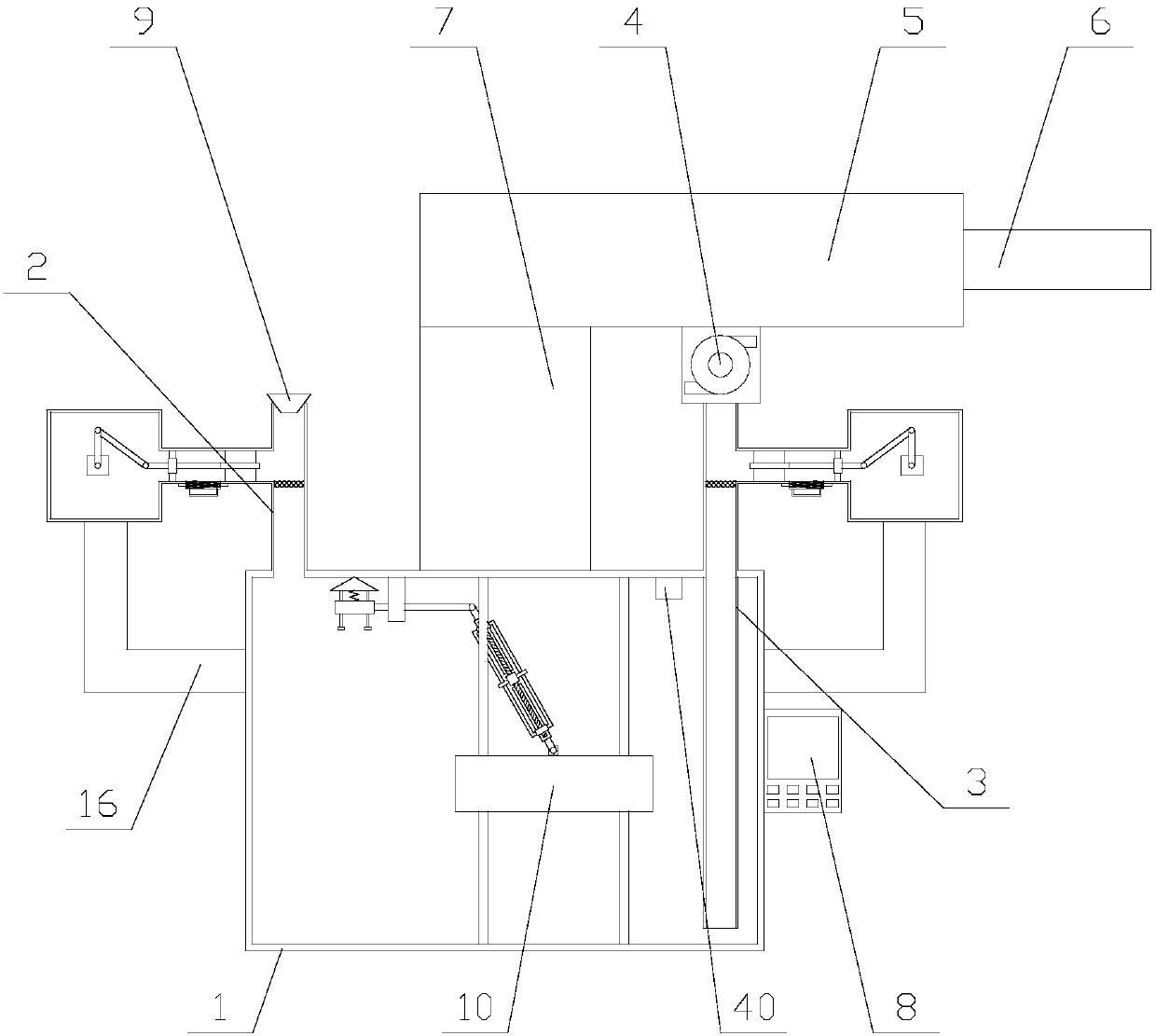

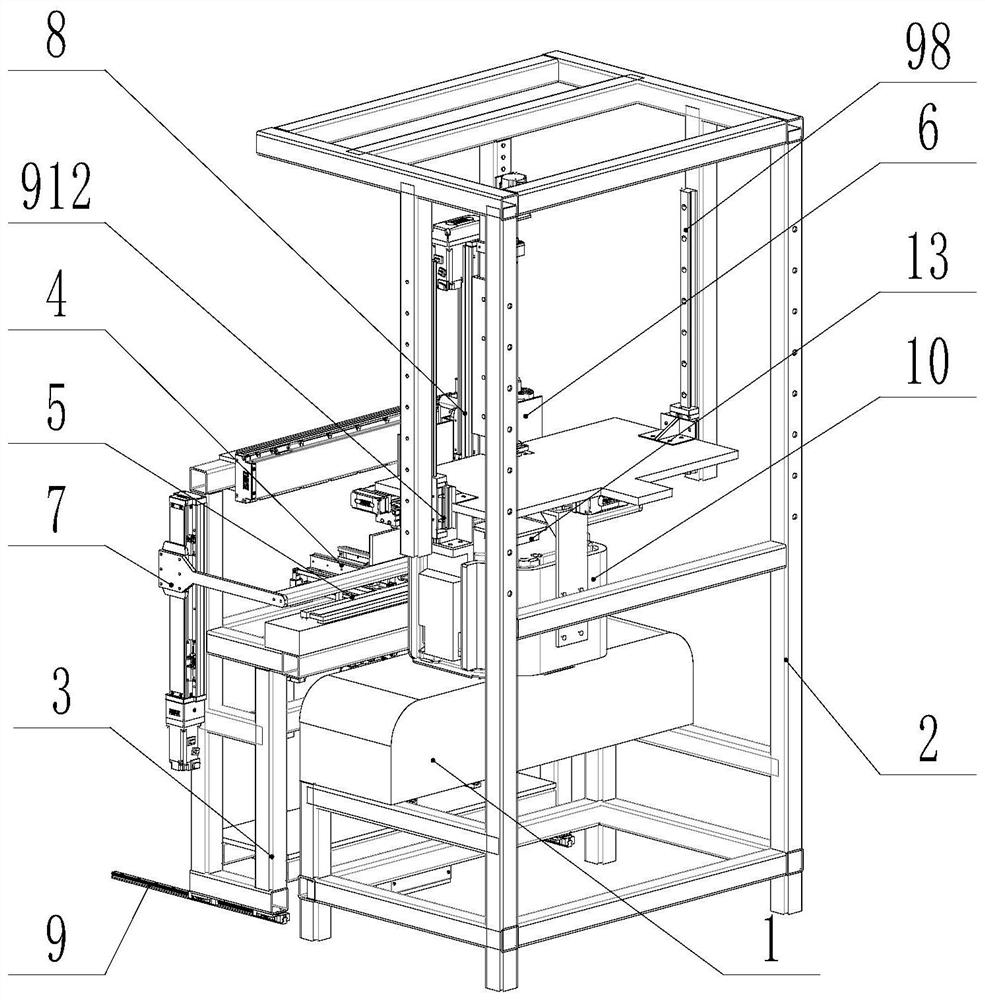

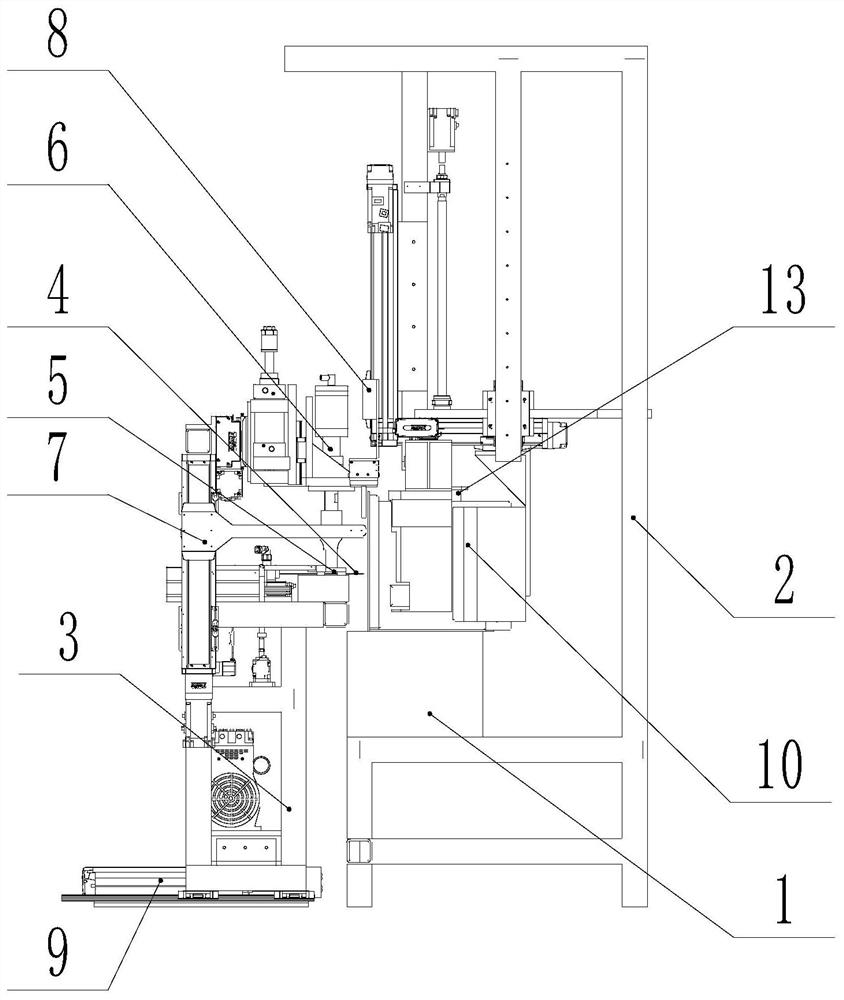

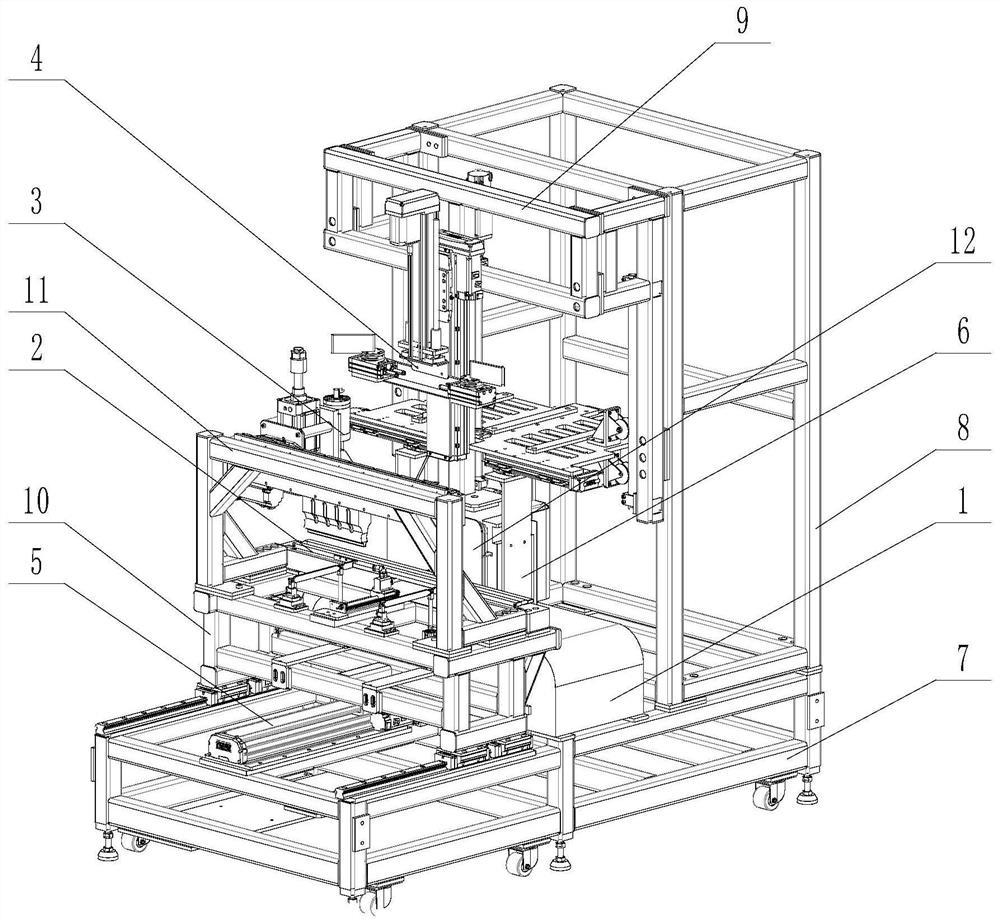

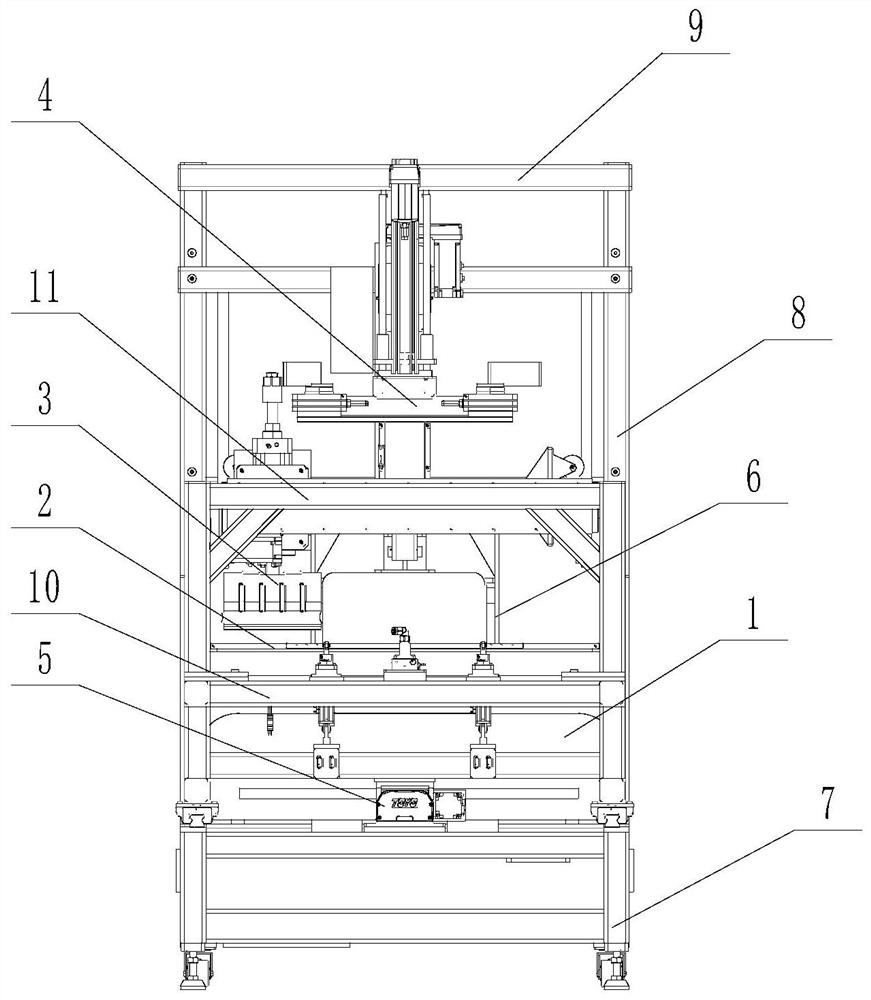

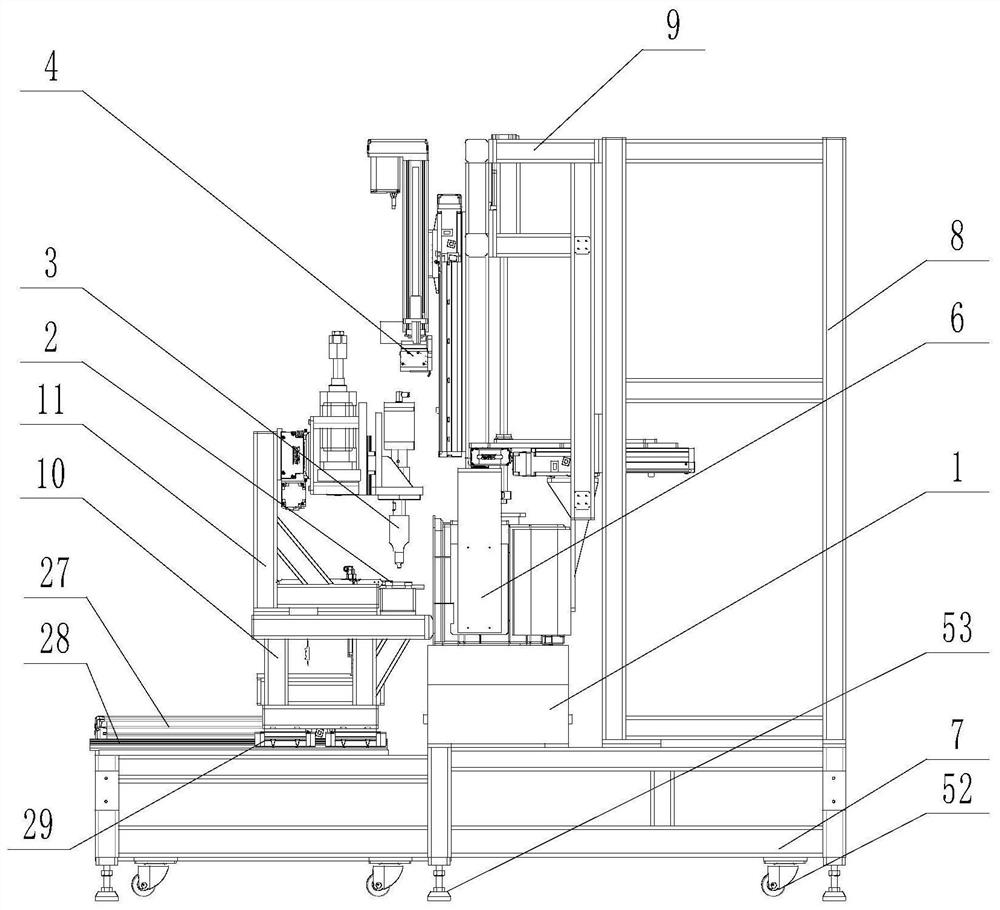

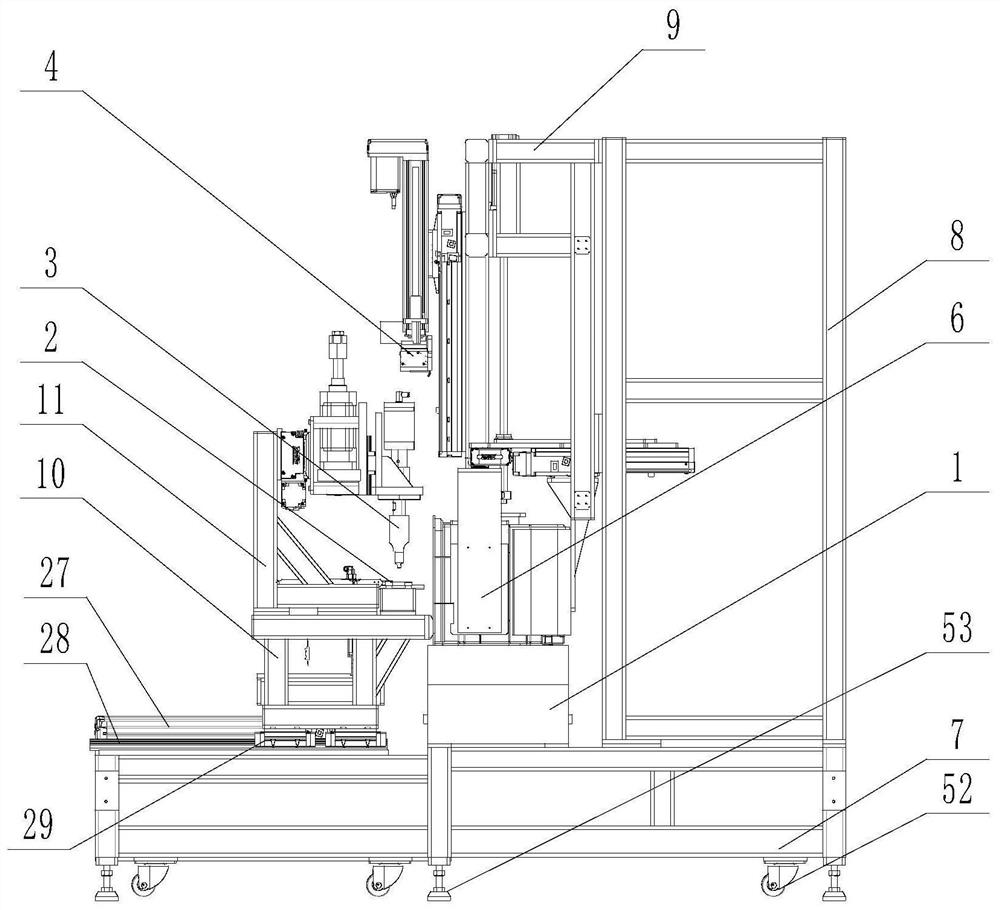

Bubble bag packaging equipment

PendingCN113022965ARealize the opening actionSmooth feedingWrapper twisting/gatheringLogistics managementEngineering

The invention discloses bubble bag packaging equipment. The bubble bag packaging equipment comprises a bag storage groove, a bag taking mechanism and a bag opening and sealing mechanism, and the bag taking mechanism is connected between the bag storage groove and the bag opening and sealing mechanism. The bag opening and sealing mechanism comprises a first pressing strip, a second pressing strip, a first clamping jaw and a second clamping jaw, and the first pressing strip and the second pressing strip are oppositely arranged and can move towards to each other or back to each other. The first clamping jaw can be vertically arranged above the first pressing strip in an opening and closing mode, the second clamping jaw can be vertically arranged above the second pressing strip in an opening and closing mode, and the first clamping jaw and the second clamping jaw can move towards each other or back to each other. The bubble bag packaging equipment is provided with the bag storage groove, the bag taking mechanism and the bag opening and sealing mechanism, continuous and automatic bubble bag feeding, bag opening and sealing can be achieved, the automation degree is high, the production efficiency of wrapping the outer side of a product with a bubble bag is high, and the production efficiency of the logistics industry can be greatly improved.

Owner:惠州固尔琦智能设备有限公司

Horizontal well automatic water controlling well completion pipe column structure

The invention discloses a horizontal well automatic water controlling well completion pipe column structure. The horizontal well automatic water controlling well completion pipe column structure includes a punching outer pipe, a punching inner pipe and multiple water-swelling rubber columns uniformly arranged on the outer wall of the punching inner pipe. A concentric shaft of the punching outer tube sleeves the outside of the punching inner pipe and has a proper distance from the punching inner pipe. Multiple first punched holes are uniformly formed in the punching outer pipe along the outer wall, multiple second punched holes are uniformly formed in the punching inner pipe in the outer wall direction, and the multiple water-swelling rubber columns are independent of each other. By improving the structure, the horizontal well automatic water controlling well completion pipe column structure can automatically block the high water-cut horizontal well segment, a series of work of findingand blocking water in horizontal wells is avoided, and the horizontal well automatic water controlling well completion pipe column structure has the advantages of simple structure, relatively low cost, simple and easy construction, and no later management. The output of oil can be specially guaranteed on the basis of controlling the output of water.

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

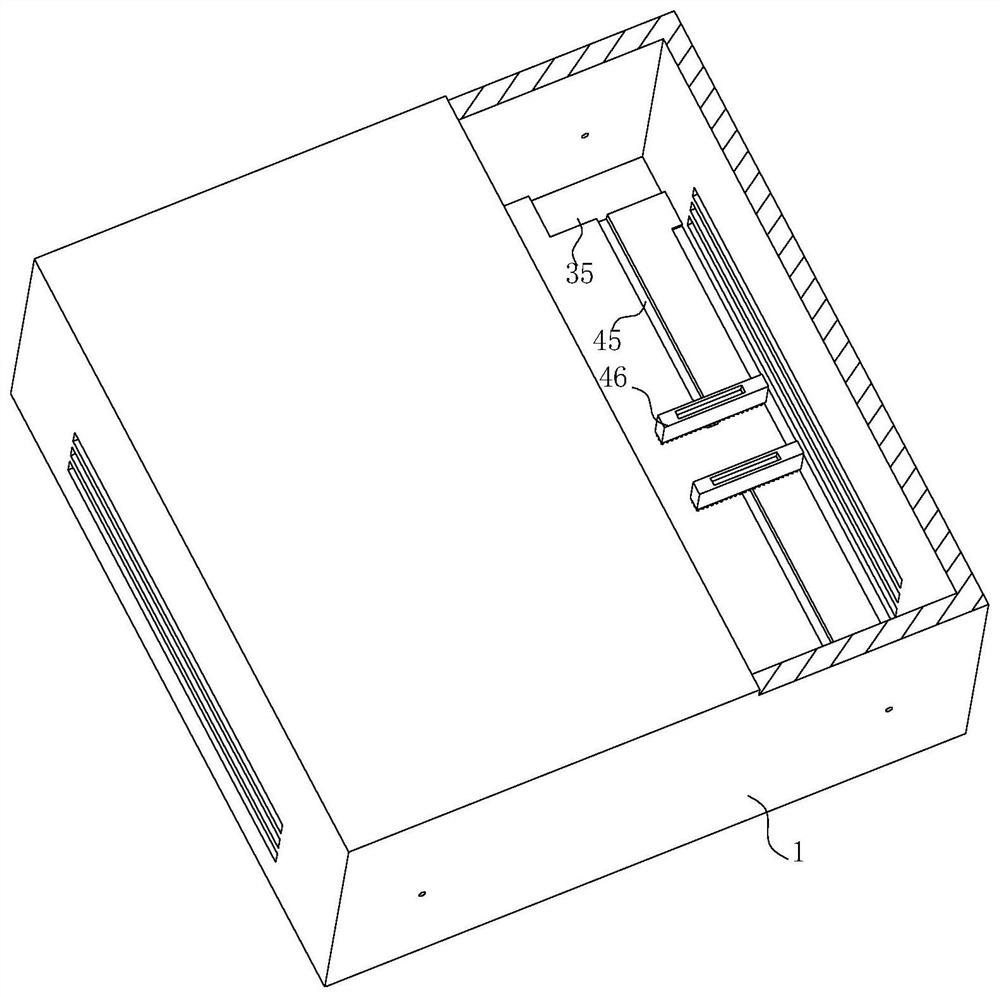

Battery protection structure of new energy automobile

The invention discloses a battery protection structure of a new energy automobile in the technical field of battery protection structures of new energy automobiles, and the battery protection structure comprises a mounting shell, first plates and sliding shells are fixedly connected to the inner walls of the two sides of the mounting shell, sealing springs are fixedly connected to the bottoms of the first plates, and sealing plates are slidably connected to the inner walls of the sliding shells, two sealing grooves are formed in the inner wall of the mounting shell, limiting releasing devices are connected to the inner walls of the two sides of the mounting shell correspondingly, and water pumping devices are connected to the corners of the inner wall of the mounting shell correspondingly; in the prior art, heat dissipation holes are formed in a mounting frame on the outer side of a battery of a new energy automobile, when natural disasters such as urban waterlogging are caused by rainstorm weather, rainwater may enter the battery mounting frame through the heat dissipation holes, the battery is damaged, meanwhile, short circuit of the battery may be caused, and the battery explosion and other hazards are caused.

Owner:王晶

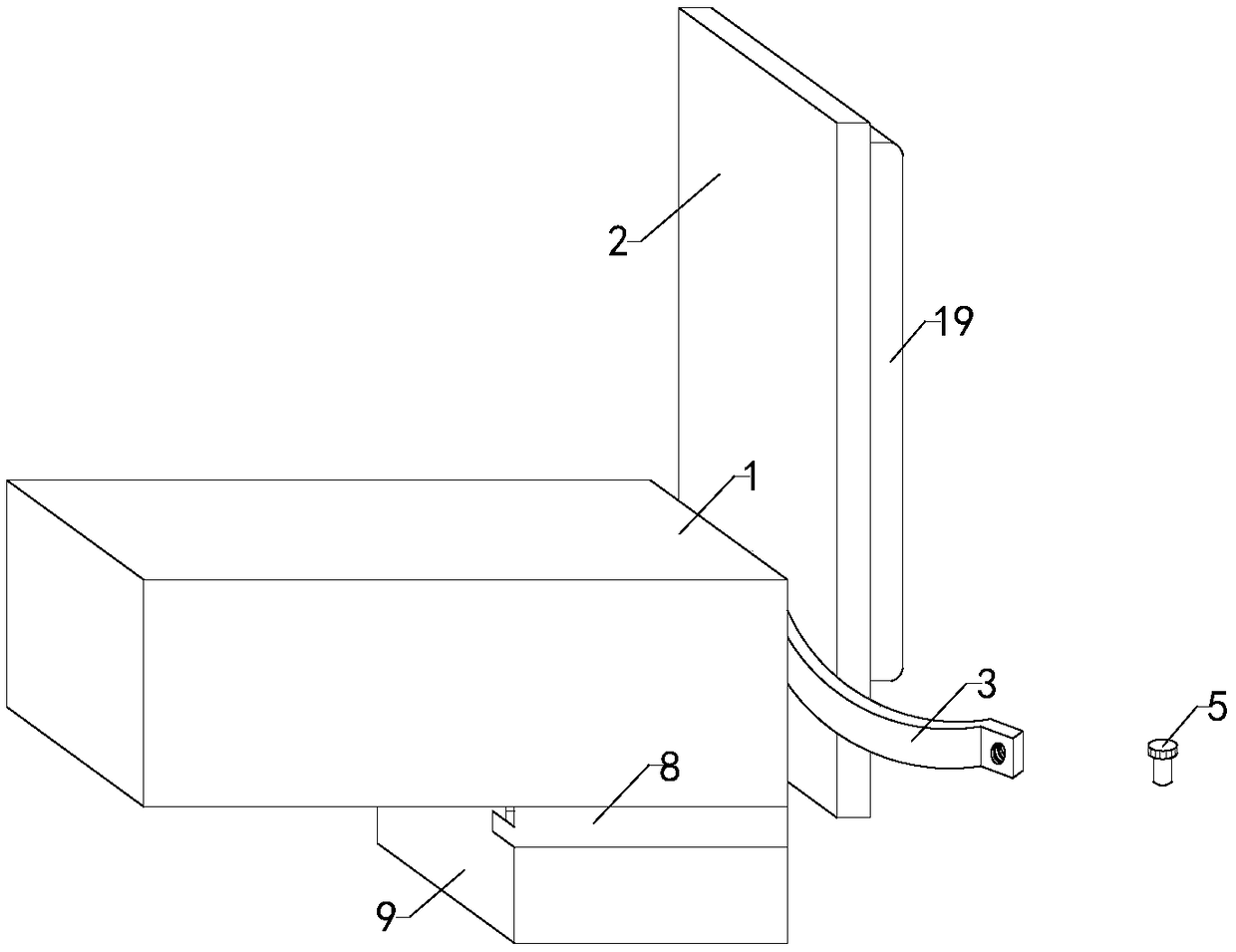

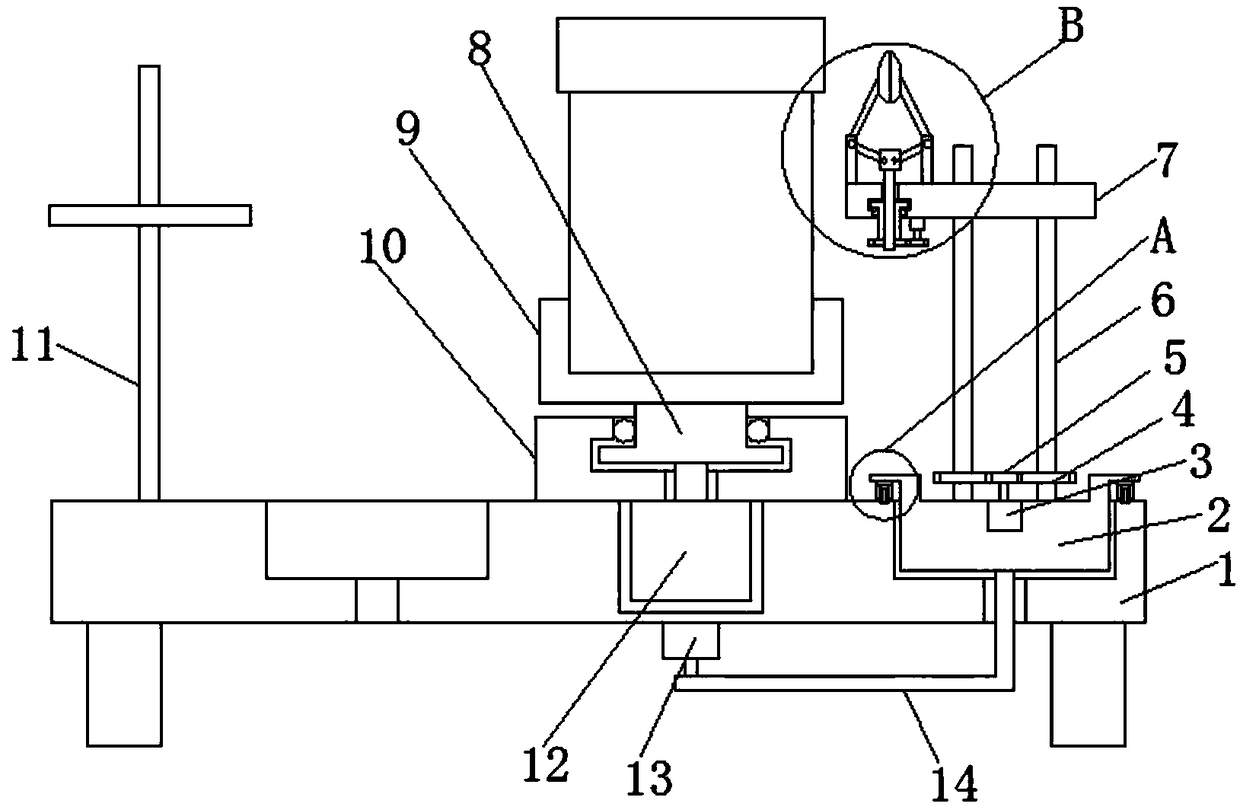

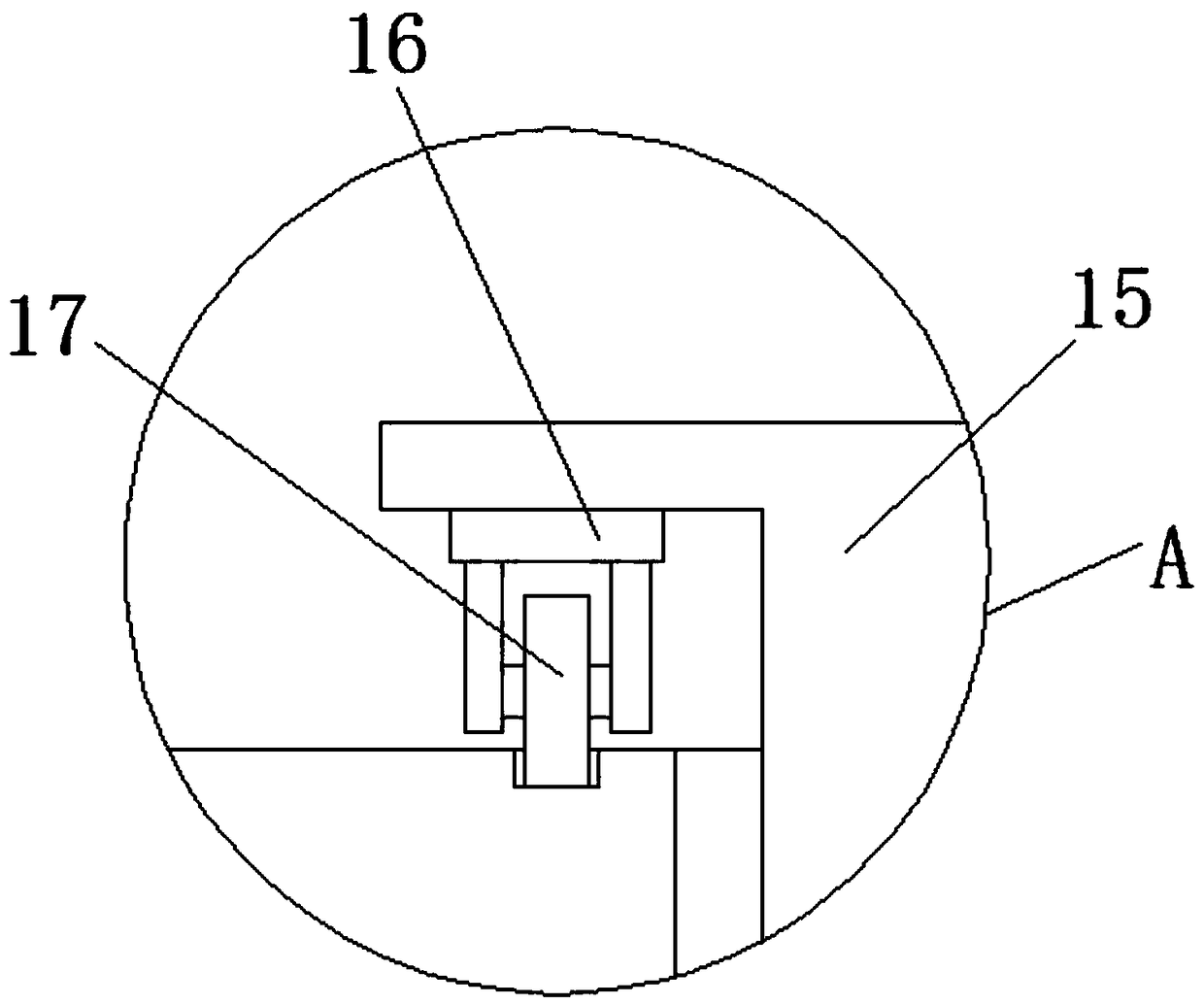

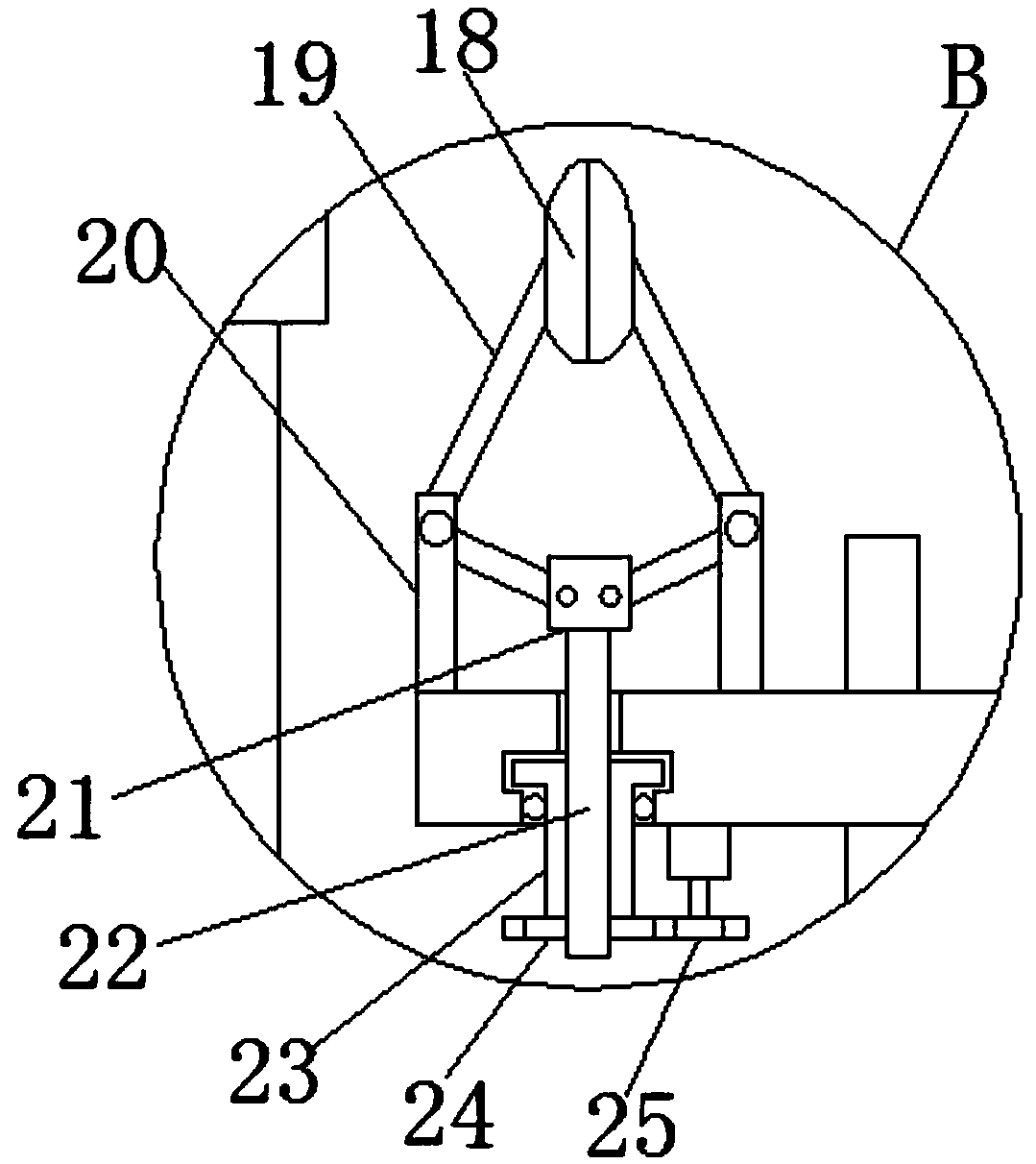

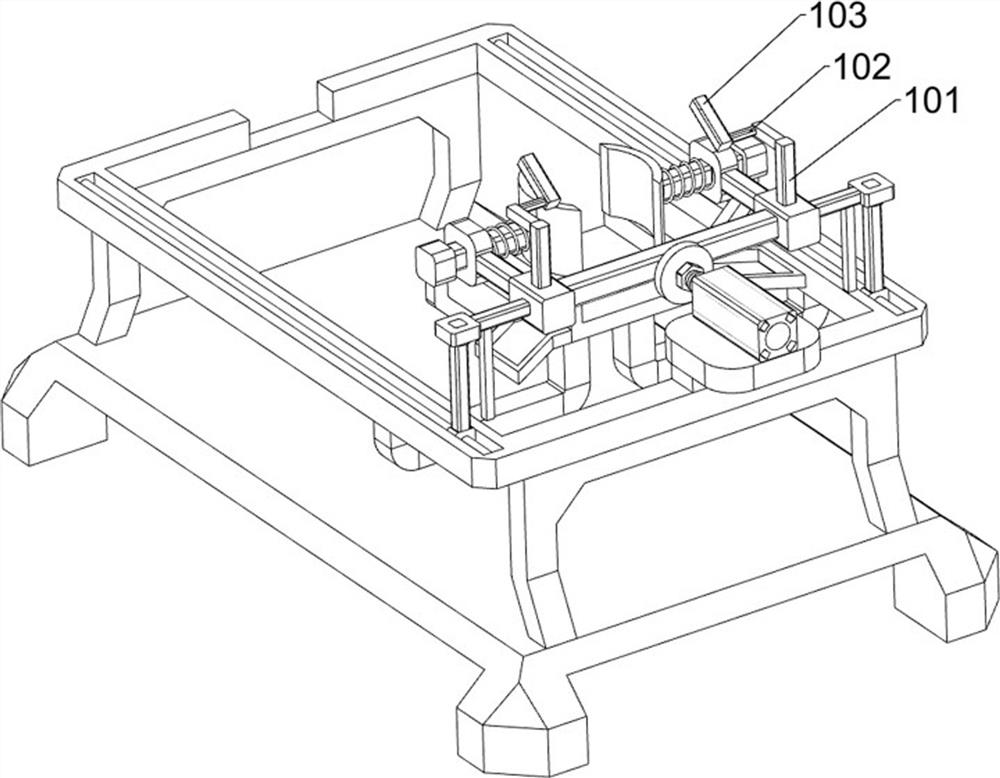

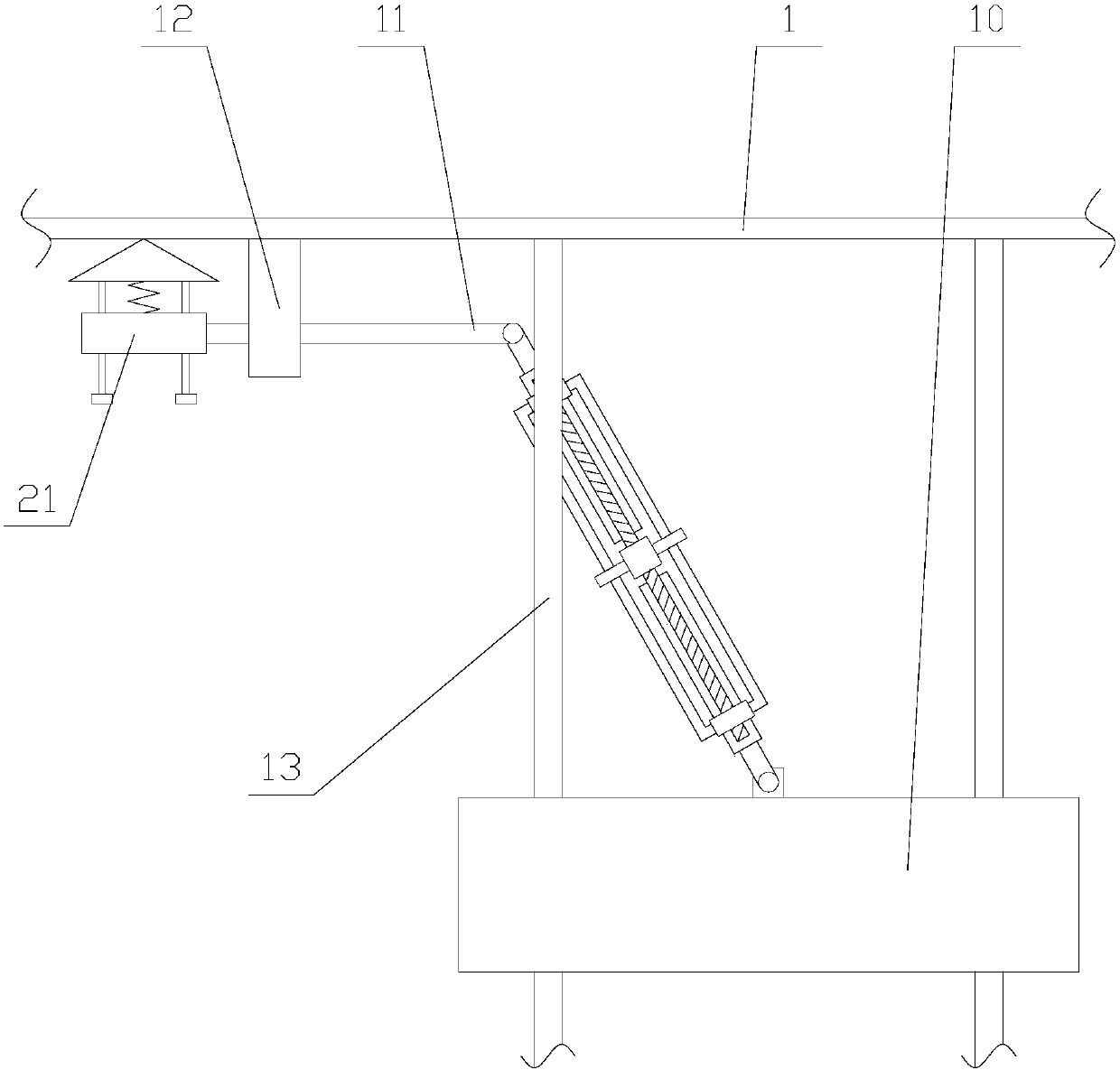

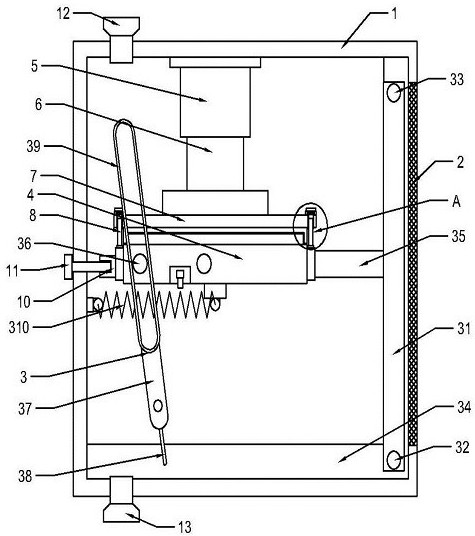

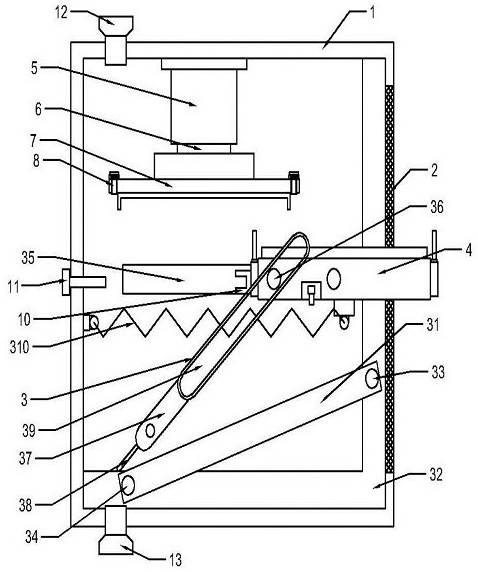

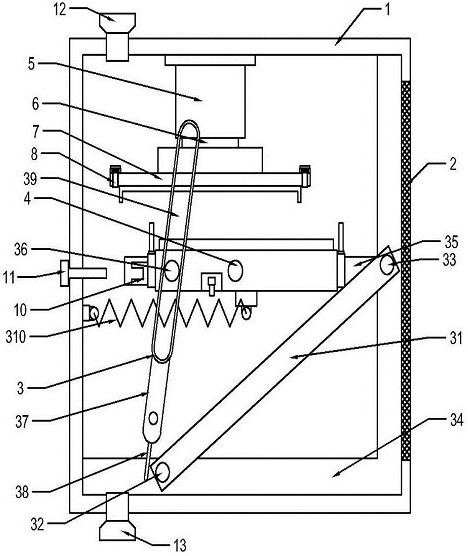

Waste collecting device for textile machine

InactiveCN109436413AAutomatic sealingBinding material applicationBundling machine detailsEngineeringScrap

The invention discloses a waste collecting device for a textile machine. The waste collecting device comprises a rectangular box body I and a conveying device mounted in the rectangular box body I, and further comprises a compacting device and a bundling device; the compacting device is arranged on the rectangular box body I; the bundling device is arranged below the compacting device; a controller is arranged on the side surface of the rectangular box body I, and is fixedly connected with the rectangular box body I; an anti-skid base is arranged on the lower surface of the rectangular box body I, and is fixedly connected with the rectangular box body I; and a power interface is arranged on the side surface of the rectangular box body I, and is fixedly connected with the rectangular box body I. The waste collecting device has the beneficial effects of simple structure and high practicability.

Owner:王建跃

Liquid tank leakage stopping device

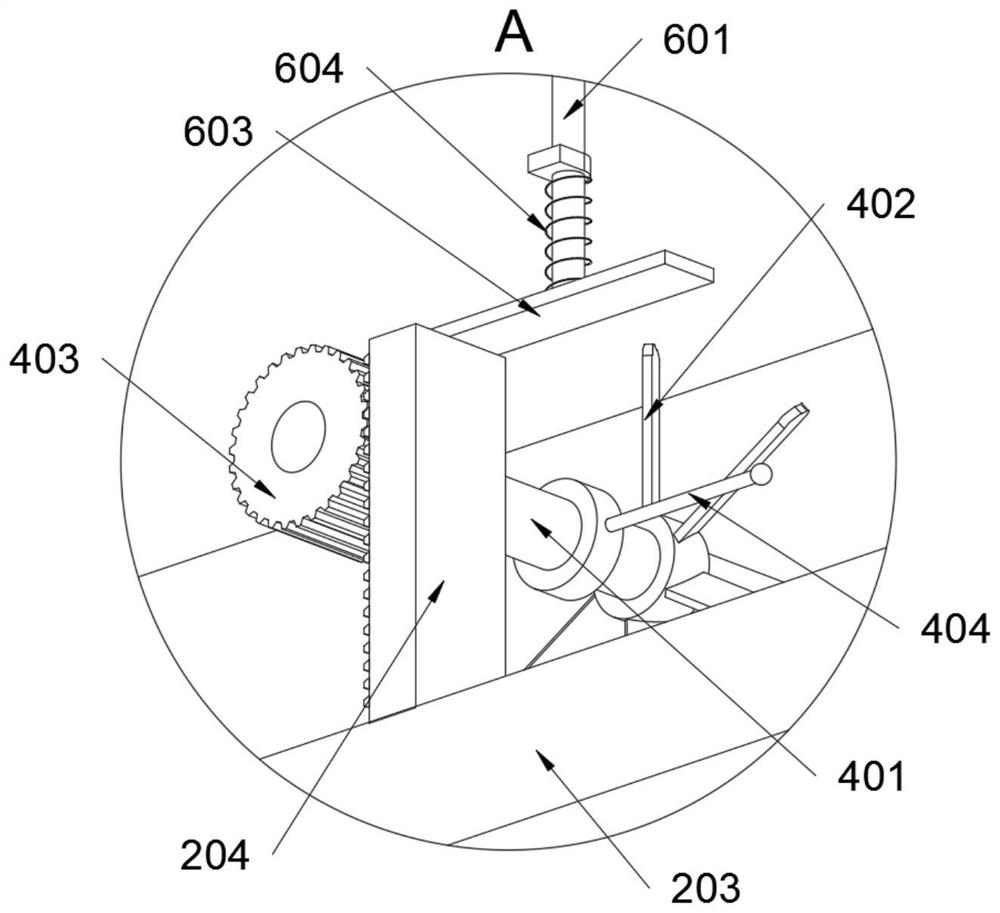

InactiveCN108750433AAutomatic sealingImprove the stability of useLarge containersElectricityGear wheel

The invention relates to the technical field of mechanical equipment accessory devices, in particular to a liquid tank leakage stopping device. The liquid tank leakage stopping device is relatively convenient to use, is capable of automatically blocking leakage holes to bring convenience to users, and is relatively high in practicability, relatively high in using stability and relatively strong inusing effect so as to improve the using reliability. The liquid tank leakage stopping device comprises a shrinkage frame, a baffle, a first flange connection disk, a second flange connection disk, two groups of bolts and two groups of nuts, wherein the shrinkage frame is internally provided with a working cavity; an opening is formed in the right end of the shrinkage frame; both the outer side walls of the two groups of bolts and the inner side walls of the two groups of nuts are of threaded structures; the liquid tank leakage stopping device furthermore comprises a liquid sensor, a sensor, two groups of limiting frames, a storage box, a threaded rod, a threaded pipe, a driving gear, a driven gear, a chain and a servo motor; the sensor is mounted in a placing groove and electrically connected with the liquid sensor; the chain is sleeved on the driving gear and the driven gear; the liquid tank leakage stopping device furthermore comprises a plurality of groups of sucking disks; and a plurality of groups of brackets are arranged on the right side wall of the first flange connection disk.

Owner:贾乙

Sealing equipment

InactiveCN108190125AReasonable structureEasy to operateWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses sealing equipment. The sealing equipment comprises a base plate. A first groove is formed in the top end of the base plate. A first supporting block is arranged at the top endof the base plate in a sliding manner. The top end of the first supporting block is rotationally provided with a first rotation shaft. A containing disc is fixedly arranged at the top end of the firstrotation shaft. A first motor is fixedly arranged at the bottom end of the first supporting block. An output shaft of the first motor and the bottom end of the first rotation shaft are fixedly connected. The first motor is located in the first groove. A sliding groove is formed in the top end of the base plate. A sliding block is arranged in the sliding groove. A second groove is formed in the top end of the sliding block, and a second motor is fixedly arranged in the second groove. An output shaft of the second motor is fixedly provided with a first gear. The top end of the sliding block isrotationally provided with two first screws. The sealing equipment is reasonable in structure, simple in operation, convenient to use and capable of rapidly conducting adhesive tape sealing; and the structure is simple, the manufacturing cost is low, and worker operation is convenient.

Owner:佛山杰致信息科技有限公司

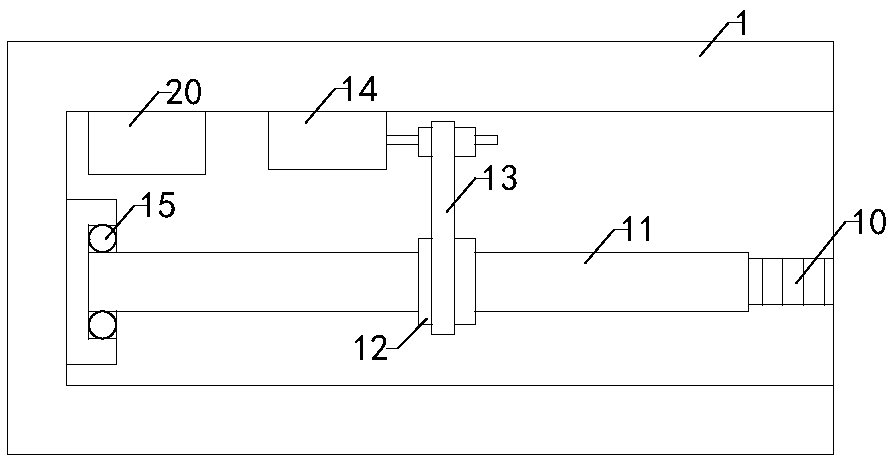

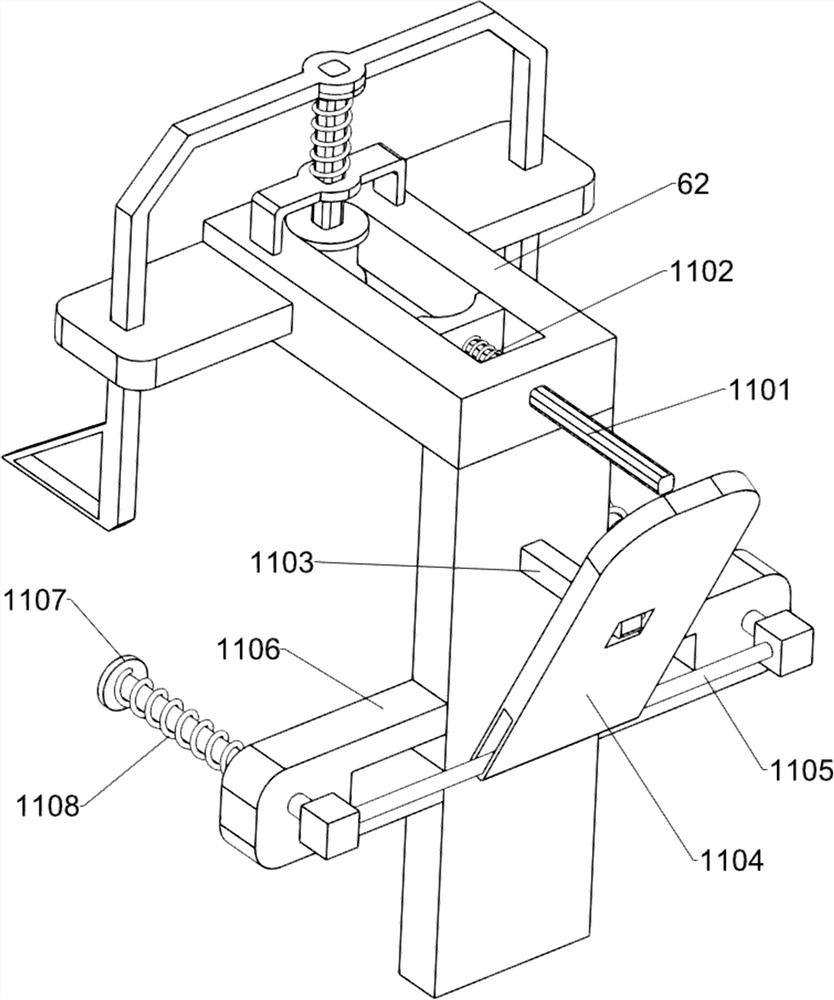

Whitening lotion bottling and sealing equipment for skin care products

ActiveCN113104796AAutomatic fillingAutomatic sealingSynchronising machinesLiquid bottlingLotionMechanical engineering

The invention relates to sealing equipment, in particular to whitening lotion bottling and sealing equipment for skin care products. In order to solve the technical problems, the invention provides the whitening lotion bottling and sealing equipment for the skin care products, and the whitening lotion bottling and sealing equipment for the skin care products is time-saving and labor-saving, and can reduce the labor intensity and improve the working efficiency. According to the technical scheme, the whitening lotion bottling and sealing equipment for the skin care products comprises a bottom plate, machine frames, a guide frame, a bearing mechanism, a manual liquid injection mechanism and a manual sealing mechanism; the machine frames are symmetrically arranged at the top of the bottom plate; the guide frame is arranged at the tops of the machine frames; the bearing mechanism is arranged on the guide frame; the manual liquid injection mechanism is arranged on the bearing mechanism; and the manual sealing mechanism is arranged on the guide frame. According to the whitening lotion bottling and sealing equipment for the skin care products, through cooperation of a power mechanism, the automatic liquid injection mechanism and the automatic sealing mechanism, the equipment can achieve automatic liquid injection and sealing, and manual pressing is not needed.

Owner:湖北谷幽兰生物科技有限公司

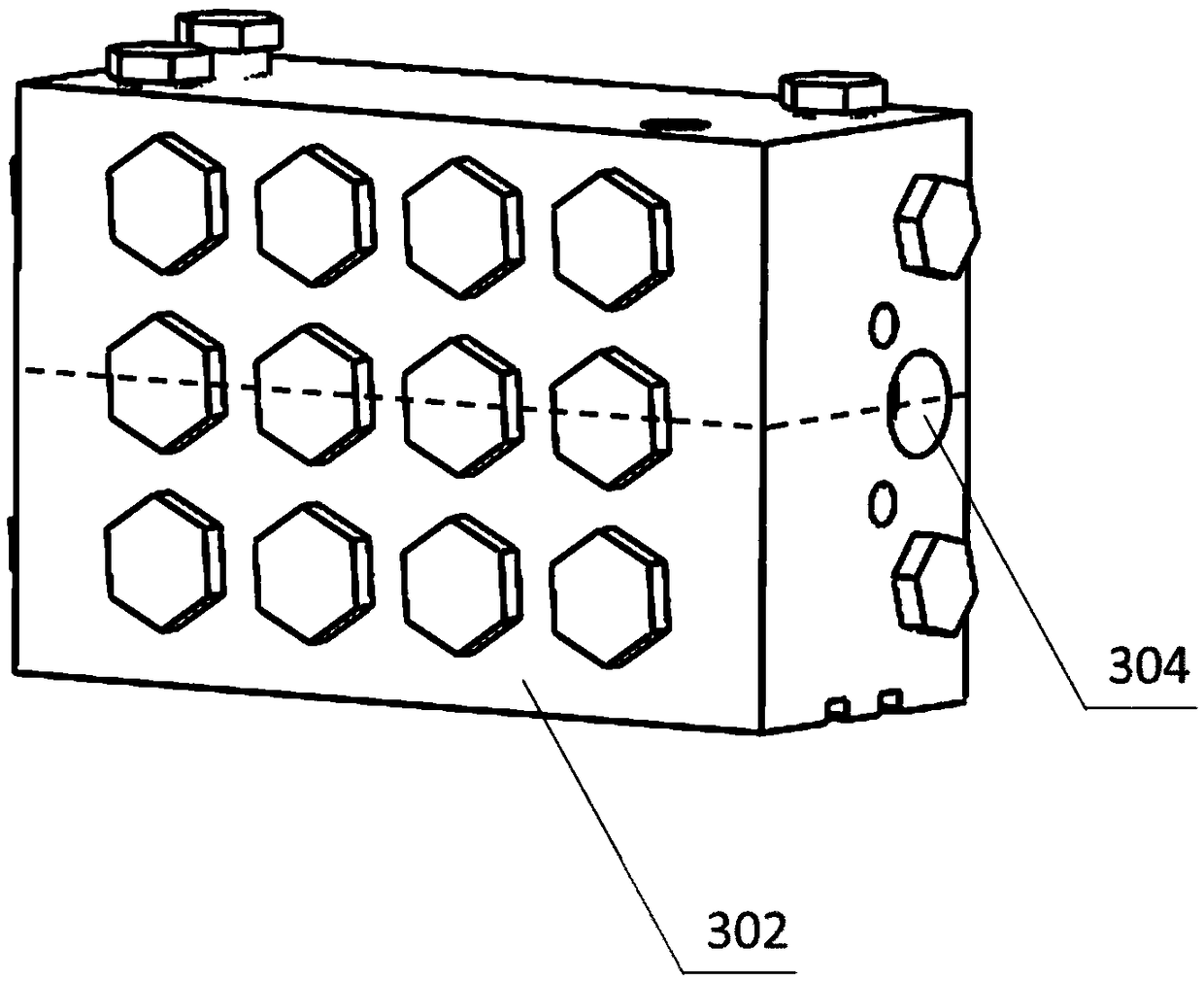

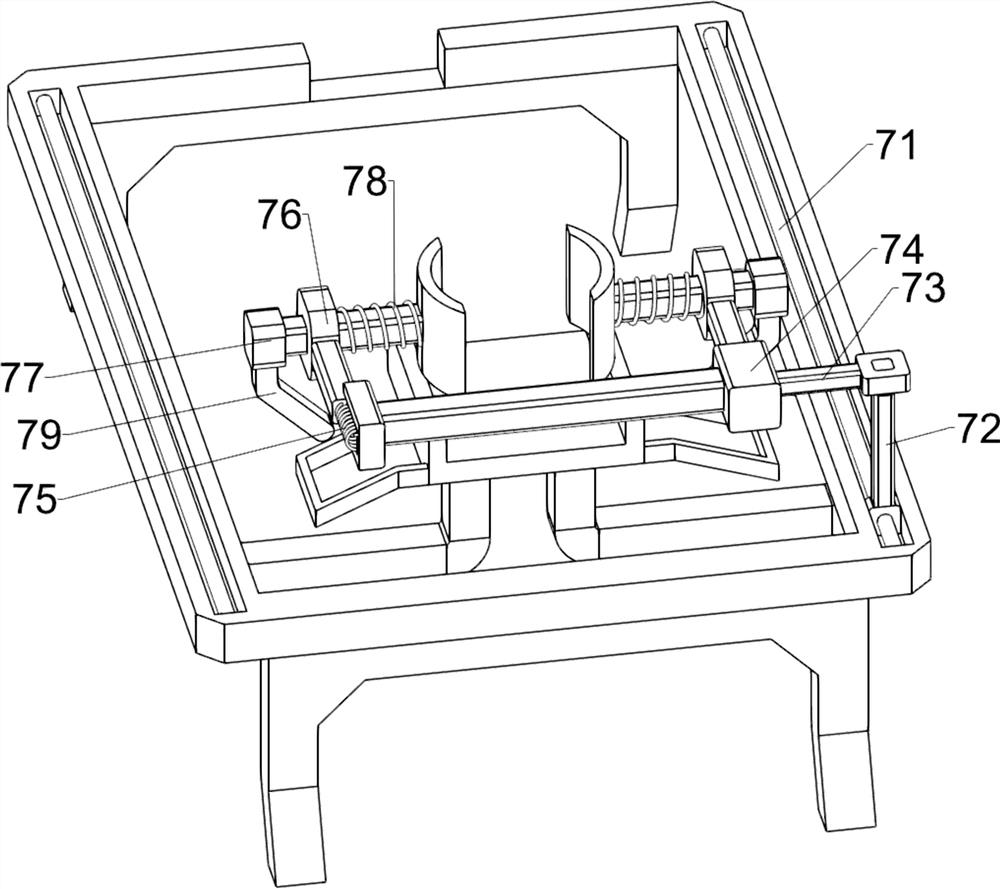

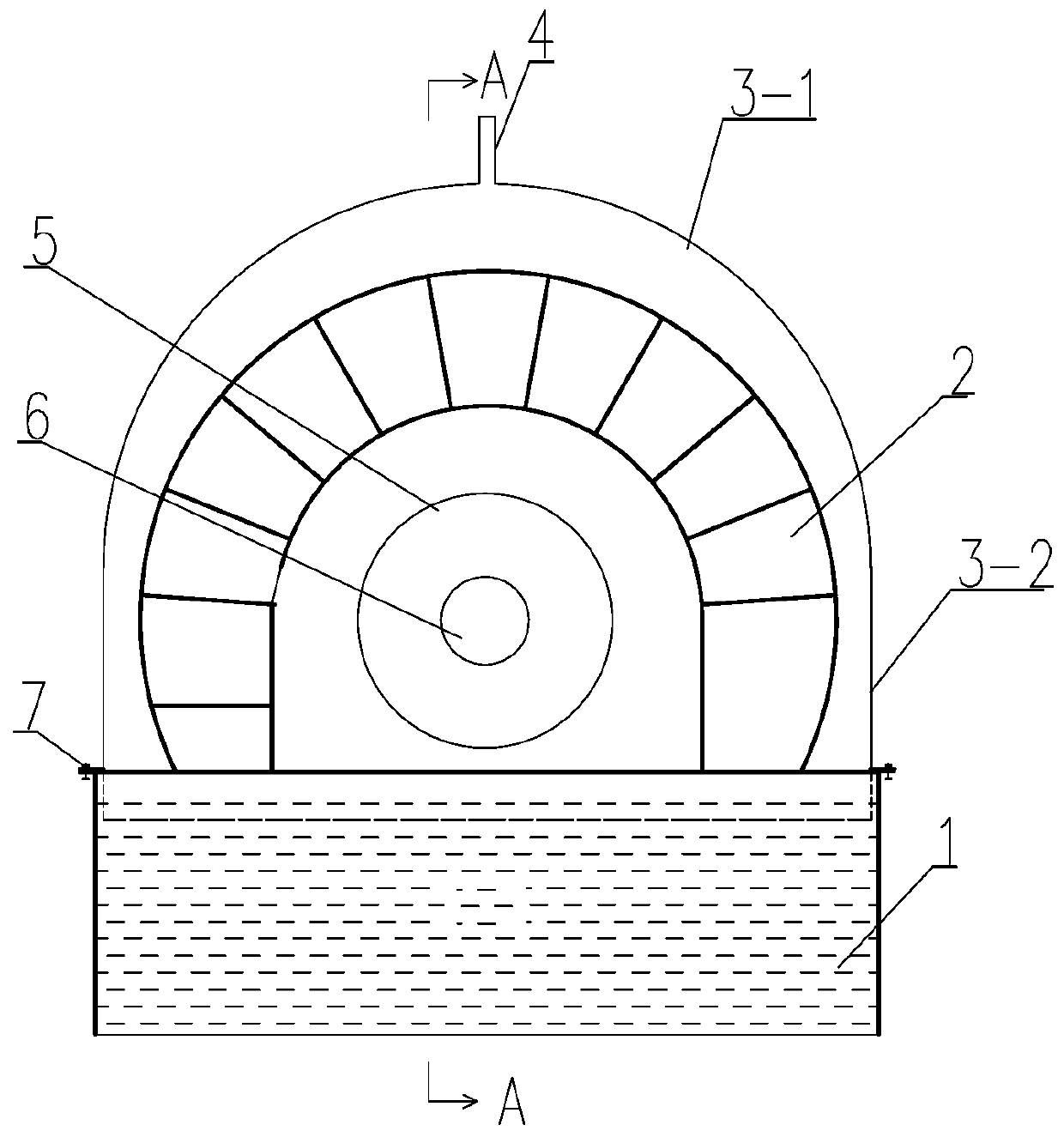

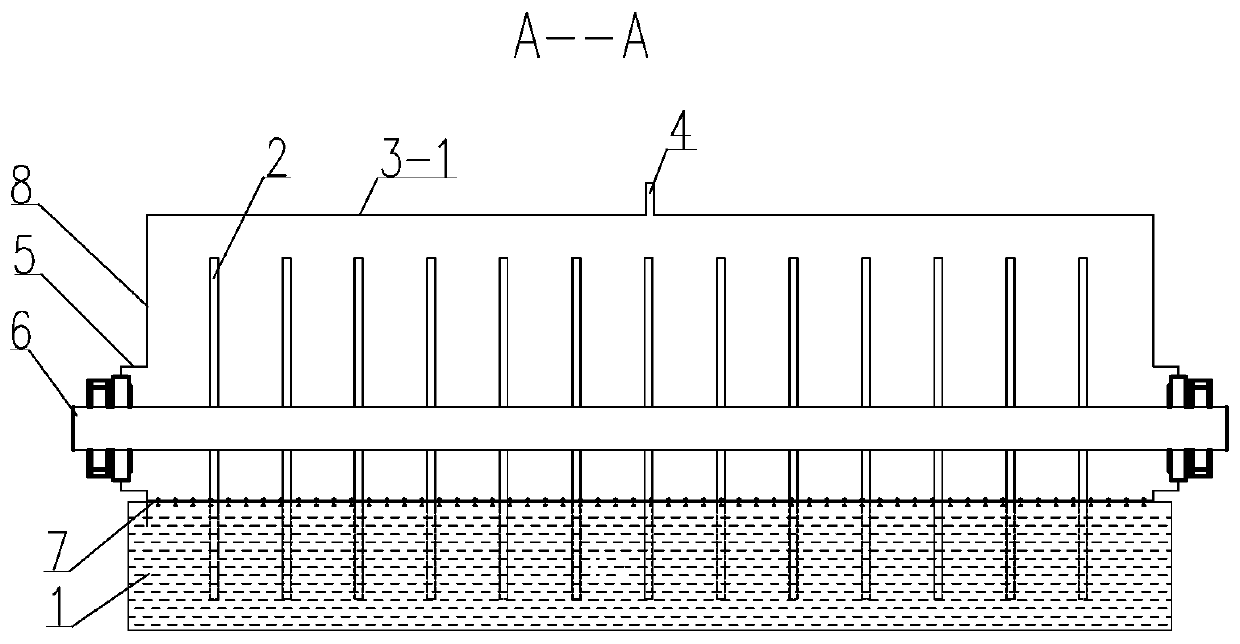

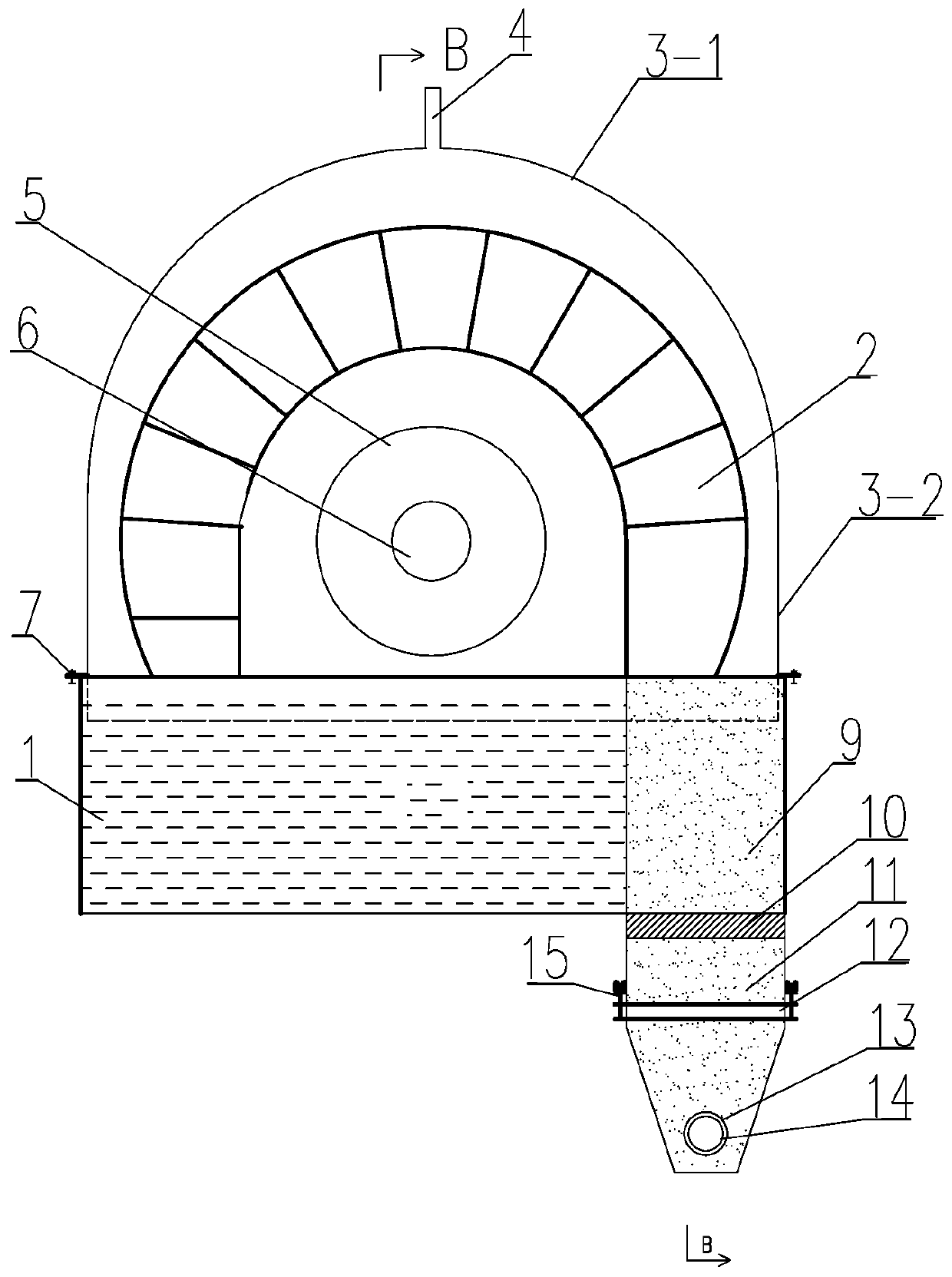

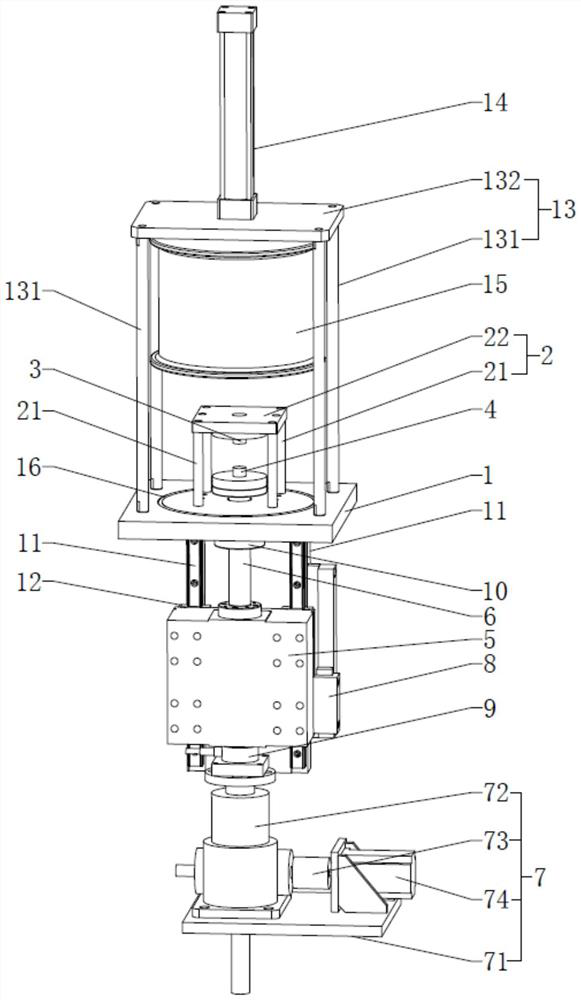

Pressurizing disc filter discharging device

ActiveCN107648922ASimple structureReduce the number of operationsMoving filtering element filtersImpellerFrequency conversion

The invention relates to a pressurizing disc filter discharging device which comprises a circular filter disc, a grout groove, a discharging groove, a scraper device for discharging, a pressurizing system and a discharging system. The device is characterized in that the discharging system is composed of a lower sealing material bin and a discharger, wherein the lower sealing material bin is used for stacking filter products and achieving the material layer sealing effect on compressed air; the discharger is located below a circular discharging outlet in the lower sealing material bin, a cylindrical feeding hopper is arranged at the upper portion of the discharger, an upper opening of the cylindrical feeding hopper is in bolt connection with the circular discharging outlet in the lower sealing material bin, a set of rotatable impellers annularly arranged at equal angles are arranged inside the discharger, an impeller shaft is connected with a frequency conversion motor of the discharger, the discharging outlet is formed in one side of the discharger, and a pressure gauge and the frequency conversion motor of the discharger are interlocked. The device has the advantages of being simple in structure, small in occupied space, small in occupied height difference, low in equipment and civil engineering investment, low in fault rate and capable of achieving continuous discharging andpreventing material blockage.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Anti-blocking intelligent hydraulic hoist with quantitative control function

ActiveCN110159601AAvoid cloggingSmooth circulationBarrages/weirsServomotor componentsHydraulic cylinderFuel tank

The invention relates to an anti-blocking intelligent hydraulic hoist with a quantitative control function. The anti-blockage intelligent hydraulic hoist comprises an oil tank, an oil injection pipe,an oil pumping pipe, a hydraulic pump, a hydraulic cylinder, a piston, a supporting block and a controller; the side, away from the supporting block, of the oil injection pipe is provided with a cleaning mechanism, and the side, away from the supporting block, of the oil pumping pipe is provided with a cleaning mechanism; a quantitative mechanism is arranged in the oil tank, wherein the quantitative mechanism comprises a floating block, a connecting assembly, a sliding rod, a balancing block, a sealing assembly and four fixing rods; and each cleaning mechanism comprises a cleaning pipe, a driving chamber, a supporting frame and a sealing assembly, and each cleaning pipe is provided with a frame and a sponge block. According to the anti-blocking intelligent hydraulic hoist with the quantitative control function, dust impurities adsorbed on a filter screen can be adsorbed in time through the cleaning mechanisms, so that net holes of the filter screen are prevented from being blocked, andthe smooth circulation of hydraulic oil is guaranteed; and moreover, in the oil tank, the quantitative mechanism can automatically realize sealing of the oil injection pipe according to the oil level, the quantitative hydraulic oil is conveniently added into the oil tank, and the practicability of equipment is improved.

Owner:扬州市慧宇科技有限公司

Leaked liquid cargo collecting device suitable for low-temperature liquid cargo tank

ActiveCN114148459AGuaranteed airtightRealize the collectionFor bulk goodsEngineeringMechanical engineering

Owner:JIANGNAN SHIPYARD GRP CO LTD +1

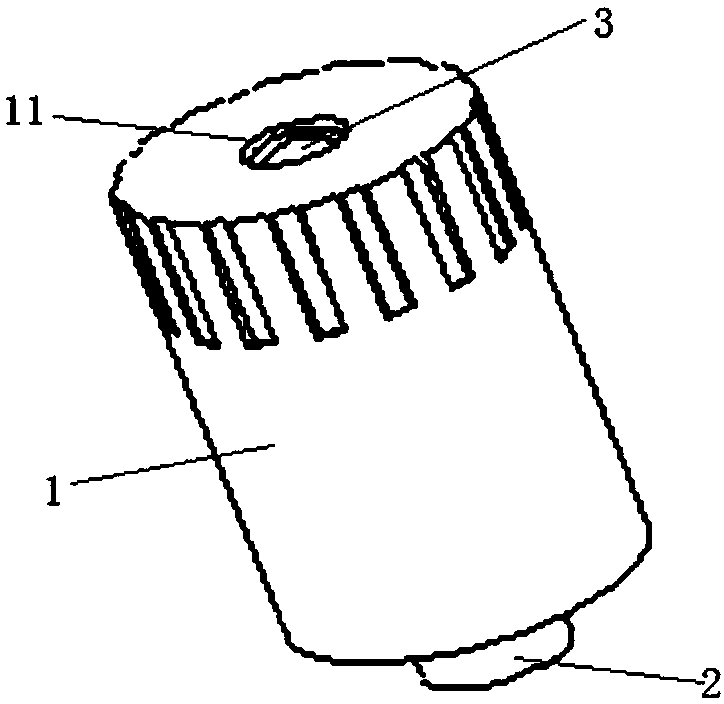

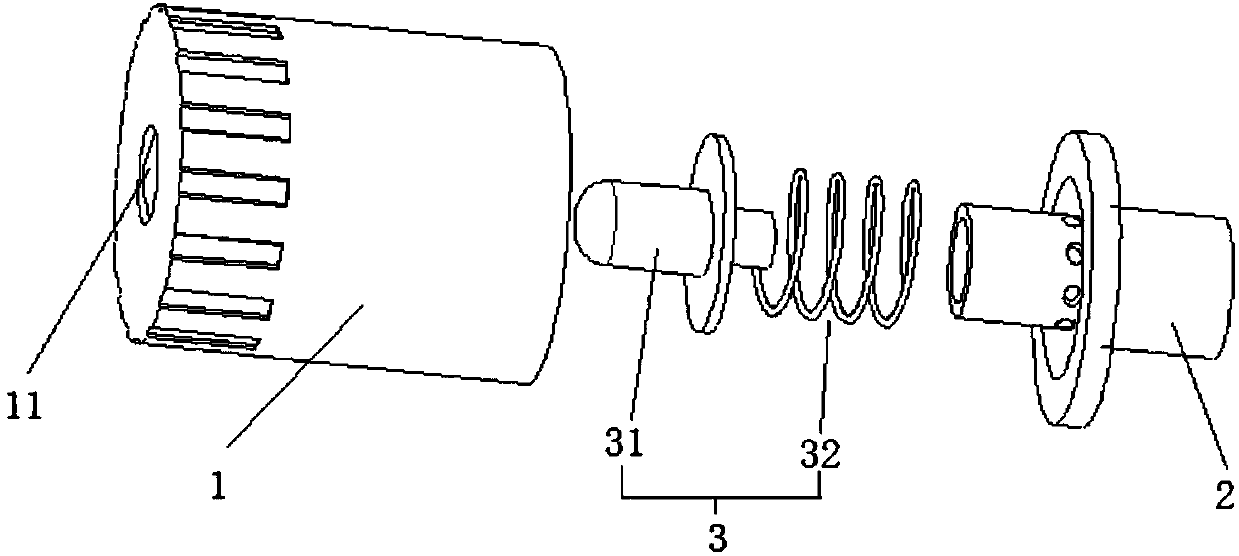

Sealing nut used for power battery

PendingCN109546021AEnough fit areaPlay the role of one-way checkSmall-sized cells cases/jacketsCell sealing materialsPower batteryInstability

The invention discloses a sealing nut used for a power battery. The sealing nut comprises a sealed outer shell, a fixed clamping base and a sealing head assembly. The fixed clamping base is arranged at the bottom part of the sealed outer shell and is used for connecting a battery cell. The sealing head assembly is arranged inside the sealed outer shell, and slides up and down in the sealed outer shell. One end of the sealing head assembly is elastically connected with the fixed clamping base. When the sealing head assembly slides to a highest point, the other end of the sealing head assembly penetrates a through hole in the top part of the sealed outer shell, and is used for sealing a liquid injection port of the battery cell. When the sealing head assembly slides to a lowest point, the sealing head assembly is arranged inside the sealed outer shell, and is used for opening the liquid injection port of the battery cell. Thus, the problem of deterioration in sealing performance becausescrew threads of a sealing column are worn by screwing / unscrewing the nut repeatedly for many times is solved, the processes of screwing / unscrewing the nut in working procedures such as liquid injection, formation and encapsulation of steel balls are reduced, the operation efficiency can be improved, the cost can be reduced, automatic sealing is realized, and the instability brought by manual operation is reduced.

Owner:YINLONG ENERGY CO LTD

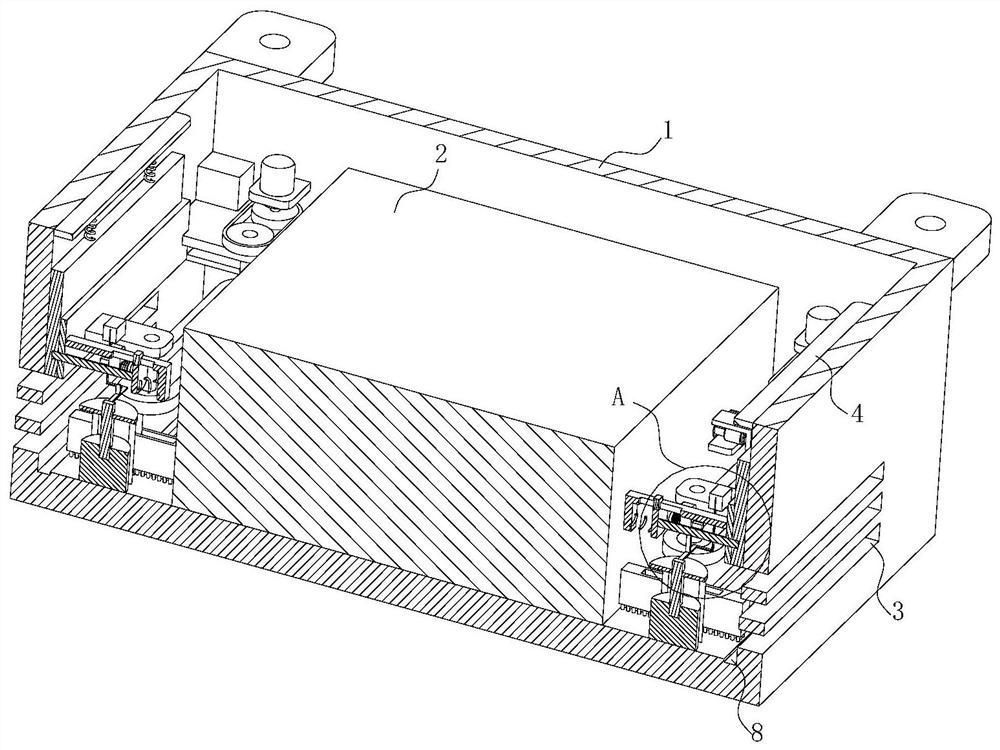

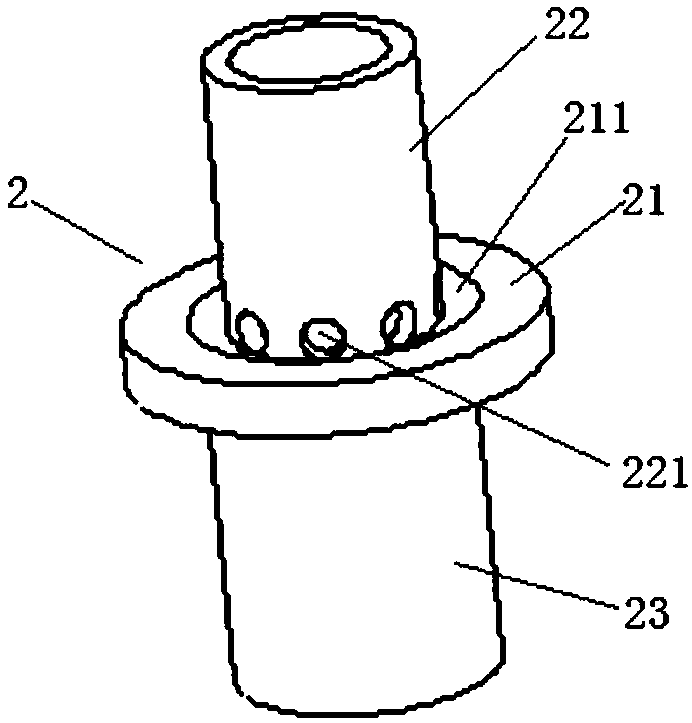

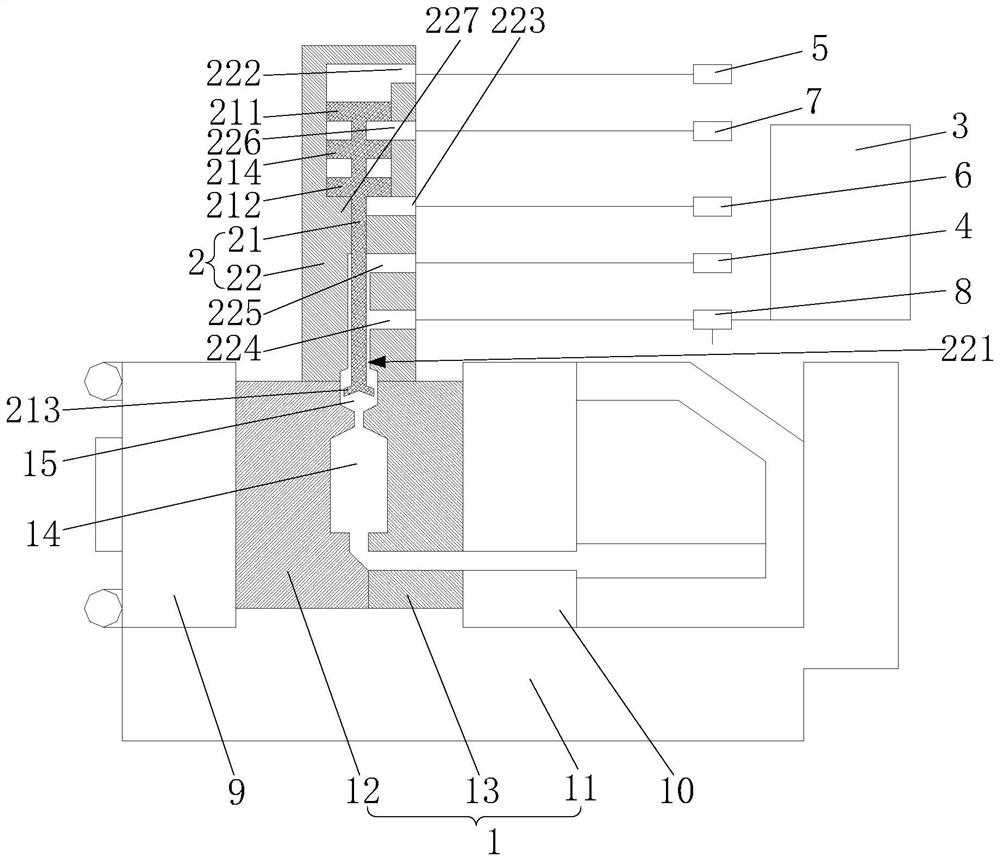

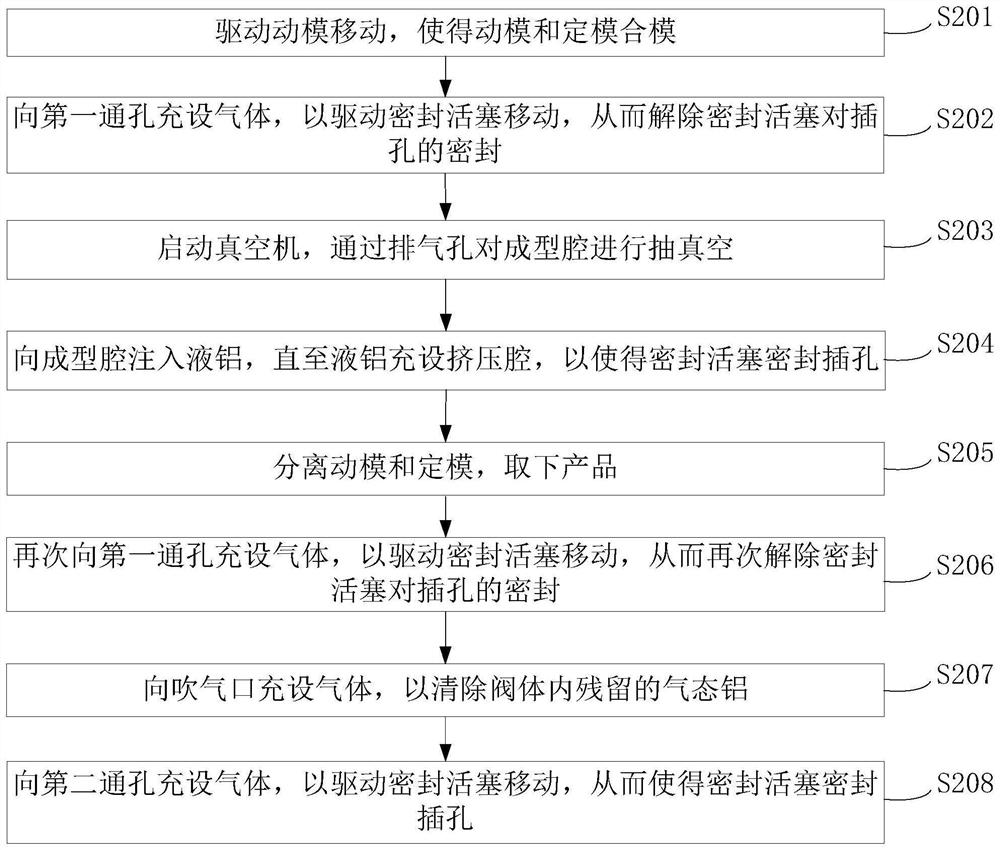

A kind of vacuum casting system and using method

The invention discloses a vacuum casting system and a using method, belonging to the field of die casting machines. The vacuum casting system includes a die-casting machine, a vacuum valve and a vacuum machine. The die-casting machine includes a base, a movable mold and a fixed mold. The fixed mold is fixed on the base. The movable mold is slidably located on the base. The molding cavity and the extrusion cavity are connected, and the molding cavity and the extrusion cavity are connected. The valve includes a valve core and a valve body. The outer wall of the valve body is slidably inserted into the inner wall of the valve body, the sealing piston is movably located in the extrusion cavity, the valve body is located on the fixed mold, and the valve body has an insertion hole, a first through hole for inflation, and a Inflatable second through hole, exhaust hole and air blowing hole, the valve core is movably inserted in the socket, and the exhaust hole communicates with the vacuum machine. The vacuum casting system provided by the invention can effectively prevent the aluminum liquid from clogging the vacuum valve.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

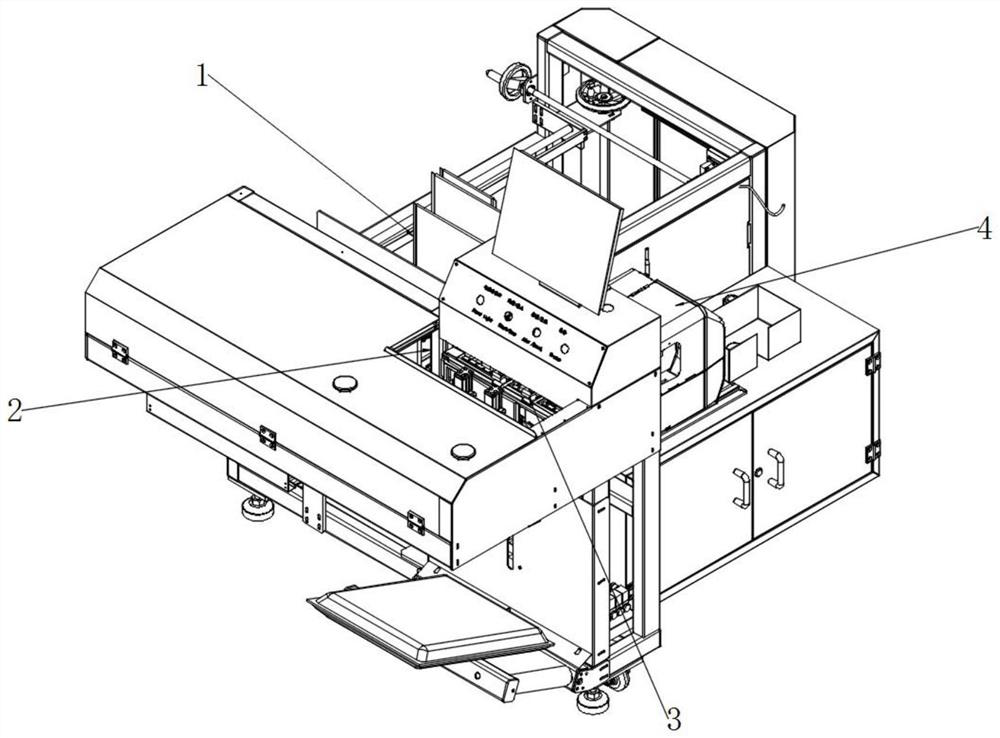

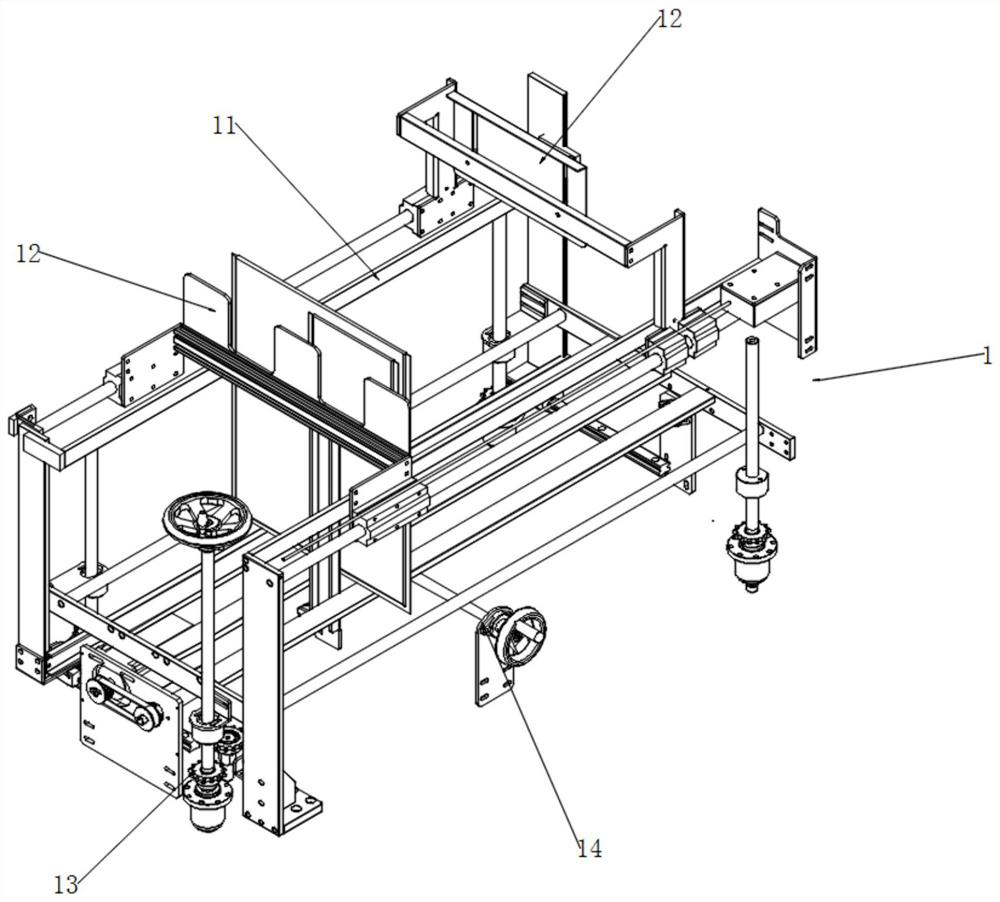

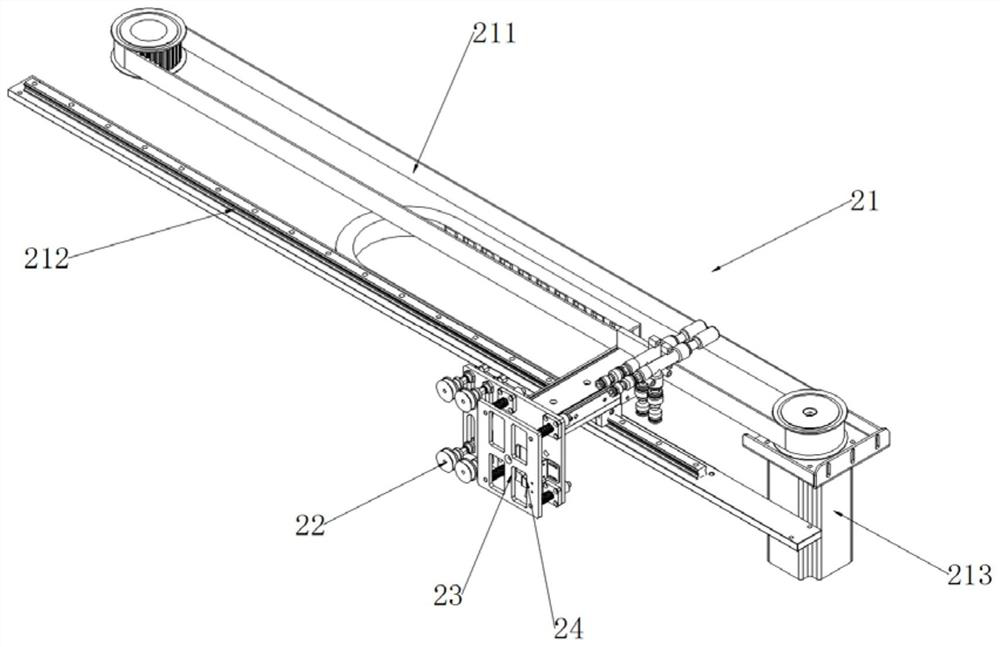

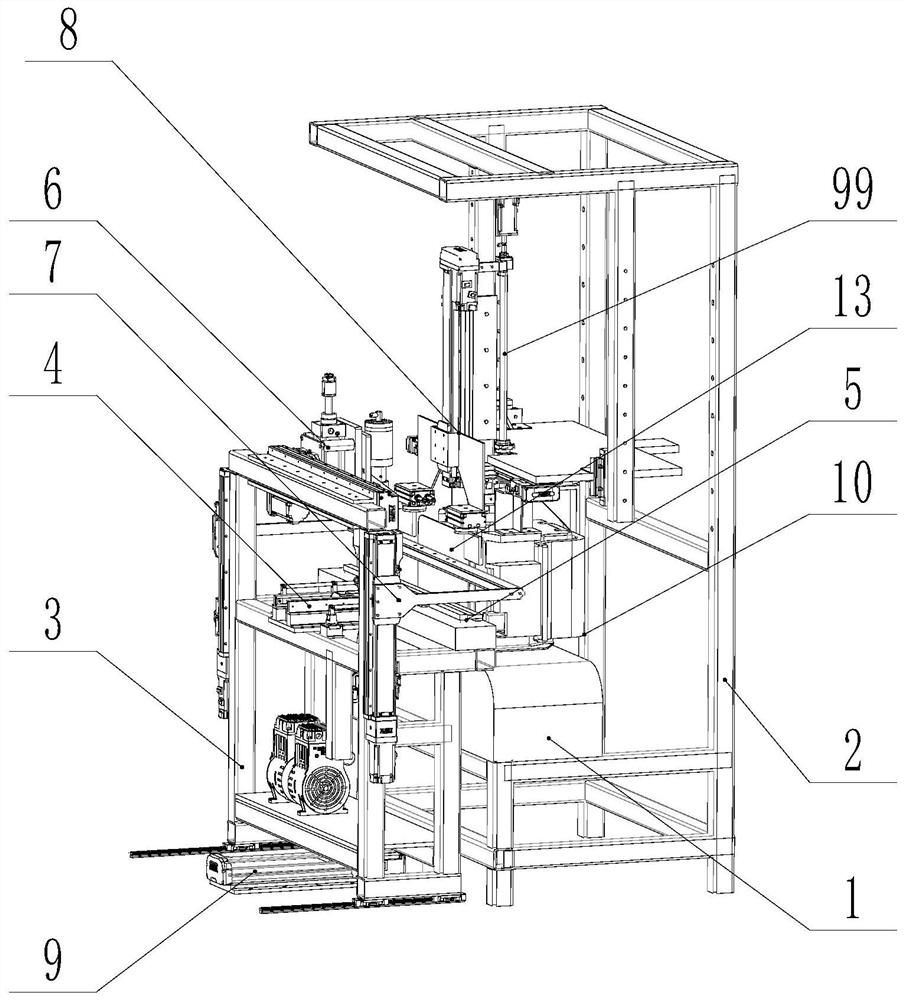

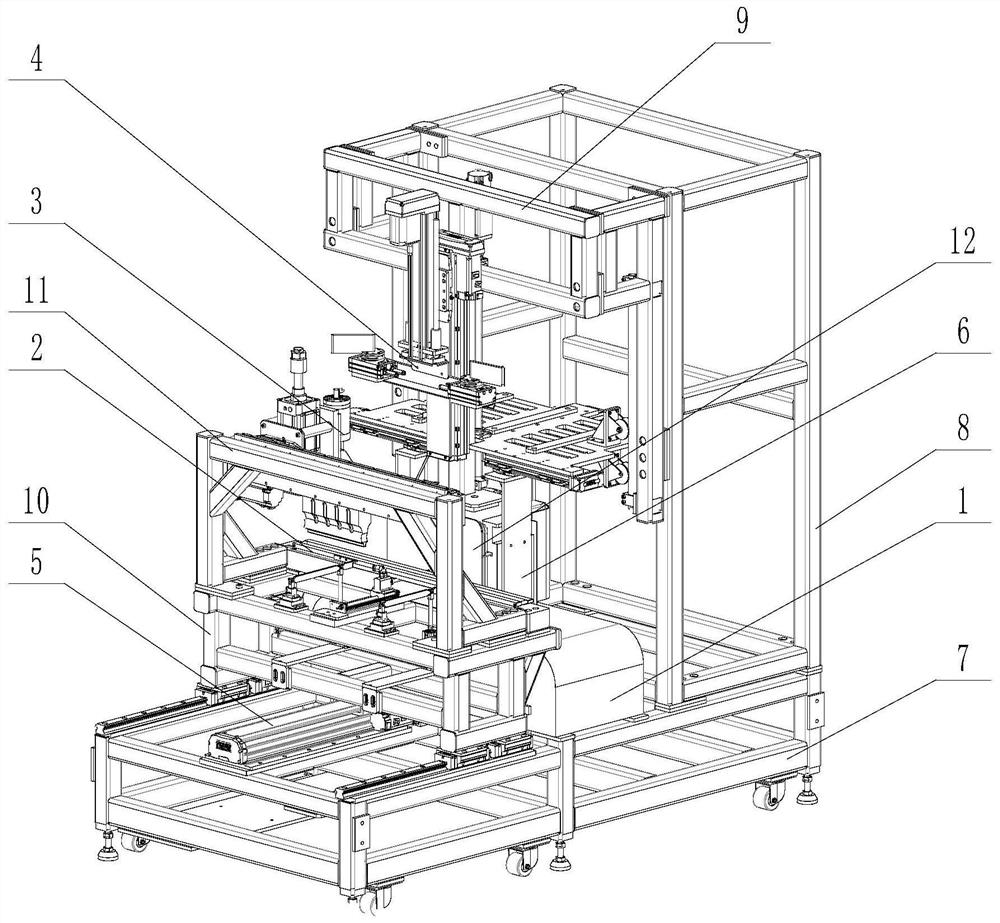

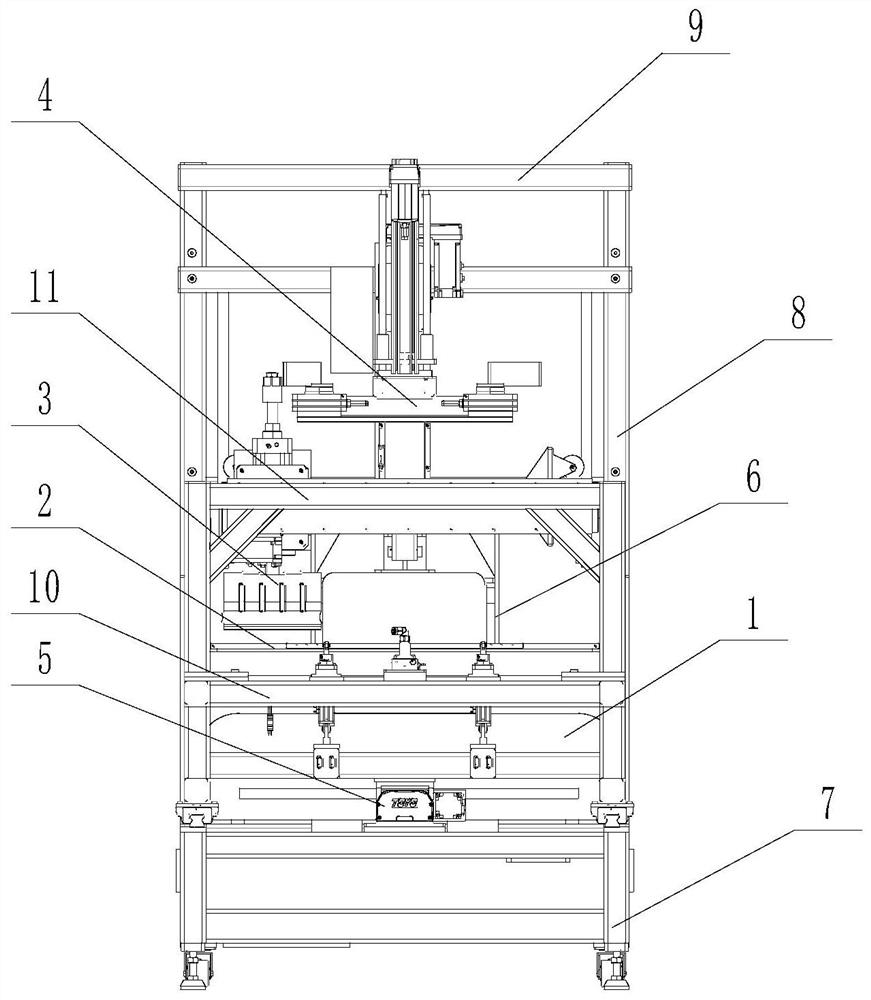

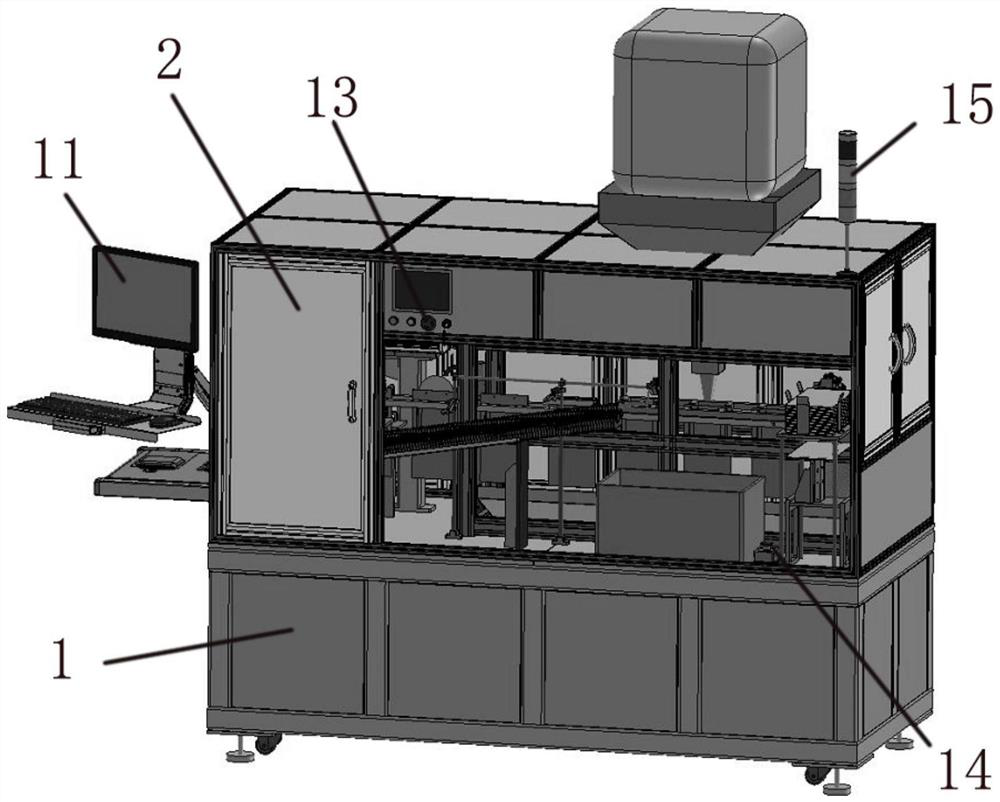

Shaping device for bagged FOSB packaging bags

InactiveCN112429305ACompact structureFit closelyPackaging by pressurising/gasifyingWrapper twisting/gatheringPumping vacuumEngineering

The invention discloses a shaping device for bagged FOSB packaging bags. The shaping device comprises a shaping machine frame, a sealing machine frame, a FOSB conveying belt, a vacuumizing device, anopening clamping device, an ultrasonic sealing device, a FOSB front-end upturning device, a FOSB front-end shaping device, a sealing station horizontal driving device and a FOSB back side surface shaping device. The FOSB conveying belt, the FOSB front-end shaping device and the FOSB back side face shaping device are installed on the shaping machine frame, the sealing station horizontal driving device is arranged on the ground on one side of the shaping machine frame, the sealing machine frame is fixed to the movable end of the sealing station horizontal driving device, and the FOSB front-end upturning device, the vacuumizing device, the opening clamping device and the ultrasonic sealing device are all fixed to the sealing machine frame. According to the shaping device for the bagged FOSB packaging bags, the bagged FOSB packaging bags can be vacuumized and automatically shaped, the shaping efficiency is improved, the whole process is fully automatically carried out, and the labor cost is reduced.

Owner:无锡迪渊特科技有限公司

A special chemical product transportation device

ActiveCN111619628BImproved Hybrid StructureReduce Rigid DamageShaking/oscillating/vibrating mixersSledge wheelsReciprocating motionLiquid storage tank

The invention provides a special chemical product transportation device, which relates to the field of chemical raw material transportation, and solves the problem that the up and down buffering of the buffer wheel cannot be used to drive the unpowered mixing of the liquid in the liquid storage tank; it cannot realize the cooperation of multiple sealing structures. The improvement of the sealing effect cannot be achieved in conjunction with non-powered mixing to improve the sealing effect. A transport device for special chemical products, comprising a main body of a transport vehicle, a sealing block and a force plate; a liquid storage barrel is fixedly placed on the main body of the transport vehicle. Second, because the distance from the force plate to the rotating shaft is less than the length of the toggling rod, when the toggling rod rotates with the rotating shaft, the cylindrical sliding rod and the sealing plate are in a state of reciprocating up and down under the toggling of the toggling rod, and at this time The sponge pad is in a squeezed state under the extrusion of the sealing plate, thereby realizing the sealing between the sealing block and the cylindrical tube, thereby preventing the liquid storage barrel from shaking and causing the liquid to splash out.

Owner:SHANGHAI DINGMING CONTAINER STORAGE & TRANSPORTATION CO LTD

Forming mold for aluminum-plastic panel

The present invention is applicable to the technical field of forming aluminum-plastic panels, and provides a molding die for aluminum-plastic panels. The molding mold for aluminum-plastic panels includes: The assembly is equipped with a lower template, and the access assembly is used to automatically close the chassis and take out the lower template; a pneumatic cylinder is installed inside the chassis, and an air pressure rod is arranged inside the air cylinder, and the air pressure rod An upper template is installed at one end, and a clamping assembly is provided between the lower template and the upper template, and the clamping assembly is used to fit the upper template and the lower template during the molding process; the mold unloading assembly is located at The interior of the lower template is used to automatically jack up the formed aluminum-plastic panel; by setting the access component, the removal of the formed aluminum-plastic panel is more convenient, and by adding the mold removal component, the demoulding effect is better.

Owner:江苏吉鼎金属制品有限公司

Packaging and shaping method for bagged FOSB sealed by ultrasonic waves

ActiveCN112429307AImprove packaging efficiencyCompact designPackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpingAir pump

The invention discloses a packaging and shaping method for a bagged FOSB sealed by ultrasonic waves. The method comprises the following specific steps that the FOSB is moved onto a shaping station, abag opening of a packaging bag is clamped, a vacuum air suction pipe is inserted in, and shaping of the back surface and the side surface of the FOSB is conducted while the interior of the packaging bag is subjected to vacuum pumping by the vacuum air suction pipe; After vacuum pumping is completed, the vacuum air pumping pipe is pumped out, and an ultrasonic sealing device conducts sealing operation on the bag opening of the clamped packaging bag; and after the sealing operation is completed, a vacuumizing device and the ultrasonic sealing device are moved to the initial positions, an FOSB front-end shaping device begins to shape the packaging bag on the front face of the FOSB, the FOSB is moved away after shaping is completed, and finally the FOSB front-end shaping device is reset. By adoption of the method, vacuumizing and automatic shaping of the bagged FOSB packaging bag can be automatically achieved, the shaping efficiency is improved, the whole process is fully automatic, and the labor cost is reduced.

Owner:无锡迪渊特科技有限公司

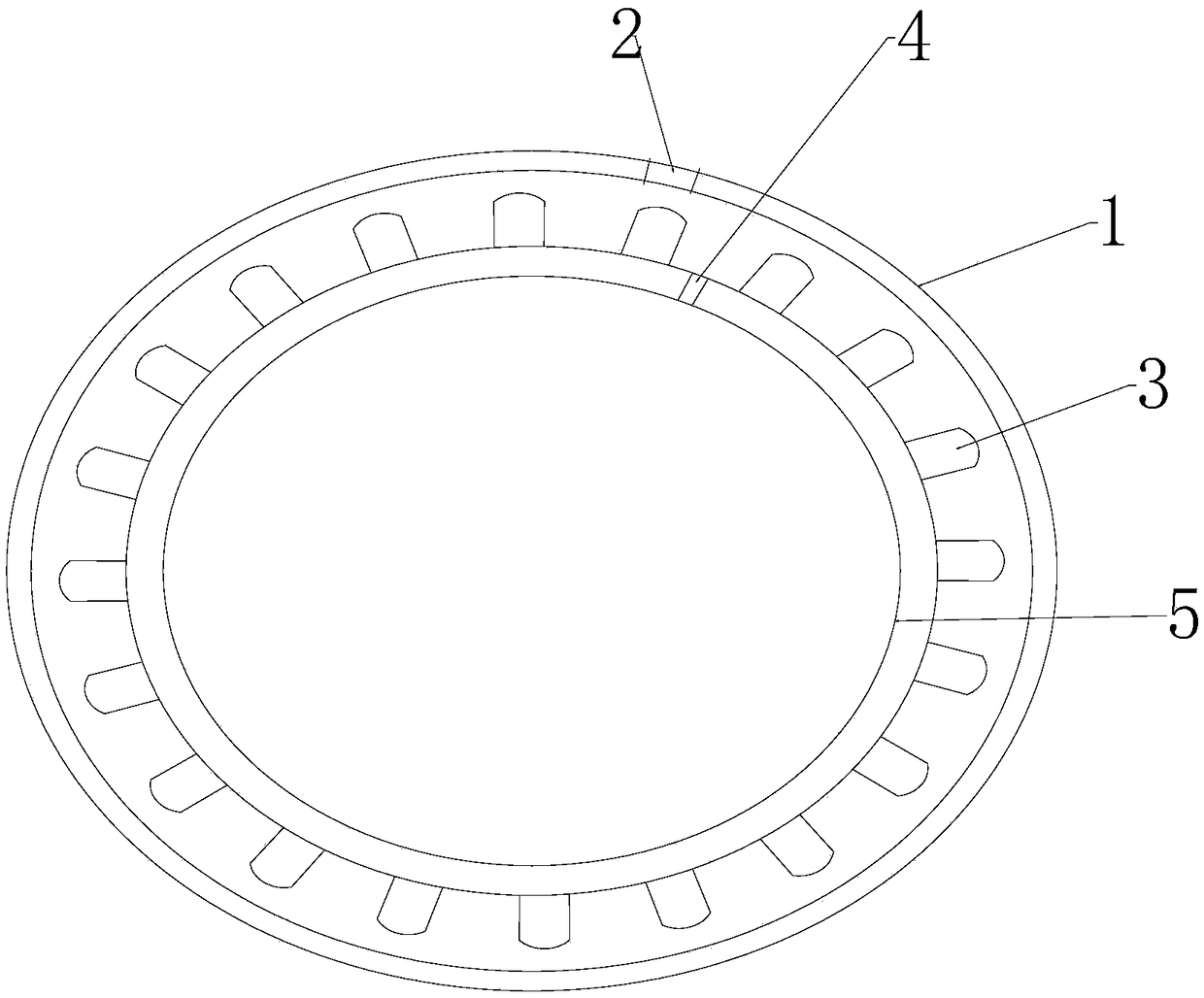

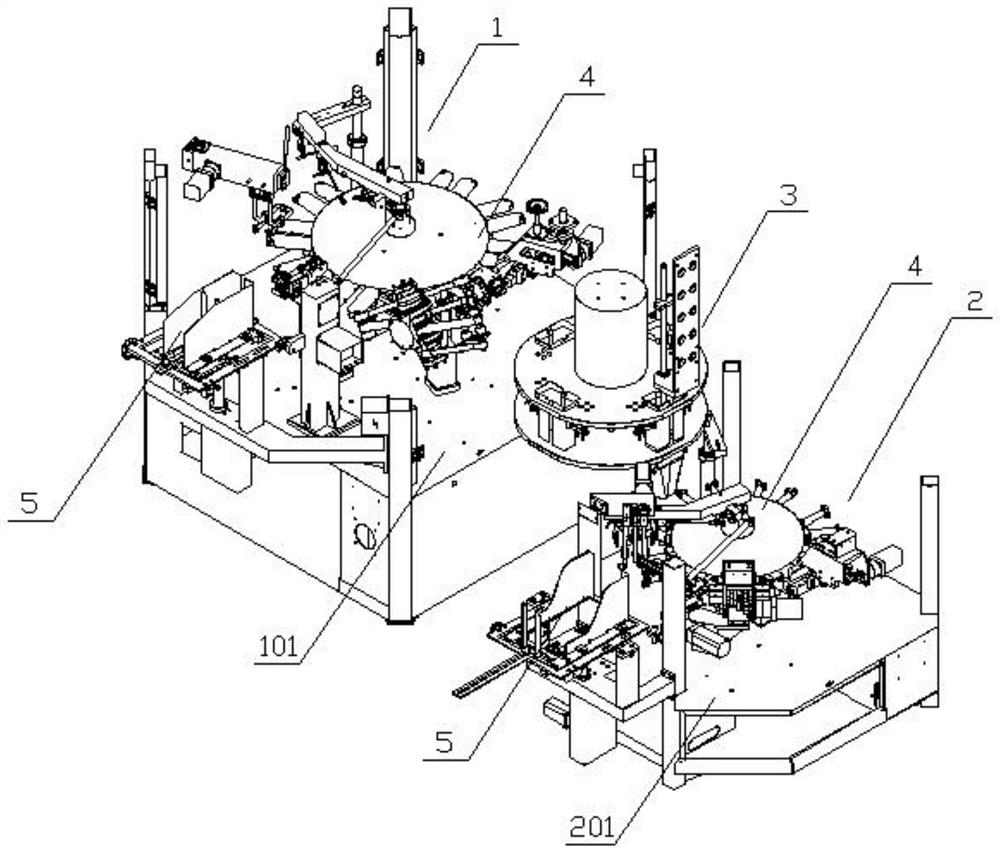

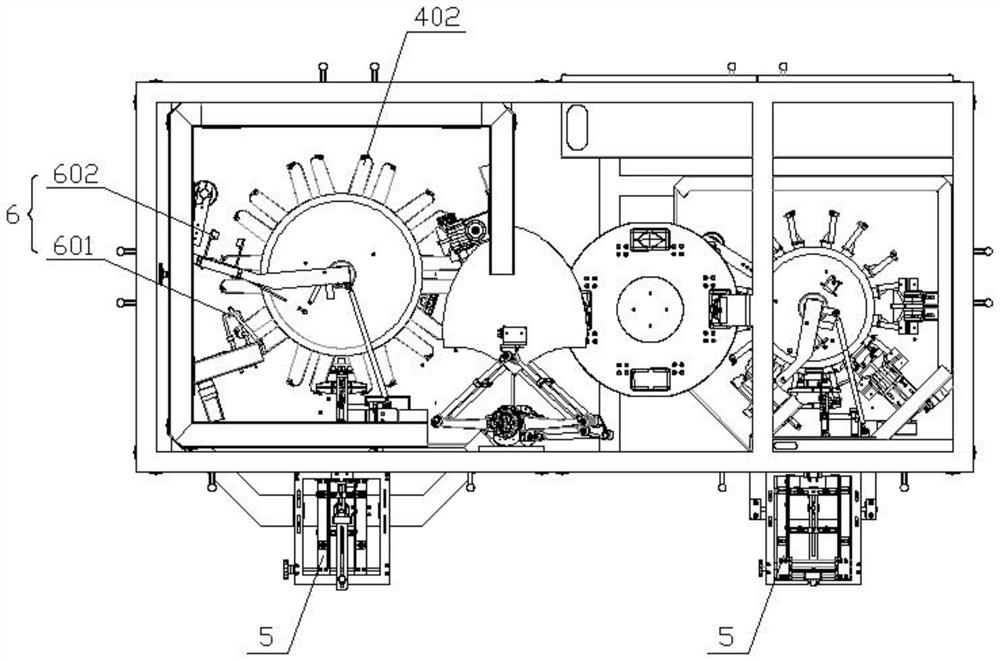

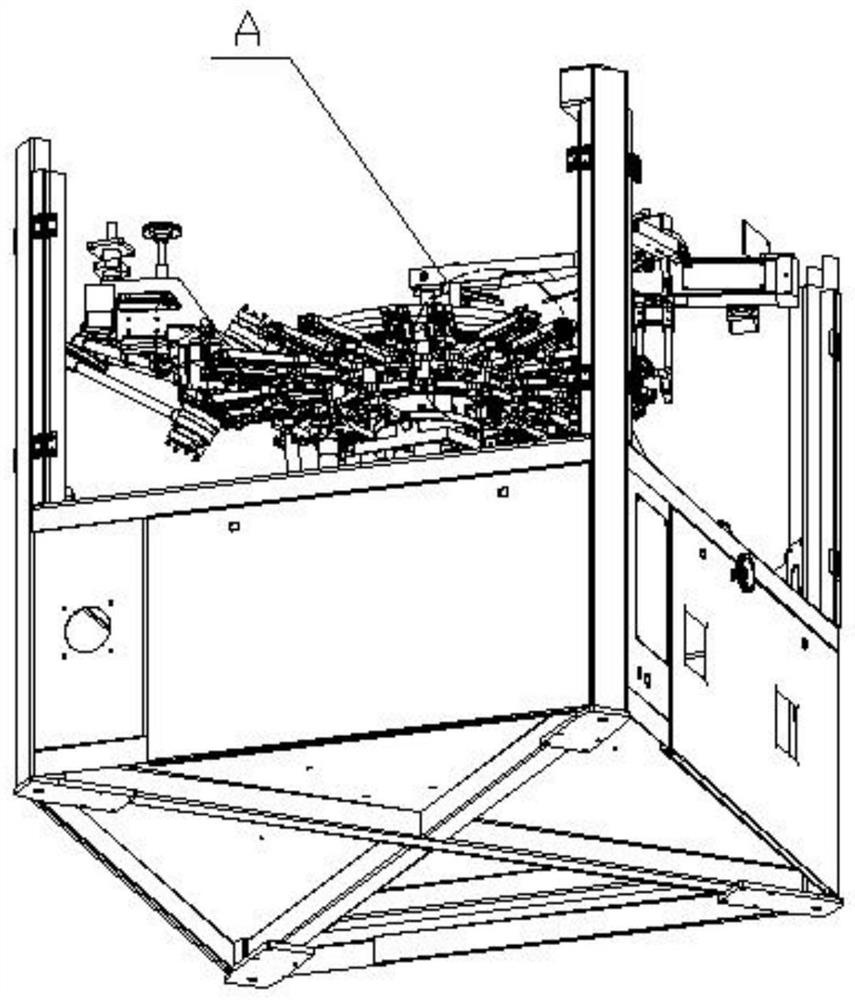

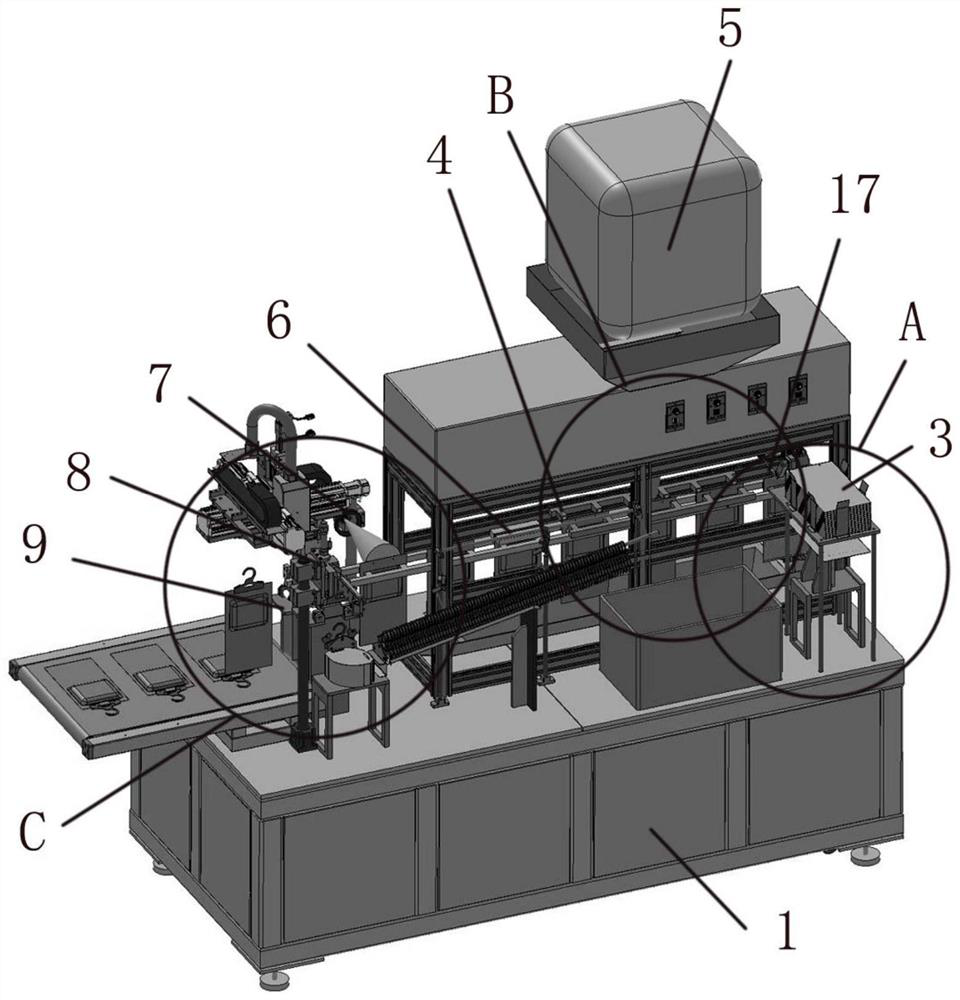

Inner and outer packaging all-in-one machine

PendingCN114802994AAutomatic fillingAutomatically realize sealing and other processesWrapper twisting/gatheringLiquid materialEngineeringMechanical engineering

The invention discloses an internal and external packaging all-in-one machine, which belongs to the field of packaging machinery and comprises an inner bag packaging part, an outer bag packaging part and a transfer part between the inner bag packaging part and the outer bag packaging part, the inner bag packaging part comprises an inner packaging workbench, the outer bag packaging part comprises an outer packaging workbench, the inner packaging workbench and the outer packaging workbench are each provided with a bagging mechanism, each bagging mechanism comprises a rotating ring rotating along the vertical axis, and each rotating ring is provided with a clamping set used for clamping the edges of the two sides of a packaging bag. The clamping set comprises clamping jaws which are horizontally arranged at intervals, and the distance between the clamping jaws on the two sides is adjustable. Bag opening devices are arranged on the inner packaging workbench and the outer packaging workbench. The invention aims to provide the internal and external packaging all-in-one machine which can improve the packaging efficiency.

Owner:湖南西胜智能装备有限公司 +1

Packaging shaping method of bagging fosb by ultrasonic sealing

ActiveCN112429307BImprove packaging efficiencyCompact designPackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpingProcess engineering

The invention discloses a packaging and shaping method of bagged FOSB using ultrasonic sealing, which specifically includes the following steps: moving the FOSB to a shaping station, clamping the mouth of the packaging bag and inserting a vacuum suction pipe, and the vacuum suction pipe is placed on the packaging bag While vacuuming the inside, the back and side of the FOSB are shaped; after the vacuuming is completed, the vacuum suction pipe is drawn out, and the ultrasonic sealing device seals the bag mouth that is clamped; after the sealing operation is completed, the vacuuming device and ultrasonic sealing The device moves to the initial position, and the FOSB front-end shaping device starts to shape the front packaging bag of the FOSB. After the shaping is completed, the FOSB is removed, and finally the FOSB front-end shaping device is reset. The invention can automatically realize the vacuuming and automatic shaping of the bagged FOSB packaging bag, improves the shaping efficiency, and the whole process is fully automated to reduce the labor cost.

Owner:无锡迪渊特科技有限公司

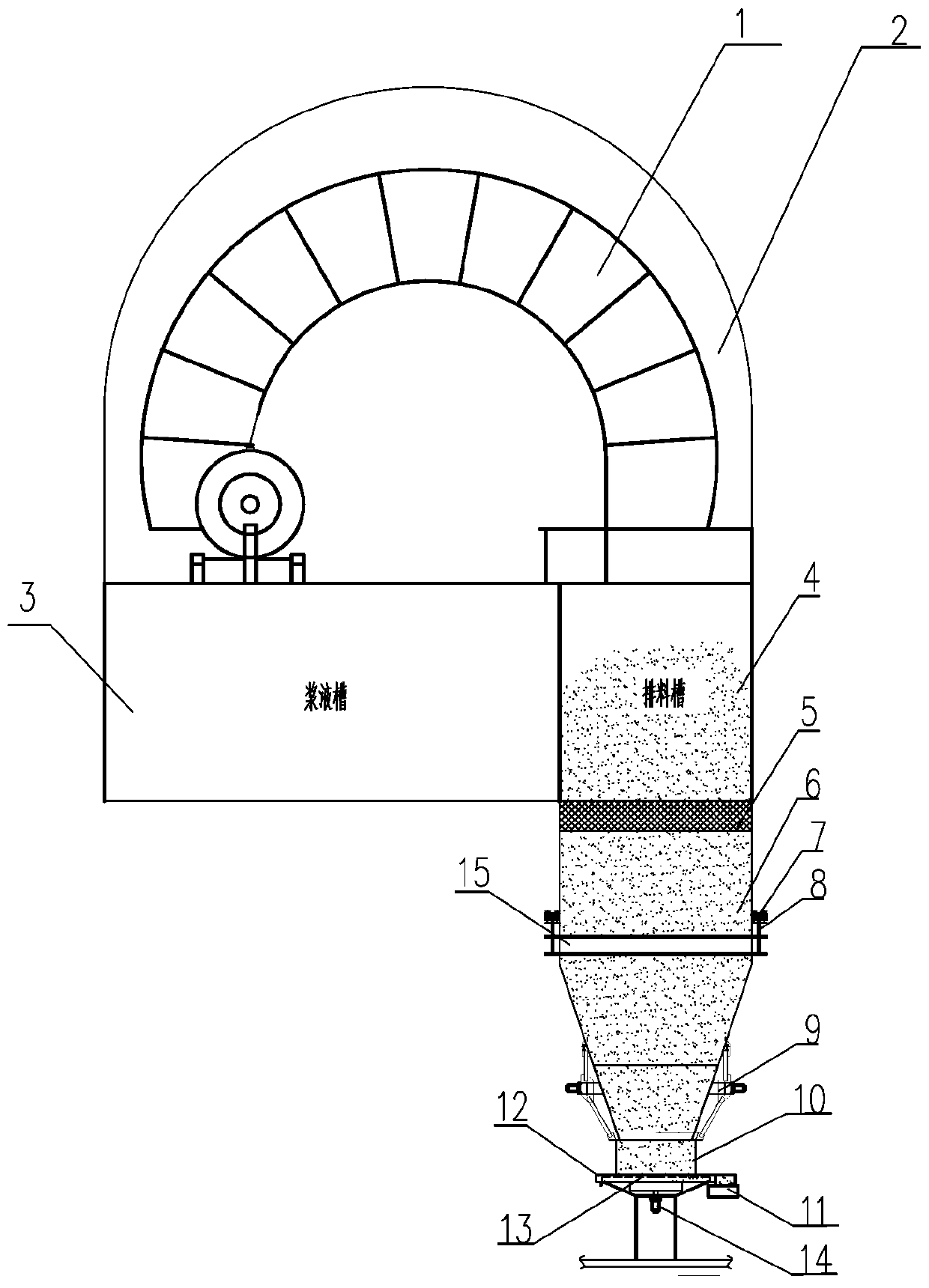

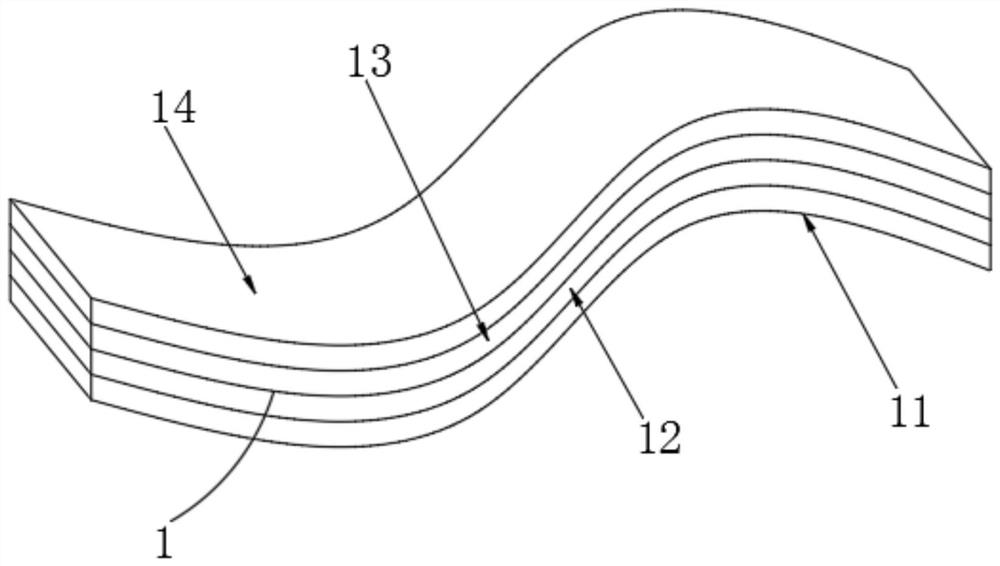

Self-sealing pressurizing plate type filter

ActiveCN107583342AReduce moistureReduce energy consumptionMoving filtering element filtersSlurryMoisture

The invention relates to a self-sealing pressurizing plate type filter which comprises a spindle, a circular filtering disc, a slurry tank, a discharge tank, a scraper device, a discharging system anda pressurizing system. The self-sealing pressurizing plate type filter is characterized in that the discharging system comprises the discharging tank, a discharging cabin and a bolt conveyer; the pressurizing system comprises a pressurizing cabin and a central cylinder; the pressurizing cabin is arranged on the upper part of the slurry tank and the discharge tank; the central cylinder is connected with the pressurizing cabin and is sleeved on an outer edge of the spindle; an interface pipeline for compressed air is arranged on an arc-shaped cabin on the upper part of the pressurizing cabin. The self-sealing pressurizing plate type filter has the advantages of simple pressurizing mode, less space occupation, small elevation difference, low equipment and civil engineering cost, low failurerate, convenience in overhauling, capability of realizing self-sealing, low energy consumption and capability of effectively reducing moisture of filtered products.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

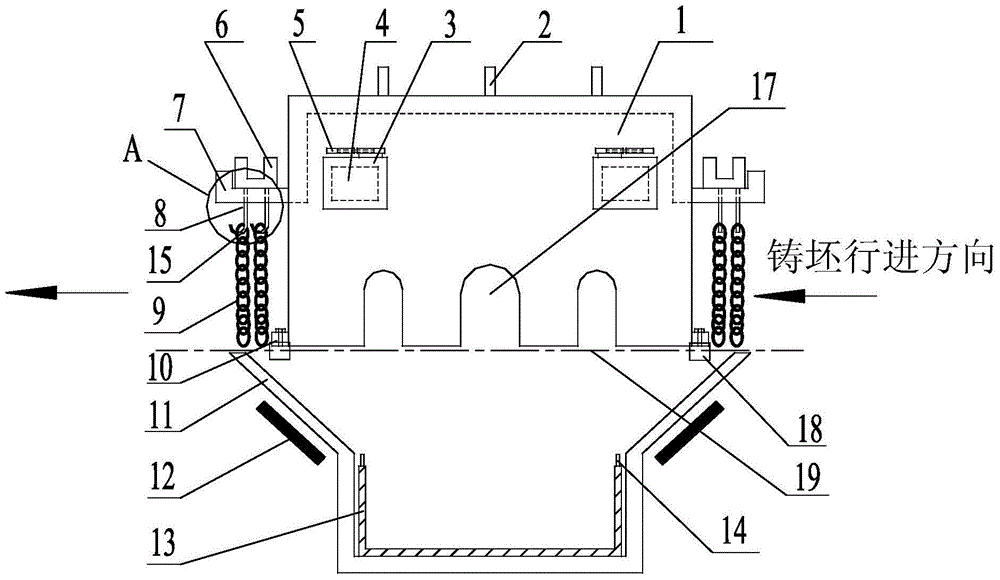

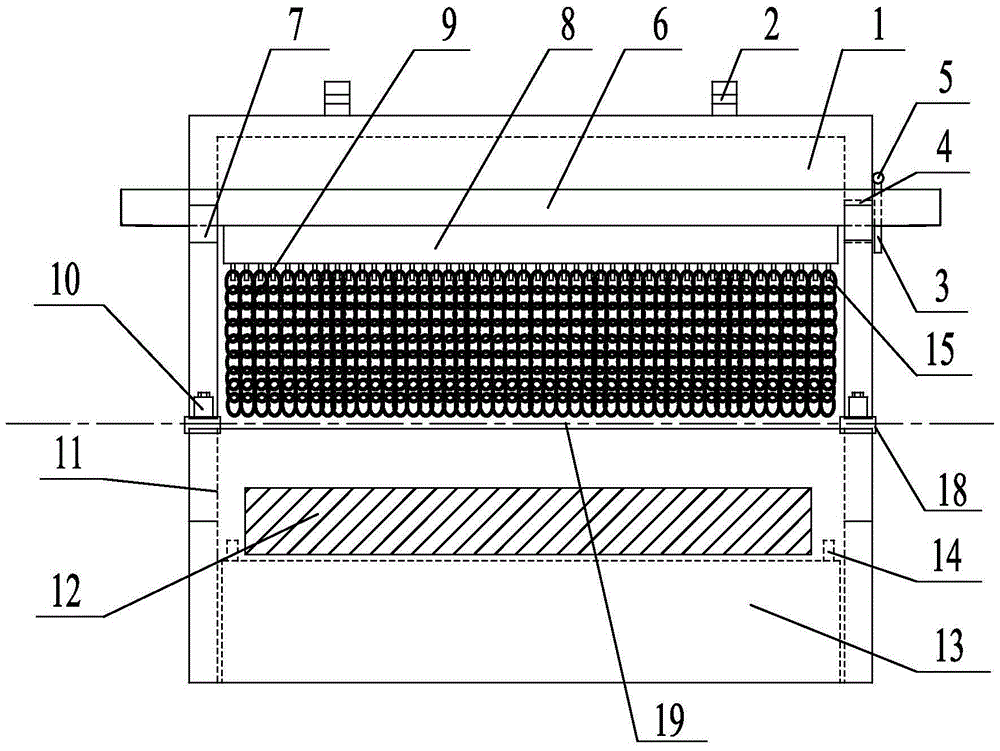

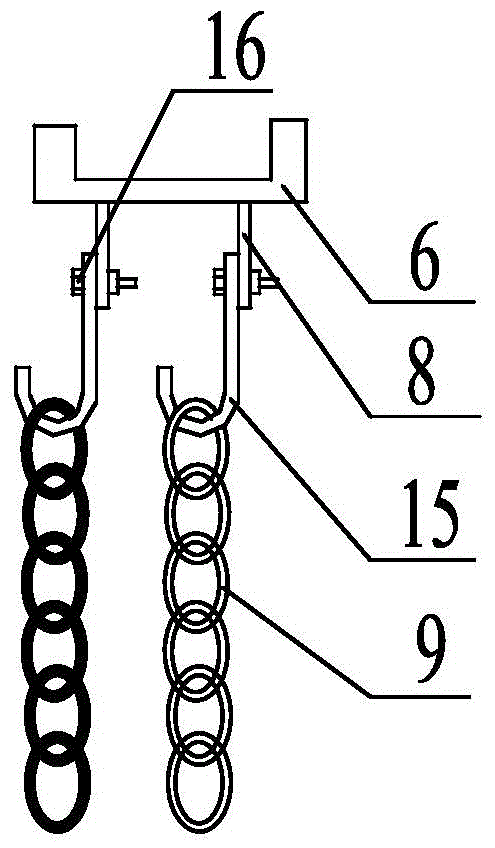

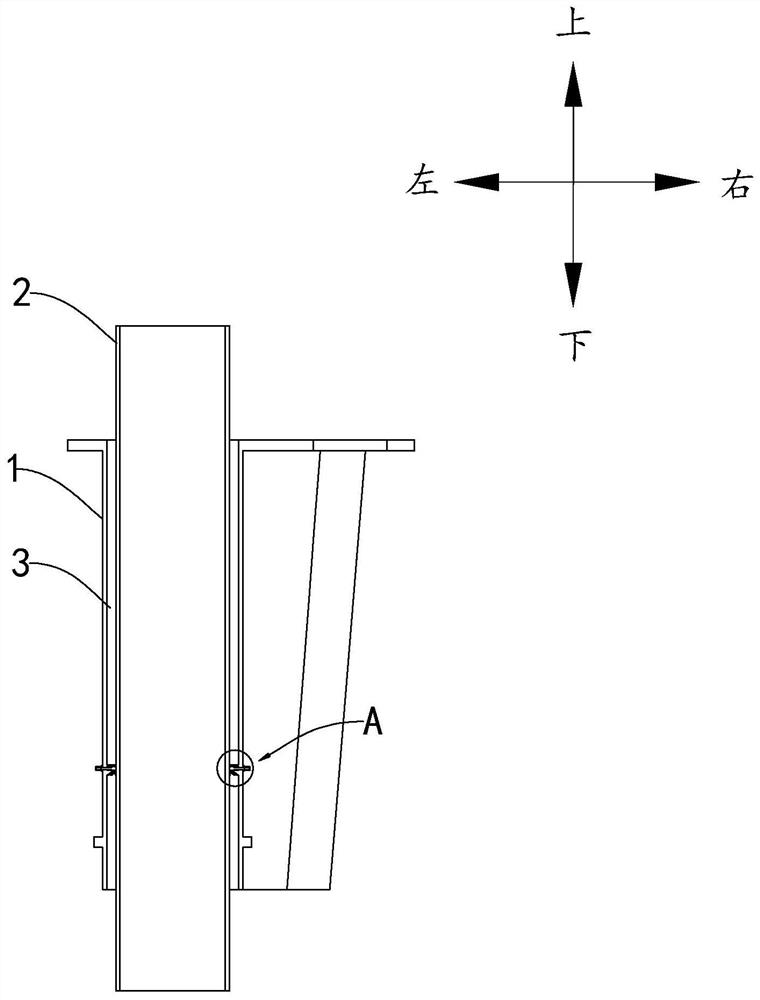

Deburring machine dust cover

The invention discloses a dustproof cover of a deburring machine. The dustproof cover comprises a protection cover with an opening in the bottom. The protection cover is fixed to foundations through positioning bases. Supporting frames are fixed to the two sides of the casting blank input end of the protection cover and the two sides of the casting blank output end of the protection cover respectively. A U-shaped rod is placed on the supporting frames on the two sides of the casting blank input end of the protection cover. A U-shaped rod is placed on the supporting frames on the two sides of the casting blank output end of the protection cover as well. A plurality of hanging chains are arranged at the bottom end of each U-shaped rod. A diversion tank is arranged below the protection cover and is located below a casting blank roll gang. Electromagnetic plates are arranged on the side walls of the diversion tank. A hopper is arranged at the bottom of the diversion tank. Installation holes matched with a roll of the casting blank roll gang are formed in the bottoms of the two sides of the protection cover. A closed area is formed in the slab deburring area through the protection cover and other devices, multiple layers of whole curtains are composed of hooks and hanging chains, and collision caused to the protection cover after casting blanks deform is avoided.

Owner:武汉钢铁有限公司

Offshore grouting auxiliary device and construction method

ActiveCN114045836AAutomatic sealingAutomatically complete blockingFoundation engineeringOffshore wind powerMechanical engineering

The invention discloses an offshore grouting auxiliary device and a construction method, and belongs to the field of offshore wind power engineering. The offshore grouting auxiliary device comprises a first plugging piece, a plurality of second plugging pieces and a baffle, the second plugging pieces are arranged on the inner wall of a sleeve in a sliding mode and can slide in the radial direction of the sleeve, when the second plugging pieces are tightly attached to the outer wall of the steel pipe pile, the second plugging pieces plug gaps between the first plugging pieces and the steel pipe pile; the baffle is positioned at the upper end of the second plugging piece, the sleeve, the first plugging piece, the second plugging piece and the baffle define a containing cavity of the outer wall, the grouting pipeline is communicated with the containing cavity, the second plugging piece is tightly attached to the outer wall of the steel pipe pile, an opening is formed in the upper end of the containing cavity, and the containing cavity is communicated with an annular space between the sleeve and the steel pipe pile through the opening. According to the offshore grouting auxiliary device, the second plugging piece is firstly driven to clamp the steel pipe pile, temporary fixing of the jacket and plugging of the grouting bottom are completed, and an operator does not need to dive into water for additional operation.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP

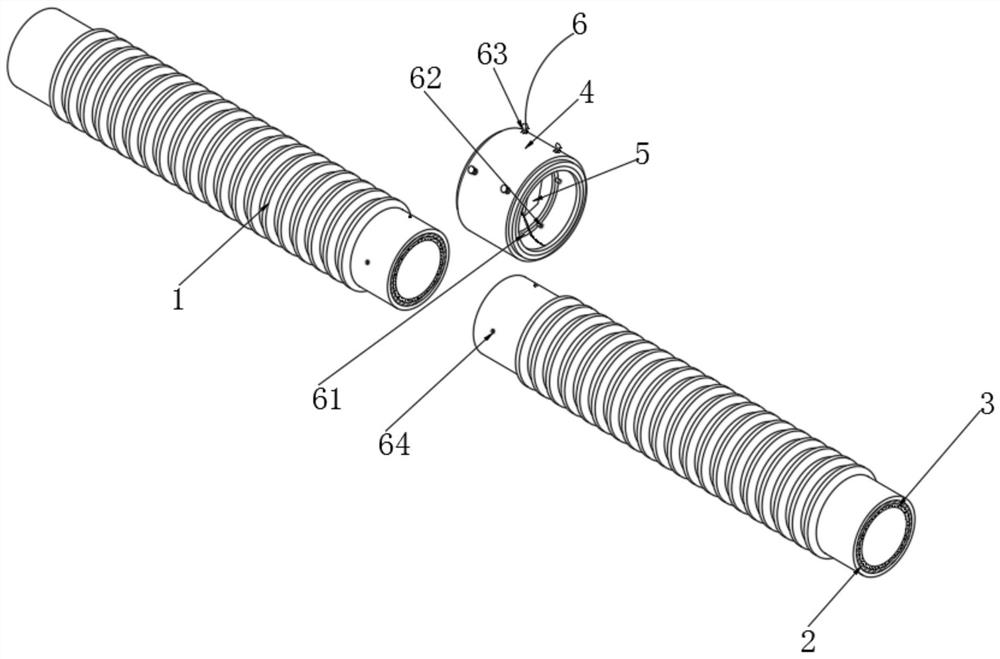

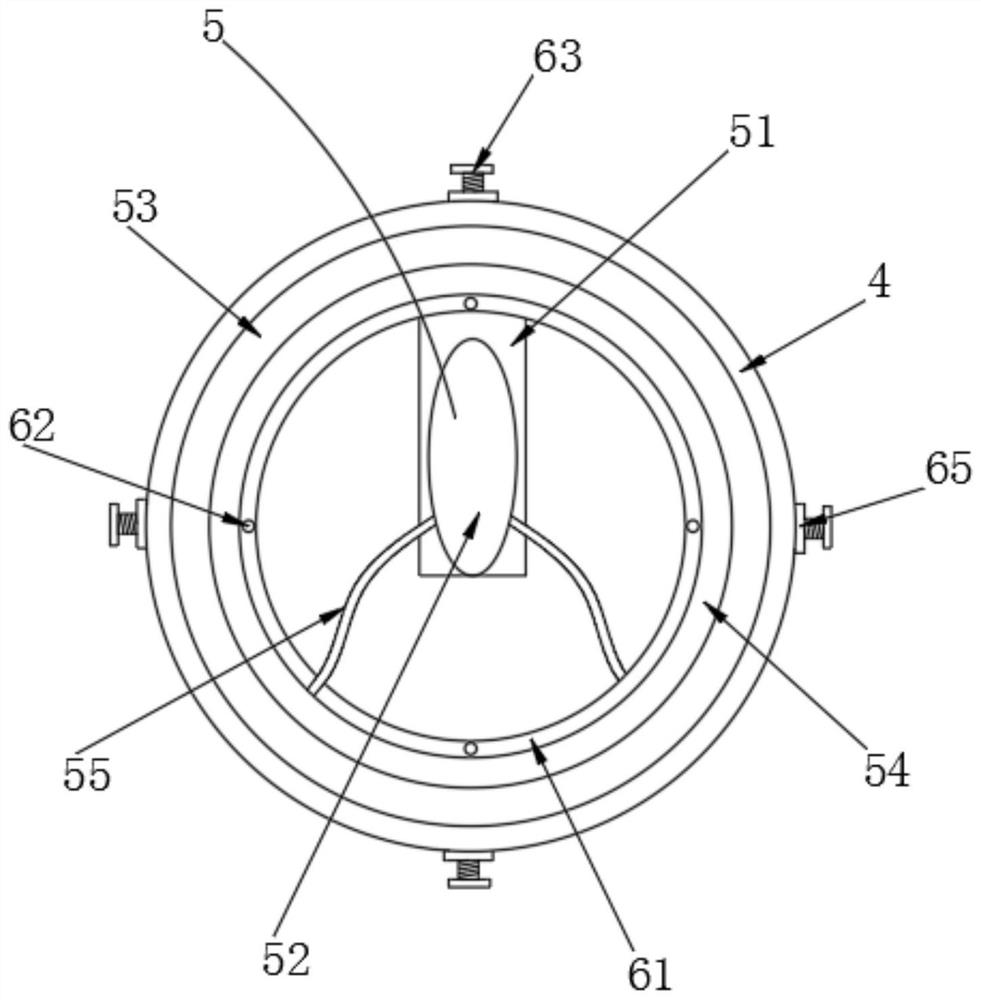

High-strength PVC compression-resistant corrugated pipe capable of reducing friction

PendingCN114046387AImprove stress resistanceImprove sealingThermal insulationPipe protection by thermal insulationWater leakageWater flow

The invention discloses a high-strength PVC compression-resistant corrugated pipe capable of reducing friction, and the corrugated pipe comprises two symmetrically-arranged PVC corrugated pipe bodies, a reinforcing buffer layer is fixed to the inner wall of each PVC corrugated pipe body, a polytetrafluoroethylene layer is fixed to the inner wall of each reinforcing buffer layer, and a connecting sleeve is arranged between the surfaces of the two PVC corrugated pipe bodies in a sleeving mode. The connecting sleeve is provided with an adaptive adjusting sealing mechanism, and a positioning mechanism is arranged between the PVC corrugated pipe body and the connecting sleeve. The invention relates to the technical field of corrugated pipes. According to the high-strength PVC compression-resistant corrugated pipe capable of reducing friction, the compression resistance of the PVC corrugated pipe bodies can be improved conveniently through the arrangement of the reinforcing buffer layers, the friction of the inner wall of the PVC corrugated pipe bodies can be reduced through the arrangement of the polytetrafluoroethylene layers, water drainage is smoother, sealing can be automatically achieved conveniently according to the water flow through the arrangement of the adaptive adjusting sealing mechanism, the larger the water flow is, the more tight sealing is achieved, the sealing effect is effectively improved, and the water leakage phenomenon is prevented.

Owner:东台市竹林高科技材料有限公司

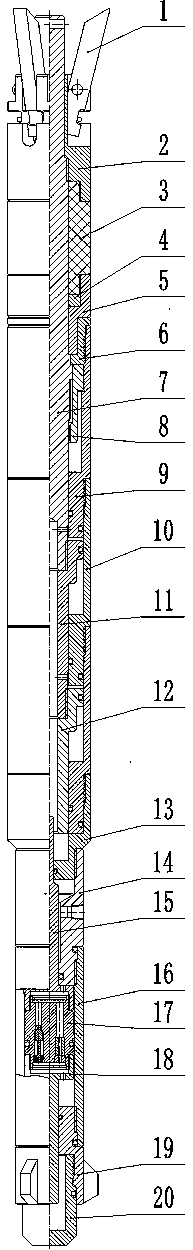

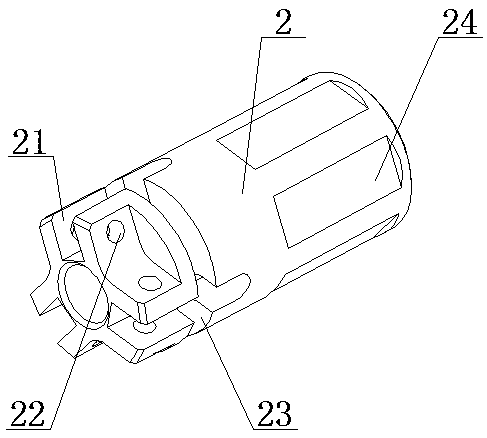

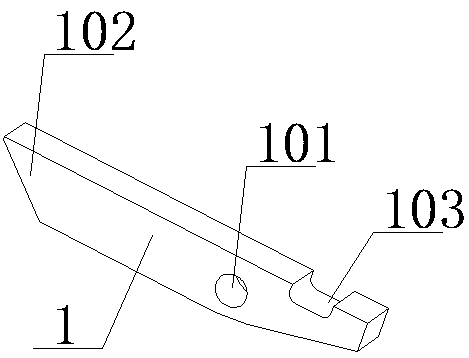

Oil pipe automatic blocking tool

PendingCN108487877ASimple construction and applicationAutomatic sealingSealing/packingOil fieldOil water

The invention discloses an oil pipe automatic blocking tool. The oil pipe automatic blocking tool comprises positioning claws, a positioning seat, a rubber cylinder, a torque sleeve, a retainer ring,a rubber cylinder mandrel, a pawl, a pawl outer cylinder, power outer cylinders, an upper power mandrel, a lower power mandrel, a transition short circuit, a pressure-transmitting short circuit, a valve element, a delay outer cylinder, a delay valve assembly, a compensation mandrel, a locating short circuit and a volume pipe. The oil pipe automatic blocking tool is used for repairing constructionof an oil field oil well or a water well, oil water is prevented from being sprayed out of an oil pipe in the pipe lifting process, and the oil pipe automatic blocking tool has the characteristics that on-site application is easy, automatic sealing and anchoring can be achieved only by putting the tool in the well, and the on-site construction cost is avoided.

Owner:YANCHENG QINGLONG MACHINERY

Glass molding press

PendingCN114292011AReduce scrap rateReduce manufacturing costGlass reforming apparatusGlass productionControl systemEngineering

The invention relates to the technical field of glass production equipment, and provides a glass molding press which comprises a fixing plate, an upper mold base, an upper mold core and a lower mold core, the upper mold base is installed on the upper surface of the fixing plate, the upper mold core is installed on the inner top of the upper mold base, the lower mold core is located between the upper mold core and the fixing plate, and the lower mold base is vertically and slidably assembled at the bottom of the fixing plate; a lower die sealing column is fixed to the top of the lower die base and penetrates through the fixing plate, the lower die core is installed at the top of the lower die sealing column, and a lifting device driving the lower die base to ascend and descend freely is arranged at the bottom of the lower die base. A grating ruler displacement sensor is arranged on one side of the lower die base, a pressure sensor is further arranged between the bottom of the lower die base and the top of the lifting device, and the grating ruler displacement sensor and the pressure sensor are both electrically connected to a control system of the glass molding press. According to the glass molding press provided by the invention, through two detection means of high-precision pressure control and high-precision position control, the product rejection rate is reduced, and the production cost is saved.

Owner:深圳市晶岛科技有限公司

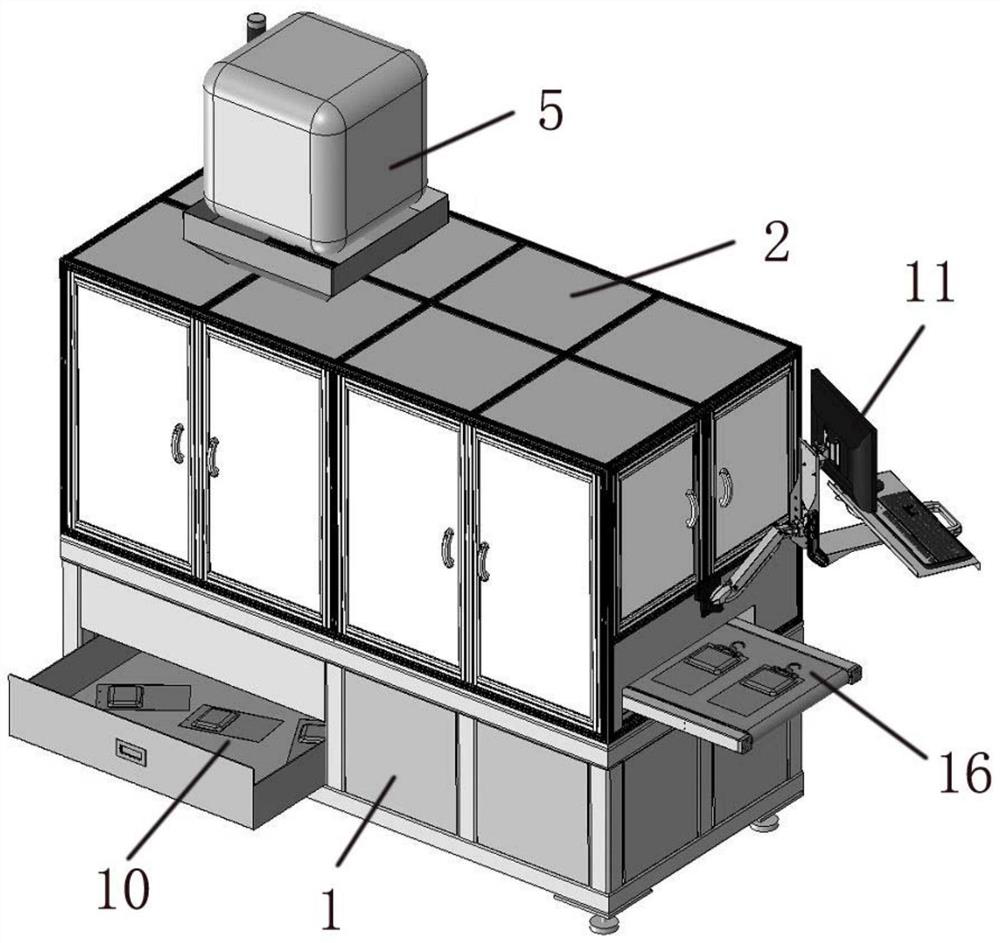

Automatic filling equipment for dehumidification bag

ActiveCN113716158AReduce investmentAutomatic fillingWrapper twisting/gatheringPackaging automatic controlEngineeringMechanical engineering

The invention discloses automatic filling equipment for a dehumidification bag. The automatic filling equipment for the dehumidification bag comprises a rack, a machine cover and a control device, wherein a packaging bag feeding mechanism is arranged on the rack; the packaging bag feeding mechanism is used for conveying a packaging bag to one end of a moving mechanism; the moving mechanism moves the packaging bag to a gripper mechanism; the gripper mechanism is used for opening the packaging bag; a filling mechanism is arranged and is used for filling dehumidifying particles into the packaging bag; a hot pressing mechanism is arranged for sealing the packaging bag; a recognition device is arranged and used for recognizing whether the packaging bag is sealed or not; an automatic alignment hook mechanism is arranged and used for connecting a hook with the packaging bag; a finished product discharging mechanism is arranged and used for placing finished products at designated positions; and the gripper mechanism, the packaging bag feeding mechanism, the filling mechanism, the hot-pressing sealing mechanism, the recognition device, the automatic alignment hook mechanism and the finished product discharging mechanism are all in communication connection with the control device.

Owner:ZHUHAI HERMESIN ENTERPRISES CO LTD

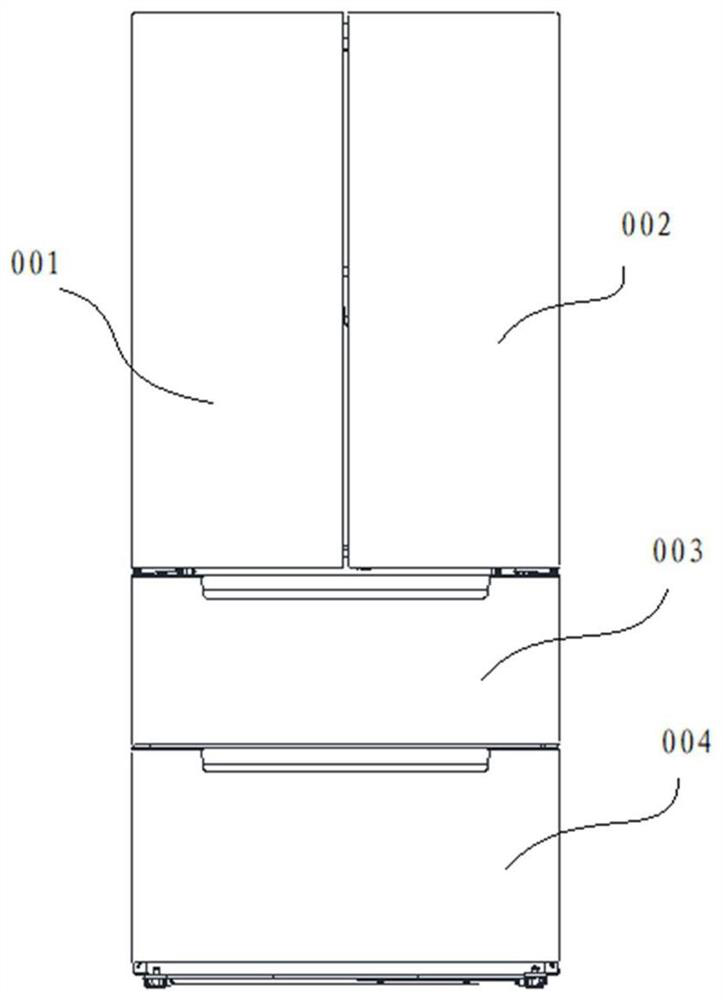

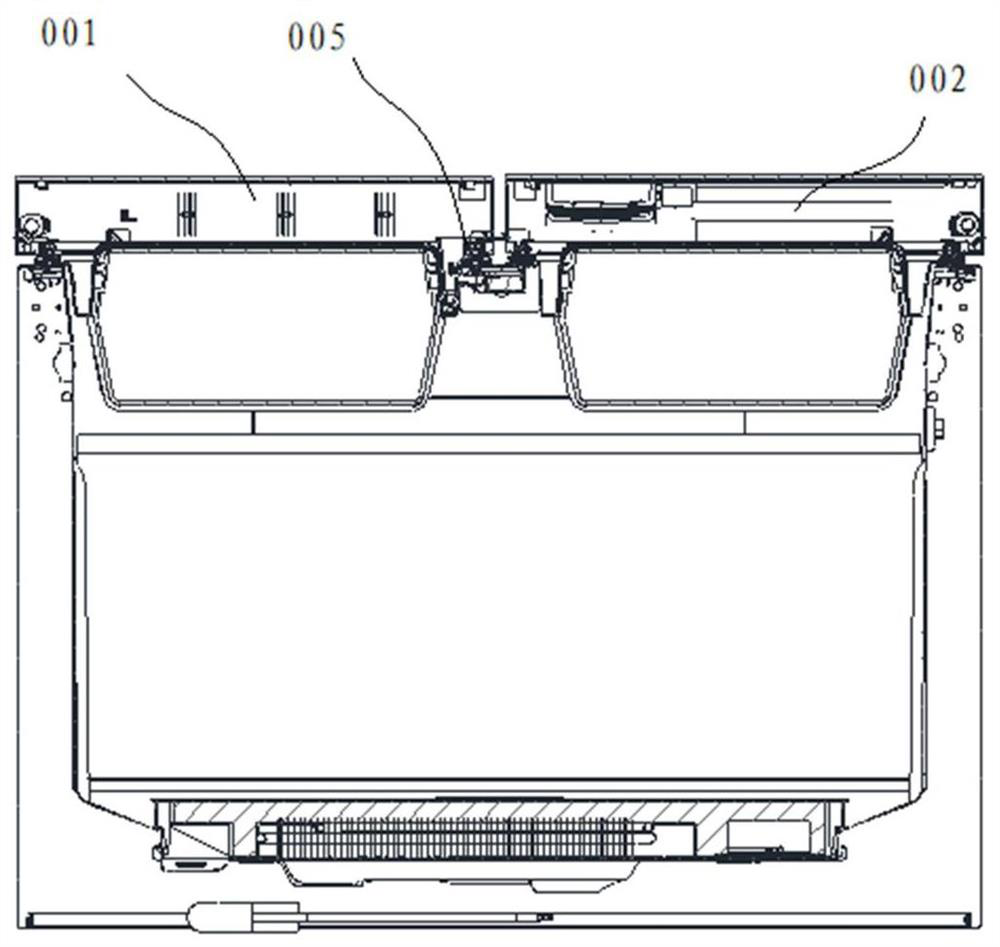

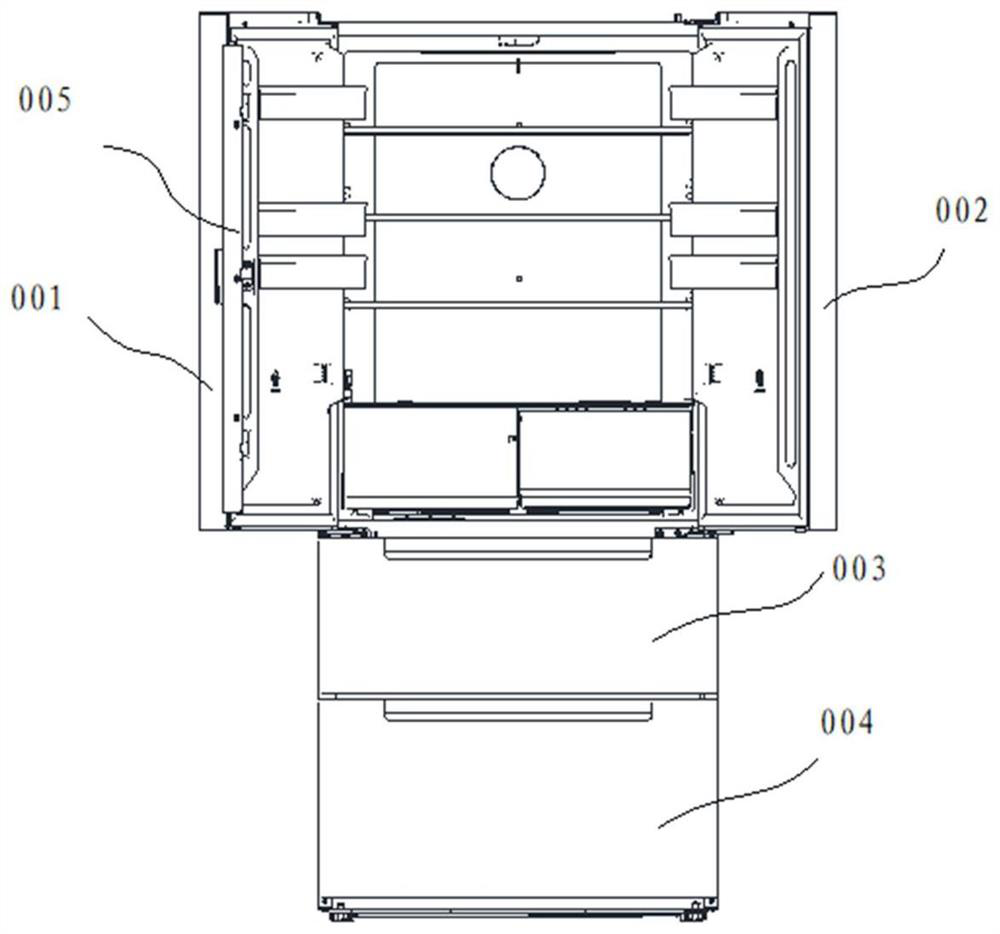

Door assemblies and refrigeration equipment

ActiveCN113154774BAutomatic sealingPrevent openingLighting and heating apparatusDomestic refrigeratorsStructural engineeringCam

The invention relates to the technical field of refrigeration, and provides a door assembly and refrigeration equipment. The door assembly includes: a door leaf, which can be switched between a closed state and an open state, and includes a first door body and a second door body, the first door body is connected to the component to be installed through a cam hinge, and the second door body is opposite to the first door body It moves toward the opening side or the hinge side of the first door body, and the second door body is provided with a driving part that is in contact with the cam hinge; in the process of switching the door leaf from the closed state to the open state, the driving part rotates relative to the cam hinge, and The distance between the driving part and the axis of the cam hinge becomes smaller, so that the second door body moves toward the hinge side of the first door body relative to the first door body. The door assembly can automatically seal the door assembly when opening and closing the door, or automatically move the door leaf to the avoidance position to prevent interference with the opening of the door assembly. Avoid the defect of inflexible storage space division.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

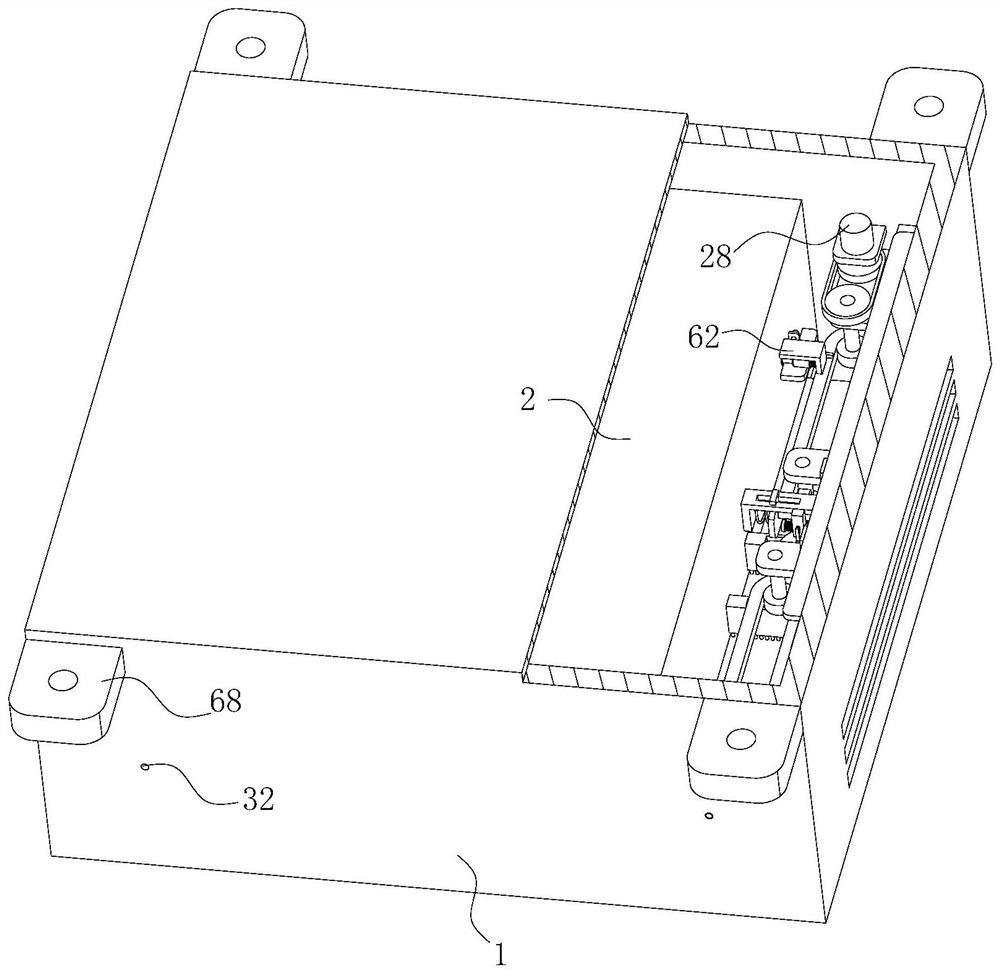

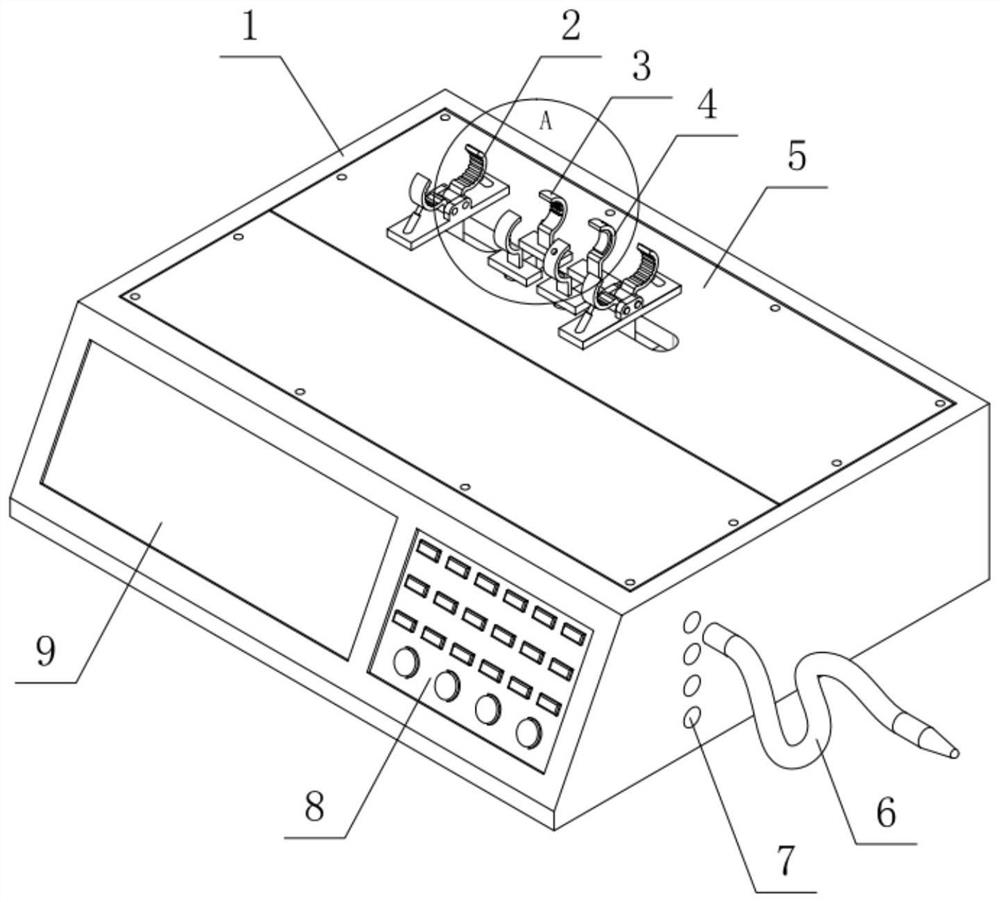

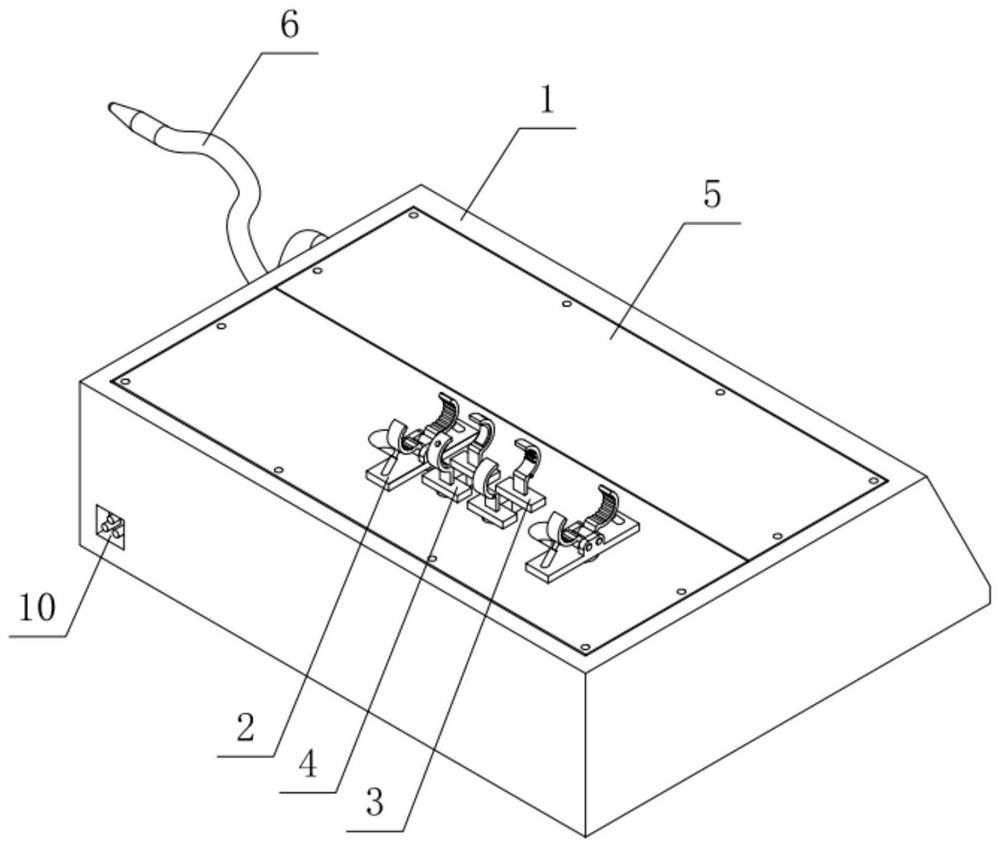

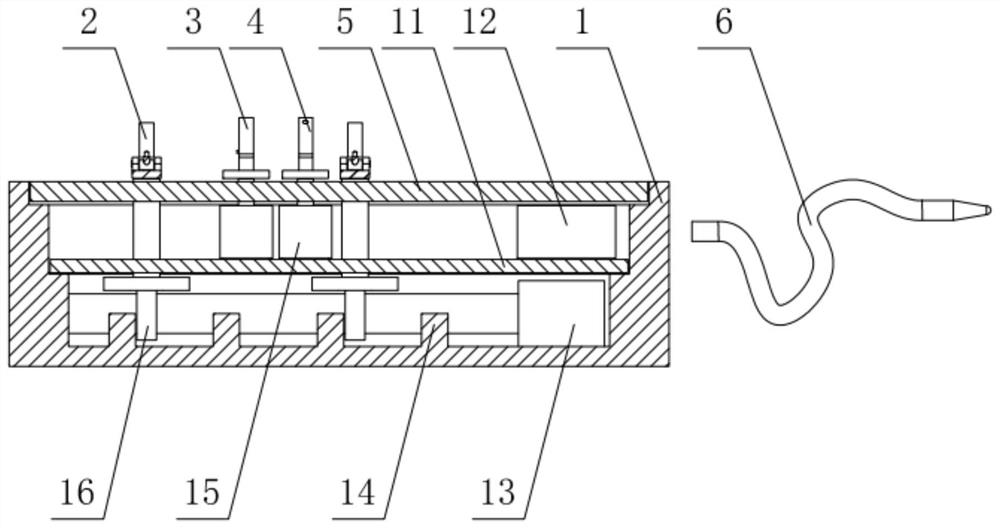

Meter integral wiring live-line detection auxiliary tool

PendingCN112630719AAutomatic sealingSolve the problem of damage to the insulation layer of wires and the risk of electric shockEngine sealsTime integral measurementInsulation layerControl engineering

The invention discloses a meter integral wiring live-line inspection auxiliary tool, and belongs to the technical field of electric power measurement inspection auxiliary equipment. The tool comprises a box body; a current detection generator and a transverse moving mechanism are arranged in the box body; the transverse moving mechanism is connected with a clamping assembly and drives the clamping assembly to move transversely; two sets of longitudinal moving mechanisms are arranged above the transverse moving mechanism; the two sets of longitudinal moving mechanisms are connected with an electric detection assembly and a sealing assembly correspondingly; the electric detection assembly and the sealing assembly are used for achieving detection and sealing of an electric detection line. According to the meter integral wiring live-line detection auxiliary tool, the clamping assembly,the electric detection assembly and the sealing assembly cooperate with one another, the detection and sealing of the electric detection line can be automatically achieved, and the problems that a wire insulation layer is damaged and electric shock risks exist during existing overall wiring identification are effectively solved. The meter integral wiring live-line detection auxiliary tool is simple in structure, capable of effectively liberating the hands of workers, high in applicability, high in automation degree, convenient to operate and capable of effectively improving the working efficiency.

Owner:GANSU ELECTRIC APP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com